Page 1

Evaporative Emission (EVAP) Canisters

SECTION 310-00: Fuel System 2004 Freestar/Monterey Workshop Manual

Page

1

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

DIAGNOSIS AND TESTING

Procedure revision date: 07/31/ 2003

Evaporative Emissions

Printable View (184 KB)

Special Tool(s)

Worldwide Diagnostic System (WDS)

418-F224

New Generation STAR (NGS) Tester

418-F052, or equivalent scan tool

Evaporative Emission System Leak Tester

310-F007 (134-00056) or equivalent

The EVAP running loss system leak test:

utilizes intake manifold vacuum to test the system and involves several stages.

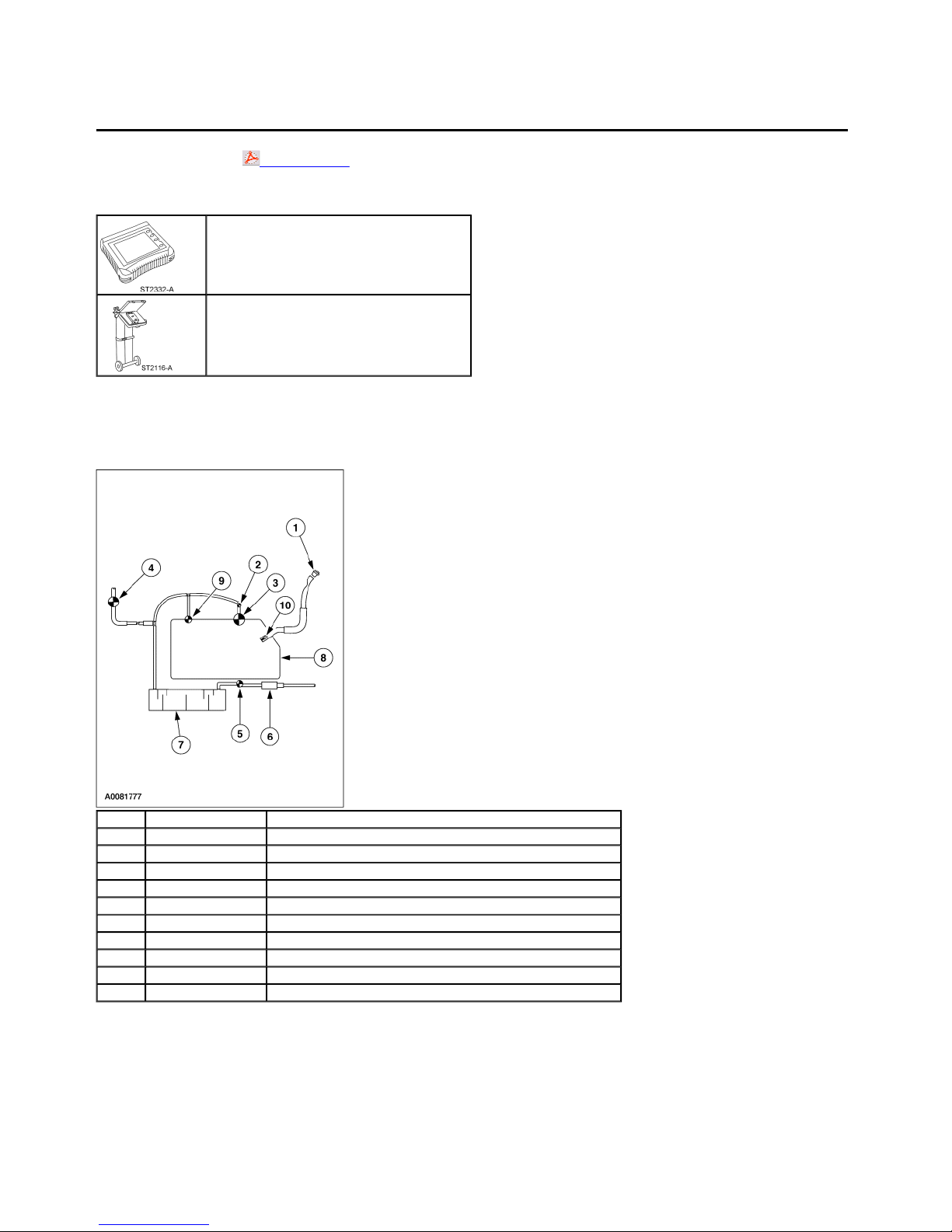

Evaporative Emission System

Item Part Number Description

1 9030 Fuel filler cap

2 9C052 Fuel tank pressure sensor

3 9B190 RIU limit vent valve

4 9C915 Evaporative emission canister purge valve

5 9F945 Canister vent solenoid

6 9B328 Evaporative emission dust separator

7 9D653 Evaporative emission canister

8 9002 Fuel tank

9 9B593 Fuel vapor vent valve

10 9189 Fuel filler pipe check valve

Principles of Operation

Evaporative Emission (EVAP) Canister Purge Valve

The EVAP canister purge valve is controlled by the powertrain control module (PCM). The EVAP canister purge valve controls the flow of fuel vapors from the EVAP

canisters to the engine intake manifold during various engine operating modes. The EVAP canister purge valve is normally closed.

Page 2

Fuel vapors from the fuel tank are stored in the EVAP canisters. When the engine is running, the vapors are purged from the EVAP canisters for combustion.

EVAP canisters or vent solenoid

Page

2

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

Canister Vent Solenoid

During the Evaporative Emission Running Loss System Monitor Test, Evaporative Emissions Repair Verification Drive Cycle, and the Evaporative Emission System

Leak Test, the canister vent solenoid is closed to allow either a vacuum to be drawn on the fuel tank or to hold a specified pressure in the system. The canister vent

solenoid is normally open.

Fuel Tank Pressure (FTP) Sensor

The fuel tank pressure (FTP) sensor is used to measure the fuel tank pressure during the Evaporative Emissions Monitor Test. It is also used to control excessive fuel

tank pressures by forcing the EVAP system to purge. The fuel tank pressure sensor is mounted in the main vapor line.

Fuel Vapor Vent (FVV) Valve Assembly

The fuel vapor vent (FVV) valve assembly is mounted on the top of the fuel tank. It is used to control the flow of fuel vapors entering the EVAP system. The head portion

