fs

ForeRunner

User’s Manual

MANU0149-01 - March, 1997

Software V ersion 4.1.x

™ ATM Switch

FORE Systems, Inc.

1000 FORE Drive

Warrendale, PA 15086

Phone: 412-742-4444

FAX: 412-772-6500

http://www.fore.com

Legal Notices

Copyright © 1995-1997 FORE Systems, Inc . All rights reserved. FORE Sys tems is a registered trademark, and ForeRunner,

ForeView, ForeThought, ForeRunnerLE, PowerHub, and CellPath are trademarks of FORE Systems, Inc. All ot her brands or

product names are trademarks of their respective holders.

U.S. Government Restricted Rights.

the following provisions appl y to you. If the Softwa re is supplied to the D epartm ent o f Defen se (“ DoD” ), it is c lassifi ed a s

“Commercial Computer Software” under paragraph 252.227-7014 of the DoD Supplement to the Federal Acquisition Regulations (“DFARS”) (or any successor regulations) and the Gover nment is acquirin g only the licen se rights grant ed herein

(the license rights custom ar ily provided to non-Governmen t u sers). If the Software is supplied to any unit or age n cy of the

Government other than DoD, it is classifi ed as “Restricte d Computer Software” and the Governmen t’s rights in the Software are defined in paragraph 52.227-19 of th e Federal A cquisition Regulations (“FAR”) (or any successor regulatio ns) or,

in the cases of NASA, in paragraph 18.5 2. 227 -86 of the NASA Supplement to the FAR (or any successor regulations).

Printed in the USA.

No part of this work covered by copy rig h t m a y be reproduced in any form. Reproduction, adap t at i on, or translation w it h -

out prior written p e rmission is prohibited, e xcept as allowed unde r t h e c op y right laws.

This publication is provided by FORE Systems, Inc. “as-is” without warranty of any kind, either express or implied, includ-

ing, but not limit ed to, the im plied warran ties or cond itions of me rchantability o r fitness for a particular pu rpose. FORE

Systems, Inc. shall not be liable for any errors or omissions which may occur in this publication, nor for incidental or consequential damages of any kind resulting from the furnishing, performance, or use of this publication.

Information published here is current or planned as of the date of publication of this document. Because we are improving

and adding features to our products con t in uously, the information in this document is subject to ch an ge without notice.

RESTRICTED RIGHTS LEGEND. Use, duplication, or disclosure by the government is subject to restrictions as set forth in

subparagraph (c)(1)(ii ) of the Rights in Technical Data and Computer Soft ware clause at DFARS 252.227-7013 (October

1988) and FAR 52.227-19 (June 1987).

The VxWorks software used in the Mini Loader is licensed from Wind River Systems, Inc., Copyright

If you are licensing the Software on behalf of the U.S. Government (“Government”),

©

1984-1996.

FCC CLASS A NOTICE

WARNING: Changes or modification s to this unit not expressly approved by the party responsib le for complianc e could

void this user’s authority to operate this equipment.

NOTE: The ASX-200, the ASX -200WG, the ASX -200BX and the ASX-1000 hav e been tested and foun d to comply wit h the

limits for a Class A digital devic e, pursuant to Pa rt 15 of th e FCC Rules. T hese limits are design ed to provide reasonab le

protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency en ergy and, if not installe d and used in accordanc e with the instruction

manual, may cause harmful interference to radio communications. Operation of the equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

DOC CLASS A NOTICE

This digital apparatus does not exceed Cl ass A lim its for rad io noise e mission fo r a digital device as set out in the Rad io

Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques de la class A prescrites dans le reglement sur le brouillage radioelectrique edicte par le ministere des Communications du Canada.

VCCI CLASS 1 NOTICE

This equipment is in the Class 1 category (Information Technology Equipment to be used in commercial and/or industrial

areas) and conforms to the standa rds set by the Vol untary Control Council For Interference by In formation Technology

Equipment aimed at preventing radio interference in commercial and/or industrial areas.Consequently, when used in a

residential area or in an adjacent area thereto, radio interference may be caused to radios and TV receivers, etc. Read the

instructions for correct handling.

FCC REQUIREMENTS (Notice to Users of DS1 Service)

The following instructions are provided to ensure compliance with the Federal Communications Commission (FCC) Rules,

Part 68.

(1) This device must only be connected to the DS1 network connected behind an FCC Part 68

registered ch annel service u n it. Direct conn e ct ion is not allowed.

(2) Before connecting your unit, you must inform the telephone company of the following

information:

Port ID REN/SOC FIC USOC

NM-6/DS1C 6.0N 04DU9-BN,

04DU9-DN,

NM-2/DS1C 6.0N 04DU9-1ZN, and

04DU9-1SN

(3) If the unit appears to be malfunction ing, it should be discon ne cted from the tel ephon e line s

until you learn if your equipment or the telephone line is the source of the trouble. If your

equipment needs repair, it should not be reconnected until it is repaired.

(4) If the telephone company finds that this equipment is exceeding tolerable parameters, the

telephone company can temporarily disconnect service, although they will attempt to give

you advance notice if possible.

(5) Under the FCC Rules, no customer is author ized to repair this equipment. Th is restriction

applies regardless of w het her the equipment is in or out of warranty.

(6) If the telephone company al ters their equipment in a manner that will affec t use of this

device, they must give you advance warning so as to give you the opportunity for uninterrupted service. You will be adv ised of your right to file a complaint with the FCC.

RJ48C

RJ48C

CANADIAN IC CS-03 COMPLIANCE STATEMENT

68

NOTICE: The Industry Canada label identifies certified equipment. This ce rtifi cation means tha t the equipment meets certain telecommunica tions network protective, operational an d safety requirements. The Industry Canada lab el does not

guarantee the equipment will operate to the user ’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local telecommunications company. The equipment must also be installed using an acceptable method of connection. In some cases,

the company’s ins ide wi ring a sso ciat ed with a sing le line i ndiv idua l s ervice m a y be e xten ded b y me ans o f a certi fied con nector assembly (telephone extens ion cor d) . The cust omer should be awa r e that co mpliance with the above cond itio ns may

not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier.

Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone lines and

internal metallic water pipe system, if present, are connected together. This precaution may be particularly important in

rural areas.

: Users should not attempt to make such connections themselves, but should contact the appropriate electric

Caution

inspection authority, or electrician, as appropriate.

E1 AND E3 NOTICE

The E1 (NM-6/E1C and NM-2/ E1C) and E3 (NM-4/E3C and NM-2/E3C) ne twork modules that are described in this

manual are approved for use in FORE Systems’ host systems providing that the instructions belo w are strictly observed.

Failure to follow these instructions invalidates the approval.

Pan European Approval - CE Marking

Pan European approval of the E1 network mod ule was issue d by BABT following a ssessment against CTR1 2. This mea ns

that it can be conn ected to ONP and unstruct ured PTO-provided private circuits w ith 120 Ω interfaces in all European

countries, according to Telecommunications Terminal Equipment (TTE) Directive 91/263/EE C. Thus, the following CE

mark applies:

1

The E1 and E3 network modules conform to safety standard EN60950 1992 following the provisions of Low Voltage

Product Safety Directive 73/23/EEC and CE Marking D irective 93/68/E EC, and can be marked acc ordingly with the CE

symbol.

The E1 and E3 netwo rk modules conform to EN550 22 1994 and EN50082-1 1992 fo llowing the provisions of the EMC

Directive 89/336/EEC, and c an be m arke d accordingly with the CE symbol.

National Approvals

UK

Network Module Connects to Approval Number

E1 Structured and unstructured

E3 PTO-provided private circuits

PTO-provided private circuits

with 75 Ω interfaces

with 75 Ω interfaces

AA60953

NS/4387/1/T/605954

Germany

Network Module Connects to Approval Number

E3 Structured PTO-provided private circuits

with 75 Ω interfaces

A127535H for the ASX-1000

A127534H for the ASX-200BX or ASX-200WG

Switzerland

Network Module Connects to Approval Number

E1 Structured PTO-provided private circuits

with 120 Ω interfaces

E3 Structured PTO-provided private circuits

with 75 Ω interfaces

96.0872.J.N

96.0873.J.N

Required User Guide Statements - UK Installation

The use of auxiliary products not authorized by FORE Systems in FORE Systems ATM Switches may cause the power specification to be exceeded and is a potential safety hazard.

