Page 1

SECTION 308-07A: Tr ansfer Case — Genera l Information 2000 Ranger Worksho p Manual

Page

1

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

DIAGNOSIS AND TES TING

Transfer Case

Refer to Wiring Diagrams Ce ll 34, Electronic Shift Control for schematic and connector inform ation.

Refer to Wiring Diagrams Ce ll 59, Generic Electronic Module for schematic and connector information.

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

Worldwide Diagnostic System (W DS)

418-F224,

New Generation STAR (NGS) Tester

418-F052, or equivalent scan tool

R-134A Manifold Gauge Set or equivalent

176-R032A

Seal Depth Set/Vacuum Test Cap or equivalent

205-400

Seal Replacer/CV Tester or equivalent

205-399

Procedure revision date: 06/18/1999

Vacuum Pump or equivalent

014-R1054

Vacuum Test Cap or equivalent

205-401

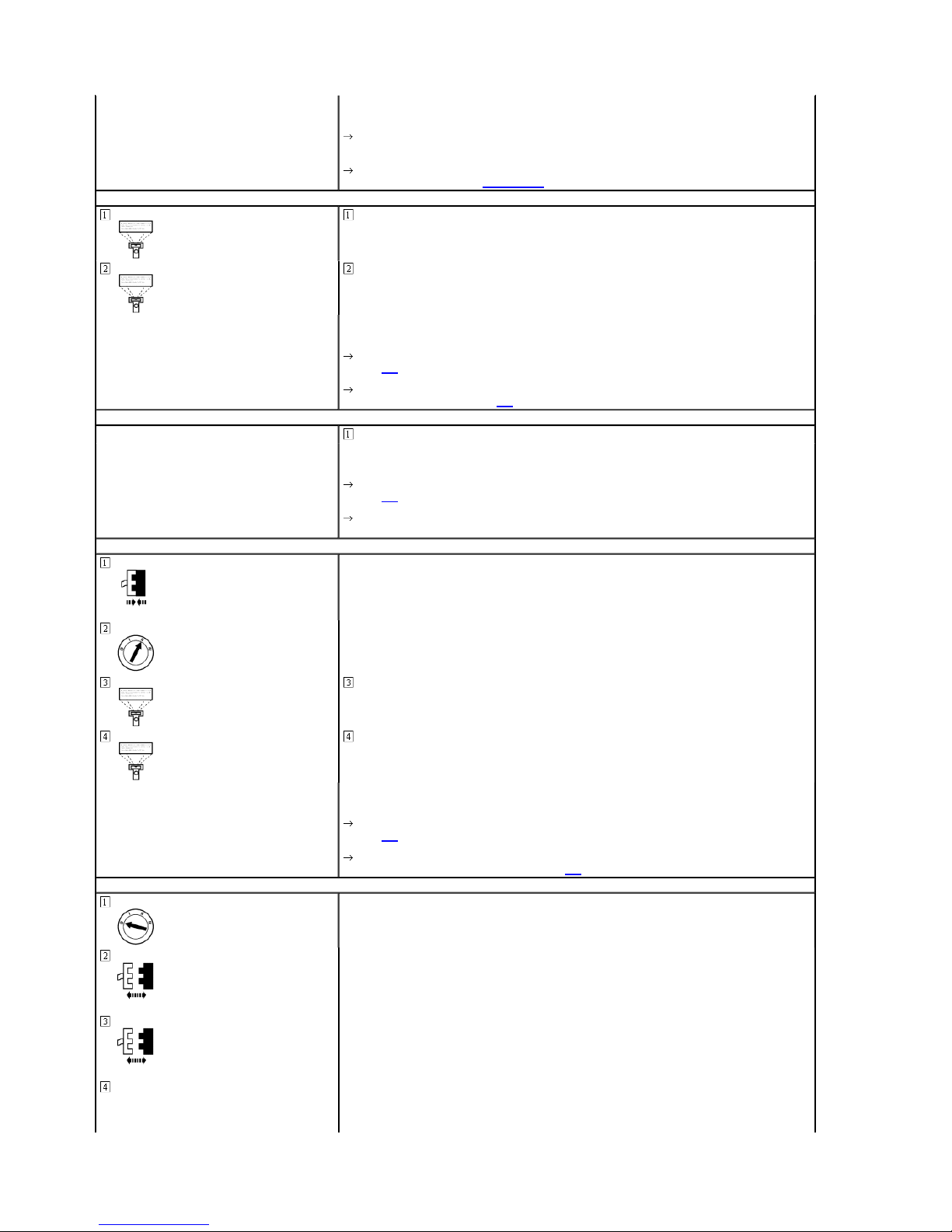

Pulse Vacuum Hublock Vacuum Schematic

Page 2

Wiring harness

Page

2

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Inspection and Verification

1. NOTE: The GEM/CTM must be reconfigured upon replacement. Refer to the scan tool help s creen on the configuration card to program the tire size and axle ratio.

The transfer case is a generic electronic module (GEM) controlled system.

2. Verify the customer concern by operating the 4X4 system.

3. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection Chart

Mechanical Electrical

Switch(es)

4. If the concern remains after the inspection connect the scan too l to the data link connector (DLC) located beneath the instrument panel and select the vehicle to be tested from the

scan tool menu. If the scan tool does not communicate with the vehicle:

5. If the scan tool still does not communicate with the vehicle, re fer to the scan tool manual.

6. Perform the DATA LINK DIAGN OSTIC TEST. If the scan tool responds with:

7. If the DTCs retrieved are related to the concern, go to GEM/CTM Diagnostic Trouble Code (DT C) Index to continue diagnostics.

8. If no DTCs related to the concern are retrieved, proceed to Sym ptom Chart to continue diagno stics.

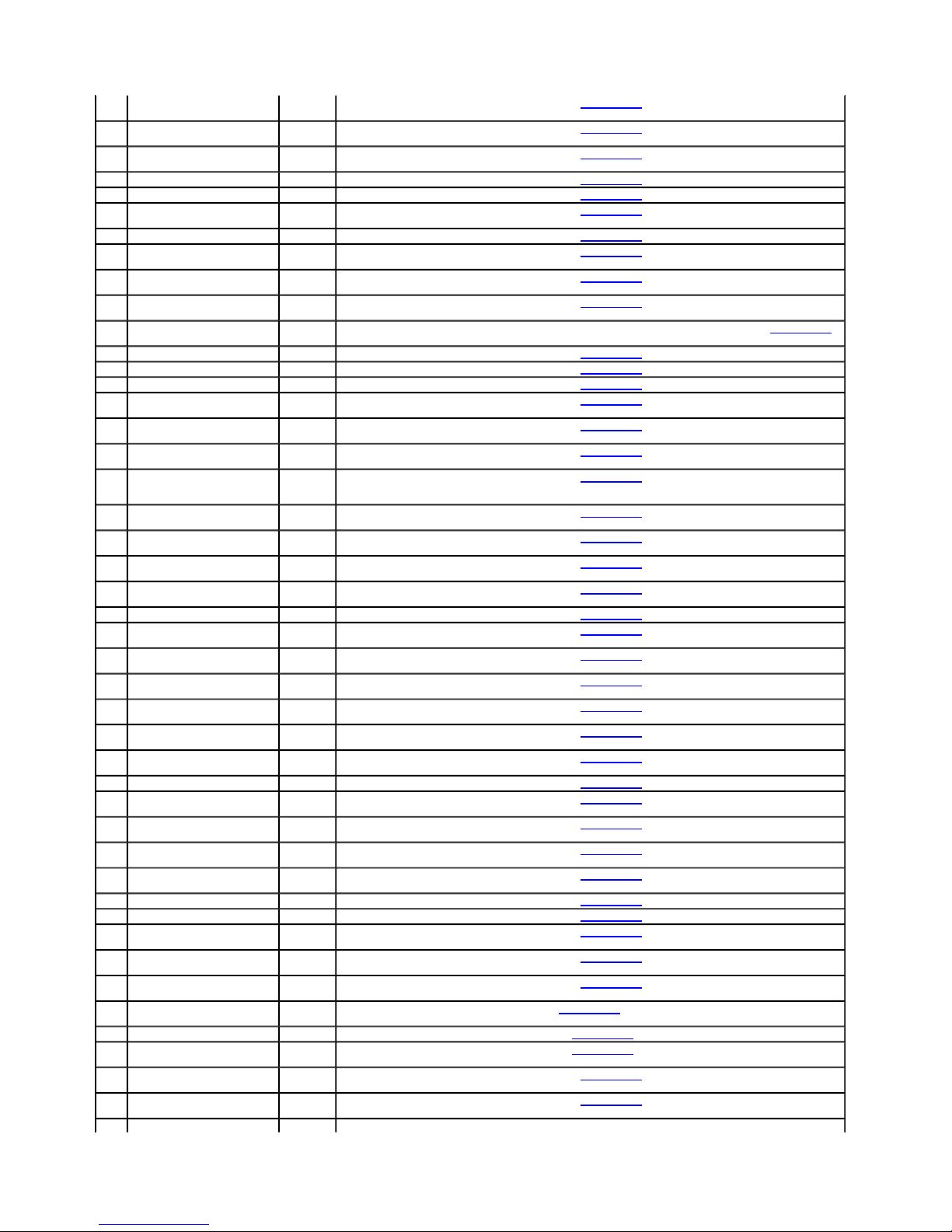

GEM/CTM Diagnostic Trouble Code (DTC) Index

GEM/CTM Diagnostic Troubl e Code (DTC) Index

DTC Description

B1302 Accessory Delay Relay Coil C ircuit

Failure

Fuse(s)

Connections

Lamps

Circuitry

check that the program card is properly installed.

check the connections to the vehicle.

check the ignition switch position.

CKT914, CKT915 or CKT70 =ALL ECUS NO RESP/NOT EQUI P, refer to Section 418-00.

NO RESP/NOT EQUIP for GEM/CTM, go to Pinpoint Test D.

SYSTEM PASSED, retrieve and record the continuous diagno stic trouble codes (DTCs), era se the continuous DTCs and perf orm self-test diagnostics for the GEM/CTM.

DTC

Caused By Action

GEM REFER to Section 501-11.

Page 3

B1304 Accessory Delay Relay Coil C ircuit

Page

3

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Short to Battery

B1313 Battery Saver Relay Coil — Circuit

Failure

B1315 Battery Saver Relay Coil Circ uit

Short to Battery

B1317 Battery Voltage HIGH GEM/CTM REFER to Section 414-00.

B1318 Battery Voltage Low GEM/CTM REFER to Section 414-00.

B1322 Driver Door Ajar Circuit Short to

Ground

B1323 Door Ajar Lamp Circuit Failure GEM/CTM REFER to Section 413-01.

B1325 Door Ajar Lamp Circuit Short to

Battery

B1330 Passenger Door Ajar Short to

Ground

B1340 Chime Input Request Short to

Ground

B1342 GEM/CTM is Defective GEM/CTM CLEAR the DTCs. RETRIEVE the DTCs. If DTC B1342 is retrie ved, REPLACE the GEM/CTM ; REFER to Section 419-10.

B1352 Ignition Key-In Circuit Fai lure GEM/CTM REFER to Section 413-09.

B1355 Ignition RUN Circuit Failure GEM/CTM REFER to Section 211-05.

B1359 Ignition RUN/ACC Circuit Failu re GEM/CTM REFER to Section 211-05.

B1371 Illuminated Entry Relay Circui t

Failure

B1373 Illuminated Entry Relay Short to

Battery

B1398 Power Window driver One-Touch

Window Relay Circuit Failure

B1400 Power Window driver One-Touch

Window Relay Coil Circuit Short to

Battery

B1404 Driver Power Window Down Sw itch

Input Open CKT

B1405 Driver Power Window Down Sw itch

Input Short Circuit to Battery

B1410 Driver Power Window Motor C ircuit

Failure

B1426 Seat Belt Lamp Circuit Short to

Battery

B1428 Seat Belt Lamp Circuit Failure GEM/CTM REFER to Section 413-01.

B1431 Wiper Brake/Run Relay — Ci rcuit

Failure

B1432 Wiper Brake/Run Relay — Sho rt to

Battery

B1434 Wiper Hi/Lo Speed Relay — Circuit

Failure

B1436 Wiper Hi/Lo Speed Relay Circ uit

Short to Battery

B1438 Wiper Mode Select Switch Circu it

Failure

B1441 Wiper Mode Select Switch Short to

Ground

B1446 Wiper Park Sense Circuit Failu re GEM/CTM REFER to Section 501-16.

B1450 Wiper/Wash Interval Delay Swit ch

Input Circuit Failure

B1453 Wiper/Wash Interval Delay Swit ch

Input Short to Ground

B1458 Wiper/Washer Pump Motor Re lay

Circuit Failure

B1460 Wiper/Washer Pump Motor Re lay

Coil Short to Battery

B1462 Seat Belt Switch Circuit Failure GEM/CTM REFER to Section 413-09.

B1466 Wiper Hi/Low Speed Not Switching GEM/CTM REFER to Section 501-16.

B1467 Wiper Hi/Low Speed Circuit Mot or

Short to Battery

B1473 Wiper Low Speed Circuit Motor

Failure

B1475 Accessory Delayed Relay Contacts

Short to Battery

B1476 Wiper High Speed Circuit Motor

Failure

B1483 Brake Pedal Input Circuit Failure GEM GO to Pinpoint Test B.

B1485 Brake Pedal Input Short Circuit to

Battery

B1577 Park Lamp Input Circuit Short to

Battery

B1610 Illuminated Entry Input (From RAP

Module) Circuit Short to Ground

GEM REFER to Section 501-11.

GEM/CTM REFER to Section 417-02.

GEM/CTM REFER to Section 417-02.

GEM/CTM REFER to Section 417-02.

GEM/CTM REFER to Section 413-01.

GEM/CTM REFER to Section 417-02.

GEM/CTM REFER to Section 413-09.

TEST the system for normal opera tion.

GEM/CTM REFER to Section 417-02.

GEM/CTM REFER to Section 417-02.

GEM REFER to Section 501-11.

GEM REFER to Section 501-11.

GEM REFER to Section 501-11.

GEM REFER to Section 501-11.

GEM REFER to Section 501-11.

GEM/CTM REFER to Section 413-01.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM/CTM REFER to Section 501-16.

GEM REFER to Section 501-11.

GEM/CTM Section 501-16.

GEM GO to Pinpoint Test B.

GEM/CTM REFER to Section 413-09.

GEM/CTM REFER to Section 417-02.

Page 4

B1840 Wiper Power Circuit Failure GEM/CTM REFER to Section 501-16.

Page

4

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

B2141 NVM Configuration Failure GEM/CTM Vehicle speed calibration is not programmed into the GEM/CTM. REFER to the scan tool help screen on the config uration

C1751 VSS Output Short to Battery GEM/CTM REFER to Section 310-03or REF ER to Section 413-01.

C1752 VSS Output Short to Ground GEM/CTM REFER to Section 310-03or REF ER to Section 413-01.

P0500 Vehicle Speed Signal Circuit Fai lure GEM GO to Pinpoint Test B.

P1804 4WD High Indicator Circuit Fai lure GEM GO to Pinpoint Test C.

P1806 4WD High Indicator Short to Battery GEM GO to Pinpoint Test C .

P1808 4WD Low Indicator Circuit Fail ure GEM GO to Pinpoint Test C.

P1810 4WD Low Indicator Short to Pow er GEM GO to Pinpoint Test C.

P1812 4WD Mode Select Switch Circui t

Failure

P1815 4WD Mode Select Switch Circui t

Short to Ground

P1820 Transfer Case CW Shift Relay

Circuit — Failure

P1822 Transfer Case CW Shift Relay Co il

Short to Power

P1824 4WD Electric Clutch Relay Cir cuit

Failure

P1826 4WD Low Clutch Relay Short to

Power

P1828 Transfer Case CCW Shift Rela y Coil

Circuit Failure

P1830 Transfer Case CCW Shift Rela y Coil

Short to Battery

P1838 Transfer Case Shift Motor Circui t

Failure

P1846 Transfer Case CONTACT PL ATE

"A" Circuit Failure

P1850 Transfer Case CONTACT PL ATE

"B" Circuit Failure

P1854 Transfer Case CONTACT PL ATE

"C" Circuit Failure

P1858 Transfer Case CONTACT PL ATE

"D" Circuit Failure

P1863 Transfer Case CONTACT PL ATE

Power Circuit Open

P1866 Transfer Case System Concern GEM GO to Pinpoint Test A.