of the assembly prevents the fuel tank from overfilling during refueling. The assembly also has a spring float, which prevents liquid fuel from entering the vapor delivery

system under severe handling or vehicle rollover conditions. In the upright position, the open bottom of the float will lift and shut off the orifice. Under severe handling

conditions, the spring will push the float closed when angles allow liquid fuel to reach the orifice. In a rollover condition, the weight of the open bottom float and spring

pressure will close the orifice.

Fuel Filler Pipe Check Valve

The fuel filler pipe check valve is an integral part of the fuel tank or the fuel filler pipe. It is intended to prevent liquid fuel from re-entering the fuel filler pipe from the fuel

tank after refueling.

Fuel Filler Cap

The fuel filler cap is used to prevent fuel spill and to close the EVAP system to the atmosphere.

Fill Limit Vent Valve (FLVV)

The fill limit vent valve is mounted on top of the fuel tank. It has a main orifice which allows fuel vapor to route to the carbon canisters during refueling. This orifice is

controlled by a float, when the tank is full the flow of vapor is stopped and prevents the tank from overfilling.

Evaporative Emission (EVAP) System Monitor

When a fault occurs, the EVAP system monitor is reset to NO and a diagnostic trouble code (DTC) is set in the PCM memory. After the DTC is repaired, the vehicle

drive cycle must be completed to reset the monitor in preparation for inspection and maintenance testing.

EVAP Running Loss System Leak Test

To start the testing, conditions of stable purging and vehicle speed must be satisfied. During the first stage, the EVAP canister vent solenoid is closed, while the EVAP

canister purge valve remains open, applying and building vacuum in the system as indicated by the FTP sensor. This phase checks for major leaks in the EVAP system.

In the second stage, the EVAP canister purge valve closes and the system looks for minimal decay rate in the vacuum, indicating the absence of any small EVAP

system leaks.

The last stage is entered only if stage two of the leak test has failed and checks whether the failed test was due to excess vapor generation. It monitors fuel vapor

generation rate. Initially, the canister vent solenoid is opened to equalize EVAP system pressure to atmosphere. Then the canister vent solenoid is closed, allowing

pressure to build if vapor generation is present in sufficient quantity. If the rate of generation is found to be too high, the EVAP running loss system leak test is aborted.