The equipment must be installed such that with the exception of the connections to the host, clearance and creepage

distances shown in the table below are maintained bet ween the netwo rk module and an y other assembl ies which use or

generate a voltage shown in the table below. The larger distance shown in brackets applies where the local environment

within the host is subject to conductive pollution or dry non-conductive pollution which could become conductive due to

condensation. Failure to ma intain these minimum d ist an c e s in validates the approval.

Clearance (mm) Creepage (mm)

2.0 2.4 (3.8) Up to 50 V

2.6 3.0 (4.8) Up to 125 V

4.0 5.0 (8.0) Up to 250 V

4.6 6.4 (10.0) Up to 300 V

For a host or other expansion card fitted in the host, using or generating voltages greater

than 300V (rms or dc), advice from a competent telecommunications engineer must be

obtained before installation of the relevant equipment.

Voltage Used or Generated

by Host or by Network Modules

or V

rms

dc

or V

rms

dc

or V

rms

dc

or V

rms

dc

Above 300 V

rms

or V

dc

NOTE: Installing the net work modules i n the appropriate FORE Sys tems hosts, acc ording to the installa tion instructio ns

provided, satisfies the requirements listed above.

The following tables show the available ports and their safet y st atus:

NM-6/E1C and NM-2/E1C

Ports Safety Status

E1 Ports TNV operating at SELV

Bus Connector SELV

NM-4/E3C and NM-2/E3C

Ports Safety Status

E3 Ports TNV operating at SELV

Bus Connector SELV

NOTICE

CE

Marking by the symbol CE indicates compliance of this system to the EMC (Electromagnetic Compatibility) directive of the

European Comm unity and co mpliance to the Low Voltage (Safety) Directiv e. Such m arking is in dicative t hat this syste m

meets or exceeds the fol lowing technical stand ards:

• EN 55022 - “Li mi t s an d Methods of Measurement of Radio In t e rfe rence Characteristics of Information Technology Equipment.”

• EN 50082-1 - “E lectromagnetic compatib ility - G eneric imm unity sta ndard Part 1 : Residentia l, comm ercial,

and light indust ry.”

• IEC 1000-4-2 - “Elec tromagnetic compatibil ity for industrial-p rocess measurement and con trol equipment

Part 2: Electrostatic discharge requirements.”

• IEC 1000-4-3 - “Elec tromagnetic compatibil ity for industrial-p rocess measurement and con trol equipment

Part 3: Radiate electromagnetic field requirements.”

• IEC 1000-4-4 - “Elec tromagnetic compatibil ity for industrial-p rocess measurement and con trol equipment

Part 4: Electrical fast transien t /b urst requirements.”

SAFETY CERTIFICATIONS

ETL certified to meet Information Technology Equipment safety standards UL 1950, CSA 22.2 No. 950, and EN 60950.

Table of Contents

Preface

Chapter Summaries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Typographical Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Important Information Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Laser Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Modifications to Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Placement of a FORE Systems Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Power Cord Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

CHAPTER 1 Switch Hardware

1.1 Switch Hardware Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

1.2 Switch Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.2.1 Switch Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

1.2.2 Switch Control Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.2.2.1 SPARC RISC Switch Control Processor . . . . . . . . . . . . . . . . . . 1 - 4

1.2.2.1.1 RESET Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2.2.1.2 ABORT Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2.2.1.3 RUN/RESET LED. . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

1.2.2.1.4 VME BM LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2.2.1.5 STATUS LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2.2.1.6 Diagnostics Display . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2.2.1.7 RS-232 Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2.2.1.8 Ethernet AUI Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

1.2.2.2 i960 Switch Control Processor . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

1.2.2.2.1 RESET Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

1.2.2.2.2 RS-232 Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

1.2.2.2.3 Ethernet 10BaseT Port. . . . . . . . . . . . . . . . . . . . . . . 1 - 7

1.2.2.2.4 CTL Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

1.2.2.2.5 NEXT Pushbutton. . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

1.2.2.2.6 SELECT Pushbutton. . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

1.2.2.2.7 Display LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

1.2.2.2.8 Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Table of Contents

ForeRunner

ATM Switch User’s Manual

TOC - 1

Table of Contents

1.2.3 Dual SCP Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

1.2.4 Network Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

1.2.5 Power Supply Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

1.2.6 ASX-1000 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 21

1.2.7 ASX-1000 Temperature Sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 21

1.2.8 ASX-1000 Common Equipment Card (CEC). . . . . . . . . . . . . . . . . . . . 1 - 22

1.2.3.1 Adding a Standby SCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

1.2.3.2 Rebooting the Controlling SCP. . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

1.2.3.3 Ethernet Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

1.2.4.1 Port Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

1.2.5.1 ASX-200BX AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

1.2.5.2 ASX-200BX -48 Volt DC Power Supply . . . . . . . . . . . . . . . . . 1 - 14

1.2.5.3 ASX-1000 AC Power Supply (Model A) . . . . . . . . . . . . . . . . . 1 - 16

1.2.5.3.1 Power Supply LEDs. . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

1.2.5.3.2 Shutdown Conditions. . . . . . . . . . . . . . . . . . . . . . . 1 - 17

1.2.5.4 ASX-1000 AC Power Supply (Model B) . . . . . . . . . . . . . . . . . 1 - 18

1.2.5.4.1 Power Supply LEDs. . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

1.2.5.4.2 Shutdown Conditions. . . . . . . . . . . . . . . . . . . . . . . 1 - 19

1.2.5.5 ASX-1000 -48 Volt DC Power Supply. . . . . . . . . . . . . . . . . . . 1 - 20

1.2.8.1 CEC Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 22

1.2.8.2 Alarm Relay Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 23

1.2.8.3 CEC Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

1.2.8.3.1 Alarm LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 26

1.2.8.3.2 Power Supply LEDs. . . . . . . . . . . . . . . . . . . . . . . . 1 - 27

1.2.8.3.3 Switch Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . 1 - 27

1.2.8.4 Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 27

CHAPTER 2 Switch Setup

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

2.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.2.1 Inventorying the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.3 Electrical Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

2.4 Rack-Mounting an ASX-200, 200WG, or 200BX. . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

2.4.1 Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

2.4.2 Installing the Rack-mount Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.5 Rack-Mounting an ASX-1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

2.5.1 Installing the ASX-1000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

2.6 Installing the Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

TOC - 2

ForeRunner

ATM Switch User’s Manual

Table of Contents

2.7 Modem Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

2.7.1 Serial Port Configuration for an ASX-200. . . . . . . . . . . . . . . . . . . . . . . 2 - 10

2.7.2 Modem Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

2.8 Configuring IP Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 12

2.9 AMI Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 13

2.10 Subsequent Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 14

2.11 Verifying the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 15

2.12 Product Registration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 15

CHAPTER 3 Hardware Maintenance Procedures

3.1 Network Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.1.2 Multicast Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3.1.3 Hot-swapping Network Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

