Page 1

303-06-1 303-06-1Starting System

DIAGNOSIS AND TESTING

Starting System

Refer to Wiring Diagrams Cell 20, Starting System

for schematic and connector information.

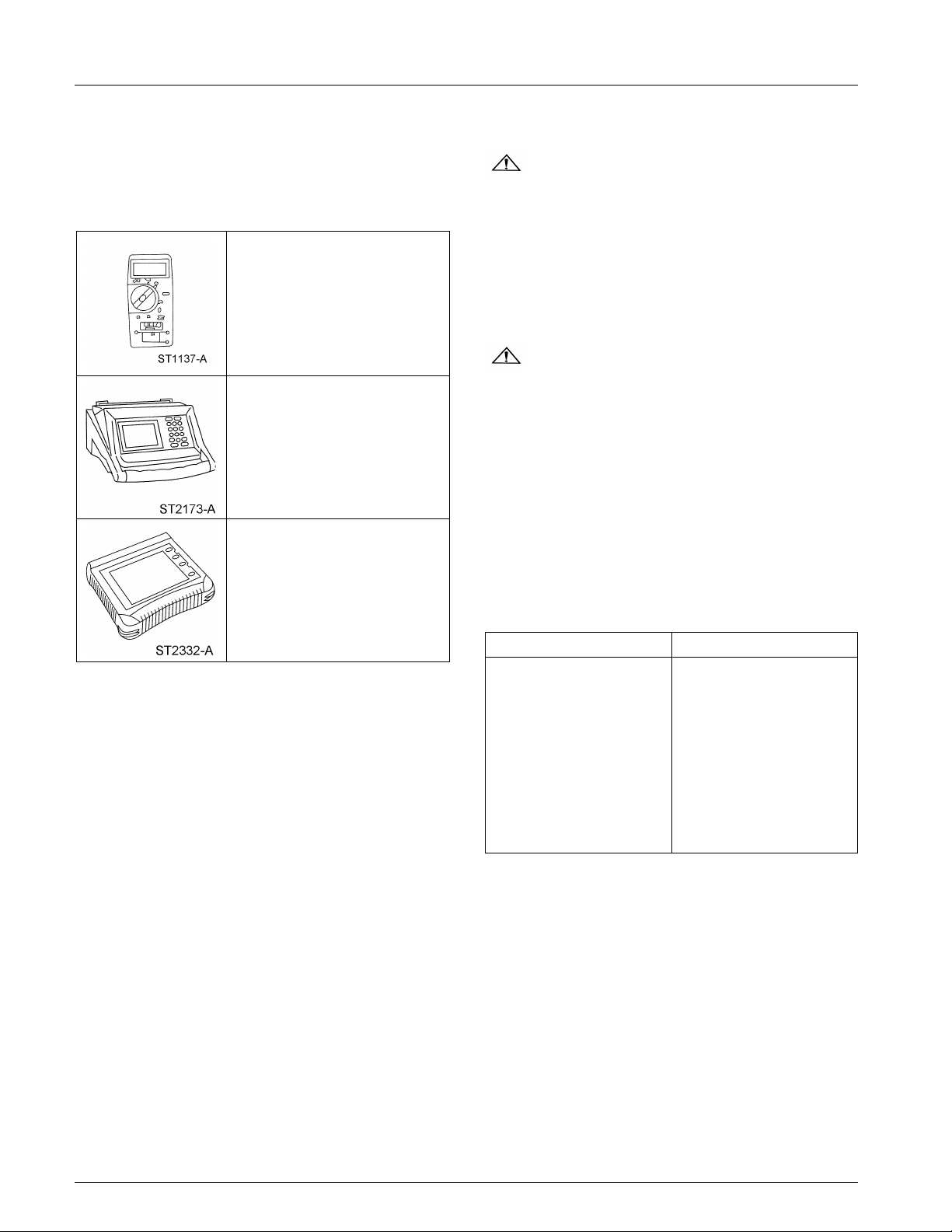

Special Tool(s)

73 Digital Multimeter

105-R0051 or equivalent

SABRE Premium Battery and

Electrical System Tester

010-00730 or equivalent

Worldwide Diagnostic System

(WDS)

Vehicle Communication Module

(VCM) with appropriate

adapters, or equivalent

diagnostic tool

Inspection and Verification

WARNING: When servicing the starter

motor or carrying out other underhood work in

the vicinity of the starter motor, be aware that

the heavy gauge battery input lead at the starter

solenoid is ‘‘electrically hot’’ at all times. A

protective cap or boot is provided over the

terminal of this lead and must be installed after

servicing. Failure to follow these instructions may

result in personal injury.

WARNING: When working in the area of

the starter motor, be careful to avoid touching

hot exhaust components. Failure to follow these

instructions may result in personal injury.

NOTE: When working on the starter system, make

sure the anti-theft system is deactivated, if equipped.

1. Verify the customer concern by operating the

starting system.

2. Visually inspect for obvious signs of

mechanical and electrical damage. Refer to the

following chart:

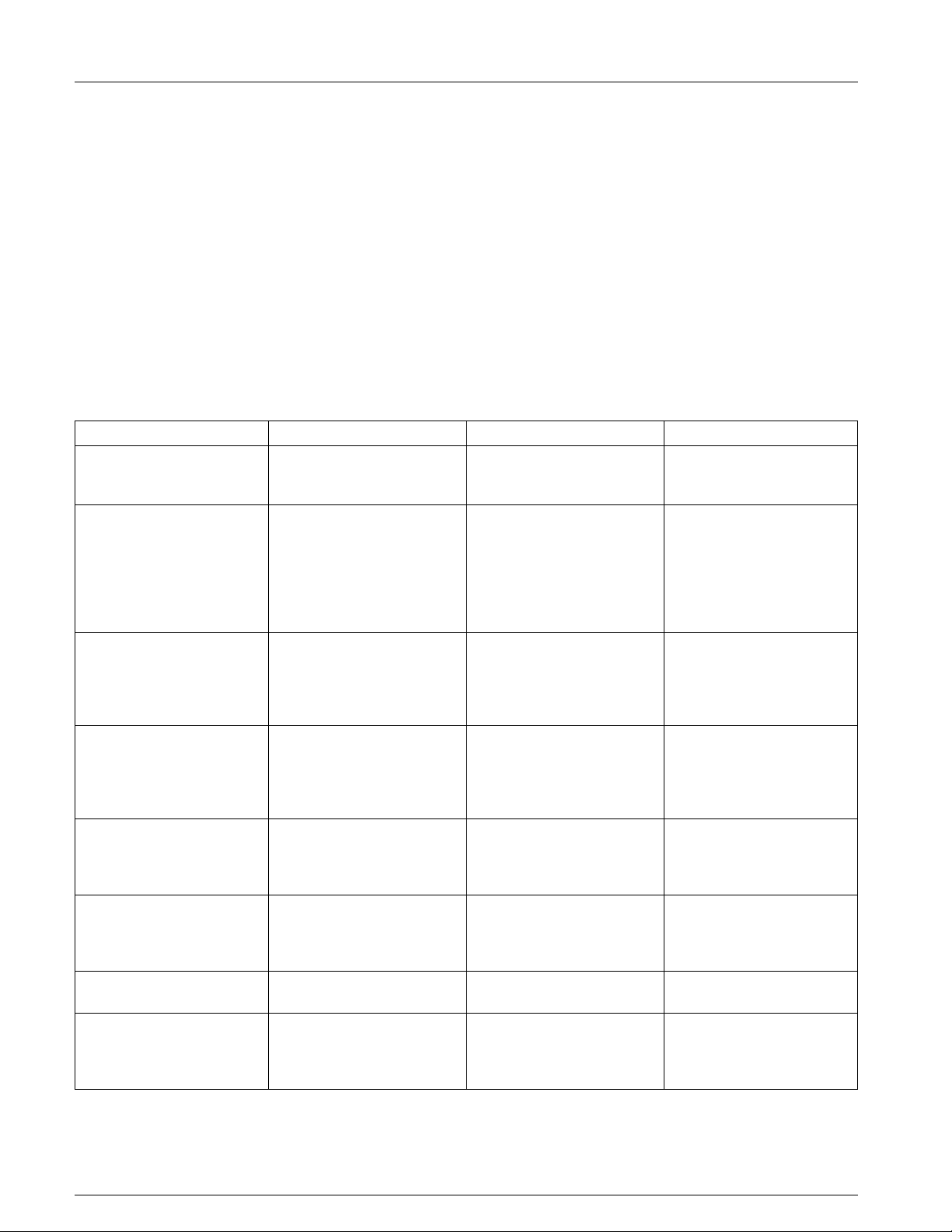

Visual Inspection Chart

Principles of Operation

The starting system is electronically controlled by

the passive anti-theft system (PATS). The PATS

recognizes the correct electronically coded ignition

key and signals the instrument cluster to provide a

ground for the starter relay. The energized relay

provides voltage to the starter solenoid with the key

in the START position, thereby allowing the starter

motor to activate.

Mechanical Electrical

• Starter motor • Battery

• Brackets • Smart junction box

(SJB) fuse:

— 21 (10A)

• Bussed electrical center

(BEC) fuse:

— 3 (30A)

• Anti-theft system

• Damaged wiring harness

• Loose or corroded

connections

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, connect the

diagnostic tool to the data link connector (DLC)

and select the vehicle to be tested from the

diagnostic tool menu. If the diagnostic tool does

not communicate with the vehicle:

• check that the program card is correctly

installed.

• check the connections to the vehicle.

• check the ignition switch position.

Copyright 2004, Ford Motor Company

Last updated: 12/8/2004

2005 Mustang, 12/2004

Page 2

303-06-2 303-06-2Starting System

DIAGNOSIS AND TESTING (Continued)

5. If the diagnostic tool still does not communicate • System passed, retrieve and record the

with the vehicle, refer to the diagnostic tool continuous diagnostic trouble codes (DTCs),

operating manual. erase the continuous DTCs and carry out the

6. Carry out the diagnostic tool data link test. If

the diagnostic tool responds with: 7. If the DTCs retrieved are related to the concern,

• [appropriate communication networks, such

as SCP, ISO, UBP, CAN] circuit fault; all

electronic control units no response/not 8. If no DTCs related to the concern are retrieved,

equipped, refer to Section 418-00. GO to Symptom Chart.

• No response/not equipped for generic

electronic module (GEM), refer to Section

419-10.

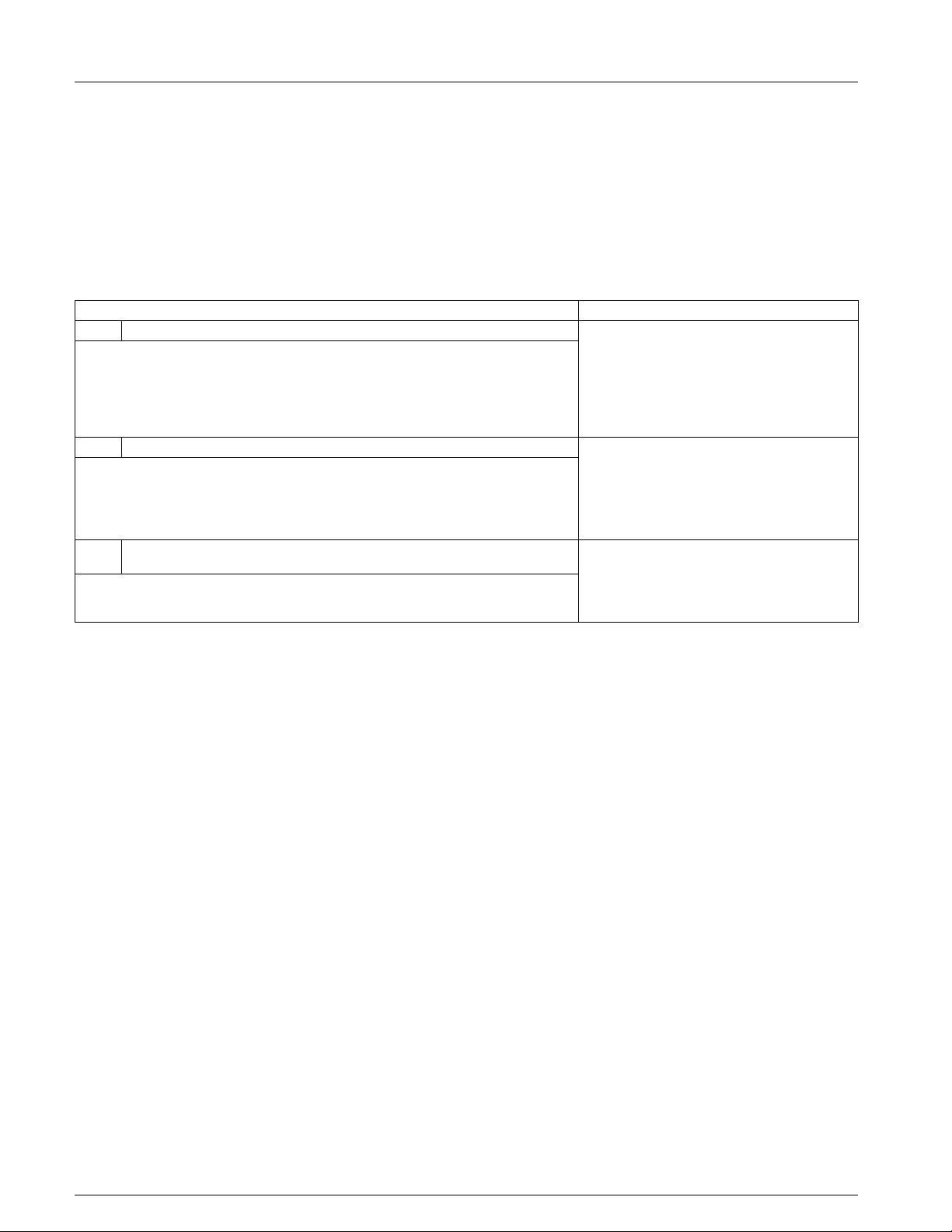

Passive Anti-Theft System (PATS) — Diagnostic Trouble Code (DTC) Index

DTC Description Source Action

B1213 Anti-Theft Number Of Powertrain Control Module REFER to Section

Programmed Keys Is (PCM) 419-01B.