If not, then a small leak is diagnosed.

Inspection and Verification

1. Verify the customer concern is with the evaporative emission (EVAP) system.

2. Visually inspect for the following obvious signs of mechanical damage.

Visual Inspection Chart

Mechanical

Fuel filler cap

EVAP test port

EVAP canister lines or hoses

Vacuum lines or hoses

3. If the concern remains after the inspection, connect the scan tool to the data link connector (DLC) located beneath the instrument panel and select the vehicle to

be tested from the scan tool menu. If the scan tool does not communicate with the vehicle:

check that the program card is correctly installed.

check the connections to the vehicle.

check the ignition switch position.

4. If the scan tool still does not communicate with the vehicle, refer to the scan tool manual.

5. Carry out the DATA LINK DIAGNOSTICS test. If the scan tool responds with:

CKT914, CKT915 or CKT70 = ALL ECUS NO RESP/N OT EQUIP, refer to Section 418-00.

NO RESP/NOT EQUIP for PCM, refer to the Powertrain Control/Emissions Diagnosis (PC/ED) manual.

Page 3

Page

3

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

SYSTEM PASSED, retrieve and record the continuous diagnostic trouble codes (DTCs), erase the continuous DTCs and carry out the PCM KOEO selftest.

6. If the DTCs retrieved are related to the concern, go to the PCM Diagnostic Trouble Code (DTC) Index to continue diagnostics.

7. If the concern remains after the inspection, determine the symptom. GO to Symptom Chart.

PCM Diagnostics Trouble Code (DTC) Index

DTC Description Source Action

P0442

Small Leak Detected in EVAP Systema

P0457 Cap Off PCM GO to Pinpoint Test A.

P0456 Very Small Leak Detected in EVAP System PCM GO to Pinpoint Test A.

P0455 Major Leak or no Flow Detected PCM GO to Pinpoint Test B.

P1443 Very Small or no Purge Flow Detected PCM GO to Pinpoint Test B.

P1450 Excessive Vacuum Detected in the Fuel Tank PCM GO to Pinpoint Test C.

— Any Other PCM DTC PCM REFER to the Powertrain Control/Emissions Diagnosis (PC/ED) manual.

a

As small as 1.02 mm (0.040 in).

Symptom Chart

SYMPTOM CHART

Condition Possible Sources Action

Hissing sound when

removing fuel cap

Excessive fuel odor

Slow fuel fill

Canister vent solenoid.

Evaporative emissions canisters.

Fuel vapor control valve tube assembly.

EVAP canister tube.

EVAP canister purge outlet tube.

Canister vent solenoid.

Evaporative emissions canisters.

Fuel vapor control valve tube assembly.

Evaporative emissions test port.

EVAP canister purge outlet tube.

Restriction in the canister vent solenoid, dust filter, carbon canisters and

canister attachment hoses or vent tubing.

Restriction in the fuel fill hose or fuel fill pipe.

Pinpoint Tests

NOTE: Reinstall or install new evaporative emission hose clamps removed or damaged during testing procedures.

PINPOINT TEST A: DTC P0442 SMALL LEAK IN EVAP SYSTEM

NOTE: Condition P0442 DTC set: less than 0.625 kPa (2.5 inches H2O) bleed-up over 15 seconds at 75% fuel fill. Vapor generation limit: more than 0.625 kPa (2.5

inches H2O) over 120 seconds.

PCM GO to Pinpoint Test A.

GO to Pinpoint

Test D.

GO to Pinpoint

Test E.

GO to Pinpoint

Test C.

Test Step Result / Action to Take

A1 VISUALLY INSPECT THE COMPONENTS FOR

SMALL LEAKS

Check for the presence of a fuel filler cap. Do not

tighten or check for correct installation at this time.

Verify the canister vent solenoid is correctly seated

on the EVAP canister.

Check for cut or loose connections to fuel vapor

hoses, tubes and connections in the following

locations:

EVAP canisters to EVAP canister purge valve

EVAP canister to fuel vapor vent valve

assembly

Check the fuel filler pipe for damage.

Is a concern with a hose, tube, connection or

valve visually evident?

A2 CHECK AT THE EVAP TEST PORT FOR SMALL

SYSTEM LEAKS

Disconnect and plug the evaporative emission return

tube at the intake manifold.

Complete the evaporative emission system leak test.

