Ford 2006 Escape J87R Bodyshop Manual

WAR NI NG

Servicing a vehicle can be dangerous. If you have not received

service-related training, the risks of injury, property damage, and

failure of servicing increase. The recommended servicing procedures

for the vehicle in this workshop manual were developed with

Ford-trained technicians in mind. This manual may be useful to

non-Ford trained technicians, but a technician with our

service-related training and experience will be at less risk when

performing service operations. However, all users of this manual are

expected to at least know general safety procedures.

This manual contains "Warnings" and "Cautions" applicable to risks

not normally encountered in a general technician's experience.

They should be followed to reduce the risk of injury and the risk that

improper service or repair may damage the vehicle or render it unsafe.

It is also important to understand that the "Warnings" and "Cautions"

are not exhaustive. It is impossible to warn of all the hazardous

consequences that might result from failure to follow the procedures.

The procedures recommended and described in this manual are

effective methods of performing service and repair. Some require tools

specifically designed for a specific purpose. Persons using procedures

and tools which are not recommended by Ford Motor Company must

satisfy themselves thoroughly that neither personal safety nor safety of

the vehicle will be jeopardized.

The contents of this manual, including drawings and specifications, are

the latest available at the time of printing, and Ford Motor Company

reserves the right to change the vehicle designs and alter the contents

of this manual without notice and without incurring obligation.

Parts should be replaced with genuine Ford replacement parts or with

parts which match the quality of genuine Ford replacement parts.

Persons using replacement parts of lesser quality than that of genuine

Ford replacement parts must satisfy themselves thoroughly that

neither personal safety nor safety of the vehicle will be jeopardized.

Ford Motor Company is not responsible for any problems which may

arise from the use of this manual. The cause of such problems

includes but is not limited to insufficient service-related training, use of

improper tools, use of replacement parts of lesser quality than that of

genuine Ford replacement parts, or not being aware of any revision of

this manual.

CONTENTS

ESCAPE

Bodyshop

Manual

FOREWORD

This bodyshop manual is intended for

use by technicians of Authorized Ford

Dealers to help them service and repair

Ford vehicles. It can also be useful to

owners and operators of Ford vehicles in

performing limited repair and maintenance on

Ford vehicles.

For proper repair and maintenance, a

thorough familiarization with this manual is

important, and should always be kept in

a handy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be

made available at Ford dealers. This

manual should be kept up-to-date.

Ford Motor Company reserves the right to

alter the specifications and contents of this

manual without obligation or advance notice.

All rights reserved. No part of this book may

be reproduced or used in any form or

by any means, electronic or mechanical

including photocopying and recording and

the use of any kind of information storage

and retrieval-system-without permission in

writing.

Ford Motor Company

APPLICATION:

This manual is applicable to vehicles

beginning with the Vehicle Identification

Numbers (VIN), shown on the following

page.

© 2006 Mazda Motor Corporation

MARCH 2006

F342–20–06C

Title

Section

GENERAL INFORMATION

00

DIMENSIONS

80A

CONSTRUCTION

80B

PANEL REPLACEMENT

80C

WATER-PROOF AND RUST PREVENTIVE

TREATMENT

80D

PLASTIC BODY PARTS

80E

PRIMARY COLOR MIXTURE CHART FOR

BODY COLORS

80F

00-00–1

00

GENERAL INFORMATION

SECTION

00

To c of S CT

GENERAL INFORMATION . . . 00-00

To c of S CT

00-00 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER

(VIN) CODE . . . . . . . . . . . . . . . . . . . . . . 00-00–1

VEHICLE IDENTIFICATION NUMBERS

(VIN). . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–1

HOW TO USE THIS MANUAL. . . . . . . . . 00-00–2

SERVICE PRECAUTIONS. . . . . . . . . . . . 00-00–6

EFFICIENT REMOVAL OF BODY

PANELS . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–7

INSTALLATION PREPARATIONS . . . . . . 00-00–9

EFFICIENT INSTALLATION OF

BODY PANELS. . . . . . . . . . . . . . . . . . . . 00-00–10

ANTICORROSION, SOUND INSULATION,

AND VIBRATION INSULATION . . . . . . . 00-00–13

ABBREVIATION . . . . . . . . . . . . . . . . . . . . 00-00–14

End of Toc

BM: GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER (VIN) CODE

id000000600800

End Of Sie

VEHICLE IDENTIFICATION NUMBERS (VIN)

id000000600100

LFA CKZTNX*2 000001—

LFA CLZTNX*2 000001—

LFA CMZTVX*2 000001—

LFA CNZTVX*2 000001—

LFA YKZTNX*2 000001—

LFA YLZTNX*2 000001—

LFA YMZTVX*2 000001—

LFA YNZTVX*2 000001—

End Of Sie

L F A C K Z T N X 7 2 1 2 3 4 5 6

Assemble Plant

Serial No.

2= FLH FAP2 Plant

Engine type

N= L3 (2.3L)

V= AJ (3.0L Duratec)

Model

Gross vehicle weight and Air bags

LFA= Ford Lio Ho

World manufacturer identification

C= 4001—5000 lbs {1814—2268 kg},

with Driver, Passenger and Side air bag

Y= 4001—5000 lbs {1814—2268 kg},

with Driver and Passenger air bag

Constant

Model year

X

6=2006, 7= 2007, 8= 2008

KZT= 4x4, Export 2.3L, 4WD, XLS, 4EAT, ABS

LZT= 4x4, Export 2.3L, 4WD, XLT, 4EAT, ABS

MZT= 4x4, Export 3.0L, 4WD, 4EAT, ABS

NZT= 4x4, Export 3.0L, 4WD, 4EAT, ABS, S/R

aesffb00000001

00-00–2

GENERAL INFORMATION

HOW TO USE THIS MANUAL

id000000600900

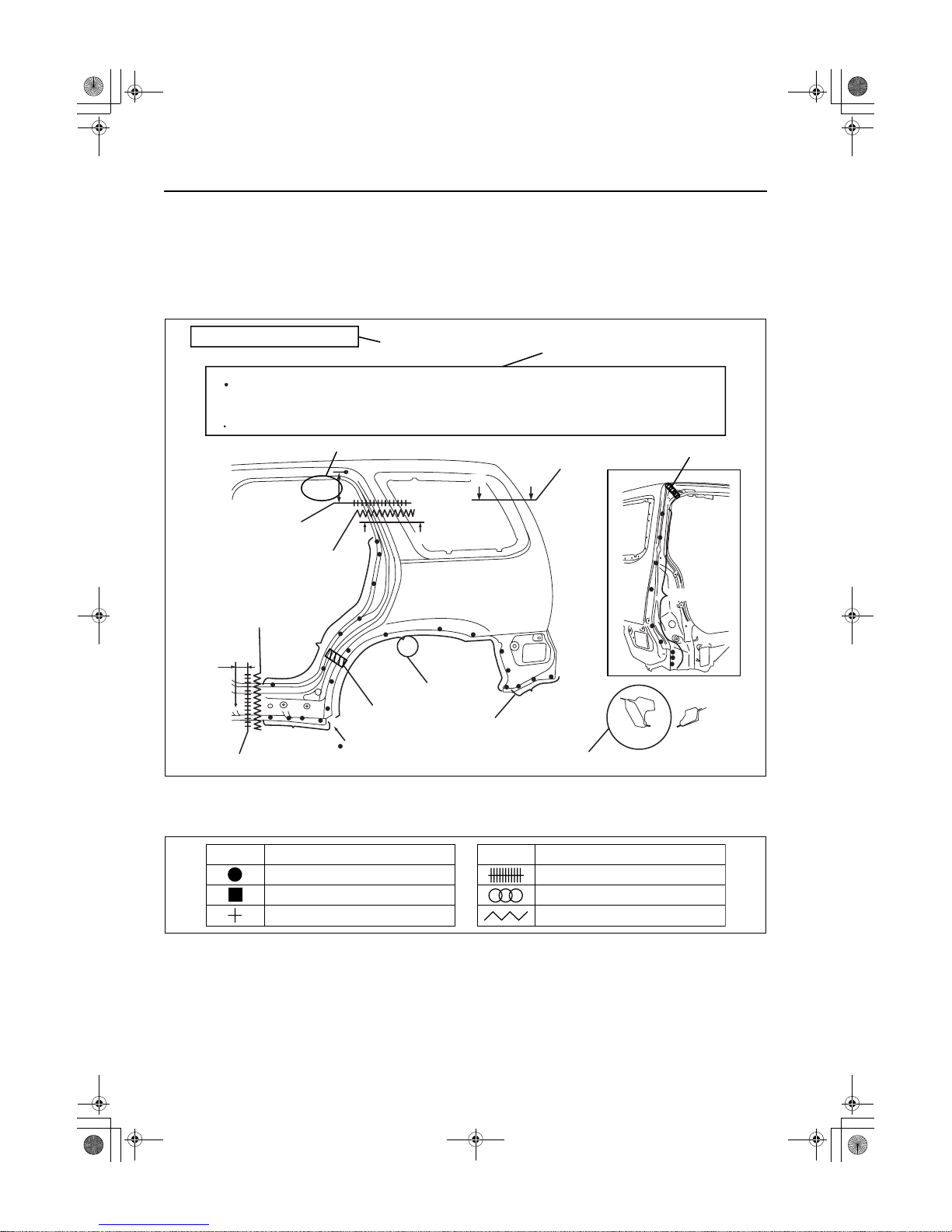

Efficient Replacement of Body Panels

• This section contains information on the body panels in regard to the welding types, number of spot welds, and

cut-and-join locations that are necessary for panel removal and installation.

• The type of weld and position are indicated by symbols.

• Some sections have notes concerning the operation being performed. Thoroughly read and understand the

notes before carrying out any procedures.

Example

Symbols of Panel Replacement

• The following 6 symbols are used to indicate the type of weld that is used when replacing body panels.

REAR FENDER PANEL REMOVAL

Shows operation section

Shows procedure, caution and note

BRAZE WELDING

CUT-AND-JOINT LOCATION

CUT-AND-JOINT LOCATION

ROUGH CUT LOCATION

ROUGH CUT LOCATION

Shows number of weld

Shows welding region

Shows a cross

Shows a insulator

Shows a dimensions

Shows a cross location

Avoid cutting with a flame as the insulator (shaded) is flammable.

1.The rear fender panel and wheel house are joined with glue at the wheel arch line.

Drill the 24 weld locations indicated by (A), from the room side.