3.2 Power Supply Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

3.2.1 ASX-200BX Power Supply Module Replacement . . . . . . . . . . . . . . . . . 3 - 4

3.2.1.1 Replacing an ASX-200BX AC Power Supply. . . . . . . . . . . . . . . 3 - 4

3.2.1.2 Replacing an ASX-200BX DC Power Supply . . . . . . . . . . . . . .3 - 6

3.2.2 ASX-1000 Power Supply Module Replacement . . . . . . . . . . . . . . . . . . . 3 - 8

3.2.2.1 Replacing an ASX-1000 AC Power Supply (Model A). . . . . . . . 3 - 8

3.2.2.2 Replacing an ASX-1000 AC Power Supply (Model B). . . . . . . 3 - 11

3.2.2.3 Replacing an ASX-1000 DC Power Supply. . . . . . . . . . . . . . . 3 - 14

3.3 ASX-1000 Fan Tray Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 17

3.4 Switch Control Processor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

3.5 Switch Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 20

Table of Contents

CHAPTER 4 Software Upgrade Instructions

4.1 Obtaining the Software Upgrade File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

4.1.1 Obtaining the Software Upgrade File via FTP . . . . . . . . . . . . . . . . . . . . 4 - 2

4.1.2 Obtaining the Software Upgrade File via Diskette . . . . . . . . . . . . . . . . . 4 - 4

4.2 Requirements for Upgrading an ASX-200WG . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

4.2.1 Downloading the Mini Loader Software . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

4.2.2 Emptying the FLASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

4.2.3 Upgrading the Switch to Mini Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

4.2.4 Deleting the Active Switch Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

4.3 Performing the Software Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

4.4 Loading the New Software Image onto the ASX-200 . . . . . . . . . . . . . . . . . . . . . . 4 - 12

4.5 Changing between Multiple Versions of Software . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

ForeRunner

ATM Switch User’s Manual

TOC - 3

Table of Contents

4.6 Booting and Upgrading with Mini Loader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 16

4.6.1 Setting the IP Address of the Switch. . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 18

4.6.2 Setting the Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 18

4.6.3 Performing the Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

4.7 Using bootp to Download Software to the Switch . . . . . . . . . . . . . . . . . . . . . . . . 4 - 21

4.7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 22

4.7.2 Setting Up a bootp Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 22

4.7.3 Adding a Switch Entry in the bootptab File . . . . . . . . . . . . . . . . . . . . . 4 - 23

4.7.4 Setting Up a TFTP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 25

APPENDIX A Troubleshooting

A.1 Adapter Hardware Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 1

A.1.1 Run Looptest. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 3

A.1.2 Check Self-Test (Automatically Performed) . . . . . . . . . . . . . . . . . . . . . . A - 4

A.1.3 Firmware Download (Automatically Performed) . . . . . . . . . . . . . . . . . . A - 4

A.1.4 Hardware Detected by Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 4

A.1.5 Check Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 5

A.1.6 Check Physical Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 6

A.2 Testing Network Connectivity Using PVCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 7

A.2.1 Verifying the Outgoing ATM ARP Entry . . . . . . . . . . . . . . . . . . . . . . . . . A - 9

A.2.2 atmstat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 10

A.2.2.1 No Cells Received by Remote End . . . . . . . . . . . . . . . . . . . . A - 11

A.2.2.2 Cells and VPI/VCI Errors Received by Remote . . . . . . . . . . . A - 11

A.2.2.3 Cells and AAL* Errors Received by Remote . . . . . . . . . . . . . A - 11

A.2.2.4 Cells and No Errors Received by Remote and

Transmitting No Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 12

A.2.2.5 Cells and No Errors Received by Remote and

Transmitting Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 12

A.3 Collecting Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 13

A.3.1 Basic Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 13

A.3.2 Adapter Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 13

A.3.3 Switch Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 16

TOC - 4

ForeRunner

ATM Switch User’s Manual

Table of Contents

APPENDIX B SCP Diagnostics

B.1 ASX-200WG, ASX-200BX, ASX-1000 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . .B - 1

B.1.1 Accessing the Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 2

B.1.2 Running the Hardware Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 4

B.1.2.1 Clock Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 4

B.1.2.2 DRAM Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 4

B.1.2.3 DRAM Chip Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 5

B.1.2.4 Ethernet Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 5

B.1.2.5 FLASH Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 5

B.1.2.6 FLASH Chip Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 6

B.1.2.7 Serial Port Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 7

B.1.2.8 SRAM Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 7

B.1.2.9 Timer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 7

B.1.2.10 Hardware Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 7

B.1.2.11 Complete Hardware Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 8

B.2 SCP-ASXHA Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 9

B.3 ASX-200 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B - 10

APPENDIX C Hardware Specifications

C.1

C.2

ForeRunner

C.1.1

C.1.2

C.1.3

C.1.4

ForeRunner

ATM Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 1

ForeRunner

ForeRunner

ForeRunner

ForeRunner

ASX-200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 2

ASX-200WG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 3

ASX-200BX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 4

ASX-1000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 5

ATM Network Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 6

C.2.1 100 Mbps TAXI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 6

C.2.2 155 Mbps OC-3c/STM-1 MM Module. . . . . . . . . . . . . . . . . . . . . . . . . . .C - 7

C.2.3 155 Mbps STS-3c/STM-1 UTP Module . . . . . . . . . . . . . . . . . . . . . . . . .C - 8

C.2.3.1 155 Mbps UTP Pinout Specifications . . . . . . . . . . . . . . . . . . . .C - 9

C.2.3.2 Connecting Switches with 155 Mbps UTP Network Modules . .C - 9

C.2.4 622 Mbps OC-12c/STM-4c MM Module. . . . . . . . . . . . . . . . . . . . . . . .C - 10

C.2.5 1.5 Mbps DS1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 11

C.2.6 1.5 Mbps DS1 Circuit Emulation Services Module. . . . . . . . . . . . . . . .C - 12

C.2.6.1 DS1 Pinout Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 13

C.2.7 2 Mbps E1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 14

C.2.7.1 E1 Pinout Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 15

C.2.8 6 Mbps J2 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 16

Table of Contents

ForeRunner

ATM Switch User’s Manual

TOC - 5

Table of Contents

C.2.9 25 Mbps TP25 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C - 17

C.2.10 34 Mbps E3 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C - 20

C.2.11 45 Mbps DS3 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C - 21

C.2.12 155 Mbps OC-3c/STM-1 SM Module . . . . . . . . . . . . . . . . . . . . . . . . . C - 22

C.2.13 155 Mbps OC-3c/STM-1 3MM/1SM Module . . . . . . . . . . . . . . . . . . . . C - 23

C.2.14 622 Mbps OC-12c/STM-4c SM Module. . . . . . . . . . . . . . . . . . . . . . . . C - 25

Acronyms

Glossary

Index

C.2.9.1 Connecting Switches with TP25 Network Modules . . . . . . . . C - 18

C.2.9.2 Connecting Switches with Token Ring Pinouts to

ForeRunner

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C - 18

C.2.9.3 Connecting Adapters with Token Ring Pinouts to

ForeRunner

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C - 19

TOC - 6

ForeRunner

ATM Switch User’s Manual

Preface

This manual provides the technical information needed to install ForeRunnerTM ATM

Switches, ForeRunner LAN and WAN

software. This document also provides safety instruction s, general product informa tion, dia gnostic information, and troubleshooting information. This document was created for users

with various levels of experience. If you have any questions or problems with the installation,

please contact FORE Systems’ Technical Support.

network modules, and the accompanying ForeThought

TM

Chapter Summaries

Chapter 1 - Switch Hardware

hardware components.

Chapter 2 - Switch Setup

verify a successful installation.

Chapter 3 - Hardware Maintenance Procedures

cedures for the switch and network modules.

Chapter 4 - Software Upgrade Instructions

upgrade switch software, and change between multiple versions of software.

Appendix A - Troubleshooting

and adapters.

Appendix B - SCP Diagnostics

- Provides a description of the various ForeRunner ATM switch

- Provides information for the installation of a switch and how to

- Describes the hot-swap replacement pro-

- Describes how to configure a TFTP server,

- Contains basic troubleshooting information for switches

- Describes the diagnostic software for the SCP.

Preface

Appendix C - Hardware Specifications

operating specifications for ForeRunner ATM switches and network modules.

ForeRunner

ATM Switch User’s Manual

- Provides cabling, pinout, hardware, and general

i

Preface

Technical Support

In the U.S.A., you can contact FORE Systems ’ Technical Support using any one of the following methods:

1. If you have access to the Internet, you may contact FORE Systems’ Technical Support via e-mail at:

support@fore.com

2. You may FAX your questions to “support” at:

412-742-7900

3. You may send questions, via U.S. Mail, to:

FORE Systems, Inc.

1000 FORE Drive

Warrendale, PA 15086

4. You may telephon e y our questions to “support” at:

800-671-FORE (3673) or 412-635-3700

Technical support for non-U.S.A. customers sh ould be handled through your local distributor.

No matter which method is used for support, please be prepared to provide your support con-

tract ID number, the serial number(s) of the product(s), and as much information as possible

describing your problem/question.

ii

ForeRunner

ATM Switch User’s Manual

Preface

Typographical Styles

Throughout this manual, all specific commands mea nt to be entered by the user appear on a

separate line in bold typeface. In addition, use of the Enter or Return key is represented as

<ENTER>. The following example demonstrates this convention:

cd /usr <ENTER>

File names that appear withi n the text of this manual are represented in the following style:

“...the fore_install program installs this distribution.”