Refer to Evaporative Emission System Leak Test in

this section.

Does the system pass the leak test?

A3 VISUALLY INSPECT THE FUEL FILLER CAP

Yes

REPAIR or INSTALL new components as necessary. GO to A2.

No

GO to A2.

Yes

GO to A3.

No

GO to A4.

Page 4

Page

4

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

Visually inspect the fuel filler cap for damage.

Is the fuel filler cap damaged?

A4 CHECK FOR SMALL LEAKS AT THE FUEL FILLER

CAP AND EVAP TEST PORT

Connect the Evaporative Emission System Leak

Tester to the fuel filler pipe.

Key in ON position.

Close the canister vent solenoid. Refer to Canister

Vent Solenoid Closing Procedure in this section.

Pressurize the EVAP system to 3.48 kPa (14 inches

H2O).

Using the ultrasonic leak detector, check the fuel

filler cap and EVAP test port for leaks.

Is a leak detected?

A5 CHECK FOR CONCERN OTHER THAN THE FUEL

FILLER CAP

Refer to previous test results.

Did the system pass the evaporative emission

system leak test carried out in pinpoint test Step

A2?

A6 CHECK FOR SMALL LEAK WITH TESTER SET AT

FILL POSITION

Connect the Evaporative Emission System Leak

Tester to the EVAP test port.

Key in ON position.

Close the canister vent solenoid. Refer to Canister

Vent Solenoid Closing Procedure in this section.

Turn the selector on the Evaporative Emission

System Leak Tester to the FILL position.

Pressurize the EVAP system to 3.48 kPa (14 inches

H2O).

Does the pressure on the EVAP system hold

between 3.43 kPa and 3.53 kPa (13.80 inches and

14.20 inches H2O)?

A7 CHECK FOR LEAKS IN THE COMPLETE EVAP

SYSTEM

Connect the Evaporative Emission System Leak

Tester to the EVAP test port.

Key in ON position.

Close the canister vent solenoid. Refer to Canister

Vent Solenoid Closing Procedure in this section.

Pressurize the EVAP system to 3.48 kPa (14 inches

H2O).

Using the ultrasonic leak detector, check the

following EVAP system locations:

EVAP return tube to EVAP canister purge

valve

EVAP canister purge valve to EVAP canister

— canister vent solenoid assembly

EVAP canisters — canister vent solenoid

assembly to fuel tank

fuel filler cap and fuel filler pipe

Is a leak detected at EVAP return tube, EVAP

canister purge outlet tube or EVAP canister tube

or associated hose?

A8 CHECK FOR SMALL LEAK FROM THE EVAP

RETURN TUBE TO THE EVAP CANISTER

Disconnect the fuel tank vapor tube (9G332) at the

fuel vapor tee. Plug the opening in the tee.

Connect the Evaporative Emission System Leak

Tester to the EVAP test port.

Key in ON position.

Close the canister vent solenoid. Refer to Canister

Vent Solenoid Closing Procedure in this section.

Pressurize the EVAP system to 3.48 kPa (14 inches

H2O).

Using the ultrasonic leak detector, check the EVAP

system from the intake manifold to the EVAP

canister vent solenoid.

Is a leak detected?

A9 CHECK FOR SMALL LEAK BETWEEN FUEL TANK

VAPOR TUBE (9C047) AND FUEL TANK FILLER PIPE

Connect the Evaporative Emission System Leak

Tester to the fuel filler pipe.

Transfer the plug from the fuel vapor tee to the fuel

tank vapor tube (9C047).

Yes

INSTALL a new fuel filler cap. GO to A4.

No

GO to A4.

Yes

REPAIR or INSTALL new components as necessary. GO to A5.

No

INSTALL the fuel filler cap. CARRY OUT the evaporative emission system leak test. REFER to

Evaporative Emission System Leak Test in this section. If the system passes the leak test,

CARRY OUT the evaporative emissions repair verification drive cycle. REFER to Evaporative

Emission Repair Verification Drive Cycle in this section.

Yes

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System

Leak Test in this section. If the system passes the leak test, CARRY OUT the evaporative

emission repair verification drive cycle. REFER to Evaporative Emission Repair Verification Drive

Cycle in this section.

No

INSTALL the fuel filler cap. GO to A6.

Yes

GO to A7.