Caution

NOTE

BOTTOM SIDE 1

{9.84in}

250mm

(A)24

19

17

A-A

A

A

B-B

30mm

BB

{1.18in}

8

4

atraab00000001

SYMBOL

MEANING

Spot welding

CO

2

arc welding (plug welding)

CO

2

spot welding

SYMBOL

MEANING

Continuous MIG welding (Cut-and-join location)

Braze welding

Rough cut location

acxuub00000032

GENERAL INFORMATION

00-00–3

00

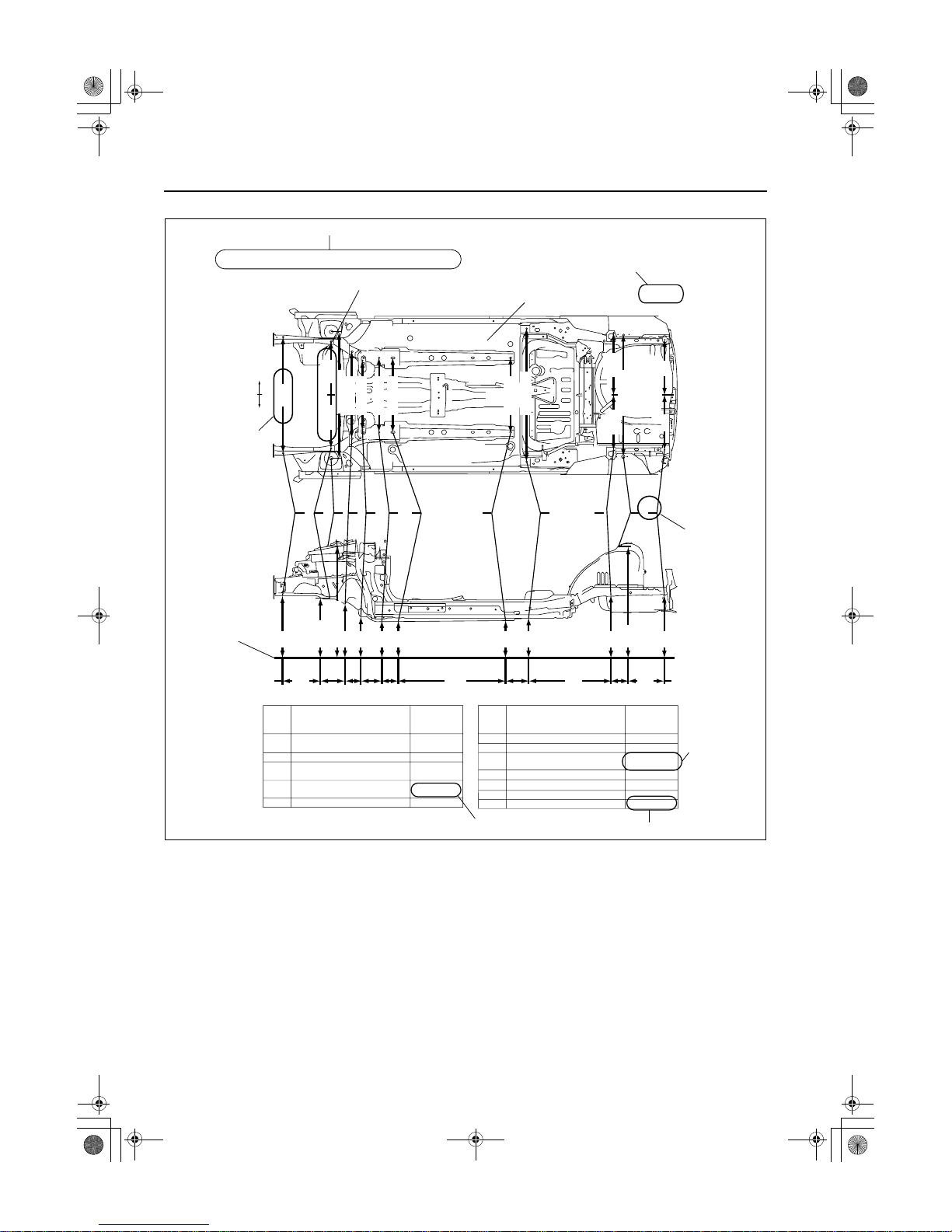

Body Dimensions (Flat-plane Dimensions)

• Flat-plane dimensions are the dimensions measured by projecting certain reference points onto a plane

surface.

• When there are no specific indications, the standard points and dimensions are symmetrical in regard to the

center of the vehicle.

• The hypothetical lines may differ according to the vehicle model.

• The schematic diagram shows the vehicle as it is projected from the underbody.

810

{31.89}

FLAT-PLANE DIMENSIONS

FRONT FENDER INSTALLATION NUT

acxuub00000033

00-00–4

GENERAL INFORMATION

Example

Shows vehicle section

When there are no specific indications, all of

units are in millimeters (mm).

Shows outline drawing

Shows dimension

The dimensions on the left

and right in regard to the center

of the vehicle are different.

Shows hypothetical

standard line

Shows point

symbol

Point

symbol

Designation

Hole diameter

or bolt or nut

size mm {in}

Crossmember No,1 standard

hole

Front side frame standard hole

Front suspension mounting

block surface hole center

Front suspension mounting

bolt

Front frame rear standard hole

Front frame rear standard hole

Rear side frame standard hole

Link bracket

Rear suspension housing

A

B

C

D

E

F

G

H

I

J

K

Rear side frame standard hole

Rear side frame standard hole

Shows bolt size

Shows hole diameter

Shows

slot

mm {in}

UNDERBODY FLAT-PLANE DIMENSIONS

φ 16 {0.62}

φ 16 {0.62}

φ 16 {0.62}

M14 {0.55}

φ 80 {3.14}

Point

symbol

Designation

Hole diameter

or bolt or nut

size mm {in}

φ 16 {0.62}

φ 31 {1.22}

φ 12 {0.47}

Rear suspension housing

L

φ 12 {0.47}

φ 16 {0.62}

φ 18 {0.62}

17 × 29.5

{0.66×1.16}

ABCDE F G H I J KL

1,016

{40.00}

687

{27.05}

420

182 93 144 120

{7.17} {3.66} {5.67} {4.72}

1,030

140

760

68

{5.51} {2.68}

379

{16.54}

{40.55}

{29.92} {14.92}

{25.75}

654

1,084 {42.84}

579

{22.80}

479

{18.86}

436

436

{17.17}

{17.17}

445

512

660

1,043

666

{17.52}

{20.16}

{25.98}

{41.06}

{26.22}

1,106 {43.54}

1,164

543

485

484

{21.37}

{19.05}

478

1,073 {37.91}

455

{17.91}

469

{18.46}

760

605

650

650

{29.92}

{23.82}

{25.59}

{25.59}

650

{45.83}

{25.59}

LH

RH

acxuub00000034

GENERAL INFORMATION

00-00–5

00

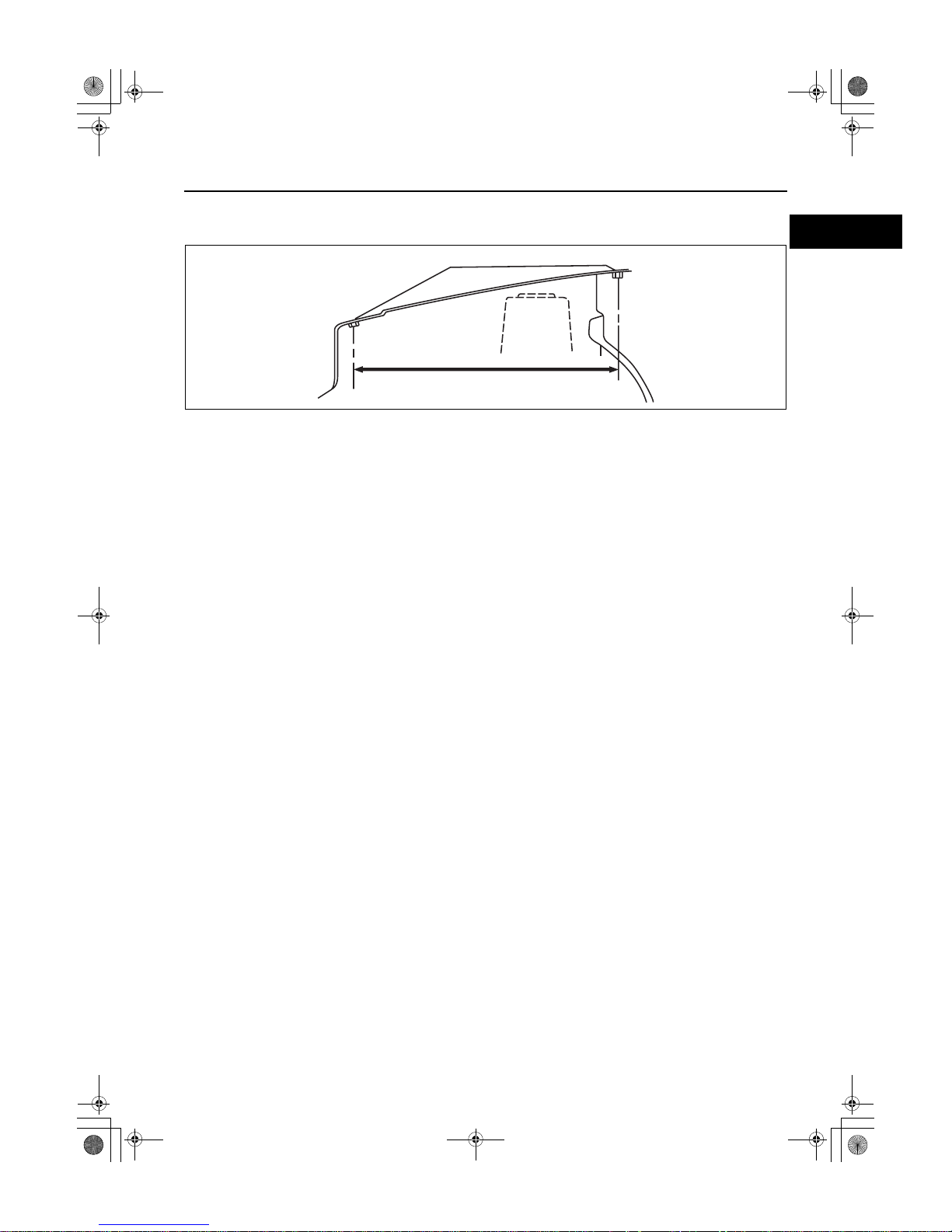

Body Dimensions (Straight-line Dimensions)

• Straight-line dimensions are the actual dimensions between two standard points.

• When there are no specific indications, the standard points and dimensions are symmetrical in regard to the

center of the vehicle.