Below Minimum

B1342 ECU is Defective PCM CLEAR the DTCs.

B1600 Passive Anti-Theft System PCM REFER to Section

(PATS) Key Transponder 419-01B.

Is Not Received —

Damaged Key Or

Non-PATS Key

B1601 PATS Received Incorrect PCM REFER to Section

Key-Code From Key 419-01B.

Transponder

(Unprogrammed PATS

Key)

B1602 or B2431 PATS Received Invalid PCM REFER to Section

Format Of Key-Code From 419-01B.

Key Transponder (Partial

Key Read)

B1681 PATS Transceiver Module PCM REFER to Section

Signal Is Not Received 419-01B.

(Damaged, Not Connected

Or Damaged Wiring)

B2103 Internal Transceiver PCM REFER to Section

Antenna Damaged 419-01B.

P1260 PCM Disabled — Vehicle PCM REPAIR the PCM. REFER

Disabled to the Powertrain

self-test diagnostics for the GEM.

go to the Generic Electronic Module (GEM)

Diagnostic Trouble Code (DTC) Index.

REPEAT the self-test. If

DTC B1342 is retrieved

again, INSTALL a PCM.

REFER to Section 303-14.

CLEAR the DTCs.

REPEAT the self-test.

Control/Emissions

Diagnosis (PC/ED) manual.

2005 Mustang, 12/2004

Page 3

303-06-3 303-06-3Starting System

DIAGNOSIS AND TESTING (Continued)

Symptom Chart

Symptom Chart

Condition Possible Sources Action

• The engine does not crank • Battery • GO to Pinpoint Test A.

and the relay does not click • Fuse

• Starter relay

• Ignition switch

• Digital transmission range

(TR) sensor (automatic

transmission only)

• Clutch pedal position (CPP)

switch (manual transmission

only)

• Circuit

• The engine does not crank • Fuse • GO to Pinpoint Test B.

and the relay does click • Battery

• Starter motor/solenoid

• Ignition switch

• Circuit

• The engine cranks slowly • Battery • GO to Pinpoint Test C.

• Starter motor/solenoid

• Circuit

• Unusual starter noise • Starter mounting • GO to Pinpoint Test D.

• Flexplate or flywheel

• Starter motor

• The starter spins but the • Starter motor • INSPECT the starter motor

engine does not crank • Damaged flexplate or mounting and engagement.

flywheel ring gear teeth INSTALL a new starter

motor. REFER to Starter

Motor — 4.0L SOHC or

Starter Motor — 4.6L (3V) in

this section.

• INSPECT the flexplate or

flywheel for damaged,

missing or worn teeth.

REPAIR as required.

Pinpoint Tests

Pinpoint Test A: The Engine Does Not Crank

And The Relay Does Not Click

Normal Operation

In normal operation, voltage from the bussed

electrical center (BEC) is supplied to the ignition

switch through circuit 1050 (LG/PK). When the

ignition switch is placed in the START position,

voltage is supplied through circuit 1522 (DG) to the

smart junction box (SJB).

For automatic transmission equipped vehicles,

voltage is supplied from the SJB to the digital

transmission range (TR) sensor through circuit 32

(RD/LB). In PARK or NEUTRAL, voltage is

supplied from the TR sensor through circuit 33

(WH/PK) to the starter relay coil located in the

BEC. The starter relay coil is supplied ground from

the PCM through circuit 1419 (LG/YE).

For manual transmission equipped vehicles, voltage

from the SJB is supplied to the clutch pedal position

switch (CPP) through circuit 32 (RD/LB). When the

clutch pedal is depressed, voltage is supplied from

the CPP to the starter relay coil located in the BEC

through circuit 32 (RD/LB). The starter relay coil is

supplied ground from the PCM through circuit 1419

(LG/YE).

2005 Mustang, 12/2004

Page 4

303-06-4 303-06-4Starting System

DIAGNOSIS AND TESTING (Continued)

When the starter relay is energized, voltage supplied

to the relay switch is sent to the starter motor

solenoid through circuit 113 (YE/LB). Battery

voltage is supplied to the starter motor through

Possible Causes

• Fuse(s)

• An open in battery voltage feed BEC, 2037 (RD)

circuit 2037 (RD) at all times.

• Starter motor relay

• Starter

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK

Test Step Result / Action to Take

A1 CHECK THE BATTERY

• Check the battery condition and charge if necessary. Refer to

Section 414-01. GO to A2.

• Is the battery OK?

A2 CHECK FOR PATS DTCS

• NOTE: The PATS DTCs are the only DTCs of concern in this

step. Only repair retrieved non-PATS DTCs if a customer GO to Section 419-01B to diagnose the

concern is reported. PATS DTCs.

Check for PATS DTCs.

• Were any PATS DTCs retrieved?

A3 CHECK CIRCUIT 33 (WH/PK) (CIRCUIT 32 [RD/LB] MANUAL

TRANSMISSION ONLY) FOR VOLTAGE

• Disconnect: Starter Motor Relay.

• Key in START position.

• If equipped, fully depress the clutch pedal.

or 113 (YE/LB)

Yes

No

CHARGE or INSTALL a new battery as

necessary. REFER to Section 414-01.

TEST the system for normal operation.

Yes

No

GO to A3.