No

DISCONTINUE pressurizing the system. GO to A8.

Yes

REPAIR or INSTALL new components as necessary. CARRY OUT the evaporative emission

system leak test. REFER to Evaporative Emission System Leak Test in this section. If the system

passes the leak test, CARRY OUT the evaporative emissions repair verification drive cycle.

REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

No

DISCONTINUE pressurizing the system. GO to A8.

Yes

REPAIR or INSTALL new components as necessary. REPEAT Step A6 to verify the repair. GO to

A9.

No

OPEN the canister vent solenoid. GO to A9.

Yes

REPAIR or INSTALL new components as necessary.

GO to A10.

Page 5

Page

5

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

Turn the Evaporative Emission System Leak Tester

selector to the FILL position.

Pressurize the EVAP system to 3.48 kPa (14 inches

H2O).

Using the ultrasonic leak detector, check the fuel

tank vapor tube to the fuel tank for leaks. Check the

fuel tank pressure sensor, fuel tank vapor tube and

the fuel filler pipe.

Is a leak detected?

A10 CHECK EVAP SYSTEM AT FUEL FILLER PIPE

Reconnect the fuel tank vapor tube (9C047) to the

fuel vapor tee.

Complete the evaporative emission system leak test.

Refer to Evaporative Emission System Leak Test in

this section.

Does the EVAP system pass the leak test?

No

GO to A10.

Yes

RESTORE the system to normal operation. CARRY OUT the evaporative emission system leak

test. REFER to Evaporative Emission System Leak Test in this section. If the system passes the

leak test, CARRY OUT the evaporative emissions repair verification drive cycle. REFER to

Evaporative Emission Repair Verification Drive Cycle in this section.

No

GO to A6.

PINPOINT TEST B: DTC P0455 MAJOR LEAK OR NO FLOW DETECTED OR DTC P1443 VERY SMALL OR NO PURGE FLOW DETECTED IN SYSTEM

NOTE: Condition DTC P0455 set: -1.74 kPa (-7.0 inches H2O) over 30 seconds.

NOTE: Condition DTC P1443 set: -1.74 kPa (-7.0 inches H2O) over 30 seconds with more than 0.02 lb/min vapor flow.

Test Step Result / Action to Take

B1 CHECK FOR DIAGNOSTIC TROUBLE

CODE P0455 OR P1443

Use the recorded results from the PCM

DTCs.

Is DTC P0455 present?

B2 VISUALLY CHECK FOR GROSS EVAP

SYSTEM LEAKS

Check for the presence of a fuel filler

cap. Do not tighten or check for correct

installation at this time.

Check the input port vacuum and EVAP

return tube are connected to the EVAP

canister purge valve.

Check that the canister vent solenoid is

correctly attached to the EVAP canister.

Check for disconnected or cracked fuel

vapor hoses or tubes between the intake

manifold and the following components:

EVAP canister purge valve

EVAP canisters

fuel vapor vent valve assembly

fuel tank vapor tube assembly

Check for damaged fuel tank or fuel filler

pipe.

Is a concern with a hose, tube,

connection or valve visually evident?

B3 CHECK FOR EVAP SYSTEM LEAKS

Disconnect the EVAP return tube from

the intake manifold and plug the EVAP

return tube.

Connect the Evaporative Emissions

System Leak Tester to the EVAP test

port.

Carry out the evaporative emissions

system leak test. Refer to Evaporative

Emission System Leak Test in this

section.

Does the system pressure stay above

1.99 kPa (8 inches H2O)?

B4 CHECK FOR BLOCKAGE BETWEEN

THE EVAP CANISTER PURGE VALVE AND

FUEL VAPOR TEE

Key in the ON position

Close the canister vent solenoid. Refer

to Canister Vent Solenoid Closing

Procedure in this section.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Open the canister vent solenoid.

Does the pressure drop immediately?

B5 CHECK FOR BLOCKAGE BETWEEN

FUEL FILLER PIPE AND THE FUEL VAPOR

TEE

Yes

GO to B2.

No

GO to B3.

Yes

REPAIR or INSTALL new EVAP components as necessary. GO to B3.

No

GO to B3.

Yes

GO to B4.

No

VERIFY that the fuel filler cap is installed correctly. REPAIR or INSTALL new components as necessary.