P1867 Transfer Case Contact Plate

General Circuit Failure

P1832 Transfer Case Differential Lock-Up

Solenoid Failure

P1833 Transfer Case Differential Lock-Up

Solenoid Open Circuit

P1834 Transfer Case Differential Lock-Up

Solenoid Short to Battery

P1835 Transfer Case Differential Lock-Up

Solenoid Short to Ground

P1878 Transfer Case Disengage Solenoid

Circuit Failure

P1879 Transfer Case Disengage Solenoid

Open Circuit

P1880 Transfer Case Disengage Solenoid

Short to Battery

P1885 Transfer Case Disengage Solenoid

Short to Ground

P1891 Transfer Case Contact Plate

Ground Return Circuit Open

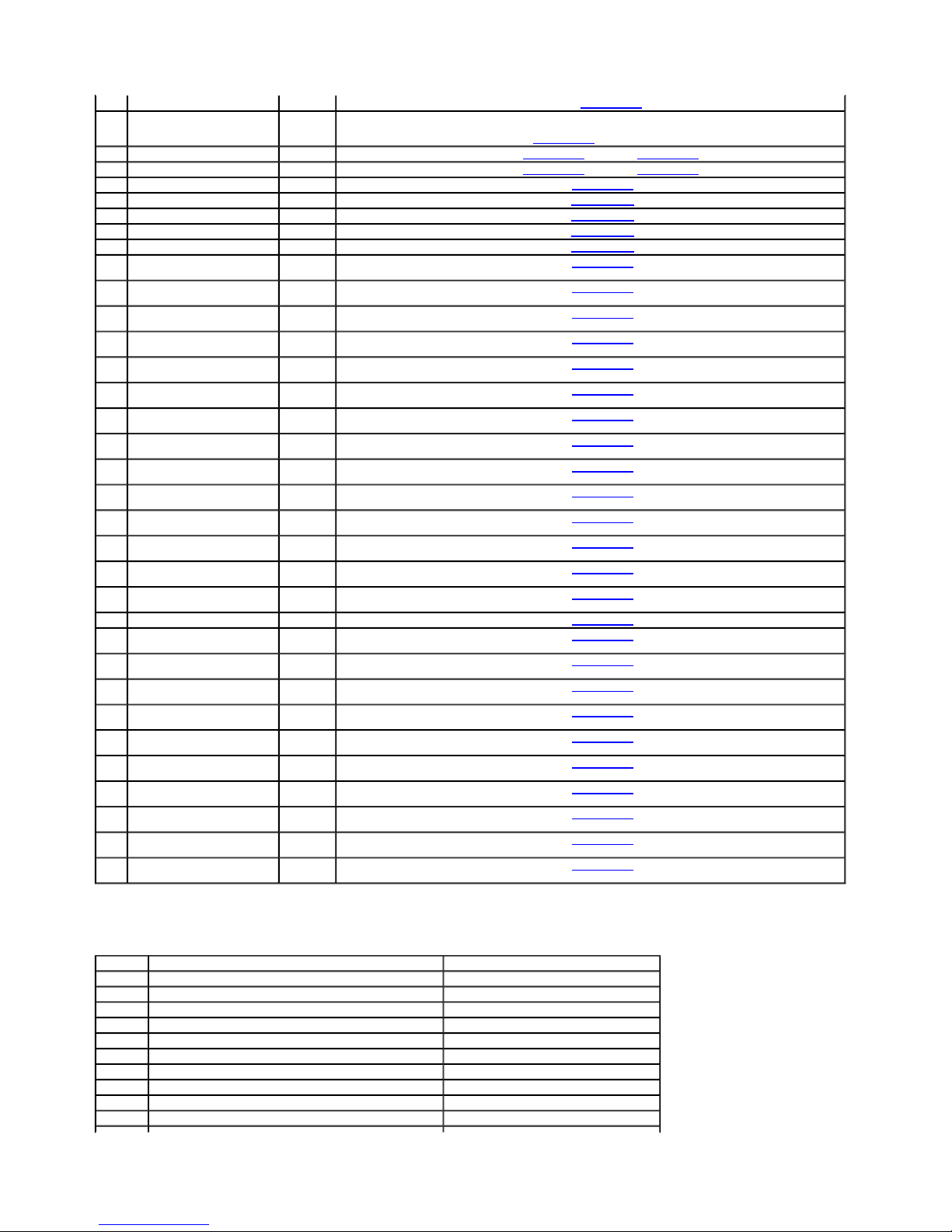

GEM/CTM Parameter Identifi cation (PID) Index

GEM/CTM Parameter Identification (PID) Index

PID Description Expected Values

VSS_GEM Vehicle Speed Input 0 - 255 KPH

PARK_SW External Access Ajar Switch Status OFF, ON

D_DR_SW Driver Door Ajar Switch Status CLOSED, AJAR

P_DR_SW Passenger Door Ajar Switch Status CLOSED, AJAR

IGN_KEY Key In Ignition Status IN, OUT

IGN_GEM Ignition Switch Status START, RUN, OFF, ACC

BATSAV Battery Saver Relay Circuit ON---, OFF---, ON-B-, OFFO- G

VBATGEM Battery Voltage 0.0 VDC - 14.3 VDC

INTLMP Illuminated Entry Relay Circui t ON-- -, OFF---, ON-B-, OFFO-G

CLTCHSW Transmission Clutch Interlock Switch ENGAGED, NOT ENGAGED

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test A.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test E.

GEM GO to Pinpoint Test A.

card to program the tire size and axle ratio. TEST the system for normal operation. If DTC B 2141 is still present, REPLACE

the GEM/CTM; REFER to Section 419-10. TEST the system for normal operation.

Page 5

NTRL_SW Neutral Safety Switch Input NTRL, not NTRL

Page

5

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

MTR_CCW Transmis sion Transfer CCW Motor Output (GEM Only) ON---, OFF---, OFFO-G, ON-B-

MTR_CW CW Shift Relay Coil Status (GEM Only) OFF---, ON---, OFFO-G, ON-B-

4WDCLCH 4WD Electronic Clutch Output Status (GEM Only) ON---, OFF---, OFFO-G, ON-B-

4WDLOW 4WD Low Indicator Status (GEM Only) ON---, OFF---, ON-B-, OFFO- G

4WDHIGH 4WD High Indicator Status (GE M Only) ON---, OFF---, ON-B-, OFFO- G

4WD_SW 4WD Switch Status (GEM Only) 2WD, 4WD HIGH, 4WD LOW

PLATE_A Transfer Case Contact Plate Switch A (GEM Only) OPEN, CLOSED

PLATE_B Transfer Case Contact Plate Switch B (GEM Only) OPEN, CLOSED

PLATE_C Transfer Case Contact Plate Switch C (GEM Only) OPEN, CLOSED

PLATE_D Transfer Case Contact Plate Switch D (GEM Only) OPEN, CLOSED

BOO_GEM Brake Pedal Position (BPP) Switc h Input ON, OFF

PLATEPW Contact Plate Ground Output (GEM Only) ON---, OFF---

D_SBELT Driver Seat Belt Status OUT, IN

IPCHIME External Chime Request ON, OFF

SBLTMP Seat Belt Indicator Status OFF, ON, OFFO-G, ON-B-

DRAJR_L Door Ajar Warning Lamp Circuit OFF, ON

D_PWRLY One Touch Down Relay Coil Circuit Status (GEM Only) ON---, OFF---, ON-B-, OFFO-G

D_

Driver Power Window Regulator Electric Drive Current (GEM Only) 0.25 amp increments

PWAMP

D_PWPK Driver Power Win dow Regulator Electric Drive Pe ak Current (GEM Only) 0.25 amp increments

ACCDLY Accessory Delay Relay Coil Circuit (GEM Only) ON---, OFF---, ON-B -, OFFO-G

WPPK_PK Wiper Park-to-Par k Time 0 - 6.5 Seconds

WPMODE Wiper Control Mod e Status WASH, OPEN, INVLD, OFF, INTVL 1-7, LOW, HIGH

WPPRKSW Wiper Motor Status PARKED, notPRK

WPRUN Wiper M ode Run Relay ON---, OFF---, ON-B-, OFFO- G

WPHISP Wiper HI/LO Relay Status ON---, OFF---, ON-B-, OFFO- G

WASH_SW Washer Pump Relay Switch Status ON, OFF, ON-B -, OFFO-G

GEM/CTM Active Command Index

GEM/CTM Active Command Index

Active Command Display Action

PID LATCH PID LATCH ON, OFF

FRONT WIPER WIPER RLY ON, OFF

FRONT WIPER SPEED RLY ON, OFF

FRONT WIPER WASH RLY ON, OFF

WARNING LAMPS AND CHIME SBLT LAMP ON, OFF

WARNING LAMPS AND CHIME CHIME ON, OFF

WARNING LAMPS AND CHIME AJAR LAMP ON, OFF

BATTERY SAVER BATT SAVR ON, OFF

INTERIOR COURTESY LAMPS INT LAMPS ON, OFF

ONE TOUCH DOWN AND ACCY DELAY (GEM only) ACCY RLY ON, OFF

ONE TOUCH DOWN AND ACCY DELAY (GEM only) ONE TOUCH ON, OFF

4-WHEEL ELECTRONIC SHI FT (GEM only) CW/CCW ON, OFF

4-WHEEL ELECTRONIC SHI FT (GEM only) HIGH LAMP On, OFF

4-WHEEL ELECTRONIC SHI FT (GEM only) LOW LAMP ON, OFF

4-WHEEL ELECTRONIC SHI FT (GEM only) PLAT E PWR ON, OFF

4-WHEEL ELECTRONIC SHI FT (GEM only) SHF T CLCH ON, OFF

SHIFT CLUTCH CONTROL CLUTCH SOL ANALOG %

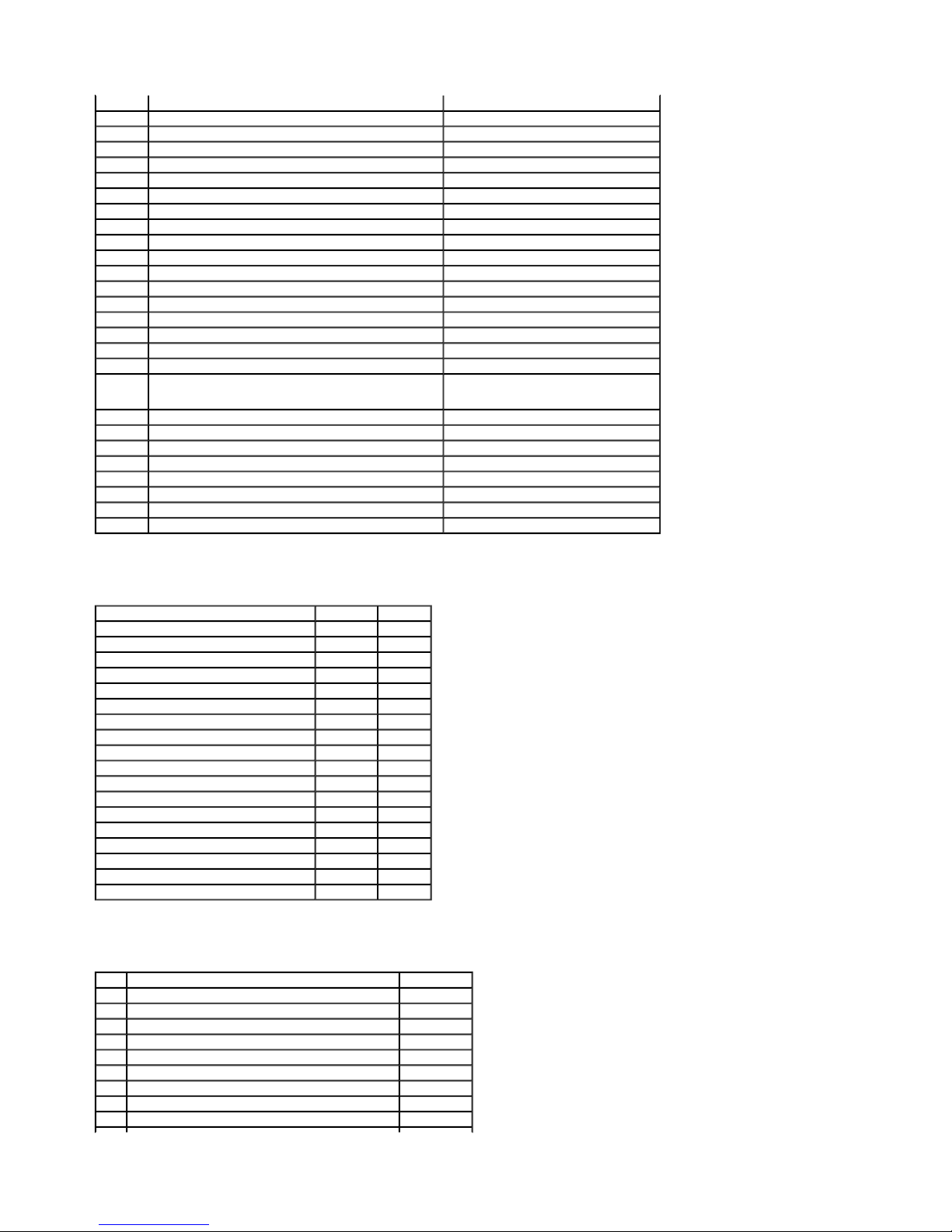

GEM/CTM Wiggle Test Diagno stic Trouble Code (DTC) Index

GEM/CTM Wiggle Test Diagn ostic Trouble Code (DTC) Index

DTC Description DTC Caused By

B1317 Battery Voltage HIGH G EM/CTM

B1318 Battery Voltage Low GEM/CTM

B1322 Driver Door Ajar Circuit Short to Ground GEM/CTM

B1330 Passenger Door Ajar Short to Groun d GEM/CTM

B1352 Ignition Key-In Circuit Failure GEM/CTM

B1410 Driver Power Window Motor Circuit Failure GEM

B1438 Wiper Mode Select Switch Circuit Failure GEM/CTM

B1441 Wiper Mode Select Switch Short to Gr ound GEM/CTM

B1446 Wiper Park Sense Circuit Failure GEM/CTM

DOOR LOCK CONTROL DD UNLOCK ON, OFF

Page 6

DTCs and it may exhibit erratic operation after installation.

B1450 Wiper/Wash Interval Delay Switch Input Circuit Failure GEM/CTM

Page

6

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

B1453 Wiper/Wash Interval Delay Switch Input Short to Ground GEM/CTM

B1462 Seat Belt Switch Circuit Failure GEM/CTM

B1577 Park Lamp Input Circuit Short to Batt ery GEM/CTM

B1610 Illuminated Entry Input (From RAP Module) Circuit Short to Ground GEM/ CTM

Symptom Chart

Symptom Chart

Condition Possible Sources Action

The Vehicle Does Not Shift Between 2WD and 4WD Modes Properly

The Vehicle Does Not Shift Between 4WD HIGH and 4WD LOW Modes Properly

The 4x4 HIGH and/or 4x4 LOW Indicator(s) Do/Does Not Operate Properly

No Communication With the Mo dule — GEM/CTM

The Pulse Vacuum Hublocks Do Not Operate Properly (Transfer Case Motor Movement and Front

Driveshaft Operate Properly)

Pinpoint Tests

4WD mode switch.

Electric shift relay.

Electronic shift control

module.

GEM.

Circuitry.

Transfer case shift motor.

Transfer case electric

clutch.

Transfer case mechanism.

DTC B1313.

DTC B1315.

DTC P1812.

DTC P1815.

DTC P1820.

DTC P1822.

DTC P1824.

DTC P1826.

DTC P1828.

DTC P1830.

DTC P1838.

DTC P1846.

DTC P1850.

DTC P1854.

DTC P1858.

DTC P1863.

DTC P1866.

DTC P1867.

DTC P1891.

4WD mode switch.

Neutral safety switch.

Circuitry.

Brake switch.

Electric shift relay.

Electronic shift control

module.

Transfer case mechanism.

Transfer case electric

clutch.

Digital TR sensor.

Vehicle speed

sensor/circuits.

GEM.

DTC P1483.

DTC P1485.

DTC P1812.

DTC P1815.

DTC P0500.

Bulb.

Digital TR sensor.

Circuitry.

DTC P1804.

DTC P1806.

DTC P1808.

DTC P1810.

Fuse.

Circuitry.

GEM/CTM.

Circuitry.

GEM.

PVH solenoid.

Vacuum lines.

Hublock.

Wheel and knuckle.

Wheel hub.

ABS sensor (if equipped).

DTC P1832.