(Continued)

2005 Mustang, 12/2004

Page 5

303-06-5 303-06-5Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A3 CHECK CIRCUIT 33 (WH/PK) (CIRCUIT 32 [RD/LB] MANUAL

TRANSMISSION ONLY) FOR VOLTAGE (Continued)

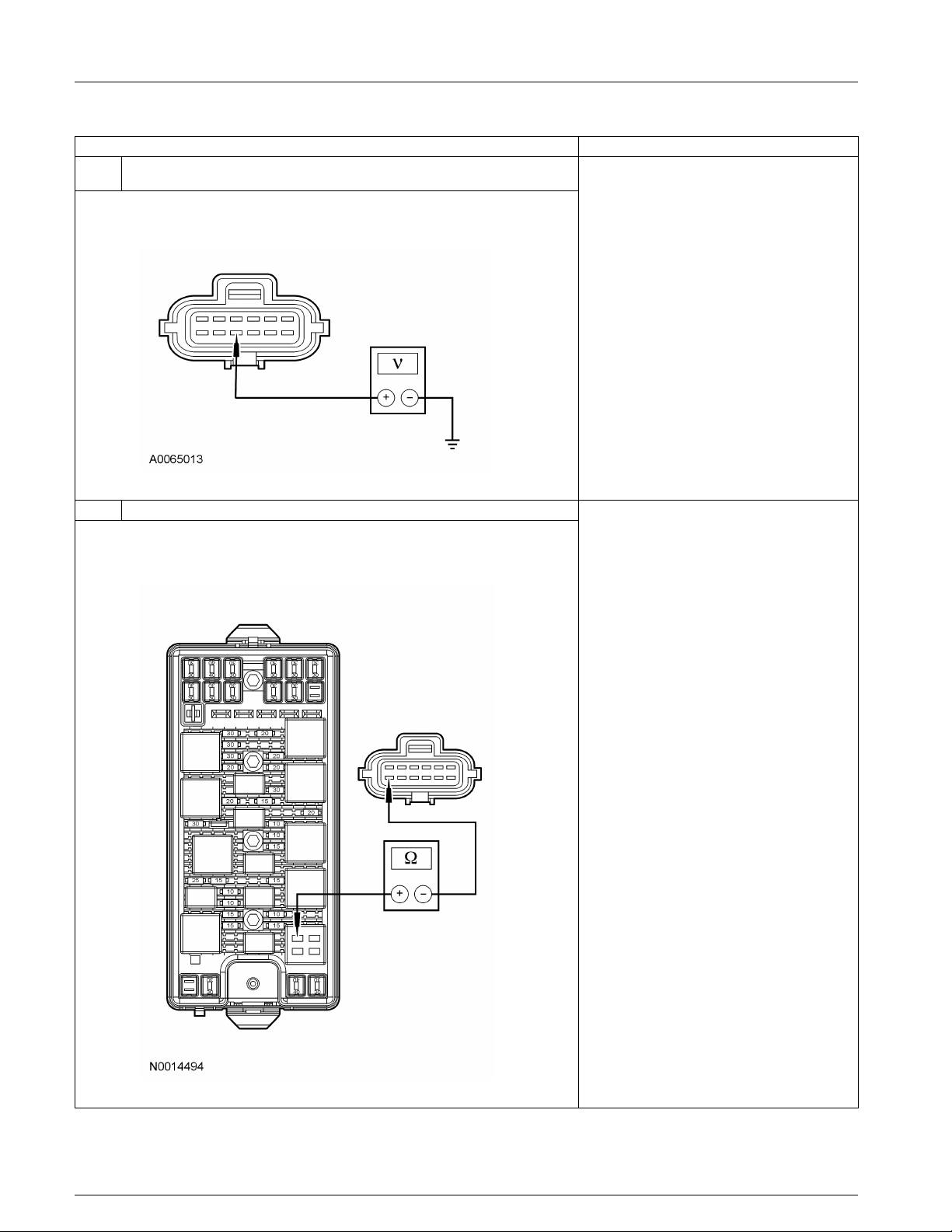

• Measure the voltage between starter motor relay C1017-85,

circuit 33 (WH/PK) (circuit 32 [RD/LB] manual transmission only)

and ground while holding the key in the START position and

with the clutch pedal, if equipped, fully depressed.

• Is the voltage greater than 10 volts? to A7.

A4 CHECK CIRCUIT 32 (RD/LB) FOR VOLTAGE AT THE DIGITAL

TR SENSOR (AUTOMATIC TRANSMISSION ONLY)

• Key in OFF position.

• Disconnect: Digital TR Sensor C167.

• Key in START position.

Yes

GO to A12.

No

Vehicles equipped with an automatic

transmission, GO to A4. Vehicles

equipped with a manual transmission, GO

(Continued)

2005 Mustang, 12/2004

Page 6

303-06-6 303-06-6Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A4 CHECK CIRCUIT 32 (RD/LB) FOR VOLTAGE AT THE DIGITAL

TR SENSOR (AUTOMATIC TRANSMISSION ONLY) (Continued)

• Measure the voltage between digital TR sensor C167-10, circuit

32 (RD/LB) and ground while holding the key in the START

position.

Yes

GO to A5.

• Is the voltage greater than 10 volts? GO to A8.

