Page 1

Clean the valve covers and mating surfaces.

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 41997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B14.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Valve Cover and Gasket

NOTE: The rocker covers installed on the 3.0L engine incorporate integral (built-in) gaskets which

should last the life of the vehicle. Be sure to adhere to the following steps when removing and

replacing rocker covers. Replacement gaskets are available if required.

Removal

1. Disconnect battery ground cable (14301) and set aside.

2. Disconnect the crankcase ventilation hose from the air cleaner outlet tube. Disconnect the wiring

connectors from the mass air flow (MAF) sensor, intake air temperature (IAT) sensor, and the

harness locator from the outlet tube. Loosen the clamps at the throttle body and air cleaner and

remove the outlet tube.

3. Remove air cleaner outlet tube.

4. Disconnect the canister purge hose from the canister purge valve at the LH frame rail and the locator

from the accelerator control bracket. Remove the accelerator control splash shield.

5. Disconnect the throttle cable (09A758A) and speed control cable (9A825) from the throttle body and

the locator at the top of the intake manifold. Remove the cable bracket retaining bolts and remove

bracket with cables attached. Position the bracket and cables out of the way.

6. Disconnect the wiring connectors from the coil connector, radio noise suppressor, the EVR and left

side spark plug wires from coil. Disconnect right side spark plug wires from the locators and wires

from the spark plugs. Disconnect the vacuum hose from the EVR and heater control tee. Remove the

brace from the coil bracket and the exhaust manifold. Remove the coil assembly.

7. Disconnect the right side valve cover harness locators. Disconnect the IAT harness locator from the

generator bracket. Remove the right side valve cover and gasket.

8. Disconnect the DPFE vacuum hoses and the wiring connector. Remove the EGR valve tube from the

valve and exhaust manifold.

9. Disconnect the vacuum hoses from the brake booster, EGR, and the engine vacuum harness from

upper intake and position the harness out of the way.

10. Disconnec the wiring connectors from the throttle position sensor (TPS) and idle air control (IAC).

Disconnect the 42-pin connector from the bracket at the rear of intake manifold. Remove the positive

crankcase ventilation (PCV) valve from the valve cover.

11. Remove the upper intake manifold and gasket. Tape the lower intake openings closed.

12. Disconnect the left side spark plug wire locators and wires from the spark plugs. Remove the left side

valve cover and gasket.

13. NOTE: Do not clean the valve cover gasket with solvent. Damage to the valve cover gasket

may occur.

Page 2

14. Clean upper intake manifold and mating surfaces.

symptoms may occur while the powertrain control module (PCM) (12A650) relearns its

Page

2

of 41997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B14.HTM~gen~ref.HTM

tomsn048@gmail.com

Installation

1. NOTE: Use Silicone Gasket and Sealant F6AZ-19562-AA or equivalent meeting Ford

specification WSE-M4G323-A6.

Apply sealant and install the left valve cover and a new gasket. Tighten the bolts to 14 Nm (10 lb-ft).

2. NOTE: Use Silicone Gasket and Sealant F6AZ-19562-AA or equivalent meeting Ford

specification WSE-M4G323-A6.

Apply sealant and install the right valve cover and a new gasket. Tighten the bolts to 14 Nm (10 lb-ft).

3. Route the left side spark plug wires and connect the wires to the locators on the valve cover and to

the spark plugs.

4. NOTE: Tighten the bolts in sequence in two steps.

Remove the tape from the lower intake manifold and install a new gasket. Install upper intake

manifold, and the three bolts and the three stud bolts. Tighten the bolts in two steps. Tighten to 20

Nm (14 (lb-ft) then tighten to 25 Nm (18 lb-ft). Route and connect the PCV valve and hose.

5. Connect the brake booster vacuum, EGR valve and the engine vacuum harness to the upper intake

manifold.

6. Install the coil and bracket assembly to the upper intake manifold. Install the coil bracket brace to the

bracket and exhaust manifold. Tighten the retainers to 18 Nm (13 lb-ft).

7. Connect the wiring connectors to the coil connector, radio noise suppressor, EVR vacuum and

electrical connectors, left side spark plug wires to the coil and right side spark plug wires to the spark

plugs.

8. Connect the right side valve cover harness locators. Connect the heater control vacuum hose source

to the engine vacuum harness. Connect the IAT harness locator to the generator bracket.

9. Install the EGR valve tube. Tighten the tube nut to 20 Nm (15 lb-ft). Tighten the bolt to 16 Nm (11 lbft). Connect the DPFE vacuum hoses and electrical connector.