Command names that appear within the text of this manual are represented in the following

style: “...using the flush-cache command clears the bridge cache.”

Subsystem names that appea r within the text of this manua l are represented in the following

style: “...to access the bridge subsystem...”

Parameter names that appear within the text of this manual are represented in the following

style: “...using

<seg-list>

allows you to specify the segments for which you want to display

the specified bridge statistics.”

Any messages that appear on t he screen during software installation and network interface

administration are shown in Courier font to distinguish them from the rest of the text as fol-

lows:

.... Are all four conditions true?

Preface

ForeRunner

ATM Switch User’s Manual

iii

Preface

Important Information Indicators

To call your attention to safety and otherwise important information that must be reviewed to

ensure correct and complete installation, as well as to avoid damage to the FORE Systems

product or to your system, FORE Systems utilizes the following WARNING/CAUTION/NOTE

indicators.

WARNING statements contain information that is critical to the safety of the operator and/or

the system. Do not proceed beyond a WARNING statement until the indicated conditions are

fully understood or met. This information co uld prevent serious injury to the operator, damage to the FORE Systems product, the system, or currently loaded software, and is indicated

as follows:

WARNING!

CAUTION statements contain information that is important for proper installation/operation. Compliance with CAUTION statements can prevent possible equipment damage and/

or loss of data and are indicated as follows:

CAUTION

NOTE statements contain information that has been found important enough to be called to

the special attention of the operator and is set off from the text as follows:

NOTE

Hazardous voltages are present. To reduce the

risk of electrical shock and danger to personal

health, follow the instructions carefully.

You risk damaging your equipment and/or

software if you do not follow these instructions.

If you change the value of the LECS control

parameters while the LECS process is running,

the new values do not take effect until the LECS

process is stopped, and then restarted.

iv

ForeRunner

ATM Switch User’s Manual

Preface

Laser Notice

Class 1 Laser Product:

This product conforms to

applicable requirements of

21 CFR 1040 at the date of

manufacture.

Class 1 lasers are defined as products which do not permit human access to laser radiation in

excess of the accessible limits of Class 1 for applicable wavelengths and durations. These

lasers are safe under reasonably foreseeable conditions of operation.

Every FORE Systems network module having a fiber optic interface contains a Class 1 laser.

The Laser Notice section only applies to

NOTE

products or components containing Class 1

lasers.

Preface

ForeRunner

ATM Switch User’s Manual

v

Preface

Safety Precautions

For your protection, observe the following safety precautions when setting up equipment:

• Follow all warnings and instructions marked on the equipment.

• Ensure that the voltage and frequency of your power source matches the voltage

and frequency inscribed on the equipment’s electrical rating label.

• Never push objects of any kind through openings in the equipment. Dangerous

voltages may be present. Conductive foreign objects could produce a short circuit

that could cause fire, electric shock, or damage to your equipment.

Modifications to Equipment

Do not make mechanical or electrical modifications to the equipment. FORE Systems, Inc., is

not responsible for regulatory compliance of a modified FORE product.

Placement of a FORE Systems Product

CAUTION

To ensure reliable operation of your FORE

Systems product and to protect it from

overheating, openings in the equipment must

not be blocked or covered. A FORE Systems

product should never be placed near a radiator

or heat register.

vi

ForeRunner

ATM Switch User’s Manual

Power Cord Connection

Preface

WARNING!

WARNING!

FORE Systems products are designed to work

with single-phase power systems having a

grounded neutral conductor. To reduce the risk

of electrical shock, do not plug FORE Systems

products into any other type of power system.

Contact your facilities manager or a qualified

electrician if you are not sure what type of power

is supplied to your building.

Preface

Your FORE Systems product is shipped with a

grounding type (3-wire) power cord. To reduce

the risk of electric shock, always plug the cord

into a grounded power outlet.

ForeRunner

ATM Switch User’s Manual

vii

Preface

viii

ForeRunner

ATM Switch User’s Manual

CHAPTER 1

Switch Hardware

FORE Systems offers a full line of ForeRunner

complete ATM network solution. The ForeRunner

TM

ASX-200WG ATM switch provide high-performance ATM connectivity for LAN work-

ner

group and desktop applications. The ForeRunner

TM

ForeRunner

ASX-1000 ATM switch offer high reliability and port density for LAN backbon e

TM

ATM products that work together to provide a

TM

ASX-200 ATM switch and the ForeRun-

TM

ASX-200BX ATM switch and the

and LAN/WAN internetworking applications. Together with the ForeRunner series of ATM

LAN and WAN Network Modules, these switches meet the networking demands of today’s

distributed, time-critical applications.

All of the F oreRunner ATM switches deliver high-performance switching capacity and speed

for ATM applications. A non-blocking s witching capacity of 2.5 Gbps is con tinually avai lable

on the ASX-200, the ASX-200WG, and the ASX-200BX. Each switch provides up to 4 ports of

connectivity, each running at speeds up to 622 Mbps; or up to 16 ports, each running at speeds

up to 155 Mbps; or up to 24 ports, each running at speeds up to 100 Mbps. The

ASX-1000 provides 10 Gbps of switching capacity for up to 16 ports of connectivity, each running at speeds

up to 622 Mbps; or up to 64 ports, each running at speeds up to 155 Mbps; or up to 96 ports,

each running at speeds up to 100 Mbps.

Wide-area network (WAN) connectivity is seamlessly integrated into the AS X-200BX and the

ASX-1000 for connection to private networks or ATM SONET, DS3, DS1, E3, E1, or J2 services.

Interconnecting multiple ForeRunner sw itches at various speeds i s simple. Once a new sw itch

is added to the network, all other switches recognize it s presence and dynamically establish

connections to ports on the new switch. Furthermore, scaling th e network is accomplished

without costly and time consuming address reconfiguration and LAN segmentation.

Switch Hardware

This chapter provides an overview of the FORE Systems’

family

of

ForeRunner

AT M

switches.

It details the hardware requirements necessary to use these switches and also provides information on the contents of each of the switch packages.

ForeRunner

ATM Switch User’s Manual

1 - 1

Switch Hardware

1.1 Switch Hardware Configurations

For information about the technical and

NOTE

The ASX-200, as shown in Figure 1.1, is a self-contained ATM switch that provides an Ethernet

connection for network management access. The ASX-200 hardware consists of a single switch

board, a SPARC RISC switch control processor (SCP), network modules, and fans housed in a

rack-mount 19-inch horizontal enclosure. These components work together to provide ATM

switching capabilities, as well as distributed connection setup and management.

operating specifications for all of the ForeRunner

ATM switches, see Appendix C, “ForeRunner

Hardware Specifications,” in this manual.

Figure 1.1 -

The ASX-200WG, as shown in Figure 1.2, is a self-contained ATM switch that provides an

Ethernet connection for network management access. The ASX-200WG ATM switch hardware

consists of a single switch board with an i960 SCP, network modules, and fans. These components work together to provide ATM switching capabilities, as well as distributed connection

setup and management.

Figure 1.2 -

1 - 2

ASX-200 Switch Configuration

ASX-200WG Switch C onfiguration

ForeRunner

ATM Switch User’s Manual

Switch Hardware

The ASX-200BX, as shown in Figure 1.3, is a self-contained ATM switch that provides an

Ethernet conn ection for ne twork manage ment ac cess. The AS X-200B X hardware cons ists of a

single switch board with an i 960 SCP, network modules, redundant power supplies, and fans.

These components work together to provide ATM switching capabilities, as well as distributed connection setup and management.

Figure 1.3 -

ASX-200BX Switch Configuration

The ASX-1000, as shown in Figure 1.4, is a self-contained ATM switch that provides an Ethernet

connection for network management access. The hardware for the ASX-1000 consists of up to

four switch boards, each with an i960 SCP; network modules; redundant power supplies; a

Common Equipment Card (CEC); and a r emovable fan tray. These components work together to

provide ATM switching capabilities, as well as distributed connection setup and management.