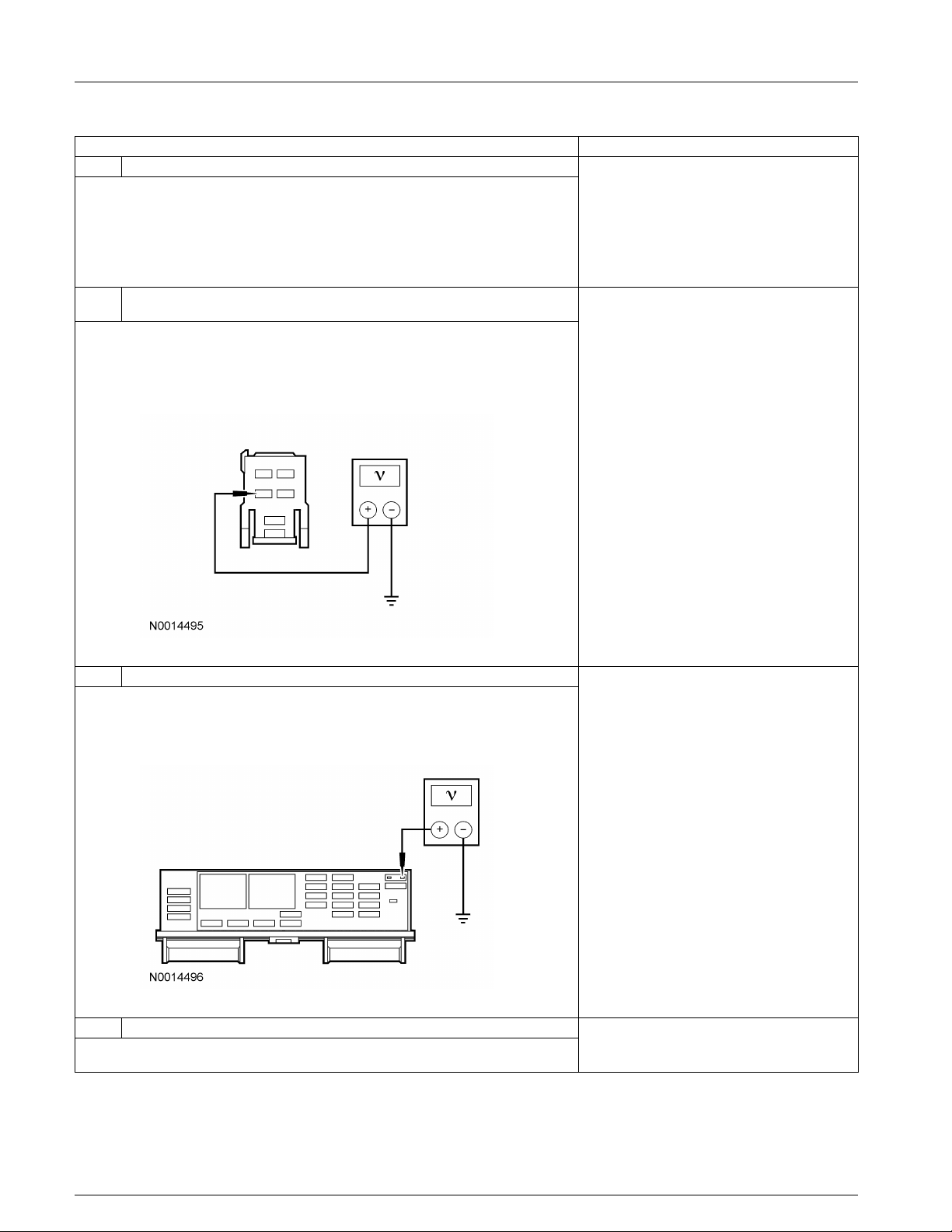

A5 CHECK CIRCUIT 33 (WH/PK) FOR AN OPEN

• Key in OFF position.

• Measure the resistance between digital TR sensor C167-12,

circuit 33 (WH/PK) and starter motor relay C1017-85, circuit 33

(WH/PK).

No

Yes

GO to A6.

No

REPAIR circuit 33 (WH/PK). TEST the

• Is the resistance less than 5 ohms? system for normal operation.

2005 Mustang, 12/2004

(Continued)

Page 7

303-06-7 303-06-7Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A6 CHECK DIGITAL TR SENSOR ADJUSTMENT

• Carry out the digital TR sensor adjustment. Refer to Section

307-01. INSTALL a new digital TR sensor. TEST

• Is the digital TR sensor adjusted correctly? the system for normal operation.

A7 CHECK CIRCUIT 32 (RD/LB) FOR VOLTAGE AT THE CLUTCH

PEDAL POSITION (CPP) SWITCH

• Key in OFF position.

• Disconnect: CPP Switch C257.

• Key in START position.

• Measure the voltage between CPP switch C257-1, circuit 32

(RD/LB) and ground while holding the key in the START

position.

Yes

No

ADJUST the digital TR sensor as

necessary. TEST the system for normal

operation.

• Is the voltage greater than 10 volts? GO to A8.

A8 CHECK CIRCUIT 1522 (DG) FOR AN OPEN

• Key in OFF position.

• Disconnect: SJB Fuse 21.

• Key in START position.

• Measure the voltage between SJB fuse 21, circuit 1522 (DG)

and ground while holding the key in the START position.

• Is the voltage greater than 10 volts? GO to A9.

A9 CHECK CIRCUIT 1050 (LG/PK) FOR VOLTAGE

• Key in OFF position.

• Disconnect: Ignition Switch C250.

Yes

GO to A11.

No

Yes

REPAIR circuit 32 (RD/LB). TEST the

system for normal operation.

No

(Continued)

2005 Mustang, 12/2004

Page 8

303-06-8 303-06-8Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A9 CHECK CIRCUIT 1050 (LG/PK) FOR VOLTAGE (Continued)

• Measure the voltage between ignition switch C250-4, circuit

1050 (LG/PK) and ground.

Yes

GO to A10.

No

• Is the voltage greater than 10 volts? system for normal operation.

A10 CHECK CIRCUIT 1522 (DG) FOR AN OPEN

• Measure the resistance between ignition switch C250-7, circuit

1522 (DG) and SJB fuse 21. INSTALL a new ignition switch. REFER to

• Is the resistance less than 5 ohms? Section 211-05. TEST the system for

A11 CHECK CIRCUIT 32 (RD/LB) FOR AN OPEN

• Key in OFF position.

REPAIR circuit 1050 (LG/PK). TEST the

Yes

normal operation.

No

REPAIR circuit 1522 (DG). TEST the

system for normal operation.

(Continued)

2005 Mustang, 12/2004

Page 9

303-06-9 303-06-9Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A11 CHECK CIRCUIT 32 (RD/LB) FOR AN OPEN (Continued)

• Measure the resistance between CPP switch C257-2, circuit 32

(RD/LB) and starter motor relay C1017-85, circuit 32 (RD/LB).

Yes

INSTALL a new CPP switch. REFER to

Section 303-14. TEST the system for

normal operation.

No

REPAIR circuit 32 (RD/LB). TEST the

• Is the resistance less than 5 ohms? system for normal operation.

A12 CHECK THE STARTER MOTOR RELAY GROUND CIRCUIT FOR

AN OPEN

• Key in START position.

(Continued)

2005 Mustang, 12/2004

Page 10

303-06-10 303-06-10Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A12 CHECK THE STARTER MOTOR RELAY GROUND CIRCUIT FOR

AN OPEN (Continued)

• Measure the voltage between starter motor relay C1017-86,

circuit 1419 (LG/YE) and starter motor relay C1017-85, circuit 33

(WH/PK) (circuit 32 [RD/LB] manual transmission only) while

holding the key in the START position and clutch pedal, if

equipped, fully depressed.

• Is the voltage greater than 10 volts? GO to A13.

A13 CHECK CIRCUIT 1419 (LG/YE) FOR AN OPEN

• Key in OFF position.

• Disconnect: PCM C175B.

Yes

INSTALL a new starter motor relay. TEST

the system for normal operation.

No

(Continued)

2005 Mustang, 12/2004

Page 11

303-06-11 303-06-11Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK (Continued)

Test Step Result / Action to Take

A13 CHECK CIRCUIT 1419 (LG/YE) FOR AN OPEN (Continued)

• Measure the resistance between PCM C175B-2, circuit 1419

(LG/YE) and starter relay C1017-86, circuit 1419 (LG/YE).

Yes

INSTALL a new PCM. REFER to Section

303-14. TEST the system for normal

operation.

No

• Is the resistance less than 5 ohms? system for normal operation.

Pinpoint Test B: The Engine Does Not Crank

And The Relay Does Click

Normal Operation

In normal operation, voltage from the bussed

electrical center (BEC) is supplied to the ignition

switch through circuit 1050 (LG/PK). When the

ignition switch is placed in the START position,

voltage is supplied through circuit 1522 (DG) to the

smart junction box (SJB).

For automatic transmission equipped vehicles,

voltage is supplied from the SJB to the digital

transmission range (TR) sensor through circuit 32

(RD/LB). In PARK or NEUTRAL, voltage is

For manual transmission equipped vehicles, voltage

from the SJB is supplied to the clutch pedal position

switch (CPP) through circuit 32 (RD/LB). When the

clutch pedal is depressed, voltage is supplied from

the CPP to the starter relay coil located in the BEC

through circuit 32 (RD/LB). The starter relay coil is

supplied ground from the PCM through circuit 1419

(LG/YE).