Example

817

FRONT FENDER INSTALLATION NUT

STRAIGHT-LINE DIMENSIONS

{32.17}

acxuub00000035

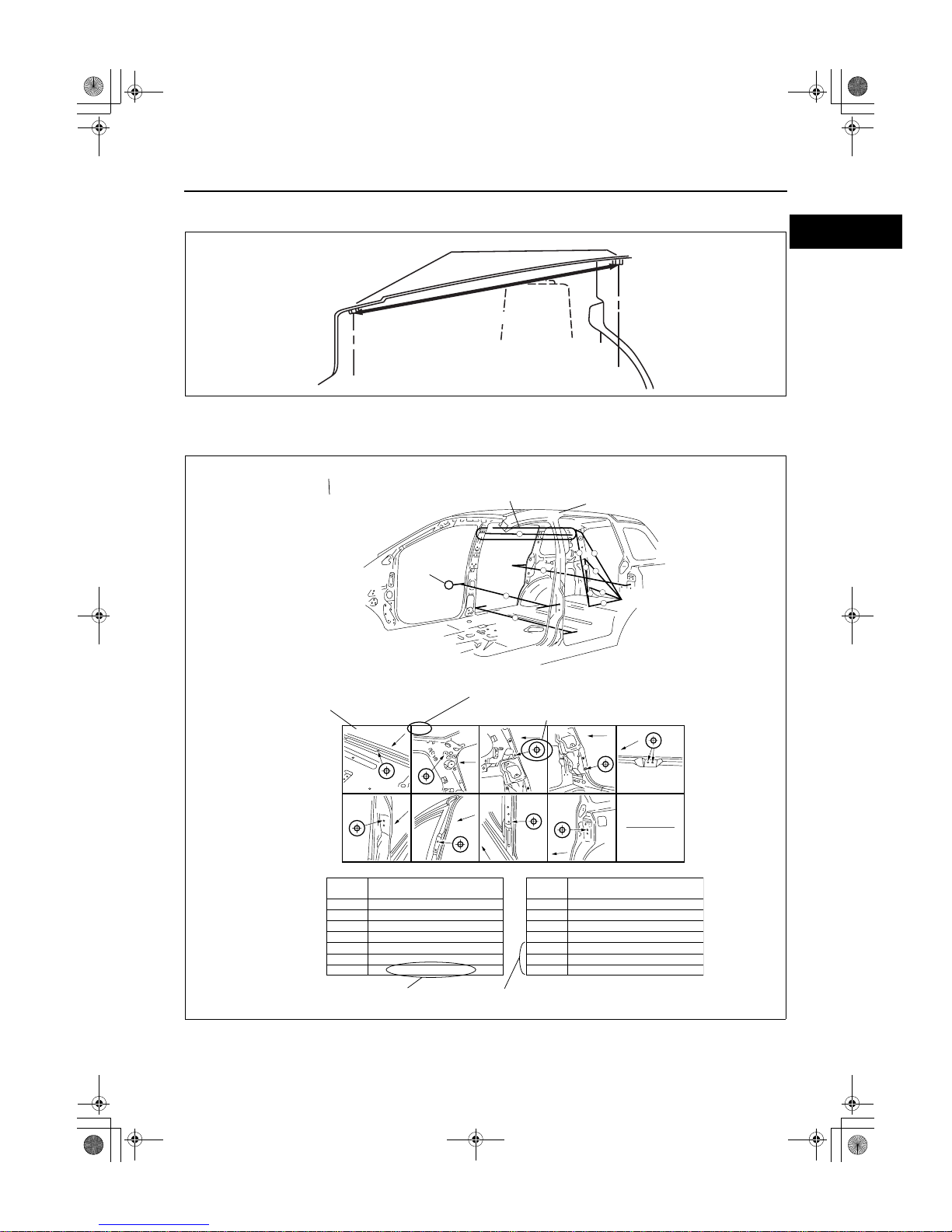

ROOM STRAIGHT-LINE DIMENSIONS (2)

Shows vehicle section

Shows dimension location

Shows outline drawing

C

D

A

G

Shows point

symbol

Shows point indication

Without apostrophe:RH

With apostrophe:LH

Shows details of the standard

point location

Shows position and shape of the points

Shows dimension

No indication are shown within the

outline drawing.

A

Fr

Fr

Fr

Fr

Fr

Fr

Fr

Fr

Fr

Measured

location

Dimension mm {in}

1

2

3

4

5

6

7

1,184 {46.61}

1,064 {41.89}

919 {36.18}

690 {27.17}

1,185 {46.65}

901 {35,47}

607 {23.90}

Measured

location

Dimension mm {in}

8

9

10

11

B-B'

C-C'

D-D'

1,667 {65.63}

1,672 {65.83}

1,037 {40.83}

1,290 {50.79}

1,208 {47.56}

1,463 {57.60}

1,642 {64.65}

B-B

,

C-C

,

D-D

,

H-H

,

G-G

,

F-F

,

E-E

,

H

,

E. E

,

H

I

B

F

,

I - I

,

1

5

6

9

7

3

2

4

8

F

11

10

atraab00000002

00-00–6

GENERAL INFORMATION

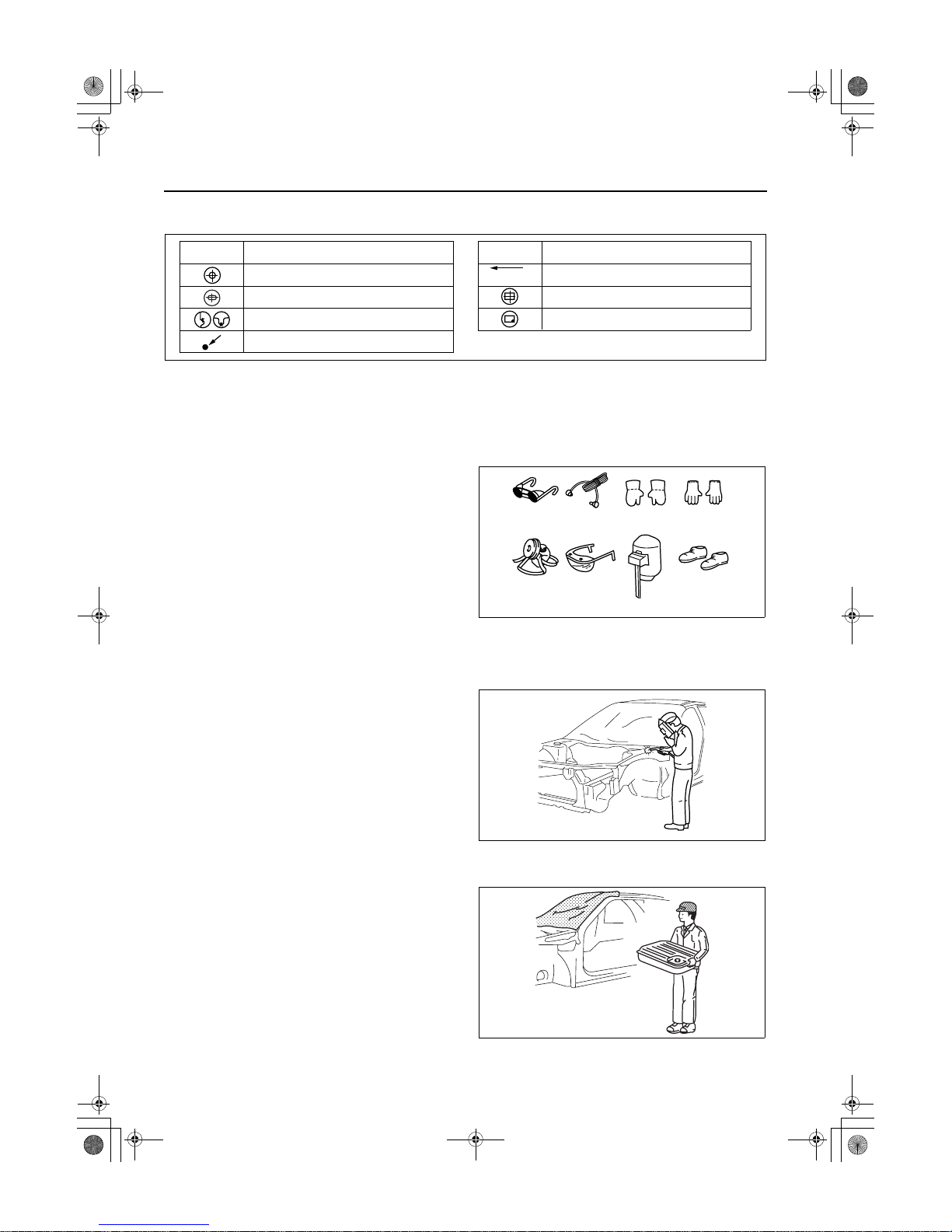

Symbols of Body Dimensions

• The following 8 symbols are used to indicate the standard points.

End Of Sie

SERVICE PRECAUTIONS

id000000600200

Arrangement of Workshop

• Arrangement of the workshop is important for safe and efficient work.

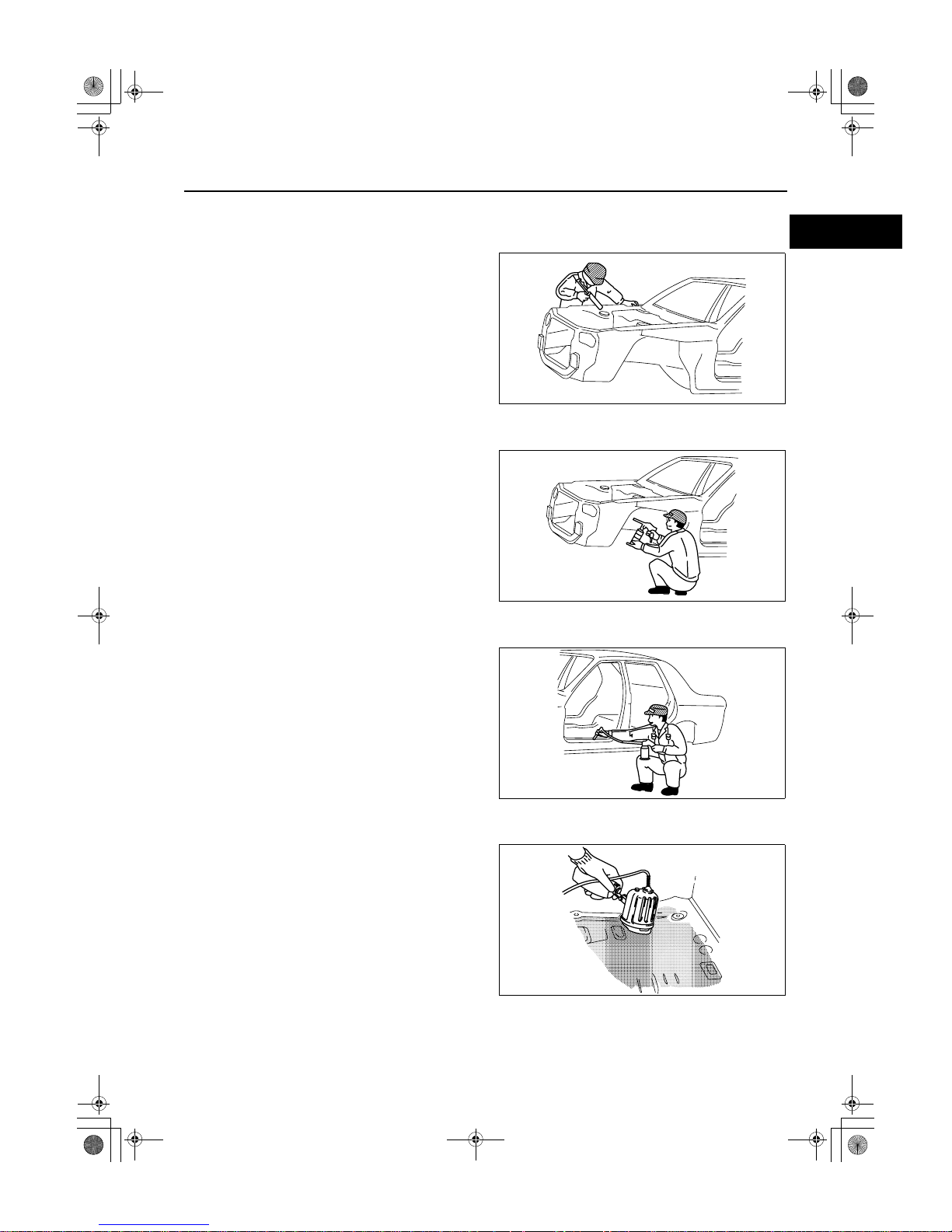

Safety Precautions

• Protective head covering and safety shoes should

always be worn. Depending upon the nature of

the work, gloves, safety glasses, ear protectors,

face shield, etc., should also be used.

Vehicle Protection

• Use seat covers and floor covers.

• Use heat-resistant protective covers to protect glass areas and seats from heat or sparks during welding.

• Protect items such as moldings, garnishes, and

ornaments with tape when welding.