DTC P1833.

DTC P1834.

DTC P1835.

DTC P1878.

DTC P1879.

DTC P1880.

DTC P1885.

GO to Pinpoint

Test A.

GO to Pinpoint

Test B.

GO to Pinpoint

Test C.

GO to Pinpoint

Test D.

GO to Pinpoint

Test E.

CAUTION: Before removing and installing the GEM or its connectors, disconnect the batte ry. Failure to follow this caution will result in GEM storin g many erroneous

Page 7

CAUTION: Be careful when probing the fuse junction panel, power distribution box or an y connectors. Damage will result to the connector recepta cle if the probe or

Page

7

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

terminal being used is too large.

CAUTION: Electronic module s are sensitive to electrostatic discharges. If exposed to thes e charges, damage may result.

NOTE: If continuous DTCs are recorded and the symptom is not present when performing th e pinpoint tests, an intermittent concern may be the cause. Always check for loose connections

and corroded terminals.

NOTE: Complete the entire pinpoint test related to the symptom before replacing the GEM.

PINPOINT TEST A: THE VEHI CLE DOES NOT SHIFT BETWEEN 2WD AND 4WD MODES PROPERLY

A1 CHECK THE IGNITION S TATES — MONITOR THE GEM PID IGN_GEM

CONDITIONS DETAILS/RESULTS/ACTIO NS

Scan Tool

Monitor the GEM PID IGN_GEM while turning the ignition switch through the RUN, OFF and ACC positions.

A2 RETRIEVE THE DIAGNOST IC TROUBLE CODES (DTCS)

NOTE: DTCs P1838 and P1866 require clearing the GEM keep alive memory (KAM) after repairs have been completed. Scan tool will not clear these codes. The battery must be

disconnected and reconnected to clear these DTCs.

Clear Continuous DTCs

GEM On-Demand Self-Test

Do the PID values agree with the ignition switch positions?

Yes

GO to A2.

No

REFER to Section 417-02.

Retrieve and document continuous DTCs.

Are any DTCs recorded?

Yes

If DTC B1342, REPLACE the GEM. REFER to Section 419- 10. CLEAR the DTCs. TEST the system for normal

operation.

If DTC B1313, GO to A22 .

If DTC B1315, GO to A22 .

If DTC P1812, GO to A5 .

If DTC P1815, GO to A5 .

If DTC P1820, GO to A41 .

If DTC P1822, GO to A41 .

If DTC P1824, GO to A18 .

If DTC P1826, GO to A18 .

If DTC P1828, GO to A41 .

If DTC P1830, GO to A41 .

If DTC P1838, GO to A37 .

If DTC P1846, GO to A58 .

If DTC P1850, GO to A58 .

Page 8

Page

8

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

If DTC P1854, GO to A58 .

If DTC P1858, GO to A58 .

If DTC P1863, GO to A58 .

If DTC P1866, GO to A58 .

If DTC P1867, GO to A58 .

If DTC P1891, GO to A58 .

No

A3 CHECK THE 4X4 HIGH L AMP INDICATOR — TRIGGER THE GEM ACTIVE COMMAND HIGH LAMP ON

GO to A3.

Trigger the GEM active command HIGH LAMP ON then OFF.

A4 CHECK THE 4X4 LOW LAMP INDICATOR — TRIGGER THE GEM ACTIVE COMMAND LO W LAMP ON

A5 CHECK THE 4X4 MODE SW ITCH — MONITOR THE GEM PID 4WD_SW IN 2WD POSIT ION

Does the 4x4 HIGH indicator illuminate then go off?

Yes

GO to A4.

No

GO to Pinpoint Test C.

Trigger the GEM active command LOW LAMP ON then OFF.

Does the 4x4 LOW indicator illuminate then go off?

Yes

GO to A5.

No

GO to Pinpoint Test C.

Monitor the GEM PID 4WD_SW .

Place the mode switch in the 2WD position.

Does the PID indicate 2WD?

Yes

GO to A6.

No

GO to A8.

A6 CHECK THE 4X4 MODE SW ITCH — MONITOR THE GEM PID 4WD_SW IN THE 4X4 HI GH POSITION

Place the mode switch in the 4X4 HIGH position.

If the PID indicates OFFO-G, GO to A14 .

Monitor the GEM PID 4WD_SW .

Page 9

Page

9

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Does the PID indicate 4WD HIG H?

Yes

GO to A7.

No

A7 CHECK THE 4X4 MODE SW ITCH — MONITOR THE GEM PID 4WD_SW

A8 CHECK THE 4X4 MODE SW ITCH IN THE 2WD POSITION

GO to A8.

Monitor the GEM PID 4WD_SW .

Place the mode switch in the 4X4 LOW position.

Does the PID indicate 4WD L OW?

Yes

GO to A16.

No

GO to A8.

If the PID indicates OFFO-G, GO to A14 .