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak Test

in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair verification

drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

Yes

GO to B5.

No

INSTALL a new vapor line between the EVAP canister purge valve and the fuel vapor tee. CARRY OUT the

evaporative emission system leak test. REFER to Evaporative Emission System Leak Test in this section. If

the system passes the leak test, CARRY OUT the evaporative emission repair verification drive cycle. REFER

to Evaporative Emission Repair Verification Drive Cycle in this section.

Page 6

Page

6

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

Connect the Evaporative Emissions

System Leak Tester to the fuel filler pipe.

Pressurize the EVAP system to 6.47 to

6.97 kPa (26 to 28 inches H2O).

Does the pressure drop immediately?

B6 CHECK FOR FAILED EVAP CANISTER

PURGE VALVE OR FUEL TANK PRESSURE

SENSOR

Use the recorded results from the PCM

DTCs.

Are DTC codes P0455 and P1443

present?

Yes

GO to B6.

No

INSTALL new fuel tank vapor line(s). REPEAT pinpoint test Step B5 to verify the repair. CARRY OUT the

evaporative emission system leak test. REFER to Evaporative Emission System Leak Test in this section. If

the system passes the leak test, CARRY OUT the evaporative emission repair verification drive cycle. REFER

to Evaporative Emission Repair Verification Drive Cycle in this section.

Yes

INSTALL a new EVAP canister purge valve. REFER toEvaporative Emission Canister and Purge Valve in this

section. CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System

Leak Test in this section. If no leak is detected, CARRY OUT the evaporative emissions repair verification

drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

No

INSTALL a new fuel vapor control valve tube assembly, fuel tank pressure sensor. REFER to Section 310-00.

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak Test

in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair verification

drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

PINPOINT TEST C: DTC P1450 EXCESSIVE VACUUM DETECTED IN THE FUEL TANK

NOTE: Condition P1450 DTC set: more than -1.79 kPa (-7.2 inches H2O) over 30 seconds.

Test Step Result / Action to Take

C1 CHECK FOR VISUAL CAUSES OF EXCESSIVE FUEL TANK

VACUUM

Check for kinks or bends in the fuel vapor hoses and tubes.

Visually check the EVAP canister inlet port, canister vent solenoid

filter or outlet hose for contamination or foreign material.

Check the canister vent solenoid for blockage or contamination.

Is a concern with a hose, tube, connection or component

visually evident?

C2 CHECK FOR BLOCKAGE BETWEEN EVAP TEST PORT AND

CANISTER VENT SOLENOID

Disconnect and plug the EVAP return tube at the intake manifold.

Connect the Evaporative Emissions System Leak Tester to the

EVAP test port.

Pressurize the EVAP system to 3.48 kPa (14 inches H2O).

Does the pressure drop immediately?

C3 CHECK FOR BLOCKAGE BETWEEN THE FUEL FILLER PIPE

AND THE FUEL VAPOR TEE

Connect the Evaporative Emission System Leak Tester to the fuel

filler pipe.

Pressurize the EVAP system to 3.48 kPa (14 inches H2O).

Does the pressure drop immediately?

C4 CHECK FOR FUEL TANK PRESSURE SENSOR PID WITHOUT

PRESSURE APPLIED

Disconnect the EVAP canister outlet tube at the EVAP canister.

Key in ON position.

Access PCM PID FTP V.

Record the reading.

Is PID FTP V reading between 2.40 and 2.80 volts?

C5 CHECK FOR STUCK OPEN EVAP CANISTER PURGE VALVE

CONDITION AT IDLE

Connect the EVAP canister purge outlet tube.

Yes

REMOVE any contamination or foreign material around fuel vapor hoses and tubes.

REPAIR the hoses, tubes or components as necessary. After all visual concerns are

repaired, GO to C2.

No

GO to C2.

Yes

GO to C3.

No

GO to Pinpoint Test D.

Yes

GO to C4.

No

GO to Pinpoint Test D.

Yes

GO to C5.

No

REFER to the Powertrain Control/Emissions Diagnosis (PC/ED) manual to continue

diagnosis.

Yes

INSTALL a new EVAP canister purge valve. REFER toEvaporative Emission

Canister and Purge Valve in this section. CARRY OUT an EVAP system leak test.