When the starter relay is energized, voltage supplied

to the relay switch is sent to the starter motor

solenoid through circuit 113 (YE/LB). Battery

voltage is supplied to the starter motor through

circuit 2037 (RD) at all times.

REPAIR circuit 1419 (LG/YE). TEST the

supplied from the TR sensor through circuit 33 Possible Causes

(WH/PK) to the starter relay coil located in the

BEC. The starter relay coil is supplied ground from

the PCM through circuit 1419 (LG/YE).

• Fuse(s)

• An open in circuit 1050 (LG/PK), 1522 (DG), 32

(RD/LB), 33 (WH/PK) or 1419 (LG/YE)

• Powertrain control module (PCM)

2005 Mustang, 12/2004

Page 12

303-06-12 303-06-12Starting System

DIAGNOSIS AND TESTING (Continued)

• Digital transmission range (TR) switch

• Ignition switch

• Starter motor relay

• Clutch pedal position (CPP) switch

PINPOINT TEST B: THE ENGINE DOES NOT CRANK AND THE RELAY DOES CLICK

Test Step Result / Action to Take

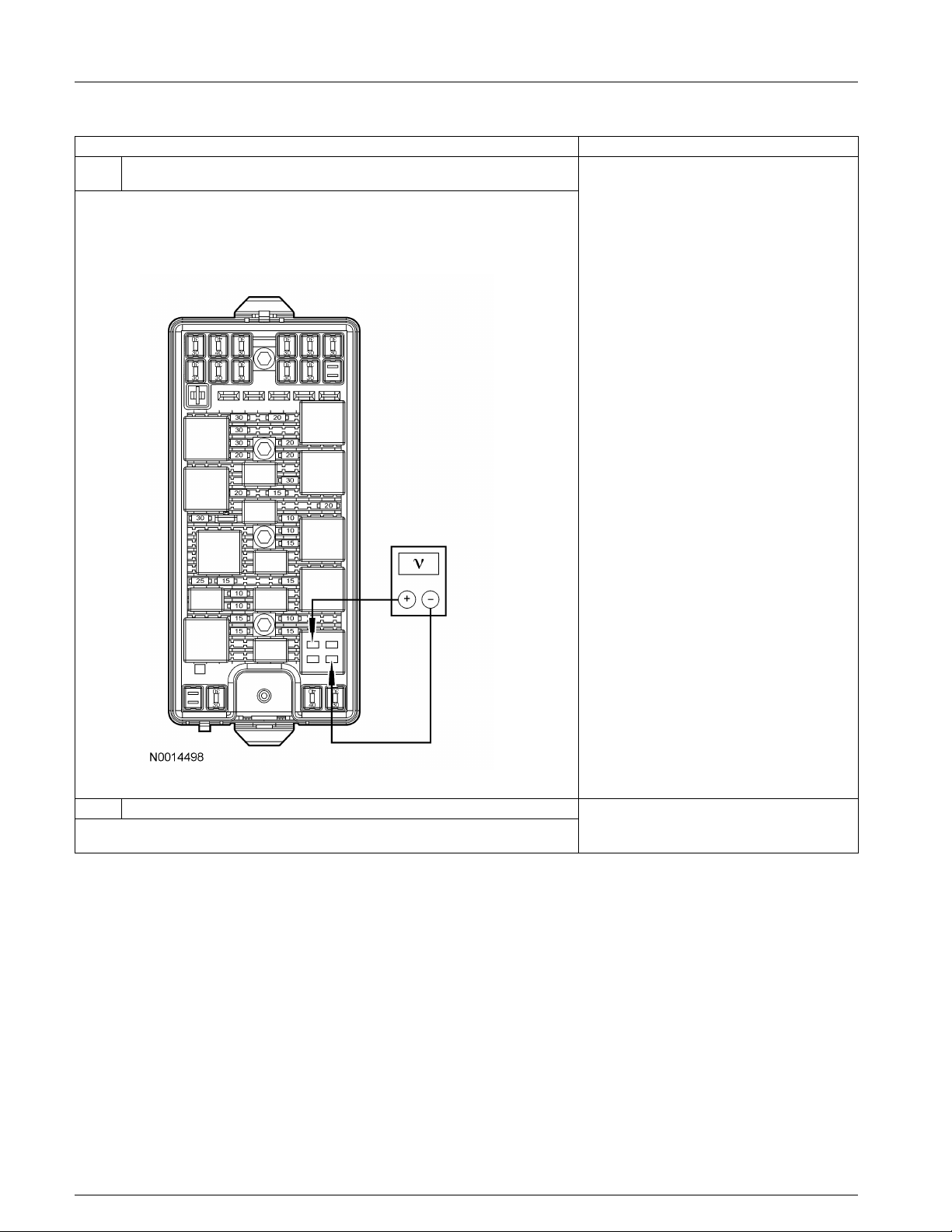

B1 CHECK THE VOLTAGE TO THE STARTER RELAY

• Measure the voltage between starter relay C1017-30 and

ground.

Yes

GO to B2.

No

INSTALL a new bussed electrical center

(BEC). TEST the system for normal

• Is the voltage greater than 10 volts? operation.

(Continued)

2005 Mustang, 12/2004

Page 13

303-06-13 303-06-13Starting System

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: THE ENGINE DOES NOT CRANK AND THE RELAY DOES CLICK (Continued)

Test Step Result / Action to Take

B2 CHECK THE VOLTAGE TO THE STARTER MOTOR SOLENOID

• Measure the voltage between starter motor solenoid positive

terminal and ground.

Yes

GO to B3.

No

• Is the voltage 10 volts or greater? TEST the system for normal operation.

B3 MANUALLY JUMP THE STARTER MOTOR

• Connect one end of a fused (15A) jumper wire to the positive

terminal of the battery and touch the other end to the starter

solenoid S-terminal.

REPAIR circuit 2037 (RD) for an open.

• Does the starter solenoid engage? the system for normal operation.

B4 TEST THE STARTER MOTOR RELAY

• Carry out the relay component test on the starter motor relay.

Refer to Wiring Diagrams Cell 149 for component testing. REPAIR circuit 113 (YE/LB) for an open.

• Does the starter motor relay test good? TEST the system for normal operation.

Pinpoint Test C: The Engine Cranks Slowly

Normal Operation

In normal operation, voltage from the bussed

electrical center (BEC) is supplied to the ignition

switch through circuit 1050 (LG/PK). When the

ignition switch is placed in the START position,

voltage is supplied through circuit 1522 (DG) to the

smart junction box (SJB).

Yes

GO to B4.

No

INSTALL a new starter motor. REFER to

Starter Motor — 4.0L SOHC or Starter

Motor — 4.6L (3V) in this section. TEST

Yes

No

INSTALL a new starter motor relay. TEST

the system for normal operation.