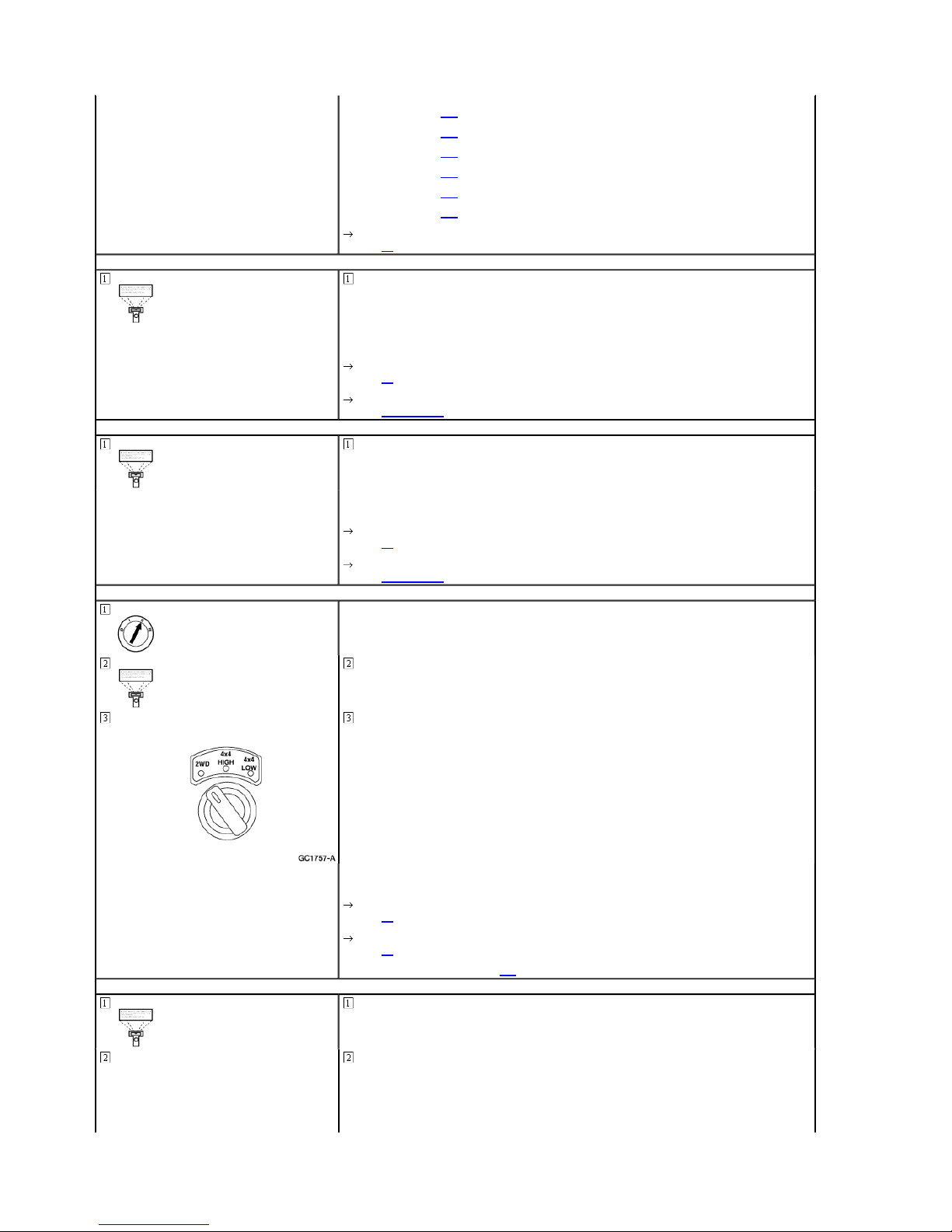

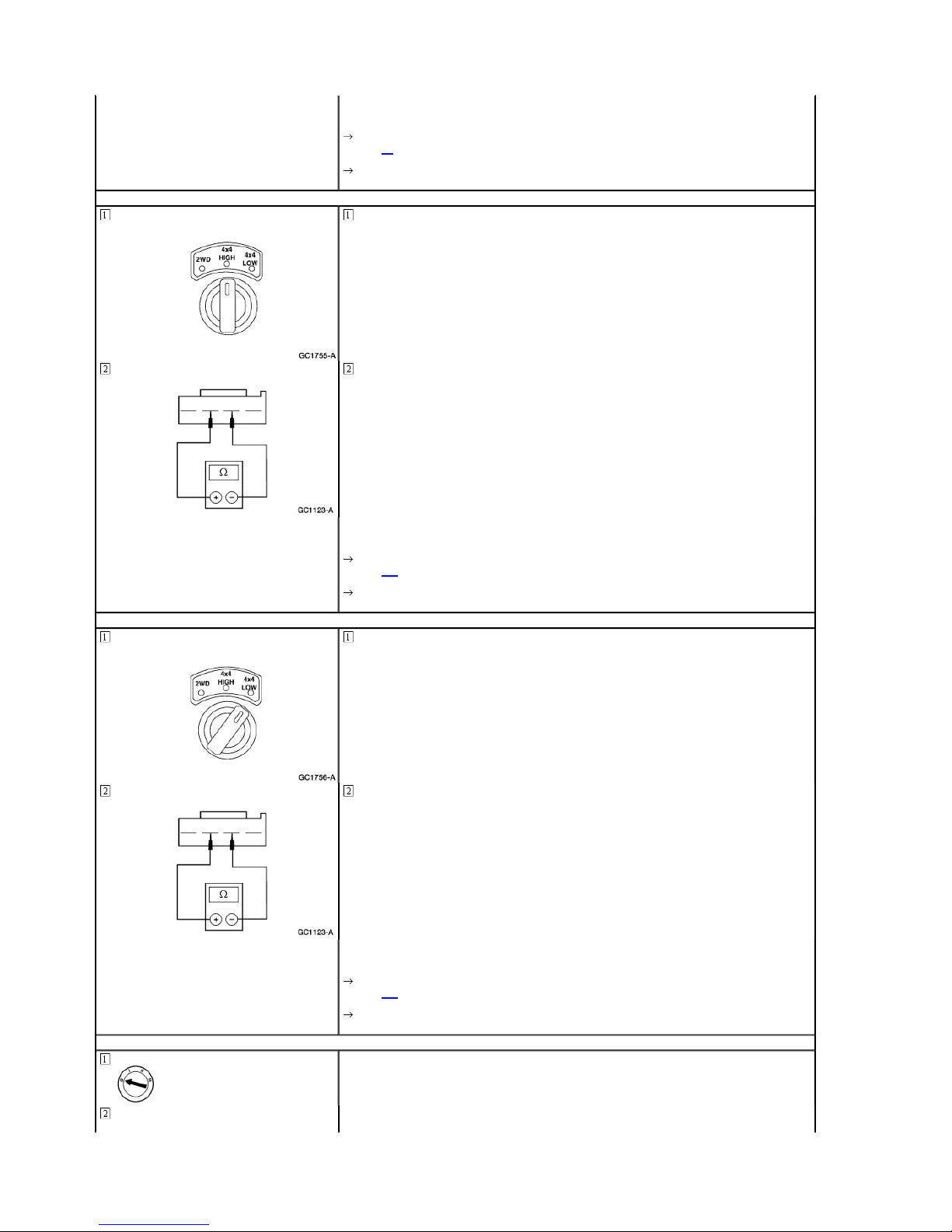

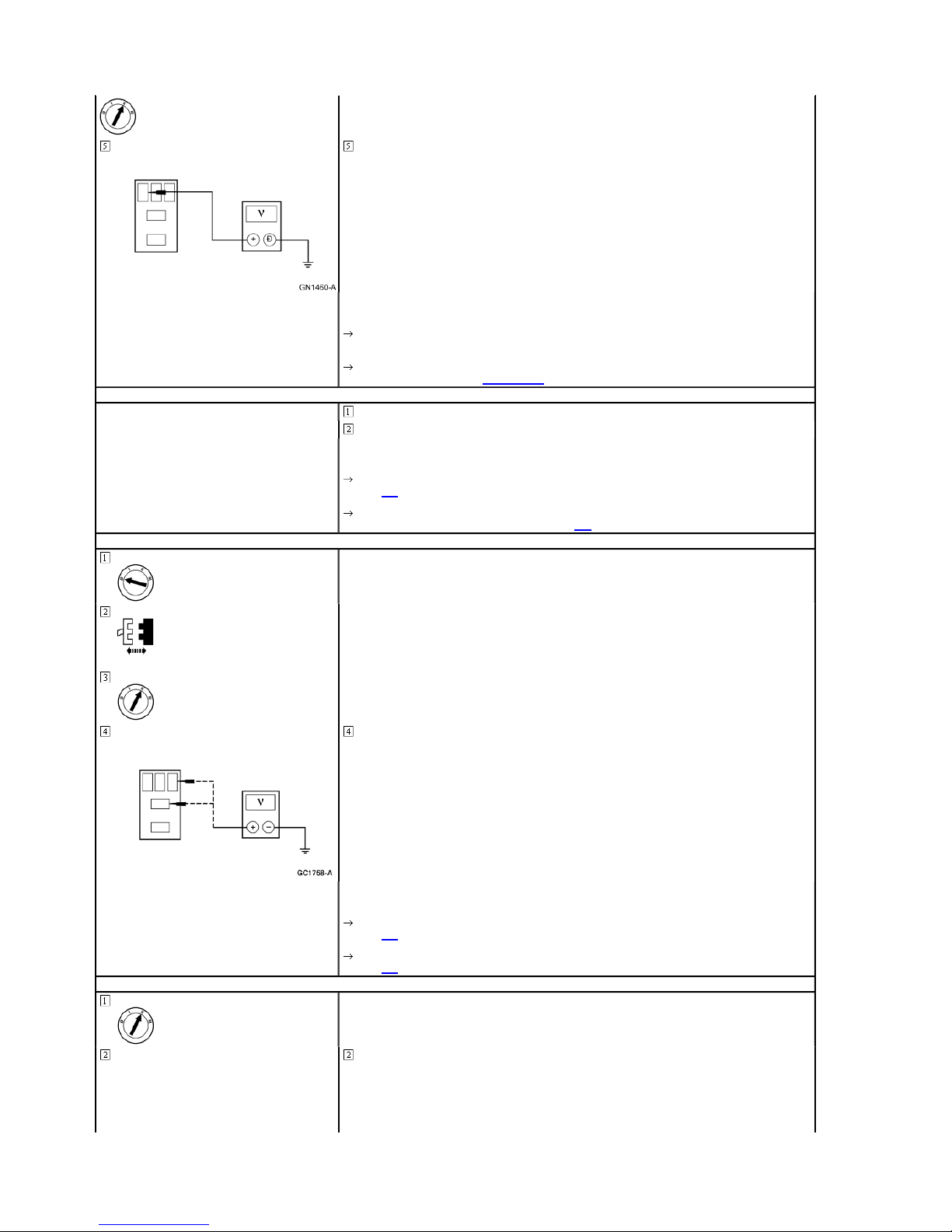

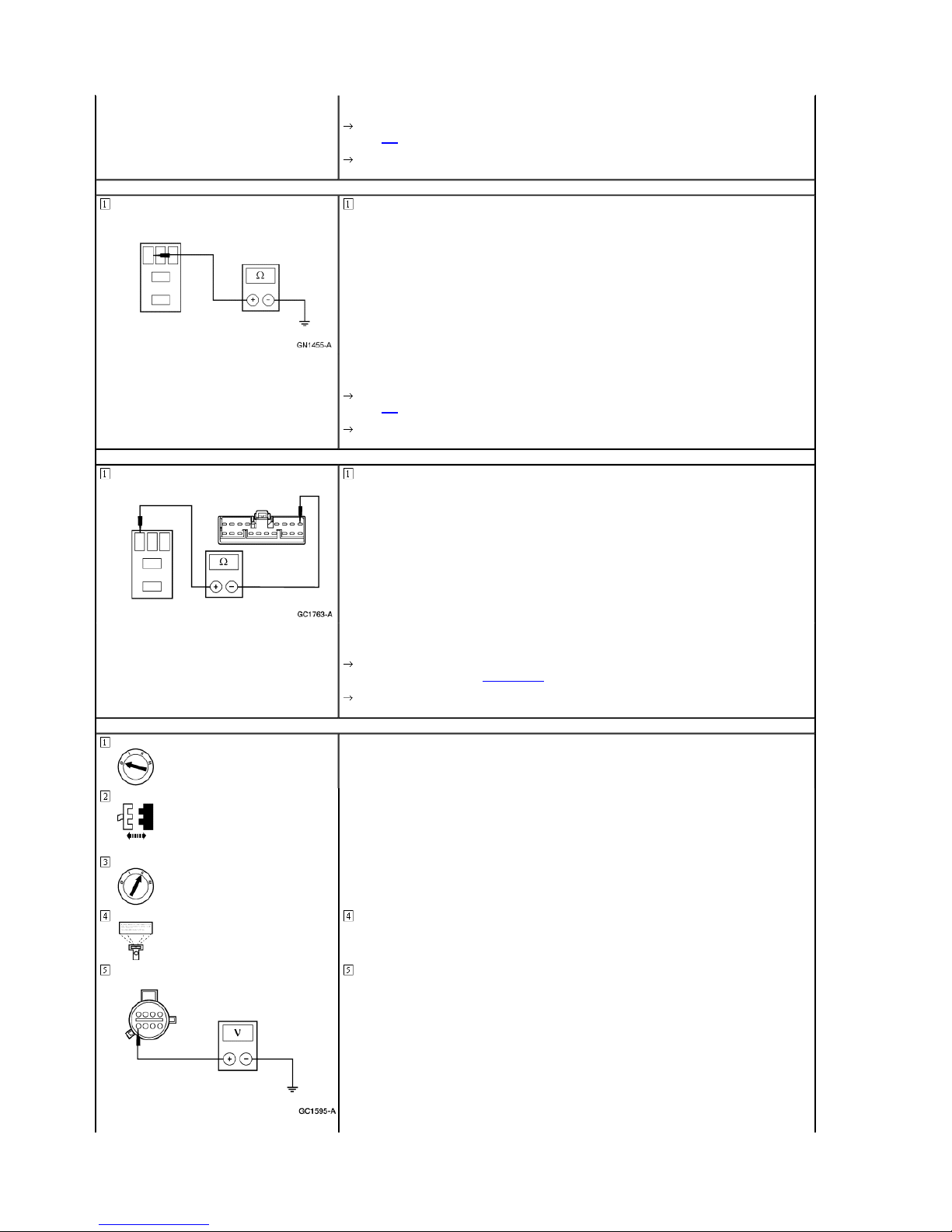

4X4 Mode Switch C225

Place the mode switch in the 2WD position.

Measure the resistance between the mode switch terminals 2 and 3.

Page 10

Page

10

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Yes

GO to A9.

No

A9 CHECK THE 4X4 MODE SW ITCH IN THE 4X4 HIGH POSI TION

REPLACE the mode switch. CLEAR the DTCs. TEST the sy stem for normal operation.

Place the mode switch in the 4X4 HIGH position.

Is the resistance between 3700 and 4100 ohms?

A10 CHECK THE 4X4 MODE SWITCH IN THE 4X4 LOW POSI TION

Measure the resistance between the mode switch, terminals 2 and 3.

Yes

GO to A10.

No

REPLACE the mode switch. CLEAR the DTCs. TEST the sy stem for normal operation.

Place the mode switch in the 4X4 LOW position.

Measure the resistance between the mode switch, terminals 2 and 3.

Is the resistance between 1050 and 1150 ohms?

Is the resistance between 340 and 380 ohms?

Yes

GO to A11.

No

A11 CHECK CIRCUIT 465 (W/LB) FOR OPEN

REPLACE the mode switch. CLEAR the DTCs. TEST the sy stem for normal operation.

Page 11

Page

11

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

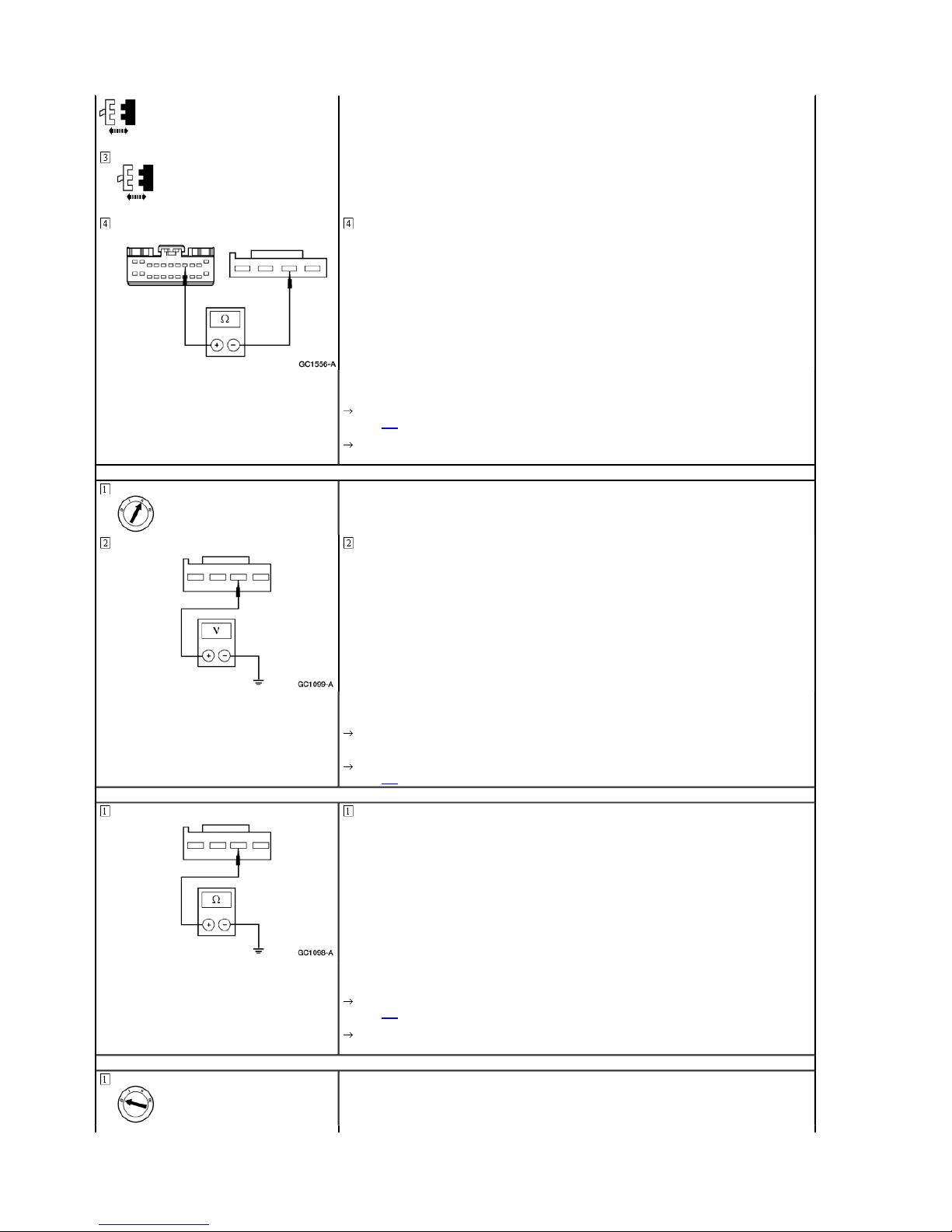

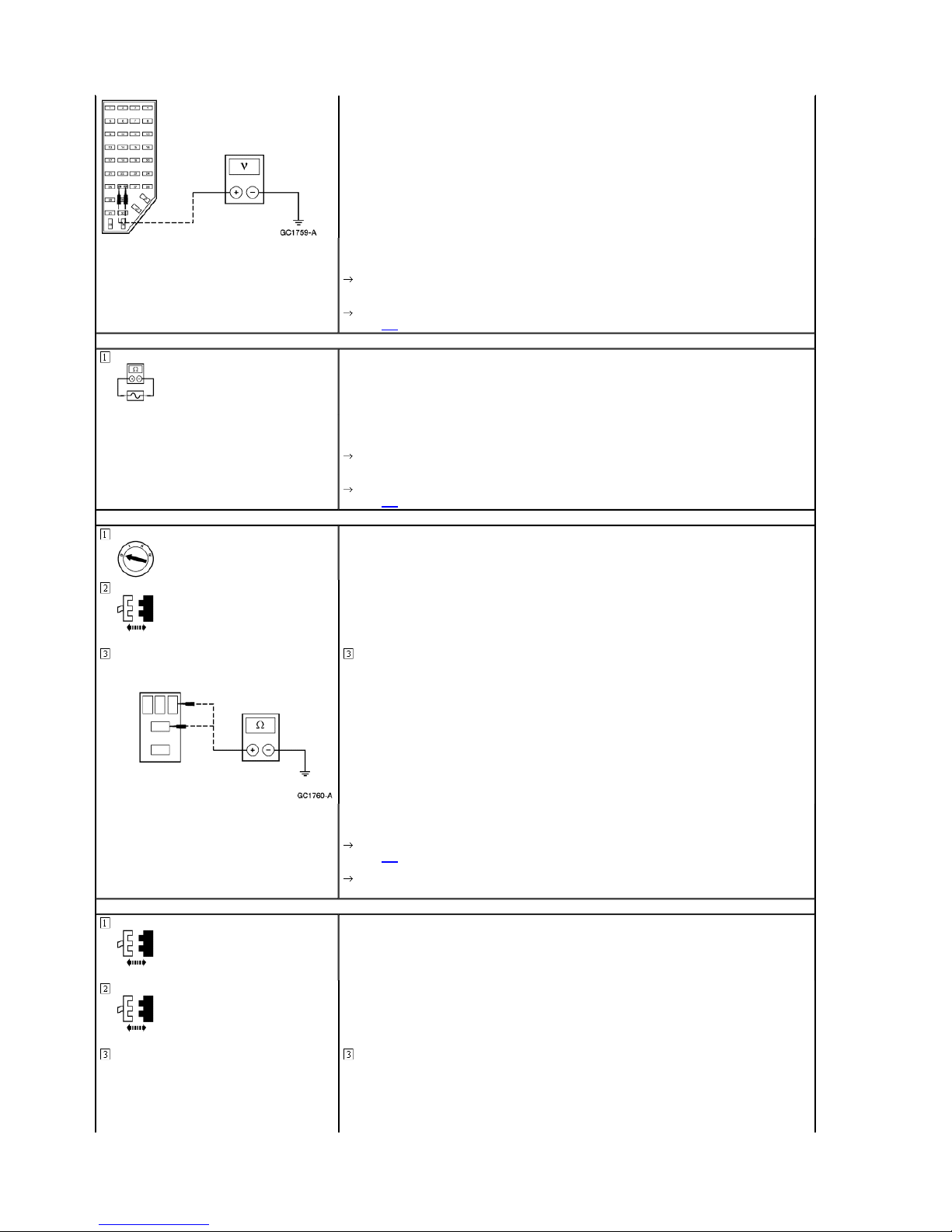

4X4 Mode Switch C225

GEM C223

A12 CHECK CIRCUIT 465 (W/LB) FOR SHORT TO POWER

Measure the resistance between mode switch C225-3, circuit 465 (W/LB), and GEM C223-8, circuit 465 (W/LB).

Is the resistance less than 5 ohms?

Yes

GO to A12.

No

REPAIR circuit 465 (W/LB). CLEAR the DTCs. TEST the system for normal operation.

Measure the voltage between mode switch C225-3, circuit 465 (W/LB), and ground.

A13 CHECK CIRCUIT 465 (W/LB) FOR SHORT TO GROUND

A14 CHECK CIRCUIT 359 (GY/ R) FOR OPEN

Is any voltage indicated?

Yes

REPAIR circuit 465 (W/LB). CLEAR the DTCs. TEST the system for normal operation.

No

GO to A13.

Measure the resistance between mode switch C225-3, circuit 465 (W/LB), and ground.

Is the resistance greater than 10,000 ohms?

Yes

GO to A14.

No

REPAIR circuit 465 (W/LB). CLEAR the DTCs. TEST the system for normal operation.

Page 12

Page

12

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

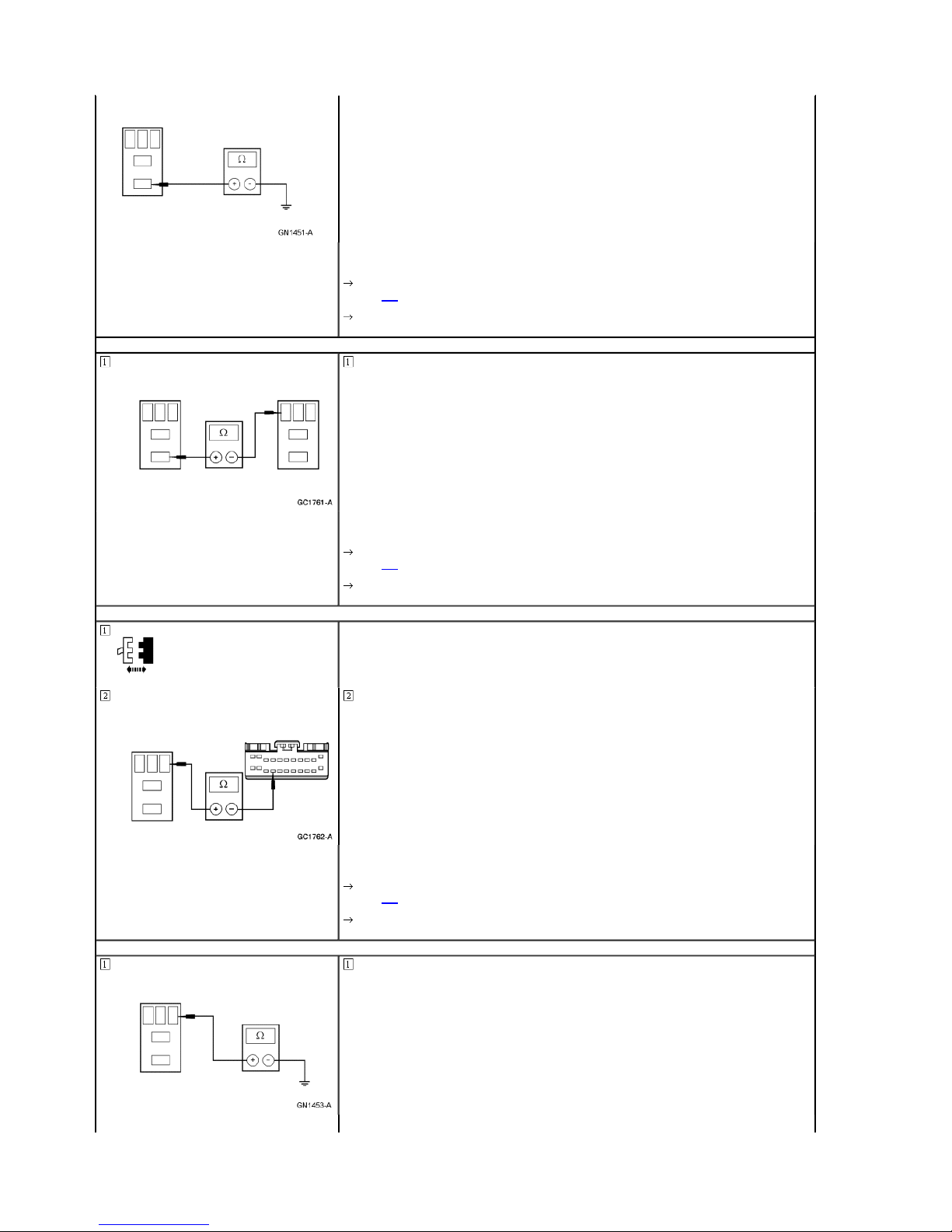

4X4 Mode Switch C225

GEM C221

A15 CHECK CIRCUIT 359 (GY/ R) FOR SHORT TO POWER

Measure the resistance between mode switch C225-2, circuit 359 (GY/R), and GEM C221-21, circuit 359 (GY/R).

Is the resistance less than 5 ohms?

Yes

GO to A15.