Switch Hardware

ForeRunner

Figure 1.4 -

ATM Switch User’s Manual

ASX-1000 Switch Configuration

1 - 3

Switch Hardware

1.2 Switch Hardware Components

1.2.1 Switch Board

The switch board (also referred to as the “switch fabric”) contains the VPI/VCI lookup tables

and routing circuitry to ensure that a cell received from an input port is correctly switched to

one or more output ports. The ASX-200, the ASX-200WG, and the ASX-200BX each come with

one switch board. The ASX-1000 can be populated with as many as four switch boards. Each

switch board can accept up to four network modules, which themselves ca n contain up to six

ports each. The switch board also has an interface, controlled by the SCP, that is functionally

equivalent to an ATM host interface.

1.2.2 Switch Control Processor

The SPARC RISC SCP in the ASX-200 and the i960 SCP in the ASX-200WG, ASX-200BX, and

the ASX-1000 provide the distributed connection setup for a network of ATM switches. The

SCP primarily provides management access through SNMP and is responsibl e for storing and

updating all SNMP managemen t information. Additionally, the SCP has direct access to the

switch board. The SCP, and associated software, manages the behavior of the switch board

(i.e., connection setup), but is not involved in the actual cell switching.

1.2.2.1 SPARC RISC Switch Control Processor

The front panel of the ASX-200’s SPARC RISC SCP includes a RESET switch; an ABORT

switch; three single LEDs: the RUN/RESET LED, the VME BM (Bus Master) LED, and the

STATUS LED; a diagnostics display; two serial ports (labeled A and B); and an Ethernet port.

All of the features are illustrated in Figure 1.5 and are described in the subsections that follow.

Figure 1.5 -

1 - 4

ASX-200 SPARC RISC Switch Control Processor Front Panel

ForeRunner

ATM Switch User’s Manual

Switch Hardware

1.2.2.1.1 RESET Switch

The RESET switch on the SPARC RISC SCP allows the user to reset the SCP. After a reset, all

open ATM Management Interface (AMI) sessions are ended on the SCP, and all ports on the

switch board lose any active sessions and initially go off-line. The ports then return to the configuration stored in the configuration database (CDB).

1.2.2.1.2 ABORT Switch

When activated, the ABORT switch on the ASX-200 causes the SCP to go into Open Boot

PROM mode. This mode allows the user to run diagnostics on the controller hardware from a

terminal connected to Serial Port A. The SCP halts normal switch operations when in the

Open Boot PROM mode.

1.2.2.1.3 RUN/RESET LED

The RUN/RESET LED is red when any reset signal on the sw itch is active. It is off when the

switch itself is not active. In all other cases, it is green.

1.2.2.1.4 VME BM LED

The VME BM LED on the ASX-200 reflects all accesses from the SCP to the ASX-200 switch

board. When the SCP accesses the switch , this LED illuminates green. In all oth er cases, it is

off.

Switch Hardware

1.2.2.1.5 STATUS LED

The STATUS LED on the ASX-200 indicates that the SCP is functional by illuminating green. In

all other cases, it is off.

1.2.2.1.6 Diagnostics Display

The diagnostics display on the ASX-200 performs a count during a boot as part of normal

power-up diagnostics. A short LED test causes the display to flash a series of numbers indicating that the switch is booting properly. This display is only functional during the boot-u p p rocess.

1.2.2.1.7 RS-232 Serial Ports

The RS-232 serial ports (A and B) on the ASX-200 provide terminal access for any VT100 (or

similar) terminal or terminal emulation package to the SCP.

Hardware/software flow control is not

NOTE

supported on the RS-232 serial ports of the

SPARC RISC SCP.

ForeRunner

ATM Switch User’s Manual

1 - 5

Switch Hardware

1.2.2.1.8 Ethernet AUI Port

The Ethernet AUI port on the front panel of the ASX-200’s SCP has a standard DB-15 female

connector to provide Ethernet access to the switch.

1.2.2.2 i960 Switch Control Processor

The front panel of an i960 SCP for the ASX-200WG, ASX-200BX, and the ASX-1000 includes

the following features: a RESET button, an RS-232 serial port, an Ethernet 10BaseT port, a

NEXT pushbutton, a SELECT pushbutton, a display LED, and a power LED. All of the features are illustrated in Figure 1.6 and are described in detail in the subsections that follow.

Figure 1.6 - i960 Switch Control Processor Front Panel

1.2.2.2.1 RESET Button

The RESET button allows the user to reset the switch control software on the SCP. Using

RESET “soft boots” the SCP a nd runs the init ial powe r-on diagnosti cs. A ll open AM I se ssion s

are ended by the SCP, and all ports lose any active sessions and initially go off-line after a

reset. The ports then return to the configuration stored in the CDB. Because the RESET button

is small (to avoid accidental resets), it is recommended that you use a straightened paper clip

to push the RESET button.

1.2.2.2.2 RS-232 Serial Port

The RS-232 serial port provides terminal access for any VT100 (or similar) terminal or terminal

emulation package to the SCP. The serial port has a standard DB-9 female connector as shown

in Figure 1.7.

Pin 5

Pin 9

Pin 1

Pin 6

Figure 1.7 - RS-232 Serial Port Pinouts

1 - 6

ForeRunner

ATM Switch User’s Manual

Table 1. 1 describes the RS-232 serial port pinouts that are illustrated in Figure 1.7.

Switch Hardware

Pin Number

Table 1.1 -

Signal

Mnemonic

RS-232 Serial Port Pinouts

Signal Name

1 DCD Data Carrier Detect

2RXD Receive Data

3TXD Transmit Data

4 DTR Data Terminal Ready

5 GND Signal Ground

6 DSR Data Set Ready

7 RTS Request to Send

8 CTS Clear to Send

9 Not Used

1.2.2.2.3 Ethernet 10BaseT Port

The Ethernet 10BaseT port on the front panel of the SCP has a standard RJ45 connector. There

is a transmit LED to the left of this port and a receive LED to the right of this port. Table 1.2

and Table 1.2 describe the states of the LEDs and their meanings.

Table 1.2 -

Ethernet 10BaseT Transmit LED Description

Switch Hardware

ForeRunner

LED Color Meaning

red There is a collision on the port.

green The port is transmitting normally.

Table 1.3 -

LED Color Meaning

red The port is failing link integrity.

green The port is receiving normally.

ATM Switch User’s Manual

Ethernet 10BaseT Receive LED Description

1 - 7

Switch Hardware

1.2.2.2.4 CTL Port

A control port inside the SCP, referred to in the switch software as the CTL port, is a logical

(not physical) location where cells that are d irected to the SCP itself are sent. The CTL port has

two roles, serving as both a host and a s witch board controller. All signalling from the switch

host and every attached host must interact with the switch board controller.

1.2.2.2.5 NEXT Pushbutton

The NEXT pushbutton lets you scroll through the menu th at is shown on the display LED

after the power is turned on or after the SCP is reset/rebooted.

1.2.2.2.6 SELECT Pushbutton

The SELECT pushbutton lets you choose an option from the menu that is shown on the display LED after the power is turned on or after the SCP is reset/rebooted.

1.2.2.2.7 Display LED

During the boot process and the initial power-on diagnostics, the displa y LED shows messages about what is happening to the SCP. It is also used to show the men u choices for the

NEXT and SELECT pushbuttons after the power is turned on or after the SCP is reset/rebooted. The choices shown on the display LED are as follows:

Flash ?

When chosen, the SCP will attempt to boot from the

FLASH file.

Ethernet ?

Monitor ?

When chosen, the SCP boots from the network.

When chosen, the user can connect a terminal to the

serial port and run hardware self-diagnostics.

Auto ?

When chosen, the SCP will attempt to boot from the

FLASH. If this is unsuccessful, then the SCP will

perform an Ethernet boot.

To access the modes listed above, press the NEXT pushbutton while the switch is booting until

the mode you want to access is displayed LED. Then, press the SELECT pushbutton.

After the boot process and self-diagnostics are complete, the name of the SCP is shown in the

display LED during normal operations, if an SCP name has been assigned. If an SCP name has

not been assigned, it will display ATM SWITCH. For information on creating or modifying the

SCP name, please refer to the section on configuring the SCP name in the ATM Management

Interface Manual.