Remove Dangerous Articles

• Remove the fuel tank before using an open flame

in that area. Plug connection piping to prevent

fuel leakage.

SYMBOL

MEANING

SYMBOL

MEANING

Center of circular hole

Center elliptical hole

Notch

Panel seam, bead, etc.

Bolt tip

(arrow only)

Center of rectangular-shaped hole

Edge of rectangular-shaped hole

acxuub00000037

Welding

glasses

Ear

protectors

Weldlng

gloves

Cotton

gloves

Dust mask Safety glasses

Face shield

Safety shoes

acxuub00000038

acxuub00000063

acxuub00000064

GENERAL INFORMATION

00-00–7

00

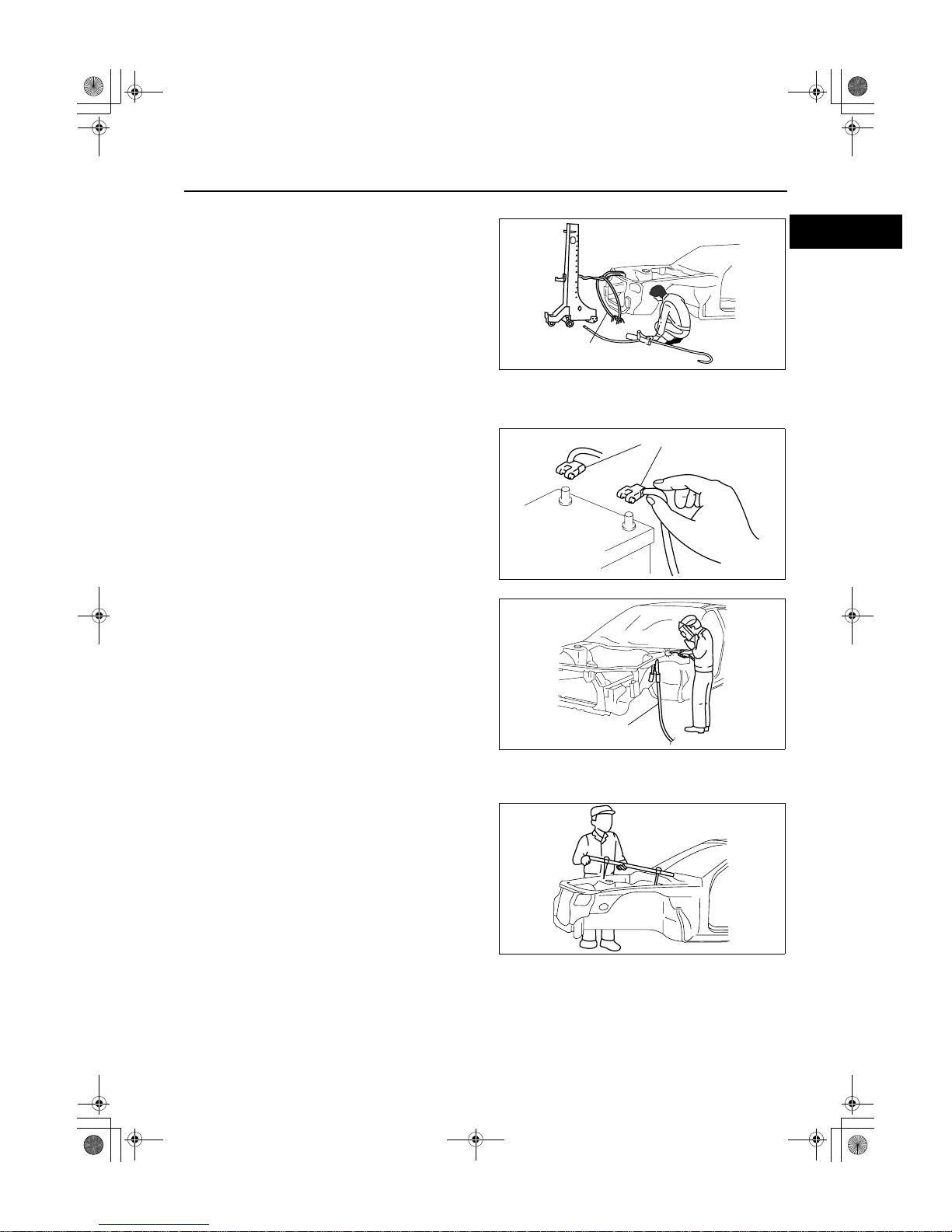

Use of Pulling Equipment

• When using pulling equipment, keep away from

the pulling area and use safety wires to prevent

accidents.

Prevent Short Circuits

• Turn the ignition switch to the LOCK position.

• Disconnect the battery cables.

• Securely connect the welding machine ground

near the welding area.

End Of Sie

EFFICIENT REMOVAL OF BODY PANELS

id000000600300

Body Measurements

• Before removal or rough-cutting, first measure the

body at and around the damaged area against

the standard reference dimension specifications.

If there is deformation, use frame repair

equipment to make a rough correction.

Safety wires

acxuub00000041

Battery cable

acxuub00000042

Ground

acxuub00000043

acxuub00000065

00-00–8

GENERAL INFORMATION

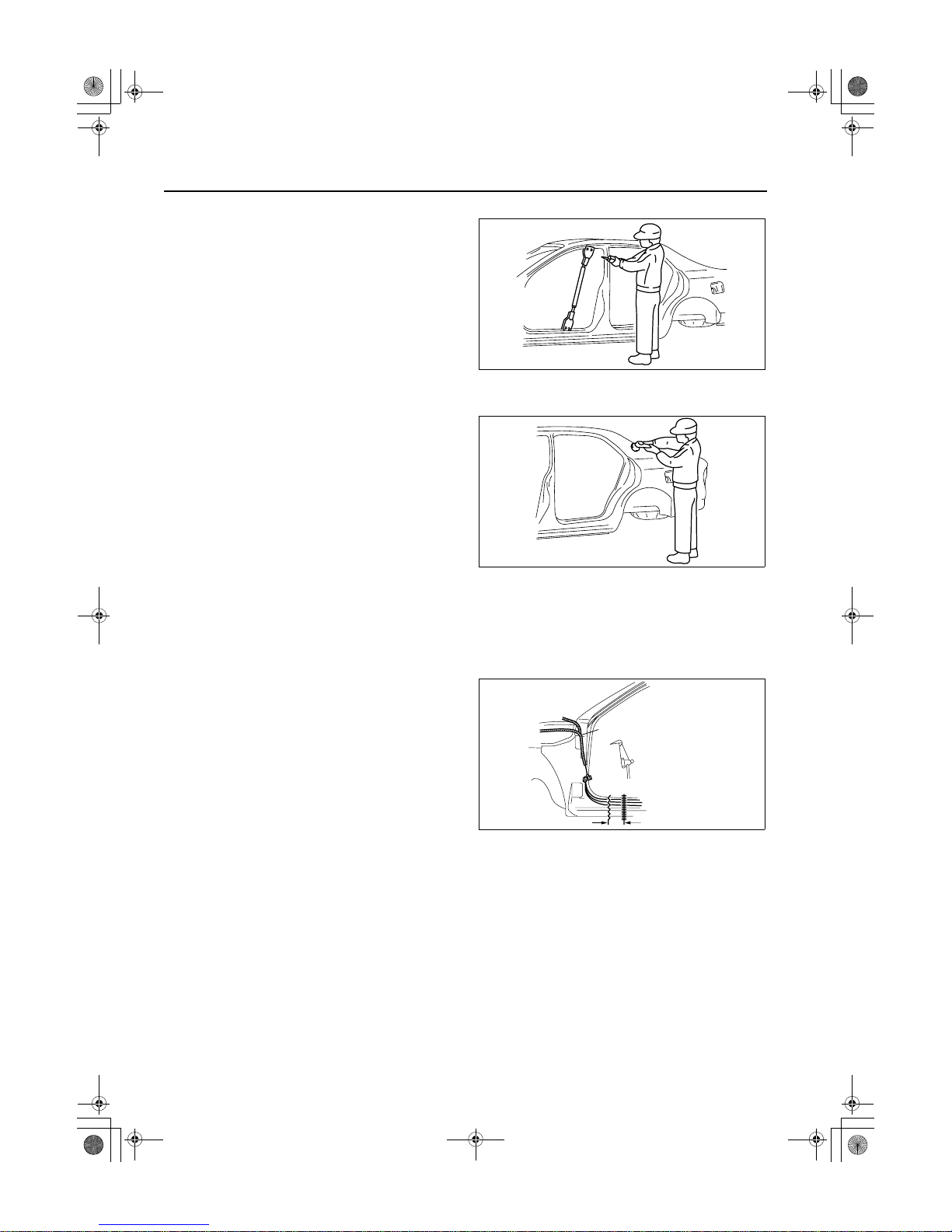

Prevention of Body Deformation

• Use a clamp or a jack for removal and reinforce at

and around the rough-cutting location to prevent

deforming of the body.

Selection of Cut-and-join Locations

• For parts where complete replacement is not

feasible, careful cutting and joining operations

should be followed. If the location to be cut is a

flat area where there is no reinforcement, the

selected cutting location should be where the

welding distortion will be minimal.

Removal of Associated Parts

• Protect moldings, garnishes, and ornaments with tape when removing associated parts.

Rough Cutting of Damaged Panel

• Verify that there are no parts (such as pipes, hoses, and wiring harness) nearby or on the opposite side of a

panel which could be damaged by heat.

• For cut-and-join areas, allow for an overlap of

30—50 mm {1.18—1.97 in} and then rough-cut

the damaged panel.