No

REPAIR circuit 359 (GY/R). CLEAR the DTCs. TEST the system for normal operation.

Measure the voltage between mode switch C225-2, circuit 359 (GY/R), and ground.

A16 CHECK THE FRONT DR IVESHAFT ENGAGEMENT

A17 CHECK THE FRONT DR IVESHAFT DISENGAGEMENT

Is any voltage indicated?

Yes

REPAIR circuit 359 (GY/R). CLEAR the DTCs. TEST the system for normal operation.

No

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

Engage 4X4 HIGH and drive a short distance.

Raise and support the vehicle; refer to Section 100-02.

NOTE: The front and rear driveshafts should both spin.

Observe the front and rear driveshafts.

Does the transfer case lock the front driveshaft to the rear driveshaft?

Yes

GO to A17.

No

GO to A41.

If 4WD engagement is prolonged, harsh or noisy, GO to A18 .

Page 13

When 4X4 is disengaged, the front driveshaft may spin due to viscous drag in the transfer case, especially

A18 CHECK THE CLUTCH RE LAY

Page

13

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Turn the 4X4 mode switch to the 2WD position.

NOTE:

if cold. If this occurs, the front drive line can easily be stopped.

Drive the vehicle in reverse for 10 feet (3 meters) to disengage the front hubs.

Does only the rear driveshaft spin?

Yes

GO to Pinpoint Test E.

No

If the front driveshaft is not working properly, GO to A41 .

A19 CHECK THE CLUTCH RE LAY COIL CIRCUIT — MONITOR THE GEM PID 4WDELCL

A20 CHECK CIRCUIT 275 (Y ) FOR SHORT TO POWER

Check the clutch relay; refer to Component Test.

Is the clutch relay OK?

Yes

RECONNECT the clutch relay. GO to A19 .

No

REPLACE the clutch relay. CLEAR the DTCs. TEST the sys tem for normal operation.

Trigger the GEM active command SHIFT CLUTCH to ON.

Monitor the GEM PID 4WDELC L.

Does the GEM PID 4WDELCL display ON---?

Yes

GO to A21.

No

If the PID displays ON-B-, GO to A20 .

Clutch Relay

GEM C223

Measure the voltage between clutch relay, connector pin 1, ci rcuit 275 (Y), and ground.

Page 14

Page

14

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is any voltage indicated?

Yes

REPAIR circuit 275 (Y). CLE AR the DTCs. TEST the system for normal operation.

No

A21 CHECK THE ELECTRIC S HIFT RELAY COIL CIRCUIT — MONITOR THE GEM PID 4WDELCL

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

Trigger the GEM active command SHIFT CLUTCH to OFF.

Monitor the GEM PID 4WDELC L.

A22 CHECK THE BATTERY SA VER RELAY

A23 CHECK THE BATTERY SA VER RELAY COIL CIRCUIT — MONITOR THE GEM PID BAT T_SAVE

Battery Saver Relay

Does the GEM PID 4WDELCL display OFF--?

Yes

GO to A36.

No

If the PID displays OFFO-G, GO to A22 .

Check the battery saver relay; refer to Component Test.

Is the battery saver relay OK?

Yes

GO to A23.

No

REPLACE the battery saver relay. CLEAR the DTCs. TEST the system for normal operation.

Trigger the GEM active command BATT_SAVR to ON.

Monitor the GEM PID BATT_SAV R.

A24 CHECK CIRCUIT 1005 (P /O) FOR SHORT TO POWER

Battery Saver Relay

GEMC

Does the GEM PID BATT_SA VR display ON---?

Yes

GO to A25.

No

If the GEM PID BATT_SAVR displays ON-B-, GO to A24 .

Page 15

Page

15

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A25 CHECK THE BATTERY SA VER RELAY COIL CIRCUIT — MONITOR THE GEM PID BAT T_SAVR

A26 CHECK FOR VOLTAGE TO THE BATTERY SAVER RELAY — CIRCUIT 792 (T/Y)

Measure the voltage between battery saver relay connector pin 2, circuit 1005 (P/O), and grou nd.

Is any voltage indicated?

Yes

REPAIR circuit 1005 (P/O). CLEAR the DTCs. TEST the system for normal operation.

No

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

Trigger the GEM active command BATT_SAVR to OFF.

Monitor the GEM PID BATT_SAV R.

Does the GEM PID BATT_SA VR display OFF---?

Yes

GO to A36.

No

If the GEM PID BATT_SAVR displays OFFO-G, GO to A26 .

Battery Saver Relay

A27 CHECK THE POWER O UTPUT FROM FUSE JUNCTION PANEL FUSE 26 (10A)

Measure the voltage between fuse 26 (10A) pin 1, and ground; and between fuse 26 (10A) pin 2, and ground.

Measure the voltage between battery saver relay connector pin 1, circuit 792 (T/Y), and groun d; and between

battery saver relay connector pin 5, circuit 792 (T/Y), and ground.

Are the voltages greater than 10 volts?

Yes

GO to A32.

No

GO to A27.

Page 16

Page

16

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A28 CHECK FUSE JUNCTIO N PANEL FUSE 26 (10A)

Fuse 26 (10A)

A29 CHECK CIRCUIT 792 (T/Y ) FOR SHORT TO GROUND

Battery Saver Relay

Are the voltages greater than 10 volts?

Yes

REPAIR open in circuit 792 (T/Y). REPLACE the fuse. CLEAR the DTCs. TEST the system for normal operation.

No

GO to A28.

Is the fuse OK?

Yes

REPAIR the fuse junction pa nel. TEST the system for norma l operation.

No

GO to A29.

Measure the resistance between battery saver relay connec tor pin 1, circuit 792 (T/Y), and g round; and between

battery saver relay connector pin 5, circuit 792 (T/Y), and ground.

Are the resistances greater than 10,000 ohms?

Yes

GO to A30.

No

A30 CHECK CIRCUIT 705 (LG /O) FOR SHORT TO GROUND

Clutch Relay

J50 Relay

Measure the resistance between battery saver relay connec tor pin 3, circuit 705 (LG/O), and ground.

REPAIR circuit 792 (T/Y). TEST the system for normal operation.

Page 17

A31 CHECK CIRCUIT 705 (LG /O) FOR OPEN

Page

17

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A32 CHECK CIRCUIT 275 (Y ) FOR OPEN

GEM C223

Is the resistance greater than 10,000 ohms?

Yes

GO to A31.

No

REPAIR circuit 705 (LG/O). TEST the system for normal operation.

Measure the resistance between battery saver relay connec tor pin 3, circuit 705 (LG/O), and clutch relay

connector pin 2, circuit 705 (LG/O ).

Is the resistance less than 5 ohms?

Yes

GO to A32.

No

REPAIR circuit 705 (LG/O). TEST the system for normal operation.

Measure the resistance between clutch relay connector pin 1, circuit 275 (Y), and GEM C223 -15, circuit 275 (Y).

Is the resistance less than 5 ohms?

Yes

GO to A33.

No

A33 CHECK CIRCUIT 275 (Y ) FOR SHORT TO GROUND

REPAIR circuit 275 (Y). TES T the system for normal operation.

Measure the resistance between clutch relay connector pin 1, circuit 275 (Y), and ground.

Page 18

A34 CHECK CIRCUIT 1005 (P /O) FOR SHORT TO GROUND

Page

18

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A35 CHECK CIRCUIT 1005 (P /O) FOR OPEN

Is the resistance greater than 10,000 ohms?

Yes

GO to A34.

No

REPAIR circuit 275 (Y). TES T the system for normal operation.

Measure the resistance between battery saver relay connec tor pin 2, circuit 1005 (P/O), and ground.

Is the resistance greater than 10,000 ohms?

Yes

GO to A35.

No

REPAIR circuit 1005 (P/O). TEST the system for normal operation.

Measure the resistance between battery saver relay connec tor pin 2, circuit 1005 (P/O), and GEM C224-8, circuit

1005 (P/O).

Is the resistance less than 5 ohms?

Yes

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

No

A36 CHECK CIRCUIT 779 (B R) FOR VOLTAGE — GEM AC TIVE COMMAND SHIFT CLUTC H ON

Transfer Case Electric Shift Motor C1001

REPAIR circuit 1005 (P/O). TEST the system for normal operation.

Trigger the GEM active command SHIFT CLUTCH to ON.

Measure the voltage between transfer case electric shift motor C1001-8, circuit 779 (BR), a nd ground.

Page 19

Page

19

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the voltage greater than 10 volts?

Yes

GO to A37.

No

A37 CHECK CIRCUIT 779 (B R) FOR VOLTAGE — GEM AC TIVE COMMAND SHIFT CLUTC H OFF

A38 CHECK CIRCUIT 779 (B R) FOR SHORT TO POWER

GO to A38.

Trigger the GEM active command SHIFT CLUTCH to OFF.

Measure the voltage between transfer case electric shift motor C1001-8, circuit 779 (BR), a nd ground.

Is the voltage zero volts?

Yes

REPLACE the clutch relay. CLEAR the DTCs. TEST the sys tem for normal operation.

No

GO to A38.

Clutch Relay

A39 CHECK THE CLUTCH RE LAY SWITCHING CIRCUIT

Measure the voltage between the clutch relay connector pin 3, circuit 779 (BR), and ground.

Is any voltage indicated?

Yes

REPAIR circuit 779 (BR). CLEA R the DTCs. TEST the system for normal operation.

No

GO to A39.

Measure the voltage between clutch relay connector pin 5, c ircuit 704 (DG/LG), and ground.

Page 20

Page

20

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the voltage greater than 10 volts?

Yes

GO to A40.

No

CHECK power distribution box mini-fuse 3 (20A). REPLACE if necessary. If OK, REPAIR circuit 704 (DG/LG).

A40 CHECK CIRCUIT 779 (B R) FOR OPEN

A41 CHECK THE ELECTRONI C SHIFT CONTROL MODULE — GEM ACTIVE COMMAND CW/CCW ON

CLEAR the DTCs. TEST the system for normal operation.

Measure the resistance between clutch relay connector pin 3, circuit 779 (BR), and transfer case electric shift

motor C1001-8, circuit 779 (BR).

Is the resistance less than 5 ohms?

Yes

REPLACE the clutch relay. CLEAR the DTCs. TEST the sys tem for normal operation.

No

REPAIR circuit 779 (BR). CLEA R the DTCs. TEST the system for normal operation.

Trigger the GEM active command CW/CCW to ON.

Monitor the GEM PIDs MTR_CCW and MTR_CW.

A42 CHECK THE ELECTRONI C SHIFT CONTROL MODULE — GEM ACTIVE COMMAND CW/CCW OFF

A43 CHECK THE VOLTAGE TO THE ELECTRONIC SHIFT CONTROL MODULE COILS — CIRCUIT 705 (LG/O)

JSO Relay C230

Measure the voltage between JSO relay C230-5, circuit 705 (LG/O), and ground.

Do/Does the GEM PIDs MTR_C CW and MTR_CW display ON?

Yes

GO to A42.

No

If the PID(s) display(s) ON-B -, GO to A47 .

Trigger the GEM active command CW/CCW to OFF.

Do/Does the GEM PIDs MTR_C CW and MTR_CW display OFF?

Yes

GO to A50.

No

If the PID displays OFFO-G, GO to A43 .

Page 21

A44 CHECK CIRCUIT 513 (B R/PK) FOR OPEN

Page

21

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

GEM C223

A45 CHECK CIRCUIT 339 (GY) FOR OPEN

Is the voltage greater than 10 volts?

Yes

GO to A44.

No

REPAIR circuit 705 (LG/O). CLEAR the DTCs. TEST the syst em for normal operation.

Measure the resistance between JSO relay C230-9, circuit 513 (BR/PK), and GEM C223-17, circuit 513 (BR/PK).

Is the resistance less than 5 ohms?

Yes

GO to A45.

No

REPAIR circuit 513 (BR/PK) . CLEAR the DTCs. TEST the sy stem for normal operation.

Measure the resistance between JSO relay C230-8, circuit 339 (GY), and GEM C223-16, circuit 339 (GY).

Is the resistance less than 5 ohms?

Yes

GO to A46.

No

A46 CHECK CIRCUITS 513 (BR/PK) AND 339 (GY) FOR SH ORT TO GROUND

REPAIR circuit 339 (GY). CLEAR the DTCs. TEST the system for normal operation.

Measure the resistance between JSO relay C230-8, circuit 339 (GY), and ground; and betw een ISO relay C2309, circuit 513 (BR/PK), and ground.

Are the resistances greater than 10,000 ohms?

Page 22

A47 CHECK CIRCUIT 339 (GY) FOR SHORT TO POWER

Page

22

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

JSO Relay C230

GEM C223

Yes

GO to A49.

No

REPAIR circuit 513 (BR/PK) and/or circuit 339 (GY). CLEAR the DTCs. TEST the system for normal operation.

Measure the voltage between JSO relay C230-8, circuit 339 (GY), and ground.

Yes

REPAIR circuit 339 (GY). CLEAR the DTCs. TEST the system for normal operation.

No

A48 CHECK CIRCUIT 513 (B R/PK) FOR SHORT TO POWER

A49 CHECK THE ELECTRONI C SHIFT CONTROL MODULE COILS

GO to A48.

Measure the voltage between JSO relay C230-9, circuit 513 (BR/PK), and ground.

Yes

REPAIR circuit 513 (BR/PK) . CLEAR the DTCs. TEST the sy stem for normal operation.

No

GO to A49.

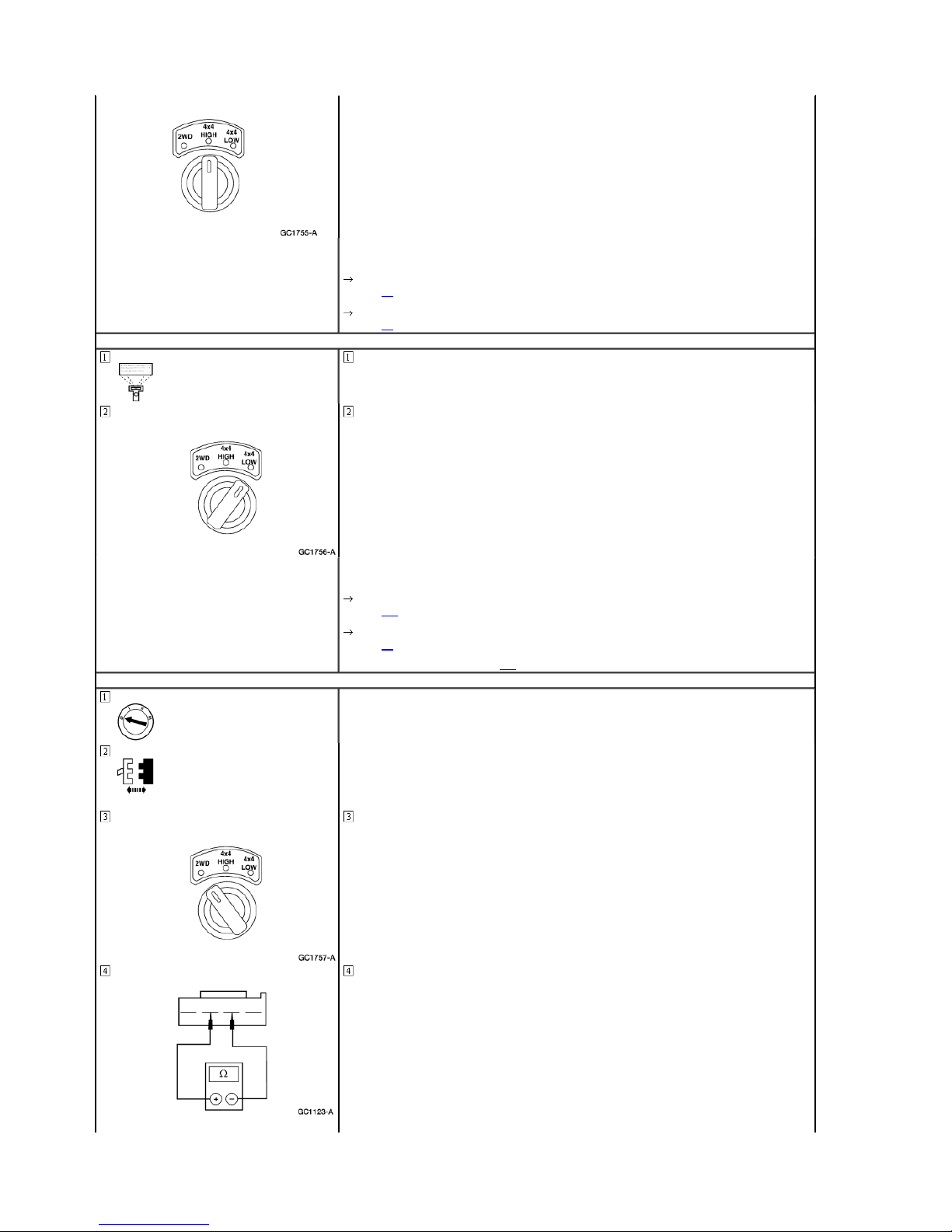

Measure the resistance between the JSO relay terminal 5 and terminals 8, 9.