1 - 8

ForeRunner

ATM Switch User’s Manual

Switch Hardware

1.2.2.2.8 Power LED

The power LED that is located to the right of the display LED on the front panel of the SCP

reflects the current state of power to the SCP. Table 1.2 lists the states of the power LED and

their meanings.

Table 1.4 -

Power LED Description

LED Color Meaning

red The SCP has power, but has failed. (The individual

SCP, not the entire switch, has not passed

self-diagnostics.)

green The SCP is powered up and is in good status.

off There is no power to the SCP.

A power switch is located on the upper right-hand corner of the ASX-200WG. When the

power is turned on, the power LED, located to the right of the display LED, illuminates green

and the initial power-on diagnostics are run. When the power is turned off, the power LED is

extinguished.

1.2.3 Dual SCP Setup

This section explains SCP failover support, a vailable when two SCPs a re installed in a single

ASX-200BX or ASX-1000 switch fabric. For more information about configuring dual SCP’s via

AMI, see the ATM Management Interface Manual.

Only SCP-ASXHAs, or later, support the dual

NOTE

SCP configuration. Using an earlier version SCP

in a redundant configuration can cause

irreparable damage to your switch fabric.

Switch Hardware

When two SCPs are installed in a switch fabric, the switch recognizes their presence and automatically runs in dual SCP mode. When the switch boots, the SCP which resides in slot X is

designated as the primary SCP by default. However, this designation can be altered via AMI.

The SCP which resides in slot Y is designated as the standby SCP by default.

While in dual SCP mode, the controlling SCP emits a “heartbeat” at regular intervals. This

heartbeat is monitored by the standby SCP. In the event of a hardware failure on the controlling SCP, the heartbeat disappears and the standby SC P takes over.

ForeRunner

ATM Switch User’s Manual

1 - 9

Switch Hardware

Switch configuration information (i.e., CDB configuration, FLASH configuration, etc.) can be

synchronized between the controlling and standby SCP so that this inform ation is maintained

if SCP failover occurs.

If a failure is detected on the controlling SCP, th e standby SCP takes control of the fabric. At

this point, PVC connections are dropped, and any SVCs that had been established are torn

down at the switch. Once the standby SCP takes contro l of the switch fabric, PVCs will be reestablished (according to the “last-synchronized” CDB), and end-stations will signal the switch

to create new SVCs. The larger the CDB (e.g., number of PVCs), the longer the standby SCP w ill

take to fully restore the switch.

The failed SCP can then be removed and replaced with another HA-based SCP.

A standby SCP (SCP-ASXHA or later) can be

NOTE

hot-inserted into the slot from which a failed SCP

has been removed.

Repeated and successive hot-insertion or

removal of a standby SCP can potentially cause a

reset on the primary SCP. This occurrence is

intermittent, but will result in cell loss if it does

occur.

For proper synchronization of information

NOTE

between SCPs, ensure that the amount of free

space on both SCPs is roughly equal before

performing these commands.

1.2.3.1 Adding a Standby SCP

If only one SCP is instal led in the switch fabric, it a utomatically assu mes itself to be the co ntrolling SCP. In this case, the S CP periodically checks the fabric for the presence of a second

SCP. If a second SCP is detected, the switch will begin to run in dual SCP mode.

While in dual mode, the controlling SCP continually monitors the presence of the standby

SCP. If the controlling S CP fails to detect a second S CP, the controlling SCP disab les all synchronization and runs in standalone mode (not dual).

1 - 10

ForeRunner

ATM Switch User’s Manual

Switch Hardware

1.2.3.2 Rebooting the Controlling SCP

When the switch is running in dual mode, a reboot request on the controlling SCP (i.e., after a

software upgrade) will not cause the standby SCP to take control of the switch. Instead, the

controlling SCP will send a pause signal to the s tandby SCP.

This pause request will force the standby SCP to disregard the absence of the controlling SCP

for two minutes. Once the controlling SCP co mes back up, both SCPs will assume normal,

dual mode operation.

1.2.3.3 Ethernet Connection

When two SCPs are installed in an ASX-200BX, Ethernet connectivity is only available if the

Ethernet port on each SCP is physically connected to the network. If dual SCP mode is utilized

on an ASX-1000, the Ethernet connection can be made using the individual SCPs or the Ethernet port on the ASX-1000’s Common Equipment Card (CEC).

If the SCP is accessed via ATM, the Ethernet connection is not necessary.

If two SCPs are installed in a switch fabric, each

NOTE

SCP must have its own entry in the bootpta b file

(used for network booting) to a ssign each SCP a

unique IP address. Using only one entry (i.e., the

same IP address) causes unpredictable Ethernet

ARP behavior (see Chapter 4 for more

information).

Switch Hardware

1.2.4 Network Modules

The network modules in a ForeRunner switch board act as the physical input/output ports to

the switch board. A network module may have one, two, four, or six physical ports, depending on its configuration.

ForeRunner

ATM Switch User’s Manual

1 - 11

Switch Hardware

1.2.4.1 Port Numbering

The individual ports on a network module are numbered according to the Board-Network

Module-Port (BNP) notation.

Board Refers to the number of the switch board that

contains the port being numbered. “Board” is always

1 in an ASX-200, ASX-200BX, or an ASX-200WG,

since these switches each contain only one switch

board. “Board” can be 1, 2, 3, or 4 in an ASX-1000,

depending on the number of the physical switch

board that contains the port being numbered.

Network Module Refers to the slot (A, B, C, or D) in the switch board

that contains the port being numbered.

Port Refers to the physical port (1 - 6) being numbered on

the individual network module.

For example, according to this notation, the fourth port on a network module in slot B of

switch board #2 is port 2B4.

Figure 1.8 illustrates how the ports of various netw ork modules, located in sw itch board #4 of

an ASX-1000, for example, would be numbered.

PORT PORT PORT PORT

4C1 4C2 4C3 4C4

C

A

PORT

4A1

NOTE

1 - 12

Figure 1.8 -

PORT PORT PORT

4D1

4D2

PORT PORT

4B1 4B2

PORT PORT PORT

4D4

4D3

4D5 4D6

Network Module Port Numbering

For information about the technical and

operating specifications fo r all ForeRunner ATM

network modules, see Appendix C, “ForeRun ner

Hardware Specifications,” in this manual.

ForeRunner

ATM Switch User’s Manual

D

B

Switch Hardware

1.2.5 Power Supply Modules

The ASX-200BX and the ASX-1000 each come with two removable power supply modules,

either AC or DC. In the event of a single power supply failure, the power supply indicator

LED(s) on the front panel of the supplies will indicate the failed supply. The failed power supply can be removed and replaced while the other supply continues to provide power to the

enclosure. In this manner, a single power supply failure will not cause the switch to stop functioning.

WARNING!

The ASX-200 and the ASX-200WG come with

internal, non-removable power supplies.

Attempting to remove these power supplies

could result in serious injury or may cause

permanent damage to the unit.

1.2.5.1 ASX-200BX AC Power Supply

The ASX-200BX has two power supply LEDs, one for each removable, hot- swappable power

supply. Each LED is located to the left of the power switch on the front panel for that supply.

On the AC power supply for the ASX-200BX, the LED is green under normal circumstances,

indicating that the 5-volt supply coming from that particular power supply is functioning

properly.

CAUTION

If the power supply LED is red, the faulty supply

should be turned off as soon as possible, using

the single power switch which controls power to

that supply. The problem should then be

diagnosed and repaired. Please refer to Chapter

3, Hardware Maintenance Procedures, for details

about how to hot-swap a power supply in the

ASX-200BX.

Switch Hardware

ForeRunner

NOTE

ATM Switch User’s Manual

A replacement AC power supply will not

function in a DC-equipped ASX-200BX, and viceversa. However, no damage will be done if this

occurs.