REFER to Evaporative Emission System Leak Test in this section. If the system

passes the leak test, CARRY OUT an evaporative emissions repair verification drive

cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this

section.

No

CARRY OUT the EVAP system leak test. REFER to Evaporative Emission System

Leak Test in this section. If the system passes the leak test, CARRY OUT the

evaporative emissions repair verification drive cycle. REFER to Evaporative

Emission Repair Verification Drive Cycle in this section.

Remove the plug from the EVAP return tube and reconnect the

tube to the intake manifold.

Verify that the fuel filler cap is correctly installed.

Key in ON position.

Access PCM PIDs FTP V and EVAPPDC.

Page 7

Page

7

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

Start the engine and allow to idle.

Monitor the FTP V and EVAPPDC PIDs.

When PID EVAPPDC is zero, is PID FTP V reading below 2.40

volts?

PINPOINT TEST D: HISS WHEN OPENING FUEL CAP

Test Step Result / Action to Take

D1 TEST FOR EVAP CANISTER, CANISTER

VENT SOLENOID AND CANISTER VENT HOSE

ASSEMBLY BLOCKAGE

Connect the Evaporative Emission System

Leak Tester to the fuel filler cap.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

D2 TEST FOR CANISTER VENT HOSE

ASSEMBLY BLOCKAGE

Disconnect the EVAP canister vent hose

assembly from the EVAP canister.

Connect the Evaporative Emission System

Leak Tester to the fuel filler pipe.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

D3 TEST FOR CANISTER VENT SOLENOID

BLOCKAGE

Remove the canister vent solenoid from the

lower EVAP canister.

Connect the Evaporative Emission System

Leak Tester to the fuel filler pipe.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

D4 TEST EVAP CANISTERS FOR BLOCKAGE

Disconnect the EVAP canister tube (from

the fuel tank) at the F-fitting from the EVAP

canister.

Connect the Evaporative Emission System

Leak Tester to the fuel filler pipe.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

D5 TEST EVAP CANISTERS FOR TUBE OR

FUEL VAPOR VENT VALVE ASSEMBLY

BLOCKAGE

Disconnect the fuel vapor vent valve

assembly from the EVAP canister tube.

Connect the Evaporative Emission System

Leak Tester to the fuel filler pipe.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

D6 TEST FOR BLOCKAGE BETWEEN THE

EVAP CANISTER PURGE VALVE AND THE

FUEL TANK

Remove the fuel vapor hose (from the fuel

tank) at the EVAP canister purge valve.

Connect the Evaporative Emission System

Leak Tester to the fuel filler pipe.

Key in ON position.

For vehicles equipped with a canister vent

solenoid, close the canister vent solenoid.

Refer to Canister Vent Solenoid Closing

Procedure in this section.

For vehicles without a canister vent

solenoid, plug the canister vent hose

assembly or plug the canister vent cap.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

Yes

The EVAP system has passed the EVAP canister and bracket assembly blockage test. GO to D6.

No

For vehicles equipped with a canister vent hose assembly, GO to D2.

For vehicles equipped with a canister vent solenoid, GO to D3.

For all others, GO to D4.

Yes

INSTALL a new EVAP canister vent solenoid vent hose assembly. CARRY OUT the evaporative emission

system leak test. REFER to Evaporative Emission System Leak Test in this section. If the system passes

the leak test, CARRY OUT the evaporative emission repair verification drive cycle. REFER to Evaporative

Emission Repair Verification Drive Cycle in this section.

No

GO to D4.

Yes

INSTALL a new canister vent solenoid. REFER to Evaporative Emission Canister Vent Solenoid in this

section. CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System

Leak Test in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair

verification drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

No

GO to D4.

Yes

INSTALL new EVAP canisters. REFER toEvaporative Emission Canister and Purge Valve in this section.

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak

Test in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair

verification drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

No

GO to D5.

Yes

INSTALL a new EVAP canister tube and/or fuel vapor tube(s) between the fuel tank and the EVAP canister

and bracket assembly. CARRY OUT the evaporative emission system leak test. REFER to Evaporative

Emission System Leak Test in this section. If the system passes the leak test, CARRY OUT the

evaporative emission repair verification drive cycle. REFER to Evaporative Emission Repair Verification

Drive Cycle in this section.

No

INSTALL a new fuel vapor vent valve(s) or assembly. REFER toFuel Vapor Tube Assembly in this section.