Is any voltage indicated?

Is any voltage indicated?

Page 23

Page

23

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Are the resistance(s) between 60 and 110 ohms?

Yes

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

No

A50 CHECK THE VOLTAGE TO THE ELECTRIC SHIFT MO TOR — GEM ACTIVE COMMAND CW/CCW ON

Transfer Case Electric Shift Motor C1001

REPLACE the JSO relay. CLEAR the DTCs. TEST the system for normal operation.

Trigger the GEM active command CW/CCW to ON.

Measure the voltage between transfer case electric shift motor C1001-7, circuit 778 (O), and ground; and

between transfer case electric sh ift motor C310-4, circuit 7 77 (Y), and ground.

Are the voltages greater than 10 volts?

Yes

GO to A52.

No

A51 CHECK THE VOLTAGE TO THE ELECTRONIC SHIFT CONTROL MODULE SWITCH — CIRCUIT 704 (DG/LG)

JSO Relay C230

A52 CHECK THE VOLTAGE TO THE ELECTRIC SHIFT MO TOR — GEM ACTIVE COMMAND CW/CCW OFF

GO to A51.

Measure the voltage between JSO relay C230-3, circuit 704 (DG/LG), and ground.

Is the voltage greater than 10 volts?

Yes

GO to A55.

No

CHECK power distribution box fuse 3 (20A). If OK, REPAIR circuit 704 (DG/LG). CLEAR the DTCs. TEST the

system for normal operation.

Page 24

4, circuit 777 (Y), and ground; and between

4, circuit 777 (Y), and ground; and between

Page

24

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A53 CHECK CIRCUITS 777 (Y) AND 778 (O) FOR SHORT T O POWER

JSO Relay C230

Trigger the GEM active command CW/CCW to OFF.

Measure the voltage between transfer case electric shift motor C1001transfer case electric shift motor C1001-7, circuit 778 (O), and ground.

Are the voltages greater than 10 volts?

Yes

GO to A53.

No

GO to A54.

A54 CHECK CIRCUITS 777 (Y) AND 778 (O) FOR OPEN — GEM ACTIVE COMMAND CW/CC W OFF

Measure the voltage between transfer case electric shift motor C1001transfer case electric shift motor C1001-7, circuit 778 (O), and ground.

Is any voltage indicated?

Yes

REPAIR circuit 778 (O) and/ or circuit 777 (Y). CLEAR the DTCs. TEST the system for norma l operation.

No

REPLACE the JSO relay. CLEAR the DTCs. TEST the system for normal operation.

Trigger the GEM active command CW/CCW to OFF.

Measure the resistance between transfer case electric shift motor C1001-4, circuit 777 (Y), and ground; and

between transfer case electric sh ift motor, C1001-7, circuit 778 (O), and ground.

Page 25

A55 CHECK CIRCUIT 777 (Y ) FOR OPEN

Page

25

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

JSO Relay C230

A56 CHECK CIRCUIT 778 (O) FOR OPEN

Are the resistances less than 5 ohms?

Yes

RECONNECT the transfer case electric shift motor. GO to A 58 .

No

GO to A57.

Measure the resistance between JSO relay, C230-7, circuit 777 (Y), and transfer case elec tric shift motor C10014, circuit 777 (Y).

Is the resistance less than 5 ohms?

Yes

GO to A56.

No

REPAIR circuit 777 (Y). CLE AR the DTCs. TEST the system for normal operation.

Measure the resistance between JSO relay C230-10, circuit 778 (O), and transfer case elect ric shift motor C10017, circuit 778 (O).

Is the resistance less than 5 ohms?

Yes

GO to A57.

No

A57 CHECK THE GROUND T O THE ELECTRONIC SHIFT CONTROL MODULE

JSO Relay C230

REPAIR circuit 778 (O). CLEAR the DTCs. TEST the system for normal operation.

Measure the resistance between JSO relay C230-1, circuit 57 (BK), and ground.

Page 26

Page

26

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the resistance less than 5 ohms?

Yes

REPLACE the JSO relay. CLEAR the DTCs. TEST the system for normal operation.

No

A58 CHECK THE CONTACT PLATE SWITCHES — MONITOR THE GEM PLATE PIDS

REPAIR circuit 57 (BK). CLEAR the DTCs. TEST the system for normal operation.

Monitor GEM PIDs PLATE_A, PLATE_B, PLATE_C, and PLAT E_D.

Place the mode switch to 2WD and record the PID values.

Depress brake pedal.

Place the mode switch to 4X4 LOW and record the PID values.

A59 CHECK CONTACT PLAT E SWITCH D — CIRCUITS 771 (P/Y) AND 762 (Y/W)

Transfer Case Electric Shift Motor C1001

Connect a jumper wire between transfer case electric shift m otor C1001-6, circuit 762 (Y/W) , and C1001-5, circuit

Compare the PIDs with the following table.

PID 2WD 4WDLOW

PLATE_A Closed Closed

PLATE_B Closed Open

PLATE_C Open Closed

PLATE_D Closed Open

Do the PIDs agree with the ta ble?

Yes

REPAIR the transfer case; RE FER to Section 308-07B. CLEA R the DTCs. TEST the system for normal operation.

No

GO to A59.

Monitor the GEM PID PLATE_D, verify the PID indicates open.

771 (P/Y).

Page 27

Page

27

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A60 CHECK CIRCUIT 771 (P /Y) FOR SHORT TO POWER

Transfer Case Electric Shift Motor C1001

GEM C223

Does the GEM PID PLATE_D ch ange states?

Yes

GO to A62.

No

GO to A60.

Measure the voltage between transfer case electric shift motor C1001-5, circuit 771 (P/Y), and ground.

A61 CHECK CIRCUIT 771 (P /Y) FOR SHORT TO GROUND

GEM C223

Is the voltage greater than 10 volts?

Yes

REPAIR circuit 771 (P/Y). CLEAR the DTCs. TEST the system for normal operation.

No

GO to A61.

Measure the resistance between transfer case electric shift motor C1001-5, circuit 771 (P/Y), and ground.

Is the resistance greater than 10,000 ohms?

Yes

Page 28

A62 CHECK CIRCUIT 771 (P /Y) FOR OPEN

Page

28

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A63 CHECK CIRCUIT 762 (Y /W) FOR OPEN

GO to A62.

No

REPAIR circuit 771 (P/Y). CLEAR the DTCs. TEST the system for normal operation. If the concern remains,

RECONNECT GEM C223. GO to A64 .

Measure the resistance between transfer case electric shift motor C1001-5, circuit 771 (P/Y), and GEM C223-21,

circuit 771 (P/Y).

Is the resistance less than 5 ohms?

Yes

GO to A63.

No

REPAIR circuit 771 (P/Y). CLEAR the DTCs. TEST the system for normal operation.

Measure the resistance between transfer case electric shift motor C1001-6, circuit 762 (Y/W), and GEM C223-12,

circuit 762 (Y/W).

Is the resistance less than 5 ohms?

Yes

GO to A64.

No

A64 CHECK CONTACT PLAT E SWITCH C — CIRCUITS 762 (Y/W) AND 770 (W)

A65 CHECK CIRCUIT 770 (W) FOR SHORT TO POWER

REPAIR circuit 762 (Y/W). CLEAR the DTCs. TEST the syst em for normal operation.

Monitor the GEM PID PLATE_C. Verify the PID indicates open.

Connect a jumper wire between transfer case electric shift m otor C1001-6, circuit 762 (Y/W) , and C1001-1, circuit

770 (W).

Does the GEM PID PLATE_C ch ange states?

Yes

GO to A67.

No

GO to A65.

Page 29

Transfer Case Electric Shift Motor C1001

Page

29

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

GEM C223

A66 CHECK CIRCUIT 770 (W) FOR SHORT TO GROUND

Measure the voltage between transfer case electric shift motor C1001-1, circuit 770 (W), and ground.

Is any voltage indicated?

Yes

REPAIR circuit 770 (W). CLEAR the DTC. TEST the system for normal operation.

No

GO to A66.

Measure the resistance between transfer case electric shift motor C1001-1, circuit 770 (W), and ground.

Is the resistance greater than 10,000 ohms?

Yes

GO to A67.

No

REPAIR circuit 770 (W). CLEAR the DTCs. TEST the system for normal operation. If the concern remains,

A67 CHECK CIRCUIT 770 (W) FOR OPEN

A68 CHECK CONTACT PLAT E SWITCH B — CIRCUITS 762 (Y/W) AND 764 (BR/W)

Monitor the GEM PID PLATE_B.

RECONNECT GEM C223. GO to A67 .

Measure the resistance between transfer case electric shift motor C1001-1, circuit 770 (W), and GEM C223-20,

circuit 770 (W).

Is the resistance less than 5 ohms?

Yes

GO to A68.

No

REPAIR circuit 770 (W). CLEAR the DTCs. TEST the system for normal operation.

Page 30

Page

30

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A69 CHECK CIRCUIT 764 (B R/W) FOR SHORT TO POWER

Transfer Case Electric Shift Motor C1001

GEM C223

Connect a jumper wire between transfer case electric shift m otor C1001-6, circuit 762 (Y/W) , and C1001-2, circuit

764 (BR/W).

Does the GEM PID PLATE_B ch ange states?

Yes

GO to A71.

No

GO to A69.

Measure the voltage between transfer case electric shift motor C1001-2, circuit 764 (BR/W), and ground.

A70 CHECK CIRCUIT 764 (B R/W) FOR SHORT TO GROUND

Is any voltage indicated?

Yes

REPAIR circuit 764 (BR/W). CLEAR the DTCs. TEST the system for normal operation.

No

GO to A70.

Measure the resistance between transfer case electric shift motor C1001-2, circuit 764 (BR/ W), and ground.

Is the resistance greater than 10,000 ohms?

Yes

GO to A71.

Page 31

Page

31

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

No

REPAIR circuit 764 (BR/W). CLEAR the DTCs. TEST the system for normal operation. If the concern remains,

A71 CHECK CIRCUIT 764 (B R/W) FOR OPEN

A72 CHECK CONTACT PLAT E SWITCH A — CIRCUITS 762 (Y/W) AND 763 (O/W)

RECONNECT GEM C223. GO to A72 .

Measure the resistance between transfer case electric shift motor C1001-2, circuit 764 (BR/ W), and GEM C23319, circuit 764 (BR/W).

Is the resistance less than 5 ohms?

Yes

GO to A72.

No

REPAIR circuit 764 (BR/W). CLEAR the DTCs. TEST the system for normal operation.

Monitor the GEM PID PLATE_A. Verify the PID indicates open.

Connect a jumper wire between transfer case electric shift m otor C1001-6, circuit 762 (Y/W) , and C1001-3, circuit

763 (O/W).

Does the GEM PID PLATE_A ch ange states?

Yes

GO to A75.

No

A73 CHECK CIRCUIT 763 (O/W ) FOR SHORT TO POWER

Transfer Case Electric Shift Motor C1001

GEM C223

Measure the voltage between transfer case electric shift motor C1001-3, circuit 763 (O/W), and ground.

GO to A73.

Page 32

Page

32

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A74 CHECK CIRCUIT 763 (O/W ) FOR SHORT TO GROUND

A75 CHECK CIRCUIT 763 (O/W ) FOR OPEN

Is any voltage indicated?

Yes

REPAIR circuit 763 (O/W). CLEAR the DTC. TEST the system for normal operation.

No

GO to A74.

Measure the resistance between transfer case electric shift motor C1001-3, circuit 763 (O/W ), and ground.

Is the resistance greater than 10,000 ohms?

Yes

GO to A75.

No

REPAIR circuit 763 (O/W). CLEAR the DTCs. TEST the syst em for normal operation.

Measure the resistance between transfer case electric shift motor C1001-3, circuit 763 (O/W ), and GEM C223-18,

circuit 763 (O/W).

Is the resistance less than 5 ohms?

Yes

REPLACE the transfer case electric shift motor. CLEAR the DTCs. TEST the system for normal operation.

No

PINPOINT TEST B: THE VEHI CLE DOES NOT SHIFT BETWEEN 4WD HIGH AND 4WD LO W MODES PROPERLY

B1 CHECK THE IGNITION S TATES — MONITOR THE GEM PID IGN_GEM

CONDITIONS DETAILS/RESULTS/ACTIO NS

Scan Tool

REPAIR circuit 763 (O/W). CLEAR the DTCs. TEST the syst em for normal operation.

Page 33

Page

33

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Monitor the GEM PID IGN_GEM while turning the ignition switch through the RUN, OFF and ACC positions.

B2 RETRIEVE THE DIAGNOST IC TROUBLE CODES (DTCS)

Clear Continuous DTCs

GEM On-Demand Self-Test

B3 CHECK THE 4X4 HIGH L AMP INDICATOR — TRIGGER THE GEM ACTIVE COMMAND HIGH LAMP ON

Do the PID values agree with the ignition switch positions?

Yes

GO to B2.

No

REFER to Section 417-02.

Retrieve and document continuous DTCs.

Are any DTCs recorded?

Yes

If DTC B1342, REPLACE the GEM; REFER to Section 419- 10. CLEAR the DTCs. TEST the system for normal

operation.

If DTC B1483, GO to B17 .

If DTC B1485, GO to B17 .

If DTC P0500 and the vehicl e is equipped with RABS, GO to B24 .

If DTC P0500 and the vehicl e is equipped with 4WABS, GO t o B27 .

If DTC P1812, GO to B5 .

If DTC P1815, GO to B5 .

No

GO to B3.

B4 CHECK THE 4X4 LOW LAMP INDICATOR — TRIGGER THE GEM ACTIVE COMMAND LO W LAMP ON

B5 CHECK THE 4X4 MODE SW ITCH — MONITOR THE GEM PID 4WD_SW IN 2WD POSIT ION

Place the mode switch in the 2WD position.

Trigger the GEM active command HIGH LAMP ON then OFF.

Does the 4x4 HIGH indicator illuminate then go off?

Yes

GO to B4.

No

GO to Pinpoint Test C.

Trigger the GEM active command LOW LAMP ON then OFF.

Does the 4x4 LOW indicator illuminate then go off?

Yes

Exit the GEM active command mode; GO to B5 .

No

GO to Pinpoint Test C.

Page 34

Page

34

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Monitor the GEM PID 4WD_SW .

B6 CHECK THE 4X4 MODE SW ITCH — MONITOR THE GEM PID 4WD_SW IN THE 4X4 HI GH POSITION

B7 CHECK THE 4X4 MODE SW ITCH — MONITOR THE GEM PID 4WD_SW IN THE 4X4 LO W POSITION

Does the PID indicate 2WD?

Yes

GO to B6.

No

GO to B8.

If the PID indicates OFFO-G, GO to B14 .

Place the mode switch in the 4X4 HIGH position.

Monitor the GEM PID 4WD_SW .

Does the PID indicate 4WD HIG H?

Yes

GO to B7.

No

GO to B8.

Place the mode switch in the 4X4 LOW position.

B8 CHECK THE 4X4 MODE SW ITCH IN THE 2WD POSITION

Monitor the GEM PID 4WD_SW .

Does the PID indicate 4WD L OW?

Yes

GO to B17.

No

GO to B8.