1 - 13

Switch Hardware

1.2.5.2 ASX-200BX -48 Volt DC Power Supply

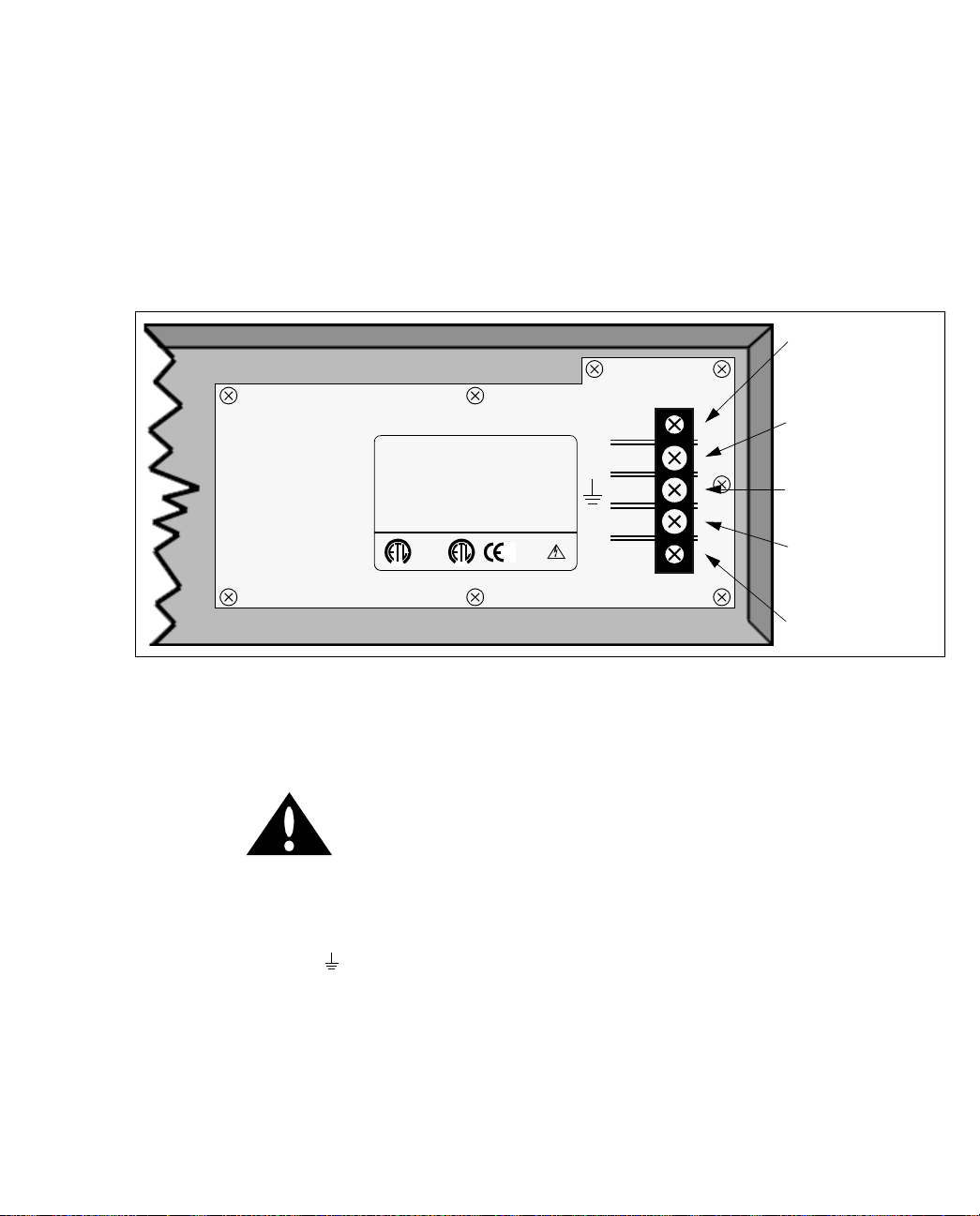

On the back of the DC-equipped ASX-200BX, there are two three-terminal barrier terminal

strips, one for each -48 volt DC power supply, as shown in Figure 1.9. The screw terminals are

#6 screws. The -48 volt feed wires should be attached to the terminal strips using wire terminals designed to fit #6 studs. FORE Systems recommends using eith er ring terminals o r locking forked tongue terminals. Wire gauge should be AWG #16 or larger.

Retaining Screw

Positive Terminal

FORE

SYSTEMS

THIS DEVICE COMPLIES WITH P ART 15 OF THE FCC R ULES, OPERA TION

IS SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE

MAY NO T CAU SE HARMF UL INTE RFEREN CE, AND (2) THI S DEVIC E MUST

ACCEPT ANY INTERFERENCE RECEI VED, INCLUDING INTERFERENCE

THAT MA Y CA USE UNDESIRED OP ERA TION.

CONFORMS TO

ANSI / UL STD 1969

CERTIFIED TO

CAN / CSA STD

C22.2 NO. 960

®

39432

Serial #

Model # ASX-200BX DC

™

U.S. PATENT # 5,32 3, 3 89

C

®

36 - 76 VDC === (DC)

10A

MADE IN U.S.A.

+

Ground Terminal

_

Negative Terminal

Retaining Screw

Figure 1.9 -

CAUTION

Rear Panel of a DC-powered ASX-200BX

Be sure to observe polarity. Failure to do so may

cause permanent damage to the unit.

The higher potential wire should be connected to the positive (+) terminal, and the lower

potential wire to the negative (–) terminal. The chassis ground wire also should be connected

to the center terminal ( ) and connected to an earth ground.

1 - 14

ForeRunner

ATM Switch User’s Manual

Power Supply LEDs

Switch Hardware

Figure 1.10 -

Front View of an ASX-200BX’s DC Power Supplies

The ASX-200BX has two power supply LEDs, one for each removable, hot-swappable power

supply. Each LED is located to the left of the power switch on the front panel for that supply as

shown in Figure 1.10. On the DC power supply for the ASX-200BX, the LED is green under

normal circumstances, indicating that the 5-volt supply coming from that particular power

supply is functioning properly.

CAUTION

If the power supply LED is red, the faulty supply

should be turned off as soon as possible, using

the single power switch which controls power to

that supply. The problem should then be

diagnosed and repaired. Please refer to Chapter

3, Hardware Maintenance Procedures, for details

about how to hot-swap a power supply in the

ASX-200BX.

A replacement DC power supply will not

NOTE

function in an AC-equipped ASX-200BX, and

vice-versa. However, no damage will be done if

this occurs.

Switch Hardware

ForeRunner

ATM Switch User’s Manual

1 - 15

Switch Hardware

1.2.5.3 ASX-1000 AC Power Supply (Model A)

The model A AC power supply for an ASX-1000 is shown in Figure 1.11.

Retention

screws

Ejection/insertion

handle

Figure 1.11 -

Model A ASX-1000 AC Power Supply

1.2.5.3.1 Power Supply LEDs

There are four status LEDs on the front panel of the model A ASX-1000 AC power supply. The

LEDs and their functions are described in Table 1.5.

1 - 16

ForeRunner

ATM Switch User’s Manual

Switch Hardware

Table 1.5 -

ASX-1000 Power Supply LED Descriptions

LED Color Meaning

Green Input voltage is OK

AC OK

extinguished No input voltage or unit has shut down

Green Backplane output is OK

DC OK

extinguished Backplane output is not present or out of range

Green Backplane standby voltage is OK

5VDC OK

extinguished Backplane standby voltage not present or out of

range

Yellow Supply is in shutdown

SHUTDOWN

extinguished Supply is operating correctly or is OFF

1.2.5.3.2 Shutdown Conditions

To av oid damaging itself or the s witch, the model B ASX-1000 A C power supply shuts itself

down under the following condition:

Overload The power supply is overloaded or the AC input is

out of specification, and the supply voluntarily shuts

down to avoid damage to the system.

Switch Hardware

The ASX-1000 CEC can not shut down the model

NOTE

A power supply. Only the power supply can

shut itself down in an overload state.

If a model A power supply goes into shutdo wn, it will remain shut down until the power

switch is turned off and turned on again (power cycle). The power switch must remain off

long enough for the SHUTDOWN LED to extinguish (this allows the capacitors to discharge).

WARNING!