End Of Sie

acxuub00000066

acxuub00000067

Wiring harness

Rough cut location

Cut-and-join location

acxuub00000047

GENERAL INFORMATION

00-00–9

00

INSTALLATION PREPARATIONS

id000000600400

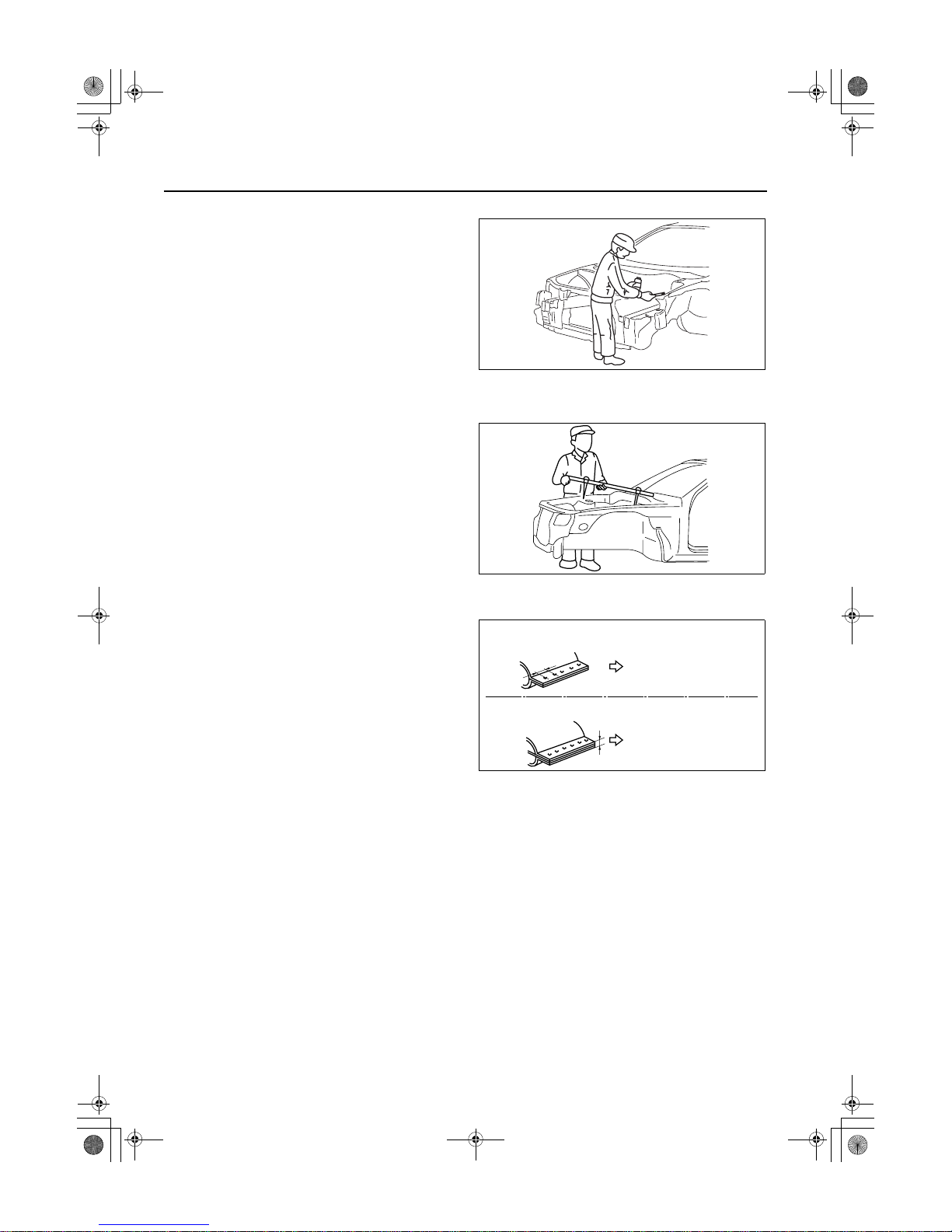

Rough Cutting of New Parts

• For cut-and-join areas, allow for an overlap of

30—50 mm {1.18—1.97 in} with the remaining

area on the body side and then rough-cut the new

parts.

Determination of Welding Method

• If the total thickness at the area to be welded is 3

mm {0.12 in} or more, use a CO2 gas

shielded-arc welder to make the plug welds.

Making Holes for CO

2

Arc Welding

• For places that cannot be spot welded, make a hole for CO

2

arc welding using a punch or drill as follows.

(mm {in})

• Grind the shaded section indicated in the diagram

below and create a hole in the part where the 3—

4 plates are put together. Also, weld the plates

together tightly so that gaps do not develop.

Over lap

Over lap

Body side rough cut location

New part rough cut location

30-50mm{1.18-1.97in}

30-50mm{1.18-1.97in}

acxuub00000048

3mm

{0.12in}or more

acxuub00000049

Panel thickness (ø) Hole diameter (ø)

0.60—0.90 {0.02—0.03} 5 {0.19}

0.91—1.20 {0.04—0.05} 6 {0.23}

1.21—1.80 {0.051—0.07} 8 {0.31}

1.81—4.50 {0.071—0.17} 10 {0.39}

φ

10mm{0.39in}

Outer panel

Middle panel

Inner panel

30°

30°

acxuub00000050

00-00–10

GENERAL INFORMATION

Application of Weld-through Primer

• For treatment against corrosion, remove the paint

grease, and other material from the portion of

new part and body to be welded, and apply

weld-through primer.

End Of Sie

EFFICIENT INSTALLATION OF BODY PANELS

id000000600500

Checking Preweld Measurements And Watching

• Align to the standard reference dimensions,

based upon the body dimensions illustration, so

that new parts are installed in the correct position.

Welding Notes

• For the number of weld points, welding should be

performed in accordance with the following

reference standards.

acxuub00000068

acxuub00000069

Spot welding

Original weld

If 3mm

{0.12in} or more

Original number of

welds x 1.3 or more

CO2 arc welding

Original spot weld

Repair weld

Repair weld

Original number of welds

or more

acxuub00000053

GENERAL INFORMATION

00-00–11

00

Spot Welding Notes

• The shape of the spot welder tip is D=(2×t)+3. If

the upper panel thickness is different from that of

the under panel, adjust to the thinner one.

• Because the weld strength is affected by the

shape of the spot welder tip, the optimum

condition of the tip should always be maintained.

• Spot welds should be made at points other than

the originally welded points.

• Before spot welding, make a trial weld using the

same material as the body panel to check the

weld strength.

D

70 - 120°

t

acxuub00000054

acxuub00000070

Test piece method

Nugget diameter

:4/5 of tip

acxuub00000071

00-00–12

GENERAL INFORMATION

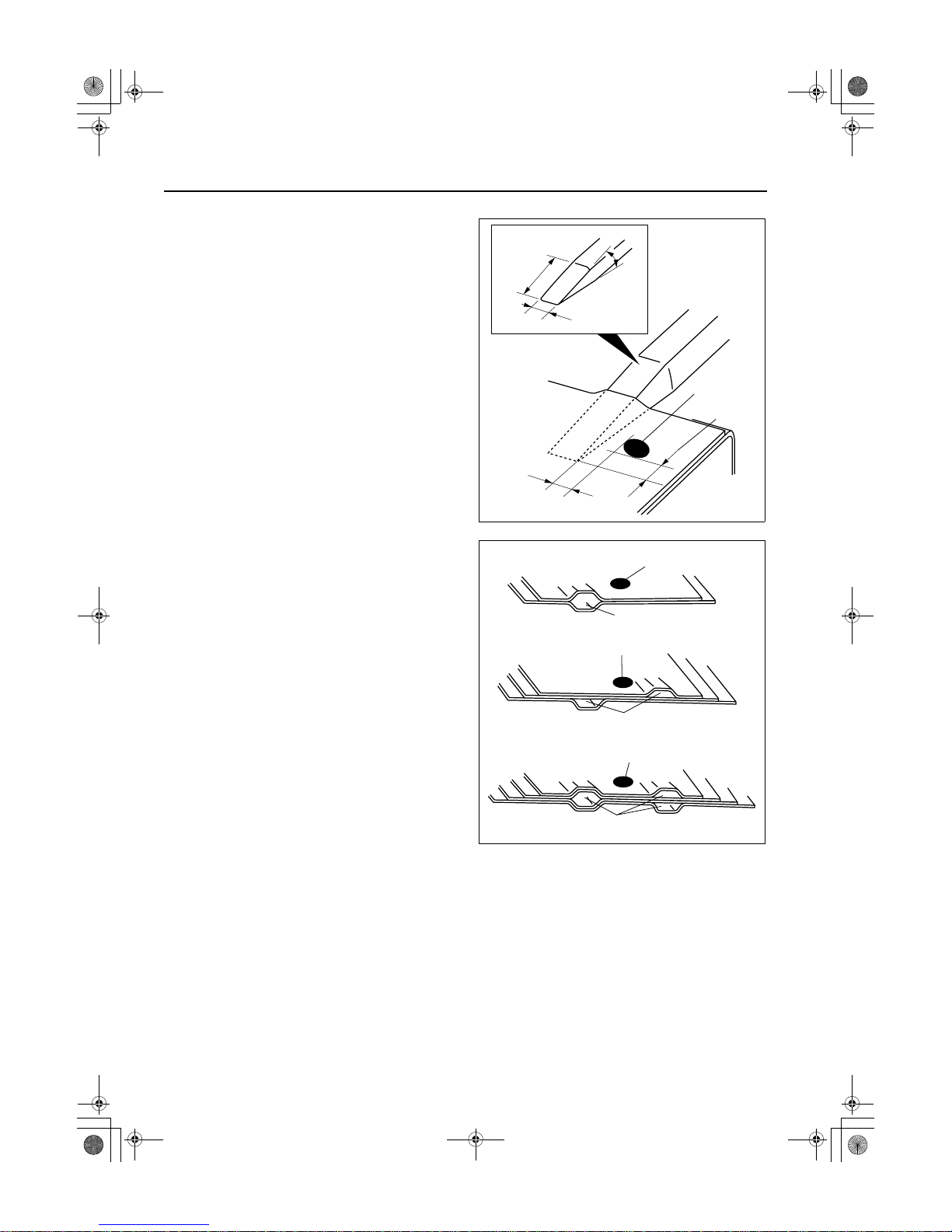

Checking Weld Strength

• Installation locations of the engine, chassis, and

seat belts are designated as important safety

locations for weld strength. Check weld strength

by driving a chisel between the panels at every

fourth or fifth weld spot, and every tenth regular

weld location.

• Drive the chisel between the panels according to

the number of panels as shown below.

• To determine weld strength, drive the chisel

between the panel and check whether the panels

come apart. If the panels come apart, make

another weld near the original weld.

• Restore the shape of the checked area.