Page 35

Page

35

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

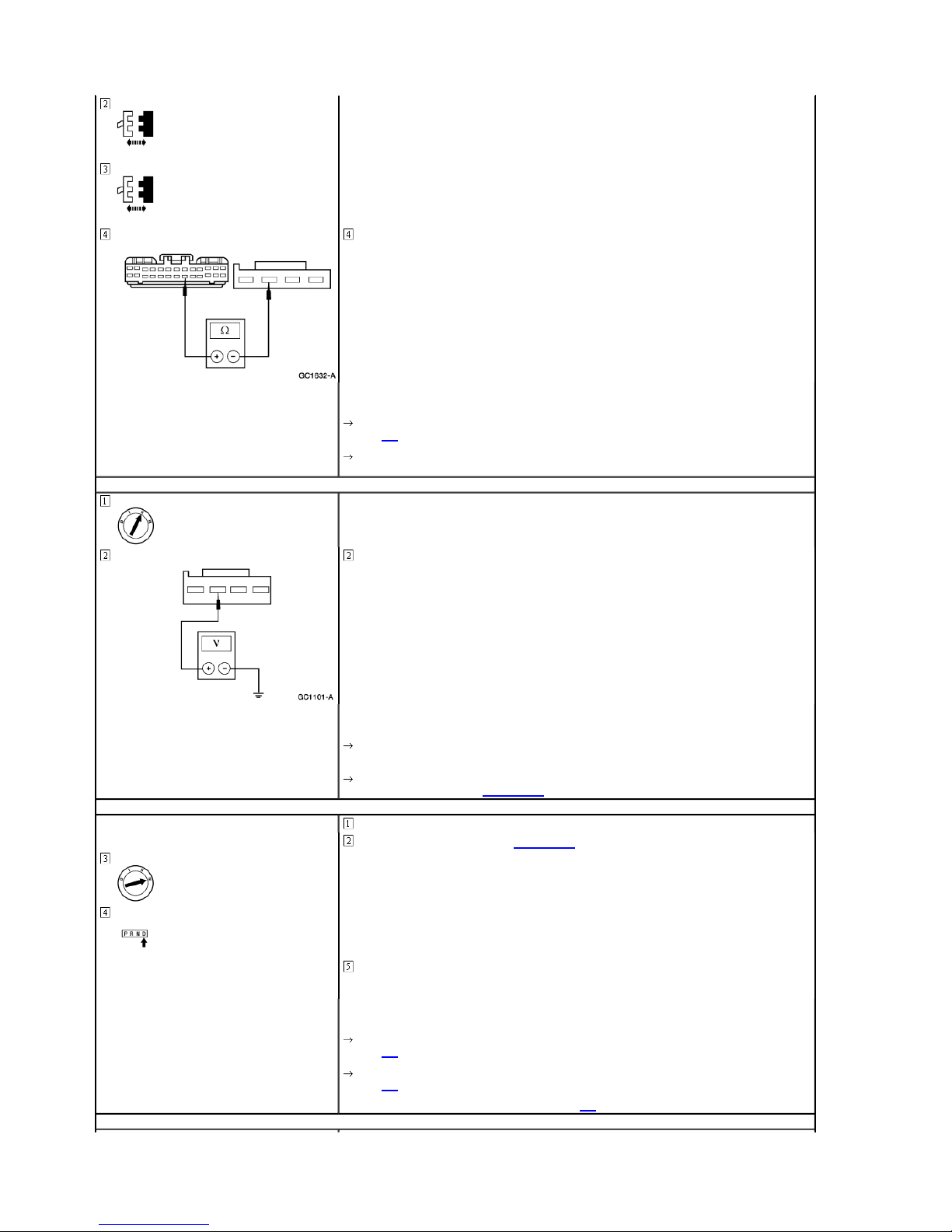

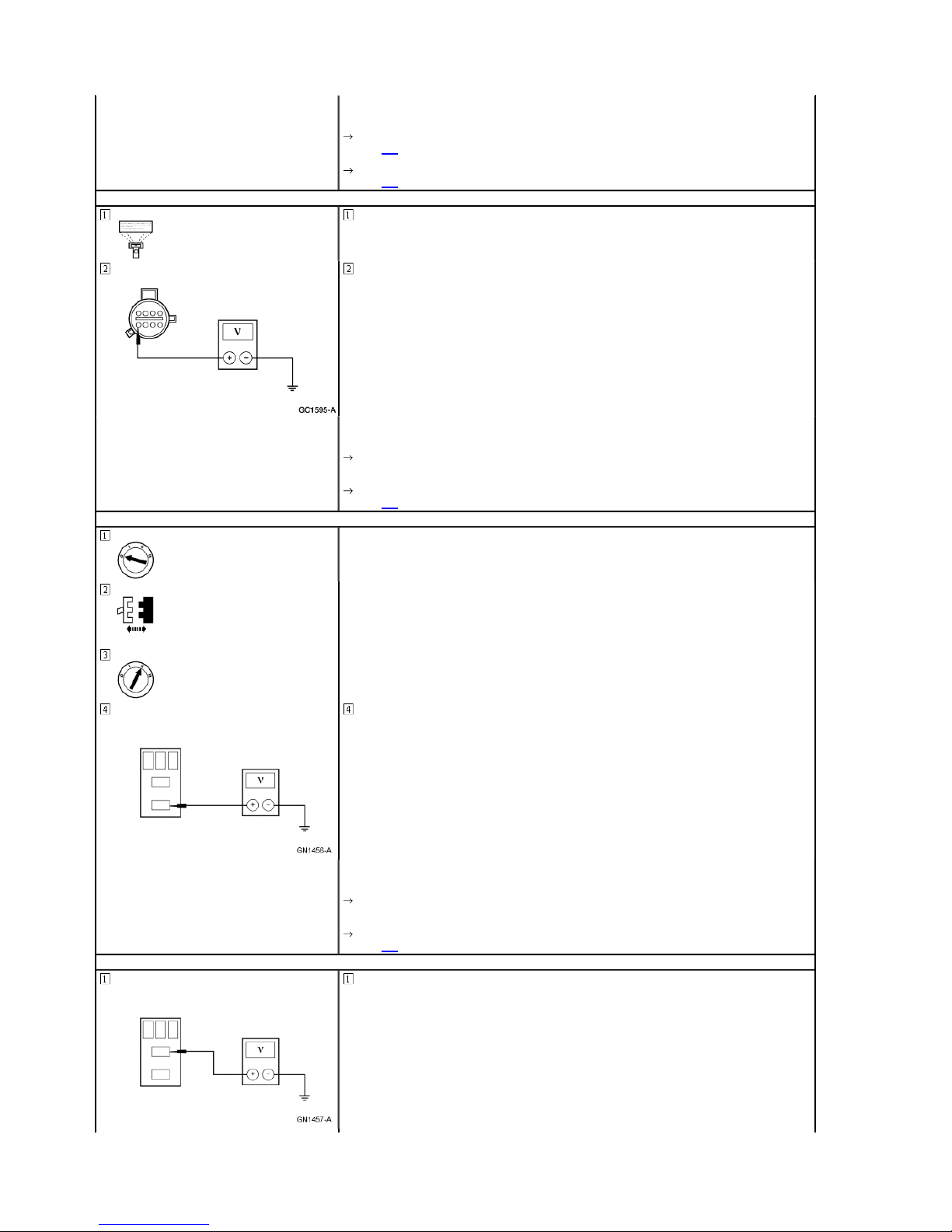

4X4 Mode Switch C225

Place the mode switch in the 2WD position.

B9 CHECK THE 4X4 MODE SW ITCH IN THE 4X4 HIGH POSI TION

Measure the resistance between the mode switch terminals 2 and 3.

Yes

GO to B9.

No

REPLACE the mode switch. CLEAR the DTCs. TEST the sy stem for normal operation.

Place the mode switch in the 4X4 HIGH position.

Measure the resistance between the mode switch terminals 2 and 3.

Is the resistance between 3700 and 4100 ohms?

Is the resistance between 1050 and 1150 ohms?

Yes

GO to B10.

No

B10 CHECK THE 4X4 MODE SELECT SWITCH IN THE 4X4 LOW POSITION

Place the mode switch in the 4X4 LOW position.

REPLACE the mode switch. CLEAR the DTCs. TEST the sy stem for normal operation.

Page 36

Page

36

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

B11 CHECK CIRCUIT 465 (W/LB) FOR OPEN

GEM C223

4X4 Mode Switch C225

Measure the resistance between the mode switch terminals 2 and 3.

Is the resistance between 340 and 380 ohms?

Yes

GO to B11.

No

REPLACE the mode switch. CLEAR the DTCs. TEST the sy stem for normal operation.

Measure the resistance between mode switch C225-3, circuit 465 (W/LB), and GEM C223-8, circuit 465 (W/LB).

Is the resistance less than 5 ohms?

Yes

GO to B12.

No

B12 CHECK CIRCUIT 465 (W/LB) FOR SHORT TO POWER

Measure the voltage between GEM C223-8, circuit 465 (W/LB), an d ground.

REPAIR circuit 465 (W/LB). CLEAR the DTCs. TEST the system for normal operation.

Page 37

Page

37

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

B13 CHECK CIRCUIT 465 (W/LB) FOR SHORT TO GROUND

B14 CHECK CIRCUIT 359 (GY/ R) FOR OPEN

Is any voltage indicated?

Yes

REPAIR circuit 465 (W/LB). CLEAR the DTCs. TEST the system for normal operation.

No

GO to B13.

Measure the resistance between GEM C223-8, circuit 465 (W/LB), and ground.

Is the resistance greater than 10,000 ohms?

Yes

GO to B14.

No

REPAIR circuit 465 (W/LB). CLEAR the DTCs. TEST the system for normal operation.

GEM C221

B15 CHECK CIRCUIT 359 (GY/ R) FOR SHORT TO GROUND

Measure the resistance between GEM C221-21, circuit 359 (G Y/R), and ground.

Measure the resistance between mode switch C225-2, circuit 359 (GY/R), and GEM C221-21, circuit 359 (GY/R).

Is the resistance less than 5 ohms?

Yes

GO to B15.

No

REPAIR circuit 359 (GY/R). CLEAR the DTCs. TEST the system for normal operation.

Page 38

Page

38

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the resistance greater than 10,000 ohms?

Yes

GO to B16.

No

B16 CHECK CIRCUIT 359 (GY/ R) FOR SHORT TO POWER

B17 CHECK BRAKE PEDAL POSITION (BPP) SWITCH — MONITOR THE GEM PID B OO_GEM

REPAIR circuit 359 (GY/R). CLEAR the DTCs. TEST the system for normal operation.

Measure the voltage between GEM C221-21, circuit 359 (GY/R), and ground.

Is the voltage greater than 10 volts?

Yes

REPAIR circuit 359 (GY/R). CLEAR the DTCs. TEST the system for normal operation.

No

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

Monitor GEM PID BOO_GEM.

B18 CHECK THE VOLTAGE TO THE BPP SWITCH — CIRCUIT 276 (BR)

BPP Switch C210

Depress the brake pedal.

Does the GEM PID BOO_GEM indicate ON?

Yes

GO to B20.

No

GO to B18.

Measure the voltage between BPP switch C210-3, circuit 276 (BR), and ground.

Page 39

B19 CHECK THE BPP SWITC H

Page

39

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the voltage greater than 10 volts?

Yes

GO to B19.

No

CHECK fuse 9 (7.5A). REPLACE if necessary. If OK, REPA IR circuit 276 (BR). CLEAR the DTCs. TEST the

system for normal operation.

Monitor the GEM PID BOO_G EM.

B20 CHECK THE CLUTCH IN TERLOCK — MONITOR THE GEM PID CLTCHSW

Verify the GEM PID BOO_GEM indicates OFF.

Connect a jumper wire between the BPP switch C210-3, circuit 276 (BR), and C210-4, circuit 810 (R/LG).

Does the GEM PID BOO_GEM indicate ON?

Yes

REPLACE the BPP switch; REFER to Section 417-01. CLEAR the DTCs. TEST the system for normal operation.

No

REPAIR circuit 810 (R/LG). If OK, REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the

system for normal operation.

Monitor the GEM PID CLTCH SW.

B21 CHECK THE TRANSMIS SION RANGE SENSOR PID NTRL_SW

Verify the GEM PID CLTCHSW indicates ENGAGED.

Place the gear selector in every position except neutral and pa rk.

Verify the GEM PID CLTCHSW indicates NOT ENGAGED.

Does the GEM PID CLTCHSW indicate correctly?

Yes

GO to B21.

No

DIAGNOSE the starter interrupt circuit and digital TR sensor. REFER to Section 303-06. If OK, REPLACE the

GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for normal operation.

Monitor the GEM PID NTRL_SW.

Verify the GEM PID NTRL_SW indicates NTRL.

Place the gear selector in every position except neutral.

Verify the GEM PID NTRL_SW indicates notNRTL.

Page 40

Page

40

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Does the GEM PID NTRL_SW indicate correctly?

Yes

GO to B24.

No

B22 CHECK THE GROUND T O THE DIGITAL TR SENSOR — CIRCUIT 57 (BK)

Digital TR Sensor C1005

B23 CHECK THE DIGITAL TR SENSOR — MONITOR THE GEM PID NTRL_SW

GO to B22.

Measure the resistance between digital TR sensor C1005-7, circuit 57 (BK), and ground.

Is the resistance less than 5 ohms?

Yes

GO to B23.

No

REPAIR circuit 57 (BK). CLEAR the DTCs. TEST the system for normal operation.

B24 CHECK CIRCUITS 523 (R/PK) AND 519 (LG/BK) FOR SH ORT TO GROUND

GEM C224

RABS Module C238

Monitor the GEM PID NTRL_SW.

Verify the GEM PID NTRL_SW indicates NOT NTRL.

Connect a jumper wire between digital TR sensor C1005-7, circuit 57 (BK), and C1005-8, ci rcuit 463 (R/W).

Does the GEM PID NTRL_SW indicate NTRL?

Yes

REPLACE the digital TR sensor; REFER to Section 307-01A or Section 307-01B. CLEAR the DTCs. TEST the

system for normal operation.

No

REPAIR circuit 463 (R/W). CL EAR the DTCs. If OK, REPLAC E the GEM; REFER to Section 419-10. CLEAR the

DTCs. TEST the system for normal operation.

Rear Anti-Lock Brake Sensor C1010

Measure the resistance between GEM C224-9, circuit 523 (R/ PK), and ground.

Page 41

Page

41

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

B25 CHECK CIRCUITS 523 (R/PK) AND 519 (LG/BK) FOR OP EN

Measure the resistance between GEM C224-18, circuit 519 (LG/BK), and ground.

Are the resistances greater than 10,000 ohms?

Yes

GO to B25.

No

REPAIR circuit 523 (R/PK) and/or 519 (LG/BK). CLEAR the DTCs. TEST the system for normal operation.

Measure the resistance between rear anti-lock brake sensor C1010, circuit 523 (R/PK) and GEM C224-9, circuit

523 (R/PK).

B26 CHECK CIRCUITS 523 (R/PK) AND 519 (LG/BK) FOR SH ORT TO POWER

Measure the voltage between GEM C224-18 circuit 519 (LG/BK), and ground.

Measure the resistance between rear anti-lock brake sensor C1010, and GEM C224-18, circuit 519 (LG/BK).

Are the resistances less than 5 ohms?

Yes

GO to B26.

No

REPAIR circuit 523 (R/PK) and/or 519 (LG/BK). CLEAR the DTCs. TEST the system for normal operation.

Measure the voltage between GEM C214-9, circuit 523 (R/PK), and ground.

Page 42

Page

42

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is any voltage indicated?

Yes

REPAIR circuit 523 (R/PK) and/or 519 (LG/BK). CLEAR the DTCs. TEST the system for normal operation.

No

B27 CHECK THE VEHICLE SP EED SIGNAL — MONITOR TH E GEM PID VSS_GEM

GEM C224

RABS Module C238

Rear Anti-Lock Brake Sensor C1010

GO to B27.

Monitor GEM PID VSS_GEM while driving the vehicle 0 to 55 mph (88.5 km/h).

B28 CHECK CIRCUIT 679 (GY/ BK) FOR OPEN

GEM C224

4WABS Module C154

Measure the resistance between GEM C224-4, circuit 679 (GY/BK), and 4WABS module C154-10, circuit 679

Is the GEM PID VSS_GEM value and speedometer reading greater than 0 mph (0 km/h)?

Yes

GO to A18.

No

If the vehicle is equipped w ith 4WABS, GO to B28 .

If the vehicle is equipped w ith RABS, CHECK the rear anti-l ock brake sensor; REFER to S ection 206-09A,

Component Test. If the sensor is OK, REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST

the system for normal operation.

(GY/BK).

Page 43

Page

43

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the resistance less than 5 ohms?

Yes

REFER to Section 206-09B.

No

PINPOINT TEST C: THE 4X4 HI GH AND/OR 4X4 LOW INDICATOR(S) DO/DOES NOT OPER ATE PROPERLY

C1 CHECK THE IGNITION S TATES — MONITOR THE GEM PID IGN_GEM

CONDITIONS DETAILS/RESULTS/ACTIO NS

Scan Tool

REPAIR circuit 679 (GY/BK). CLEAR the DTCs. TEST the system for normal operation.