A replacement AC power supply should never

be placed in a n AS X-1 00 0 that al ready con ta ins a

DC power supply, and vice-versa. If these

instructions are not heeded, there is a risk of

electrical shock, danger to personal health, and

serious damage to the equipment.

ForeRunner

ATM Switch User’s Manual

1 - 17

Switch Hardware

If the power supply needs to be replaced, please refer to Chapter 3 for hot-swap information.

1.2.5.4 ASX-1000 AC Power Supply (Model B)

The model B AC power supply for an ASX-1000 is shown in Figure 1.12.

ON/OFF Switch

Captive

Handle

fasteners

Figure 1.12 -

Model B ASX-1000 AC Power Supply

1.2.5.4.1 Power Supply LEDs

There are f our LEDs on the fr ont pa nel of the mode l B ASX-100 0 AC power supply which indicate the status of the power supply. The LEDs and their functions are described in Table 1.6:

1 - 18

ForeRunner

ATM Switch User’s Manual

Switch Hardware

Table 1.6 -

ASX-1000 Power Supply LED Descriptions

LED Color Meaning

Green Input voltage is OK

PWR OK

extinguished No input voltage or unit has shut down

Yellow Power supply has faulted

FAULT

extinguished No faults detected in power supply

Yellow Operating temperature out of range

TEMP

extinguished Running within safe temperature range

Yellow Overload condition

I LIM

extinguished Load in range

1.2.5.4.2 Shutdown Conditions

To av oid damaging itself or the s witch, the model B ASX-1000 A C power supply shuts itself

down under the following error conditions:

Input undervoltage The AC line voltage is below 87 ±5VAC RMS.

Output undervoltage Output 1 is 42 ±2 VDC o r Output 2 is below 4.5 ±0.25

VDC. Shutdown from undervoltage is defeated

during power-up period (2 seconds maximum) to

allow slow-start.

Switch Hardware

Output overvoltage The voltage at Output 1 or Output 2 is above 125%

±8% of the nominal voltage.

Overtemperature Any power semiconductor has reached 90% of its

maximum junction temper ature.

The ASX-1000 CEC can not shut down the model

NOTE

B power supply. Only the power supply can shut

down and restart itself.

If a model B power supply goes into sh utdown, i t remains turn ed off until the f ault co ndition

is rectified. At that point, the pow er supp ly restarts its elf, except in the cas e of an overvolta ge

condition.

To recover from a shutdown caused by an overvoltage state, the AC line input must be turned

off for at least one second.

ForeRunner

ATM Switch User’s Manual

1 - 19

Switch Hardware

WARNING!

If the power supply needs to be replaced, please refer to Chapter 3, Hardware Maintenance

Procedures, for hot-swap information.

A replacement AC power supply should never

be placed in a n AS X-1 00 0 that al ready con ta ins a

DC power supply, and vice-versa. If these

instructions are not heeded, there is a risk of

electrical shock, danger to personal health, and

serious damage to the equipment.

1.2.5.5 ASX-1000 -48 Volt DC Power Supply

On the front of the -48 volt ASX-1000 power supply, there are two thr ee-terminal barrier terminal strips, one for each power supply. The screw terminals are #6 screws. The -48 volt feed

wires should be attached to the terminal strips using wire terminals desig ned to fit #6 st uds.

FORE Systems recommends using either ring terminals or locking forked tongue terminal s.

Wire gauge should be AWG #12 or larger.

WARNING!

Be sure to observe polarity when attaching the

wire leads to the terminals. Failure to observe

polarity may result in injury or cause permanent

damage to the unit.

The higher potential wire should be connected to the positive (+) terminal, and the lower

potential wire to the negative (–) terminal. The chassis ground wire should be connected to the

center terminal ( ) and connected to an earth ground.

The ASX-1000 has a single power supply LED on the front panel of each -48V DC power supply module. Under normal conditions, the LED is green, indicating that the voltage supplied

to the module is above 40 volts DC. If the LED is red or is extinguished, the power supply

module should be removed and examined for defect. How ever, the LED may turn red because

the voltage being supplied to the module is insufficient. If the power su pply itself is f ound to

be defective, please refer to Chapter 3, Hardware Maintenance Procedures, for information

about how to hot-swap the failed power supply.

1 - 20

ForeRunner

ATM Switch User’s Manual

Switch Hardware

WARNING!

A replacement DC power supply should never

be placed in an ASX-1000 that already contains

an AC power supply, and vice-versa. If these

instructions are not heeded, there is a risk of

electrical shock, danger to personal health, and

serious damage to the equipment.

1.2.6 ASX-1000 Fan Tray

The ASX-1000 comes with a removable fan tray. The speed of each fan is monitored by circuitry in the CEC, and is available via SNMP. In this manner, the failure of any fan can be

detected immediately. The fan tray is hot-swappable, and the entire tray may be replaced in

the event of single or multiple fan failure. For informat ion about how to hot- swap a fan tray,

refer to Chapter 3, ”Hardware Maintenance Procedures.”

The fans in the ASX-200, the ASX-200WG, and

NOTE

the ASX-200BX are not removable.

1.2.7 ASX-1000 Temperature Sensing

In the ASX-1000, a built-in thermal temperature sensor r esides on each switch board and r ead s

out the board’s local temperature. By default, the switch control software will trigger an alarm

at 65°C and will reset the alarm when the temperature drops back down to 60°C or lower.

However, the user can configure these alarm and reset thresholds in the software on an individual board via AMI. Please refer to the ATM Management Interface Manual for more informa-

tion about configuring these thresholds. If th e tem perature of an individual switch boar d were

to reach 75°C, the switch board would shut itself down immediately.

Switch Hardware

ForeRunner

CAUTION

ATM Switch User’s Manual

This overtemperature condition is detectable by

software, and will trigger an alarm condition

which is visible through ForeView Network

Management. Upon detection of an

overtemperature condition, the ASX- 100 0 sho uld

be turned off to avoid damage to internal

components.

1 - 21

Switch Hardware

1.2.8 ASX-1000 Common Equipment Card (CEC)

The CEC provided with the ASX-1000 performs several functions. Because each SCP contains

an Ethernet port, a major function of the CEC is to provide a single, unified Ethernet port connection for all of the SCPs. The CEC is also responsible for monitoring the environmental conditions of the switch and reporting this information to the SCPs. Th e CEC reports conditions

such as malfunctioning fans, overheated power supplies, and an overheated enclosure.

Two different CECs currently exist, model A and B. Both CECs operate in exactly the same

way, and both are inserted/removed in the same way. The only difference between the model

A and model B CEC is in the front panel labelling. On the model B card, component labels are

read left to right with the CEC installed (vertically) in the switch . Also, the alarm relay contacts and alarm LEDs are labelled individually for easier identification.

1.2.8.1 CEC Front Panel

The front panel of the ASX-1000 CEC includes the following features: alarm relay contacts,

CEC status LEDs, and an Ethernet port with four LEDS. These features are illustrated in Figure 1.13 (model A) and Figure 1.14 (model B). Refer to the following subsections for detailed

descriptions of these features.

AL1 AL2

Figure 1.13 -

AL1

AL2

CEC Front Panel Status Indicators (Model A)

RX

LI

COL

POL

ETH

1 - 22

ForeRunner

ATM Switch User’s Manual

AL1

AL2

AL2 / AL1

PS1 / PS2

SW3 / SW4

SW1 / SW2

Switch Hardware

LI RX

ETH

POL COL

Figure 1.14 -

CEC Front Panel Status Indicators (Model B)

1.2.8.2 Alarm Relay Contacts

Pins 1 and 2 are the contac ts for A L1, an d pin s 3 and 4 are the c ontac ts for A L2. Al thou gh the

pins are not actually labeled on an ASX-1000 CEC, they will be referred to sequentially from

top to bottom (i.e., pin 1 is the top pin when the CEC is installed in the switch, and pin 4 is the

bottom pin).

Switch Hardware

ForeRunner

ATM Switch User’s Manual

1 - 23

Switch Hardware

Pin 1

Pin 2

Pin 3

Pin 4

Figure 1.15 - Alarm Relay Contacts for AL1 and AL2

The alarm relay contacts are normally closed when there is no power to the switch. The user