End Of Sie

Chisel dimensions

25mm

{0.98in}

8mm{0.31in}

{0.20in}

{0.20in}

20°

Weld location

Within 5mm

Within 5mm

acxuub00000057

Two panels

Weld location

Three panels

Weld location

One location

Two location

Four panels

Weld location

Three location

acxuub00000058

GENERAL INFORMATION

00-00–13

00

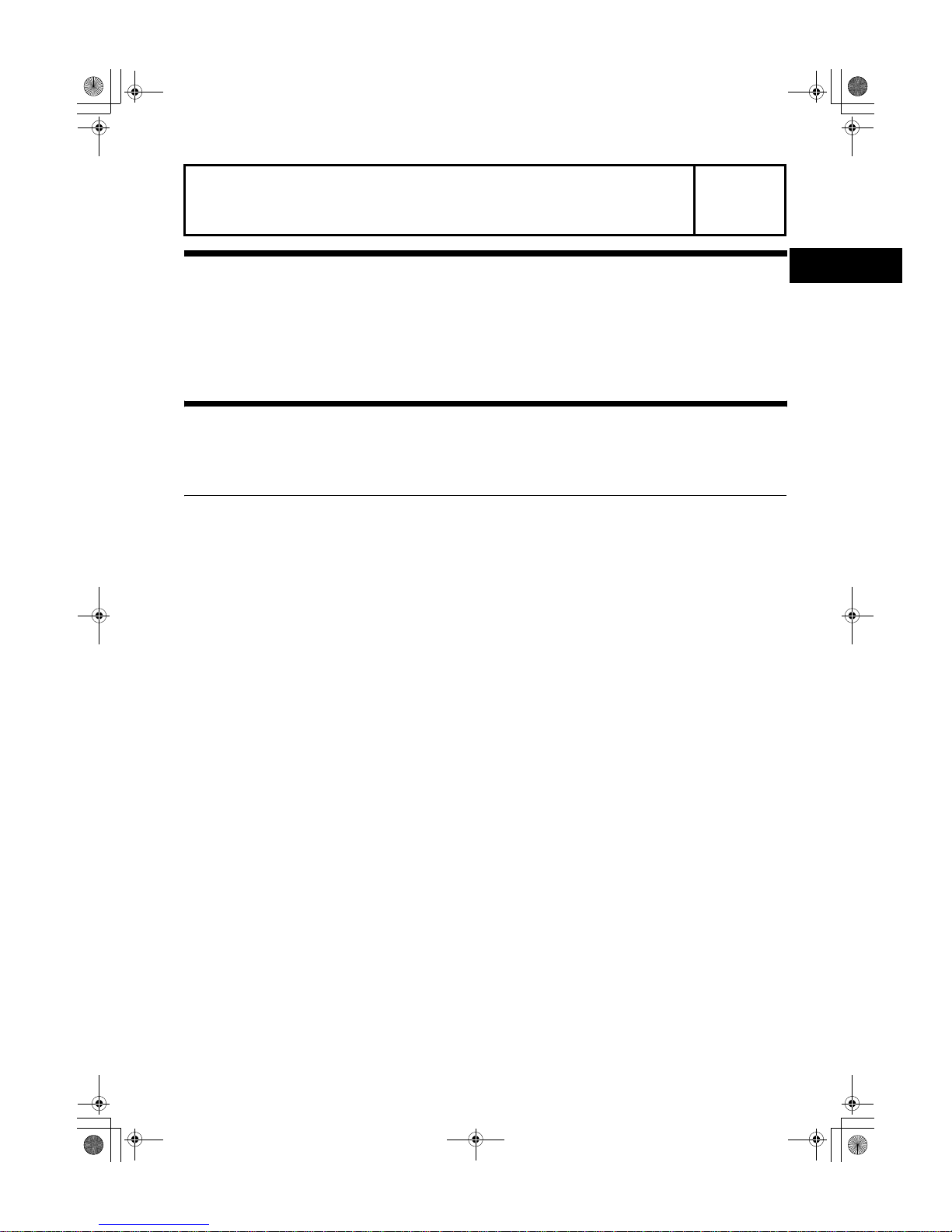

ANTICORROSION, SOUND INSULATION, AND VIBRATION INSULATION

id000000600600

Body Sealing

• Apply body sealer where necessary.

• For locations where application of body sealer is

difficult after installation, apply it before

installation.

Application of Undercoating

• Apply an undercoat to the required location of the

body.

Application of Rust Inhibitor

• Apply rust inhibitor (wax, oil, etc.) to the back of

the welded areas.

Application of Floor Silencer

• Apply floor silencer by heating with an infrared ray

lamp.

End Of Sie

acxuub00000059

acxuub00000060

acxuub00000061

acxuub00000062

00-00–14

GENERAL INFORMATION

ABBREVIATION

id000000600700

End Of Sie

CM Control module

Ctr Center

DSC Dynamic stability control

Fr Fron t

HU Hydraulic unit

LH Left

M Metallic

MC Mica

RH Right

Rr Rear

09-80A–1

09

BODY & ACCESSORIES

SECTION

80A

To c of S CT

BODY STRUCTURE

[CONSTRUCTION] . . . . . . . . 09-80A

BODY STRUCTURE[PANEL

REPLACEMENT]. . . . . . . . . . 09-80B

BODY STRUCTURE

[WATER-PROOF AND RUST

PREVENTIVE] . . . . . . . . . . . . 09-80C

BODY STRUCTURE

[DIMENSIONS] . . . . . . . . . . . . 09-80D

BODY STRUCTURE

[PLASTIC BODY PARTS]. . . . 09-80E

BODY STRUCTURE

[PRIMARY COLOR MIXTURE

CHART FOR

BODY COLOS] . . . . . . . . . . . . 09-80F

To c of S CT

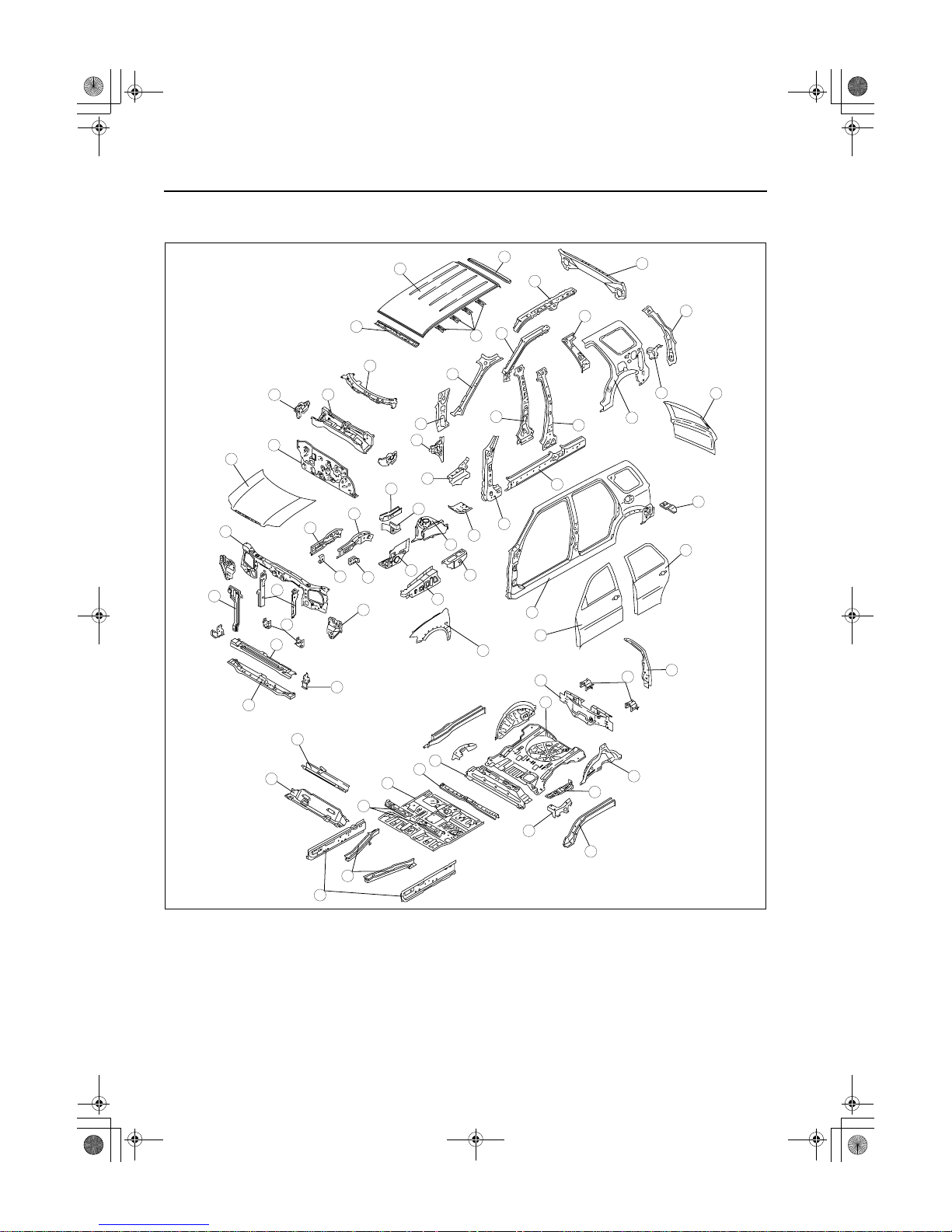

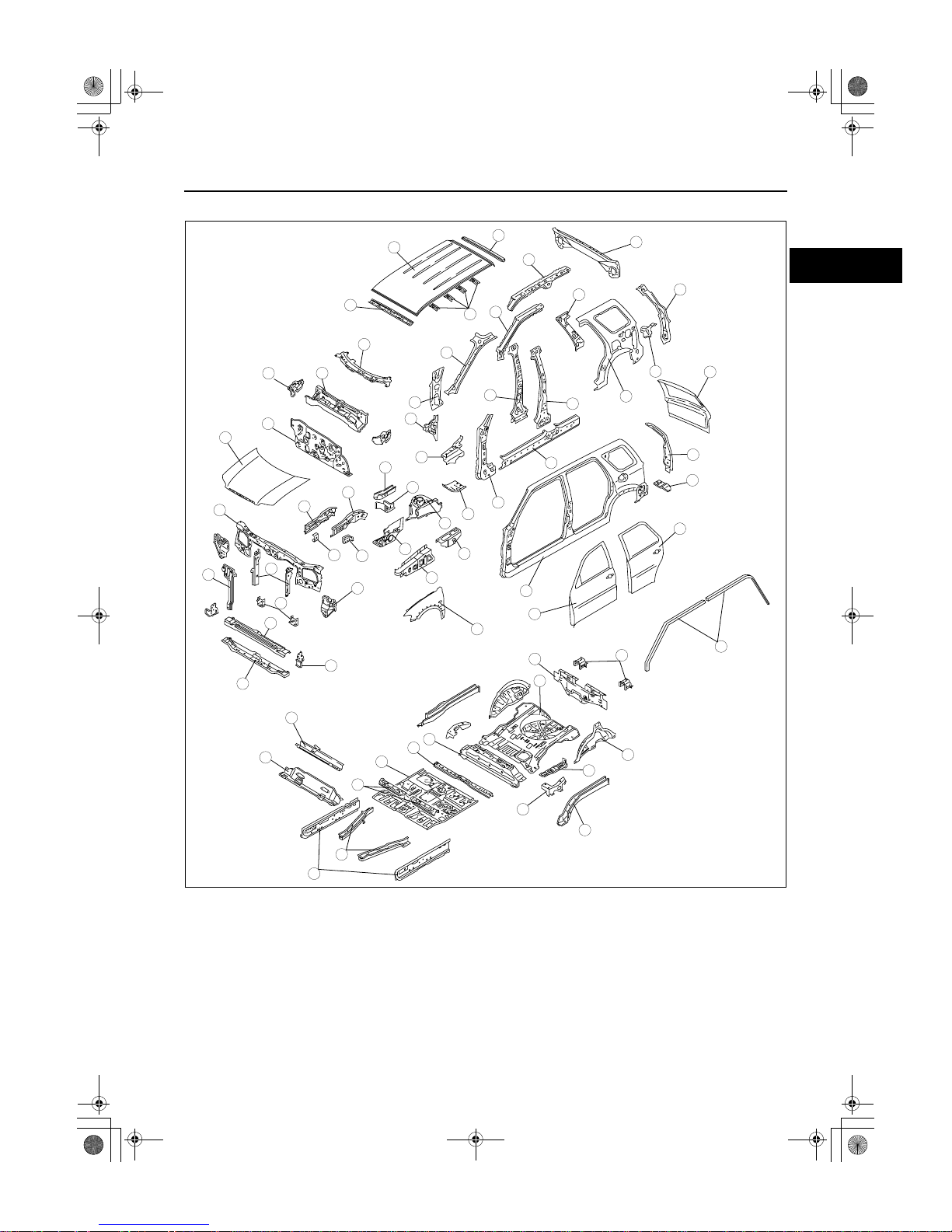

09-80A BODY STRUCTURE [CONSTRUCTION]

BODY COMPONENTS CONSTRUCTION

[CONSTRUCTION] . . . . . . . . . . . . . . . . 09-80A–2

End of Toc

BM: CONSTRUCTION

09-80A–2

BODY STRUCTURE [CONSTRUCTION]

BODY COMPONENTS CONSTRUCTION[CONSTRUCTION]

id098007739700

R.H.D. MODELS

.