Monitor the GEM PID IGN_GEM while turning the ignition switch through the RUN, OFF and ACC positions.

C2 RETRIEVE THE DIAGNOST IC TROUBLE CODES (DTCS)

Clear Continuous DTCs

GEM On-Demand Self-Test

Do the PID values agree with the ignition switch positions?

Yes

GO to C2.

No

REFER to Section 417-02.

Retrieve and document continuous DTCs.

Are any DTCs recorded?

Yes

If DTC B1342, REPLACE GE M. REFER to Section 419-10. CLEAR the DTCs. TEST the system for normal

operation.

Page 44

C3 VERIFY THE INOPERATIVE INDICATOR LAMP

Page

44

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

C4 CHECK THE GEM PID 4WD HIGH

If DTC P1804, GO to C3 .

If DTC P1806, GO to C3 .

If DTC P1808, GO to C3 .

If DTC P1810, GO to C3 .

No

GO to C3.

Verify the inoperative indicator lamp.

Is the 4X4 HIGH indicator inoperative?

Yes

GO to C4.

No

If the 4X4 LOW indicator is inoperative, GO to C9 .

If both the 4X4 HIGH and 4X4 LOW indicators are inoperative ; REFER to Section 413-01.

Monitor the GEM PID 4WDHIG H while triggering the GEM active command HIGH LAMP ON then OFF.

C5 CHECK THE GEM PID 4WD LOW

C6 CHECK CIRCUIT 784 (LB /BK) FOR OPEN

GEM C223

Does the 4X4 HIGH indicator i lluminate then go off?

Yes

GO to C5.

No

If the PID displays ON-B-, GO to C12 .

If the PID displays OFF O-G , GO to C5 .

Monitor the GEM PID 4WDLO W while triggering the GEM active command LOWLAMP ON t hen OFF.

Does the 4X4 LOW indicator i lluminate then go off?

Yes

Indicators are OK. GO to Pinpoint Test A.

No

If the PID displays ON-B-, GO to C12 .

If the PID displays OFFO-G, GO to C5 .

Measure the resistance between GEM C223-10, circuit 784 (LB/BK), and instrument cluster C214-2, circuit 784

(LB/BK).

Is the resistance less than 5 ohms?

Yes

GO to C7.

No

REPAIR circuit 784 (LB/BK). CLEAR the DTCs. TEST the sy stem for normal operation.

Page 45

C7 CHECK CIRCUIT 784 (LB /BK) FOR SHORT TO GROUND

Page

45

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

C8 CHECK THE INSTRUMENT CLUSTER

Measure the resistance between GEM C223-10, circuit 784 (LB/BK), and ground.

Is the resistance greater than 10,000 ohms?

Yes

RECONNECT instrument cl uster C214. GO to C8 .

No

REPAIR circuit 784 (LB/BK). CLEAR the DTCs. TEST the sy stem for normal operation.

Connect a jumper wire between GEM C223-10, circuit 784 (LB /BK), and ground.

Does the 4X4 LOW indicator i lluminate?

Yes

GO to C9.

No

CHECK the indicator bulbs. If OK, REPAIR the instrument cluster printed circuit. CLEAR th e DTCs. TEST the

C9 CHECK CIRCUIT 783 (GY) FOR OPEN

Instrument Cluster C214

C10 CHECK CIRCUIT 783 (GY) FOR SHORT TO GROUND

Measure the resistance between GEM C223-14, circuit 783 (G Y), and ground.

system for normal operation.

Measure the resistance between GEM C223-14, circuit 783 (G Y), and instrument cluster C2 14-3, circuit 783

(GY).

Is the resistance less than 5 ohms?

Yes

GO to C10.

No

REPAIR circuit 783 (GY). CLEAR the DTCs. TEST the system for normal operation.

Page 46

Page

46

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

C11 CHECK THE INSTRUMENT CLUSTER

C12 CHECK CIRCUIT 784 (LB /BK) FOR SHORT TO POWER

Is the resistance greater than 10,000 ohms?

Yes

GO to C11.

No

REPAIR circuit 783 (GY). CLEAR the DTCs. TEST the system for normal operation.

Connect a jumper wire between GEM C223-14, circuit 783 (GY), and ground.

Does the 4X4 HIGH indicator i lluminate?

Yes

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

No

CHECK the indicator bulbs. If OK, REPAIR the instrument cluster printed circuit. CLEAR th e DTCs. TEST the

system for normal operation.

GEM C223

Instrument Cluster C214

Measure the voltage between GEM C223-10, circuit 784 (LB/BK), and ground.

Is the voltage greater than 10 volts?

Page 47

C13 CHECK CIRCUIT 783 (GY) FOR SHORT TO POWER

Page

47

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

C14 CHECK THE INSTRUMENT CLUSTER

Yes

REPAIR circuit 784 (LB/BK). CLEAR the DTCs. TEST the sy stem for normal operation.

No

GO to C13.

Measure the voltage between GEM C223-14, circuit 783 (GY), and ground.

Is any voltage indicated?

Yes

REPAIR circuit 783 (GY). CLEAR the DTCs. TEST the system for normal operation.

No

GO to C14.

Monitor the GEM PIDs 4WDHI GH and 4WDLOW while trigge ring the GEM active command s LOW LAMP and

HIGH LAMP to OFF.

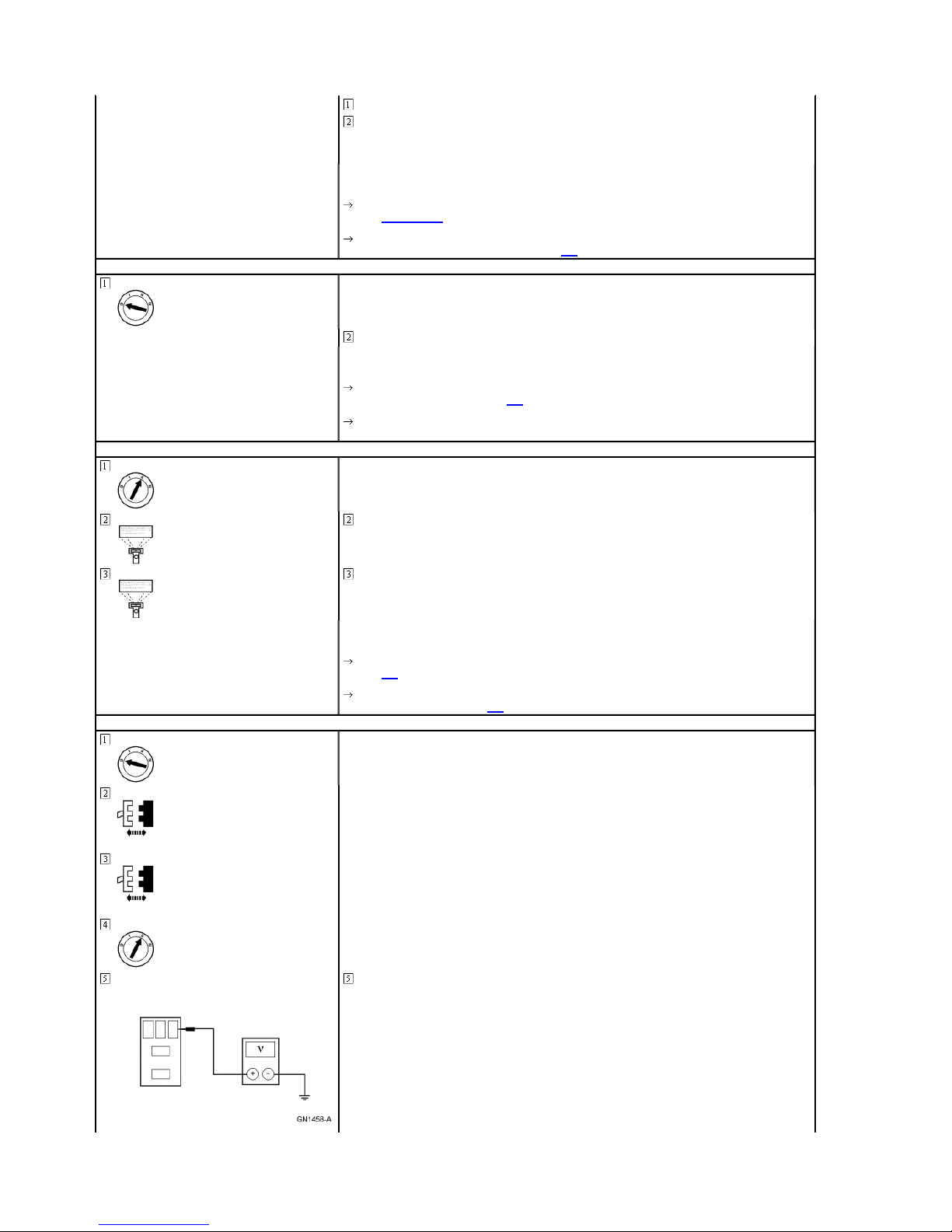

PINPOINT TEST D: NO COM MUNICATION WITH THE MODULE — GEM/CTM

D1 CHECK POWER DISTRIB UTION BOX MAXI-FUSE 1 (50A )

D2 CHECK FUSE JUNCTION PANEL FUSE 25 (7.5A)

D3 CHECK CIRCUIT 1052 (T/B K) FOR VOLTAGE

Measure the voltage between fuse junction panel fuse 25 (7.5A) pin 2, circuit 1052 (T/BK), and ground.

CONDITIONS DETAILS/RESULTS/ACTIO NS

Fuse 1 (50A)

Fuse 25 (7.5A)

Do the PIDs indicate OFFO-G?

Yes

CHECK the bulbs. If the bulbs are OK, REPAIR the instrume nt cluster printed circuit. CLEA R the DTCs. TEST the

system for normal operation.

No

REPLACE the GEM; REFER to Section 419-10. CLEAR the DTCs. TEST the system for no rmal operation.

Is the fuse OK?

Yes

GO to D2.

No

REPLACE the fuse. CLEAR the DTCs. TEST the system for normal operation. If the fuse fa ils again, CHECK

circuit 1052 (T/BK) for a short to ground. REPAIR as neces sary.

Is the fuse OK?

Yes

GO to D3.

No

REPLACE the fuse. CLEAR the DTCs. TEST the system for normal operation. If the fuse fa ils again, CHECK

circuit 1001 (W/Y) for a short to ground. REPAIR as necess ary.

Page 48

Page

48

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the voltage greater than 10 volts?

Yes

GO to D4.

No

D4 CHECK THE VOLTAGE TO THE GEM/CTM — CIRCUIT 1001 (W/Y)

GEM/CTM C224

D5 CHECK CIRCUIT 570 (BK/W ) FOR OPEN

REPAIR circuit 1052 (T/BK). CLEAR the DTCs. TEST the system for normal operation.

Measure the voltage between GEM/CTM C224-11, circuit 1001 (W/Y), and ground.

Is the voltage greater than 10 volts?

Yes

GO to D5.

No

REPAIR circuit 1001 (W/Y). CLEAR the DTCs. TEST the system for normal operation.

GEM/CTM C224

D6 CHECK CIRCUIT 519 (LG/B K) OR 57 (BK) FOR OPEN

Measure the resistance between GEM/CTM C224-18, circuit 519 (LG/BK) or 57 (BK), and ground.

Measure the resistance between GEM/CTM C221-14, circuit 570 (BK/W), and ground; and be tween GEM/CTM

C221-26, circuit 570 (BK/W), and ground.

Are the resistances less than 5 ohms?

Yes

GO to D6.

No

REPAIR circuit 570 (BK/W). CLEAR the DTCs. TEST the syst em for normal operation.

Page 49

Page

49

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Is the resistance less than 5 ohms?

Yes

REFER to Section 418-00.

No

PINPOINT TEST E: THE PULSE VACUUM HUBLOCKS DO NOT OPERATE PROPERLY (T RANSFER CASE MOTOR MO VEMENT AND FRONT DRIVE SHAFT OPERATE

PROPERLY

E1 LEAK TEST THE WHEE L ENDS AND LOWER VACUUM SYSTEM — SOLENOID OU TPUT

CONDITIONS DETAILS/RESULTS/ACTIO NS

REPAIR circuit 519 (LG/BK) or 57 (BK). CLEAR the DTCs. TEST the system for normal operation.

PVH Solenoid Vacuum Connector

E2 LEAK TEST THE UPPER VACUUM SYSTEM — SOLENO ID INPUT

Raise and support the vehicle; refer to Section 100-02.

NOTE: This step may require rapid pumping for up to 10 sec onds.

Connect a hand vacuum pump to the PVH solenoid upper port hose connector and try to pull a vacuum to 15

in/Hg.

Does the vacuum drop exceed 0.5 in/Hg in 30 seconds?

Yes

GO to E22.

No

GO to E2.

Connect a hand vacuum pump to the PVH solenoid lower po rt hose connector and try to pull a vacuum to 15

in/Hg.

Does the vacuum drop exceed 0.5 in/Hg in 30 seconds?

Yes

GO to E3.

No

E3 LEAK TEST THE A/C SYSTEM

GO to E5.

Page 50

Page

50

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

A/C Vacuum Input Line

E4 CHECK THE VACUUM SYSTEM RESERVOIR AND VACUUM LINES

A/C Vacuum Input Line

Vacuum Reservoir Output Tee Connector

Connect a hand vacuum pump to the A/C vacuum input line con nector and try to pull a vacuum to 15 in/Hg.

Does the vacuum drop exceed 0.5 in/Hg in 30 seconds?

Yes

DIAGNOSE the A/C system; REFER to Section 412-00. TEST the system for normal opera tion.

No

GO to E4.

Connect a hand vacuum pump to the vacuum reservoir outpu t line connector and try to pull a vacuum to 15 in/Hg.

Yes

DIAGNOSE the engine vacuum system; REFER to Section 303-00.

No

REPAIR and/or REPLACE the vacuum reservoir output tee fitting or vacuum line between vacuum reservoir tee

E5 CHECK THE PVH VA CUUM SYSTEM FOR ENGINE VACUUM

fitting and PVH vacuum solenoid. TEST the system for normal operation.

Yes

GO to E7.

No

GO to E6.

Does the vacuum drop exceed 0.5 in/Hg in 30 seconds?

Connect a vacuum gauge to the PVH solenoid lower port hose connector and measure the vacuum level.

Is the vacuum level greater than 11 in/Hg?

Page 51

E6 CHECK THE ENGINE AND PRIMARY VACUUM LINE FOR VACUUM

Page

51

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Engine Vacuum Output Connector

E7 CHECK THE SOLENO ID VALVE FOR LEAKAGE

Connect a vacuum gauge to the engine vacuum output connector and measure the vacuum level.

Is the vacuum level greater than 11 in/Hg?

Yes

REPAIR or REPLACE the vacuum reservoir or vacuum lines between the PVH solenoid vacuum input line and

vacuum reservoir input line. TEST the system for normal operation.

No

DIAGNOSE the engine vacuum system; REFER to Section 303-00.

PVH Solenoid Vacuum Connector

E8 CHECK THE PVH SOLENOID FOR PROPER VACUUM OUTPUT LEVEL — 4X4 ENGAG ED

Measure the vacuum while swi tching the 4X4 mode switch to 4X4 HIGH.

Disconnect the LH wheel end vacuum line connector.

Connect a tee fitting and vac uum gauge between the LH wheel end vacuum line connector and PVH solenoid

vacuum line output connector.

Wait a minimum of 60 seconds and measure the vacuum.

Is the vacuum level greater than 1 in/Hg?

Yes

REPLACE the PVH vacuum solenoid. REFER to Section 204-01B. TEST the system for no rmal operation.

No

GO to E8.

Page 52

Page

52

of 622000 Ranger Workshop Manual

1/18/2012

http://www.fordtechservice.dealerconnection.com/pubs/content/~WSYL/~MUS~LEN/21/

...

Does the vacuum gauge indicate at least 11 in/Hg after six seconds but not longer than 60 seconds

after switching the 4X4 mode switch to 4X4 HIGH?

Yes

GO to E9.

No

E9 CHECK THE PVH SOLENOID FOR PROPER VACUUM OUTPUT LEVELS — 4X4 DISENGAGED

NOTE: This step requires the use of a calibrated vacuum gauge that is accurate to within a m inimum of 0.1 in/Hg. It is recom mended that Pressure/Vacuum Module or equivalent

105-R0099 be used for this check.

E10 RETRIEVE THE DIAGNOS TIC TROUBLE CODES (DTCS)

Scan Tool

GO to E10.

Observe the vacuum gauge while switching the 4X4 mode switch to 2WD.