For automatic transmission equipped vehicles,

voltage is supplied from the SJB to the digital

transmission range (TR) sensor through circuit 32

(RD/LB). In PARK or NEUTRAL, voltage is

supplied from the TR sensor through circuit 33

(WH/PK) to the starter relay coil located in the

BEC. The starter relay coil is supplied ground from

the PCM through circuit 1419 (LG/YE).

2005 Mustang, 12/2004

Page 14

303-06-14 303-06-14Starting System

DIAGNOSIS AND TESTING (Continued)

For manual transmission equipped vehicles, voltage

from the SJB is supplied to the clutch pedal position

switch (CPP) through circuit 32 (RD/LB). When the

clutch pedal is depressed, voltage is supplied from

the CPP to the starter relay coil located in the BEC

through circuit 32 (RD/LB). The starter relay coil is

supplied ground from the PCM through circuit 1419

(LG/YE).

When the starter relay is energized, voltage supplied

to the relay switch is sent to the starter motor

solenoid through circuit 113 (YE/LB). Battery

voltage is supplied to the starter motor through

circuit 2037 (RD) at all times.

PINPOINT TEST C: THE ENGINE CRANKS SLOWLY

Test Step Result / Action to Take

C1 CHECK THE VOLTAGE TO THE STARTER

• Key in OFF position.

• Measure the voltage between starter motor solenoid positive

terminal and ground.

Possible Causes

• Fuse(s)

• Circuit 2037 (RD)

• Ground circuit

• Starter motor

• Is the voltage 12.5 volts or greater? operation.

C2 CHECK MOTOR GROUND CIRCUIT

• Carry out the Motor Ground Circuit test. Refer to Component

Tests in this section. INSTALL a new starter motor. TEST the

• Is the ground OK? system for normal operation.

Pinpoint Test D: Unusual Starter Noise

Normal Operation

In normal operation, voltage from the bussed

electrical center (BEC) is supplied to the ignition

switch through circuit 1050 (LG/PK). When the

ignition switch is placed in the START position,

voltage is supplied through circuit 1522 (DG) to the

smart junction box (SJB).

Yes

GO to C2.

No

REPAIR circuit 2037 (RD). CLEAN and

TIGHTEN the connections at the battery

terminals. TEST the system for normal

Yes

No

REPAIR the ground circuit as necessary.

TEST the system for normal operation.

For automatic transmission equipped vehicles,

voltage is supplied from the SJB to the digital

transmission range (TR) sensor through circuit 32

(RD/LB). In PARK or NEUTRAL, voltage is

supplied from the TR sensor through circuit 33

(WH/PK) to the starter relay coil located in the

BEC. The starter relay coil is supplied ground from

the PCM through circuit 1419 (LG/YE).

2005 Mustang, 12/2004

Page 15

303-06-15 303-06-15Starting System

DIAGNOSIS AND TESTING (Continued)

For manual transmission equipped vehicles, voltage

from the SJB is supplied to the clutch pedal position

switch (CPP) through circuit 32 (RD/LB). When the

clutch pedal is depressed, voltage is supplied from

the CPP to the starter relay coil located in the BEC

through circuit 32 (RD/LB). The starter relay coil is

supplied ground from the PCM through circuit 1419

(LG/YE).

When the starter relay is energized, voltage supplied

to the relay switch is sent to the starter motor

solenoid through circuit 113 (YE/LB). Battery

voltage is supplied to the starter motor through

circuit 2037 (RD) at all times.

PINPOINT TEST D: UNUSUAL STARTER NOISE

Test Step Result / Action to Take

D1 CHECK THE STARTER MOTOR MOUNTING

• Inspect the starter motor mounting for cracks.

• Check the starter motor mounting bolts for looseness. GO to D2.

• Is the starter motor mounted correctly?

D2 INSPECT THE STARTER MOTOR

• Remove the starter motor. Refer to Starter Motor — 4.0L SOHC

or Starter Motor — 4.6L (3V) in this section. INSTALL a new starter motor. TEST the

• Inspect the starter motor for damage. system for normal operation.

• Is the starter motor damaged?

Possible Causes

• Starter motor mounting

• Starter motor mounting bolts

• Starter motor drive

• Flywheel or flexplate ring gear

• Starter motor

Yes

No

REINSTALL the starter motor correctly.

REFER to Starter Motor — 4.0L SOHC or

Starter Motor — 4.6L (3V) in this section.

Yes

No

CHECK the starter drive. REFER to

Component Tests, Starter Drive Test in

this section. INSTALL a new starter motor.

TEST the system for normal operation.

Component Tests

Starter Motor — Load Test

WARNING: When servicing the starter

motor or carrying out other underhood work in

the vicinity of the starter motor, be aware that

the heavy gauge battery input lead at the starter

solenoid is ‘‘electrically hot’’ at all times.

CAUTION: A protective cap or boot is

provided over the battery input terminal on all

car lines and must be installed after repair. Be

sure to disconnect the battery ground cable

before repairing the starter motor.

1. Before carrying out this test inspection, check

the battery to determine its state of charge.

Carry out a load test of the battery using the

Starter, Alternator, Battery, Regulator and

Electrical Tester (SABRE). Refer to Section

414-00 for the test procedure.

2. Disconnect the ignition coil connector from the

ignition coil.

3. Connect the SABRE tester to the vehicle using

the amperage lead clipped around the positive

battery cable.

4. Measure the amperage of the starter motor

while activating the starting system.

5. A correctly operating starter motor will draw

from 130 to 190 amps of current.

Voltage Drop Tests

The following test procedures will be carried out

with the starter motor on the vehicle.