9

8

7

5

4

3

1

2

10

6

19

18

17

15

16

14

13

11

12

20

28

27

29

25

26

24

23

21

22

30

39

38

37

35

36

34

33

31

32

40

63

62

61

60

58

59

64

65

47

45

46

44

43

41

42

48

57

56

55

53

54

52

51

49

50

atraab00000004

BODY STRUCTURE [CONSTRUCTION]

09-80A–3

80A

x:Applied

-:Not applied

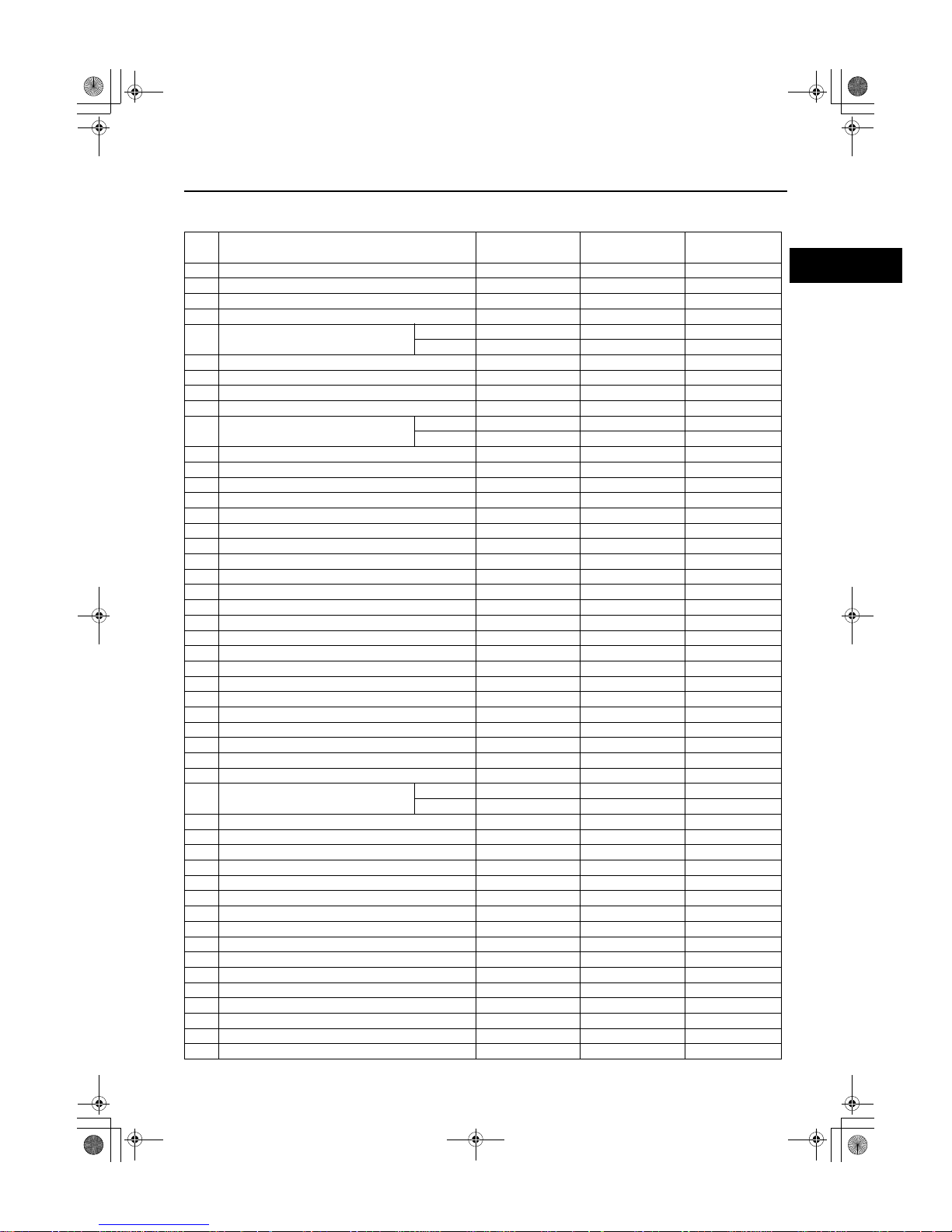

No. Part Name High- tension steel Rust proof steel

Thickness

(mm) {in}

1 Bonnet x x 0.70 {0.028}

2 Shroud upper panel - - 0.90 {0.035}

3 Lamp bracket - x 1.20 {0.047}

4 Shroud side stay x x 1.20 {0.047}

5 Front bumper bracket

RH x - 2.00 {0.079}

LH x - 2.30 {0.091}

6 Bonnet lock stay - x 1.00 {0.039}

7 Crossmember No.1 (front) - x 1.00 {0.039}

8 Crossmember No.1 (rear) - x 1.00 {0.039}

9 Cross side reinforcement x x 2.30 {0.091}

10 Hook reinforcement

RH x - 2.00 {0.079}

LH x - 1.40 {0.055}

11 Front side frame (outer) x x 1.60 {0.063}

12 Frame reinforcement - x 1.40 {0.055}

13 Front side frame (inner) x x 1.60 {0.063}

14 Apron reinforcement (front) - - 1.00 {0.039}

15 Wheel apron panel (front) - x 0.70 {0.028}

16 Apron reinforcement - - 0.80 {0.031}

17 Suspension housing (upper) x x 2.90 {0.114}

18 Torque box - x 1.20 {0.047}

19 Front frame (rear) - x 2.30 {0.091}

20 Dash lower panel - - 0.75 {0.030}

21 Cowl upper plate x x 1.20 {0.047}

22 Dash upper panel - - 0.70 {0.028}

23 Cowl panel - x 0.70 {0.028}

24 Torque box reinforcement - x 1.20 {0.047}

25 Cowl side reinforcement - x 1.40 {0.055}

26 Cowl side panel - x 0.70 {0.028}

27 Hinge pillar (inner) - - 1.00 {0.039}

28 Hinge pillar reinforcement x x 1.20 {0.047}

29 Front pillar (inner) x - 1.00 {0.039}

30 Side sill reinforcement - x 1.00 {0.039}

31 Center pillar reinforcement x - 1.60 {0.063}

32 Center pillar (inner) - - 1.20 {0.047}

33 Front pillar reinforcement

RH x - 2.00 {0.079}

LH x - 1.40 {0.055}

34 Roof rail (inner) x - 1.00 {0.039}

35 Rear pillar (inner) - x 0.65 {0.026}

36 C-pillar reinforcement x - 1.00 {0.039}

37 Corner plate - x 1.00 {0.039}

38 Rear pillar reinforcement - - 0.80 {0.031}

39 Rear end panel - - 0.70 {0.028}

40 Front header - - 0.70 {0.028}

41 Roof panel - - 0.75 {0.030}

42 Roof reinforcement - - 0.80 {0.031}

43 Rear header - - 0.70 {0.028}

44 Front fender panel x x 0.70 {0.028}

45 Side frame (outer) - x 0.70 {0.028}

46 Rear end side member - x 0.80 {0.031}

47 Rear pillar (outer) - x 0.80 {0.031}

48 Front door x x 49 Rear door x x -

09-80A–4

BODY STRUCTURE [CONSTRUCTION]

50 Side sill (inner) x x 2.00 {0.079}

51 Front B frame x x 1.40 {0.055}

52 Crossmember No.3 - - 2.00 {0.079}

53 Crossmember No.4 x x 1.40 {0.055}

54 Crossmember No.2 - - 0.80 {0.031}

55 Front floor pan - - 0.80 {0.031}

56 Crossmember No.2.5 - - 0.80 {0.031}

57 Crossmember No.3 (upper) - - 0.80 {0.031}

58 Seat bracket - - 0.70 {0.028}

59 Rear side frame x x 1.40 {0.055}

60 Hook bracket x x 1.20 {0.047}

61 Wheel house panel - x 0.70 {0.028}

62 Rear floor pan - - 0.65 {0.026}

63 Crossmember No.5 - - 0.65 {0.026}

64 Rear bumper bracket x x 1.40 {0.055}

65 Liftgate - x -

No. Part Name High- tension steel Rust proof steel

Thickness

(mm) {in}

BODY STRUCTURE [CONSTRUCTION]

09-80A–5

80A

L.H.D. MODELS

.

9

8

7

5

4

3

1

2

10

6

19

18

17

15

16

14

13

11

12

20

28

27

29

25

26

24

23

21

22

30

39

38

37

35

36

34

33

31

32

40

63

62

61

60

58

59

64

66

47

45

46

44

43

41

42

48

65

57

56

55

53

54

52

51

49

50

atraab00000005

09-80A–6

BODY STRUCTURE [CONSTRUCTION]