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak

Test in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair

verification drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

Yes

The EVAP system has passed all the blockage tests. RECONNECT all components.

For vehicles equipped with a canister vent solenoid, CARRY OUT the evaporative emission system leak

test. REFER toEvaporative Emission System Leak Test in this section. If the system passes the leak test,

CARRY OUT the evaporative emission repair verification drive cycle. REFER to Evaporative Emission

Repair Verification Drive Cycle in this section.

For vehicles not equipped with a canister vent solenoid, PLUG the canister vent hose assembly or the

canister vent cap. CARRY OUT the evaporative emission system leak test. REFER to Evaporative

Emission System Leak Test in this section. If the system passes the leak test, CARRY OUT the

evaporative emission repair verification drive cycle. REFER to Evaporative Emission Repair Verification

Drive Cycle in this section.

No

Page 8

Evaporative Emission Repair Verification

Attempt to pressurize the EVAP system to

Attempt to pressurize the EVAP system to

Connect the EVAP System Leak Tester to

Page

8

of 82004 Freestar/Monterey Workshop Manual

10/9/2010

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS4W/~MUS~LEN/20/

...

PINPOINT TEST E: EXCESSIVE FUEL ODOR

Test Step Result / Action to Take

E1 TEST THE EVAPORATIVE EMISSION

(EVAP) RUNNING LOSS SYSTEM MONITOR

Complete the evaporative emission repair

verification drive cycle. Refer to

Evaporative Emission Repair Verification

Drive Cycle in this section.

Are PCM DTCs retrieved?

E2 TEST FOR RESTRICTIONS IN THE EVAP

SYSTEM FROM THE EVAPORATIVE

EMISSION TEST PORT THROUGH THE

CANISTER VENT SOLENOID

Connect the Evaporative Emission

System Leak Tester to the evaporative

emissions test port.

3.48 kPa (14 inches H2O).

Does the pressure drop immediately?

E3 TEST FOR A RESTRICTED TUBE

BETWEEN THE FUEL TANK AND THE

EVAPORATIVE EMISSION CANISTER

Connect the Evaporative Emission

System Leak Tester to the fuel filler pipe.

3.48 kPa (14 inches H2O).

Does the pressure drop immediately?

E4 TEST FOR EVAP CANISTER TUBE OR

FUEL VAPOR VENT VALVE ASSEMBLY

BLOCKAGE

Disconnect the fuel vapor vent valve

assembly from the EVAP canister tube.

the fuel filler pipe.

Pressurize the EVAP system to 3.48 kPa

(14 inches H2O).

Does the pressure drop immediately?

INSTALL a new fuel vapor hose. CARRY OUT the evaporative emission system leak test. REFER to

Evaporative Emission System Leak Test in this section. If the system passes the leak test, CARRY OUT

the evaporative emission repair verification drive cycle. REFER to

Drive Cycle in this section.

Yes

For DTC P0442, P0455, P1443 or P1450, REFER to the Diagnostic Trouble Code Index in this section. For

all other DTCs, REFER to the Powertrain Control/Emissions Diagnosis (PC/ED) manual for diagnosis of

DTCs.

No

GO to E2.

Yes

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak Test

in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair verification

drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section. GO to E3.

No

GO to Pinpoint Test D.

Yes

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak Test

in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair verification

drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in this section.

No

GO to E4.

Yes

INSTALL a new EVAP canister tube and/or fuel vapor tube(s) between the fuel tank and the EVAP canister

and bracket assembly. CARRY OUT the evaporative emission system leak test. REFER to Evaporative

Emission System Leak Test in this section. If the system passes the leak test, CARRY OUT the evaporative

emission repair verification drive cycle. REFER to Evaporative Emission Repair Verification Drive Cycle in

this section.

No

INSTALL a new fuel vapor vent valve(s) or assembly. REFER toFuel Vapor Tube Assembly in this section.

CARRY OUT the evaporative emission system leak test. REFER to Evaporative Emission System Leak Test

in this section. If the system passes the leak test, CARRY OUT the evaporative emission repair verification

drive cycle. REFER to Powertrain Control/Emissions Diagnosis (PC/ED) manualEvaporative Emission Repair

Verification Drive Cycle in this section.

Loading...

Loading...