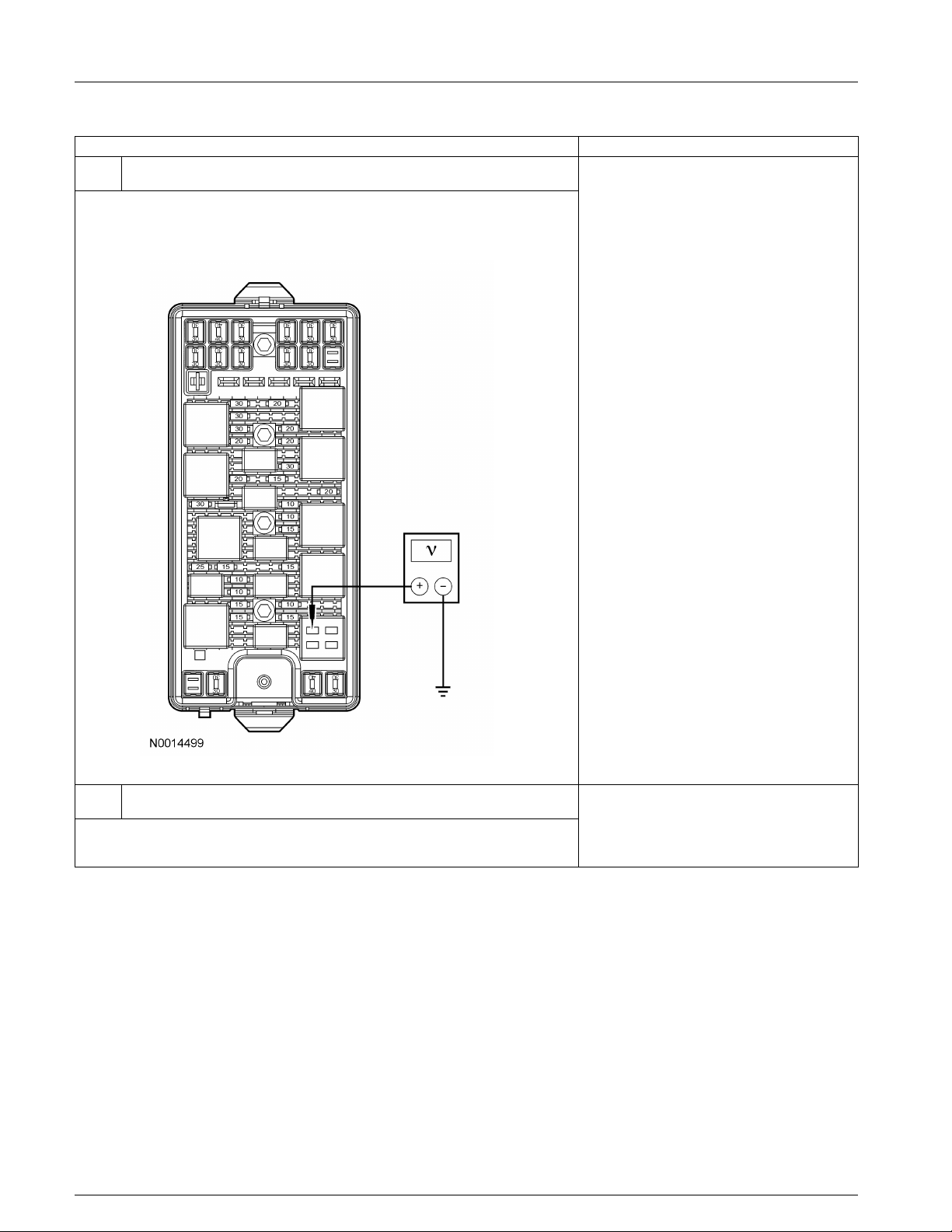

Motor Feed Circuit

NOTE: Make all multimeter connections at the

component terminal rather than the cable or wiring

terminal.

1. Disconnect the ignition coil connector from the

ignition coil.

2. Connect a remote starter switch between the

starter solenoid S-terminal and the battery

positive (+) post.

2005 Mustang, 12/2004

Page 16

303-06-16 303-06-16Starting System

DIAGNOSIS AND TESTING (Continued)

3. Connect the positive (+) lead of the 73 Digital 4. Engage the remote starter switch and read the

Multimeter to the battery positive (+) post. voltage. The reading should be 0.2 volt or less.

Connect the negative (-) lead of the multimeter

to the starter solenoid M-terminal.

4. Engage the remote starter switch. The at the battery and chassis. Also, clean the

multimeter reading should be 0.5 volt or less. engine ground cable connection at the cable

5. If the voltage at the M-terminal is greater than

0.5 volt, move the multimeter negative (-) lead

to the starter solenoid B-terminal and repeat the

test.

6. If the voltage reading at the B-terminal is less

than 0.5 volt, the problem is either in the

connections at the starter solenoid or the starter

solenoid.

7. Remove the wires at the starter solenoid B-, Sand M-terminals. Clean the connections and

install the cables. Repeat Steps 1 through 5

above. If the reading is still higher than 0.5 volt

at the M-terminal and 0.5 volt or lower at the

B-terminal, the problem is in the starter

solenoid. Install a new starter motor. Refer to

Starter Motor — 4.0L SOHC or Starter Motor

— 4.6L (3V) in this section.

8. If the voltage taken at the starter solenoid

B-terminal is greater than 0.5 volt, the problem

is either the positive (+) battery cable

connection or the positive (+) battery cable.

Motor Ground Circuit

NOTE: Make all multimeter connections at the

component terminal rather than the cable or wiring

terminal.

A slow cranking condition can be caused by

resistance in the ground or return portion of the

cranking circuit. Check the voltage drop in the

ground circuit as follows:

1. Disconnect the ignition coil connector from the

ignition coil.

2. Connect a remote starter switch between the

starter solenoid S-terminal and the battery

positive (+) terminal.

3. Connect the positive (+) lead of a 73 Digital

Multimeter to the starter motor housing. The

connection must be clean and free of rust or

grease. Connect the negative (-) lead to the

negative (-) battery terminal.

5. If the voltage drop is greater than 0.2 volt,

clean the negative (-) battery cable connections

mounting bracket. If the voltage drop is still

excessive, repair or install a new battery

ground cable.

Starter Drive Test

1. Remove the starter motor. Refer to Starter

Motor — 4.0L SOHC or Starter Motor — 4.6L

(3V) in this section.

2. Secure the starter motor in a vise.

3. Connect the battery ground cable of a fully

charged battery to the case of the starter motor.

4. CAUTION: Do not leave the positive

lead of the battery connected to the starter

motor S-terminal for more than 10 seconds.

Touch the positive lead from the battery to the

S-terminal and verify that the starter drive

ejects.

5. Remove the positive lead from the starter

motor. The ejected starter drive should return to

its original position.

6. If the starter drive does not eject and return to

position, replace the starter motor.

7. Check the starter drive. It should turn freely in

one direction, and positively engage to the

armature when turned in the opposite direction.

If not as specified, install a new starter motor.

No Load Test

The starter No Load Test will identify open or

shorted windings and a possible rubbing starter

motor armature or bent starter motor armature shaft.

2005 Mustang, 12/2004

Page 17

303-06-17 303-06-17Starting System

DIAGNOSIS AND TESTING (Continued)

1. WARNING: Make sure that the starter

motor is securely mounted on a bench

because the starter motor may move or jump

when it is energized.

Connect a fully charged battery, a Starter,

Alternator, Battery, Regulator and Electrical

Tester (SABRE) and a remote starter switch to

the starter motor. Connect the remote starter

switch between the battery positive (+) post and

the starter motor S-terminal. Connect the

starter motor B-terminal to the battery positive

(+) post. Connect the SABRE positive (+)

terminal and negative (-) terminal to the

corresponding battery post. Make sure that the

battery and starter motor are grounded.

2. Engage the remote starter switch.

3. The starter motor should eject the starter drive

and run smoothly. If the starter motor does not

run smoothly, install a new starter motor.

4. While the starter motor is running, check the

voltmeter and ammeter.

5. The voltage should be greater than 11.0 volts

and the amperage should be no more than 70

amps.

6. If the voltage is lower than the 11.0 volts, or

the amperage is higher than 70 amps, install a

new starter motor.

2005 Mustang, 12/2004

Loading...

Loading...