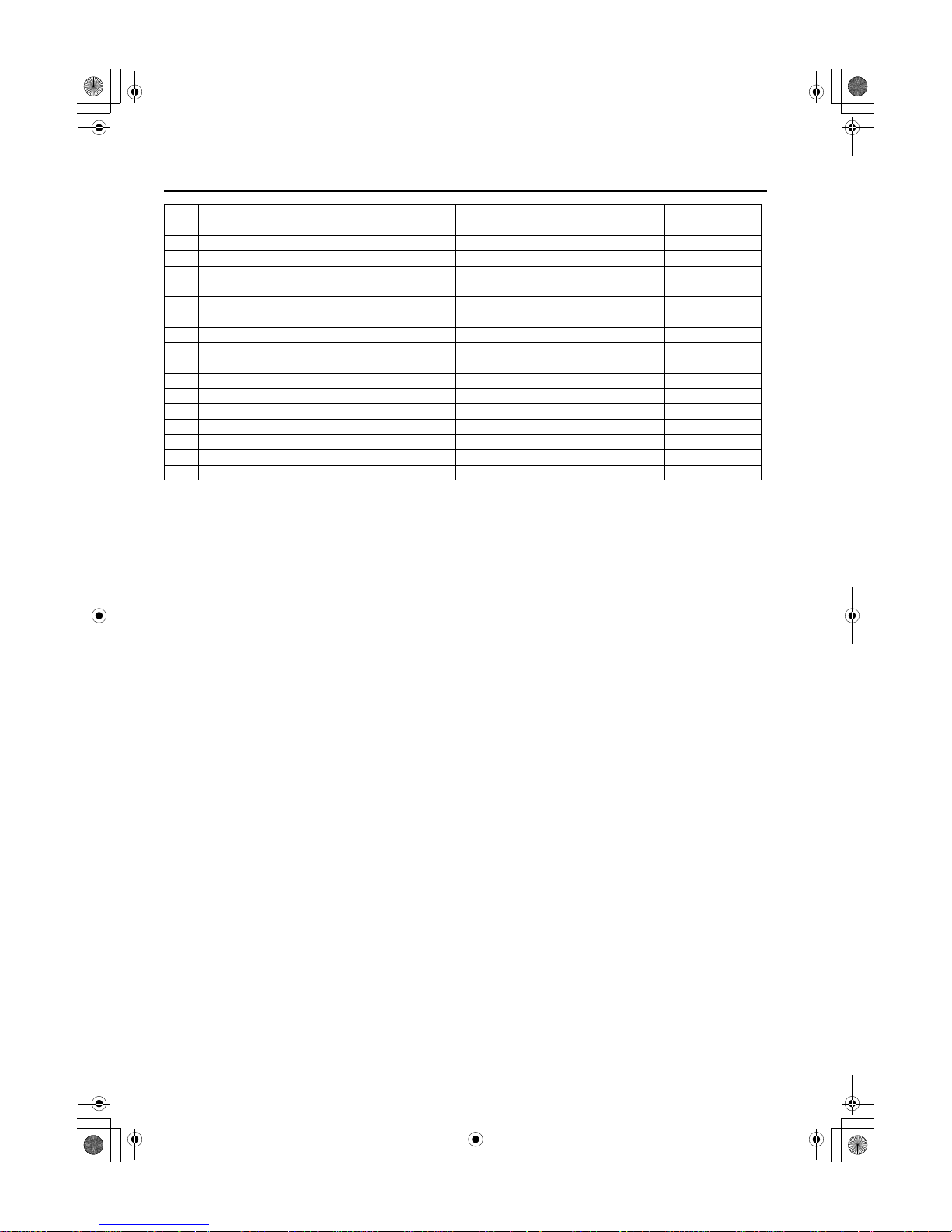

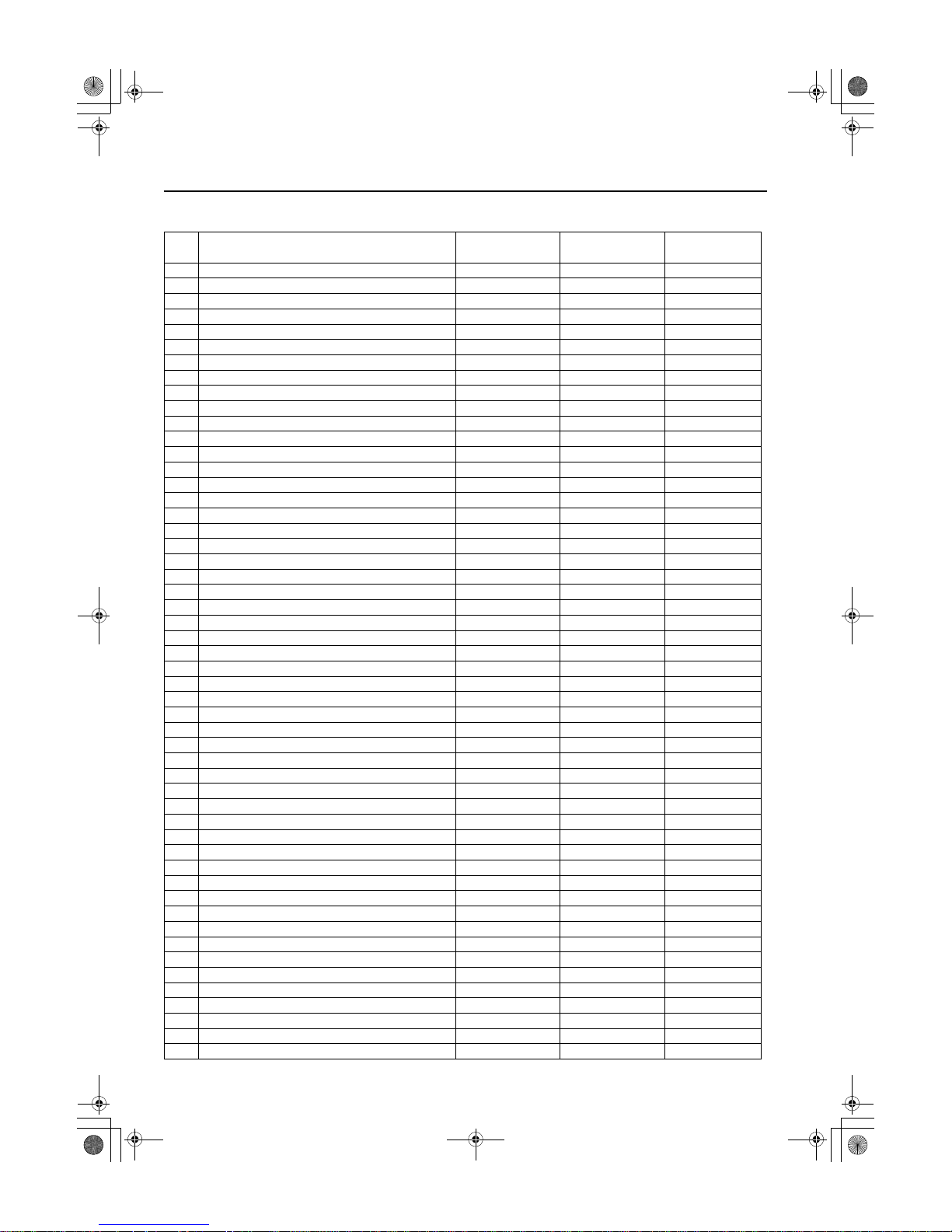

x:Applied

-:Not applied

No. Part Name High- tension steel Rust proof steel

Thickness

(mm) {in}

1 Bonnet x x 0.70 {0.028}

2 Shroud upper panel - x 0.90 {0.035}

3 Lamp bracket - x 1.20 {0.047}

4 Shroud side stay x x 1.20 {0.047}

5 Front bumper bracket x - 2.30 {0.091}

6 Bonnet lock stay - x 1.00 {0.039}

7 Crossmember No.1 (front) - x 1.00 {0.039}

8 Crossmember No.1 (rear) - x 1.00 {0.039}

9 Cross side reinforcement x - 2.30 {0.091}

10 Hook reinforcement x - 1.40 {0.055}

11 Front side frame (outer) x x 1.60 {0.063}

12 Frame reinforcement - x 1.40 {0.055}

13 Front side frame (inner) x x 1.60 {0.063}

14 Apron reinforcement (front) - x 1.00 {0.039}

15 Wheel apron panel (front) - x 0.70 {0.028}

16 Apron reinforcement - x 0.80 {0.031}

17 Suspension housing (upper) x x 2.60 {0.102}

18 Torque box - x 1.20 {0.047}

19 Front frame rear - x 2.30 {0.091}

20 Dash lower panel - x 0.75 {0.030}

21 Cowl upper plate x x 1.20 {0.047}

22 Dash upper panel - x 0.70 {0.028}

23 Cowl panel - x 0.70 {0.028}

24 Torque box reinforcement - x 1.20 {0.047}

25 Cowl side reinforcement - - 1.40 {0.055}

26 Cowl side panel - x 0.70 {0.028}

27 Hinge pillar (inner) - - 1.00 {0.039}

28 Hinge pillar reinforcement x x 1.20 {0.047}

29 Front pillar (inner) x - 1.00 {0.039}

30 Side sill reinforcement - x 1.00 {0.039}

31 Center pillar reinforcement x - 1.60 {0.063}

32 Center pillar (inner) - - 1.20 {0.047}

33 Front pillar reinforcement x - 1.40 {0.055}

34 Roof rail (inner) x - 1.00 {0.039}

35 Rear pillar (inner) - x 0.70 {0.028}

36 C-pillar reinforcement x - 1.00 {0.039}

37 Corner plate - x 1.00 {0.039}

38 Rear pillar reinforcement - - 0.80 {0.031}

39 Rear end panel - - 0.70 {0.028}

40 Front header - - 0.70 {0.028}

41 Roof panel - - 0.75 {0.030}

42 Roof reinforcement - - 0.80 {0.031}

43 Rear header - - 0.70 {0.028}

44 Front fender panel x x 0.70 {0.028}

45 Side frame (outer) - x 0.70 {0.028}

46 Rear end side member - x 0.80 {0.031}

47 Rear pillar (outer) - x 0.80 {0.031}

48 Front door x x 49 Rear door x x 50 Side sill (inner) x x 2.00 {0.079}

51 Front B frame x x 1.40 {0.055}

52 Crossmember No.3 - - 2.00 {0.079}

BODY STRUCTURE [CONSTRUCTION]

09-80A–7

80A

End Of Sie

53 Crossmember No.4 x x 1.40 {0.055}

54 Crossmember No.2 - - 0.80 {0.031}

55 Front floor pan - x 0.65 {0.026}

56 Crossmember No.2.5 - - 0.80 {0.031}

57 Crossmember No.3 (upper) - - 0.80 {0.031}

58 Seat bracket - - 0.70 {0.028}

59 Rear side frame x x 1.40 {0.055}

60 Hook bracket x x 1.20 {0.047}

61 Wheel house panel - x 0.70 {0.028}

62 Rear floor pan - x 0.65 {0.026}

63 Crossmember No.5 - x 0.65 {0.026}

64 Rear bumper bracket x - 1.40 {0.055}

65 Rain rail - x 0.70 {0.028}

66 Liftgate - x -

No. Part Name High- tension steel Rust proof steel

Thickness

(mm) {in}

BODY STRUCTURE [PANEL REPLACEMENT]

09-80B–1

80B

09-80B BODY STRUCTURE [PANEL REPLACEMENT]

RADIATOR SHROUD PANEL

COMPONENT REMOVAL

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–2

RADIATOR SHROUD PANEL

COMPONENT INSTALLATION

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–2

CROSSMEMBER No.1 REMOVAL

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–3

CROSSMEMBER No.1 INSTALLATION

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–3

APRON REINFORCEMENT AND COWL

SIDE REINFORCEMENT REMOVAL

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–4

APRON REINFORCEMENT AND COWL

SIDE REINFORCEMENT

INSTALLATION[PANEL

REPLACEMENT]. . . . . . . . . . . . . . . . . . 09-80B–5

WHEEL APRON PANEL

COMPONENT REMOVAL

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–6

WHEEL APRON PANEL COMPONENT

INSTALLATION[PANEL

REPLACEMENT]. . . . . . . . . . . . . . . . . . 09-80B–7

FRONT SIDE FRAME COMPONENT

REMOVAL[PANEL

REPLACEMENT]. . . . . . . . . . . . . . . . . . 09-80B–8

FRONT SIDE FRAME COMPONENT

INSTALLATION[PANEL

REPLACEMENT]. . . . . . . . . . . . . . . . . . 09-80B–9

FRONT SIDE FRAME

(PARTIAL CUTTING) REMOVAL

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–10

FRONT SIDE FRAME

(PARTIAL CUTTING) INSTALLATION

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–11

FRONT FRAME (REAR) REMOVAL

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–12

FRONT FRAME (REAR) INSTALLATION

[PANEL REPLACEMENT]. . . . . . . . . . . 09-80B–13

FRONT PILLAR REMOVAL[PANEL

REPLACEMENT]. . . . . . . . . . . . . . . . . . 09-80B–14

FRONT PILLAR INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–16

CENTER PILLAR REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–18

CENTER PILLAR INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–19

SIDE SILL PANEL REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–20

SIDE SILL PANEL INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–21

REAR FENDER PANEL REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–22

REAR FENDER PANEL INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–23

REAR END PANEL AND

CROSSMEMBER No.5 REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–24

REAR END PANEL AND

CROSSMEMBER No.5 INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–25

REAR PILLAR (OUTER) AND REAR

PILLAR REINFORCEMENT REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–26

REAR PILLAR (OUTER) AND REAR

PILLAR REINFORCEMENT

INSTALLATION[PANEL

REPLACEMENT] . . . . . . . . . . . . . . . . . .09-80B–27

REAR FLOOR PAN REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–28

REAR FLOOR PAN INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–29

REAR SIDE FRAME

(PARTIAL CUTTING) REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–30

REAR SIDE FRAME

(PARTIAL CUTTING) INSTALLATION

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–30

ROOF PANEL REMOVAL

[PANEL REPLACEMENT] . . . . . . . . . . . 09-80B–31

ROOF PANEL INSTALLATION[PANEL

REPLACEMENT] . . . . . . . . . . . . . . . . . .09-80B–32

End of Toc

BM: RADIATOR SHROUD PANEL

Loading...

Loading...