10. Connect the throttle cable (09A758A) and speed control cable (9A825) to the throttle body and

locator. Install the bracket with cables attached to the throttle body. Tighten the bolts to 10 Nm (89 lbin).

11. Connect the canister purge hose to the valve and the locator to the accelerator control bracket. Install

the accelerator control splash shield.

12. Connect the wiring connectors to the TPS and IAC and the 42-pin connector to the bracket at the rear

of the intake manifold.

13. Install the outlet tube and tighten the clamps securely. Connect the crankcase ventilation hose to the

air cleaner outlet tube. Connect the wiring connectors to the MAF sensor, IAT sensor, and the

harness locator to the outlet tube.

14. NOTE: When the battery has been disconnected and reconnected, some abnormal drive

Page 3

adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the

Item

Page

3

of 41997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B14.HTM~gen~ref.HTM

tomsn048@gmail.com

strategy.

Connect battery ground cable .

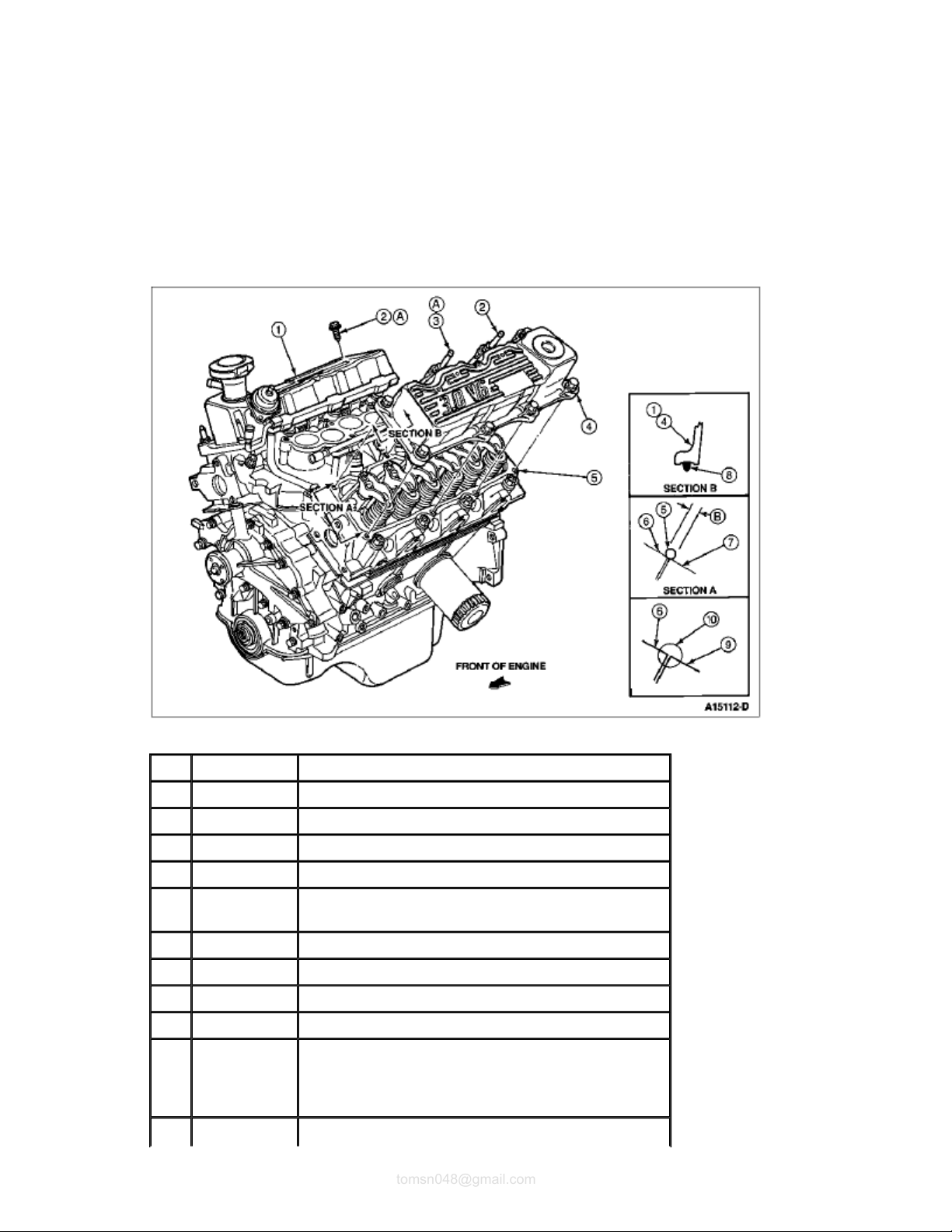

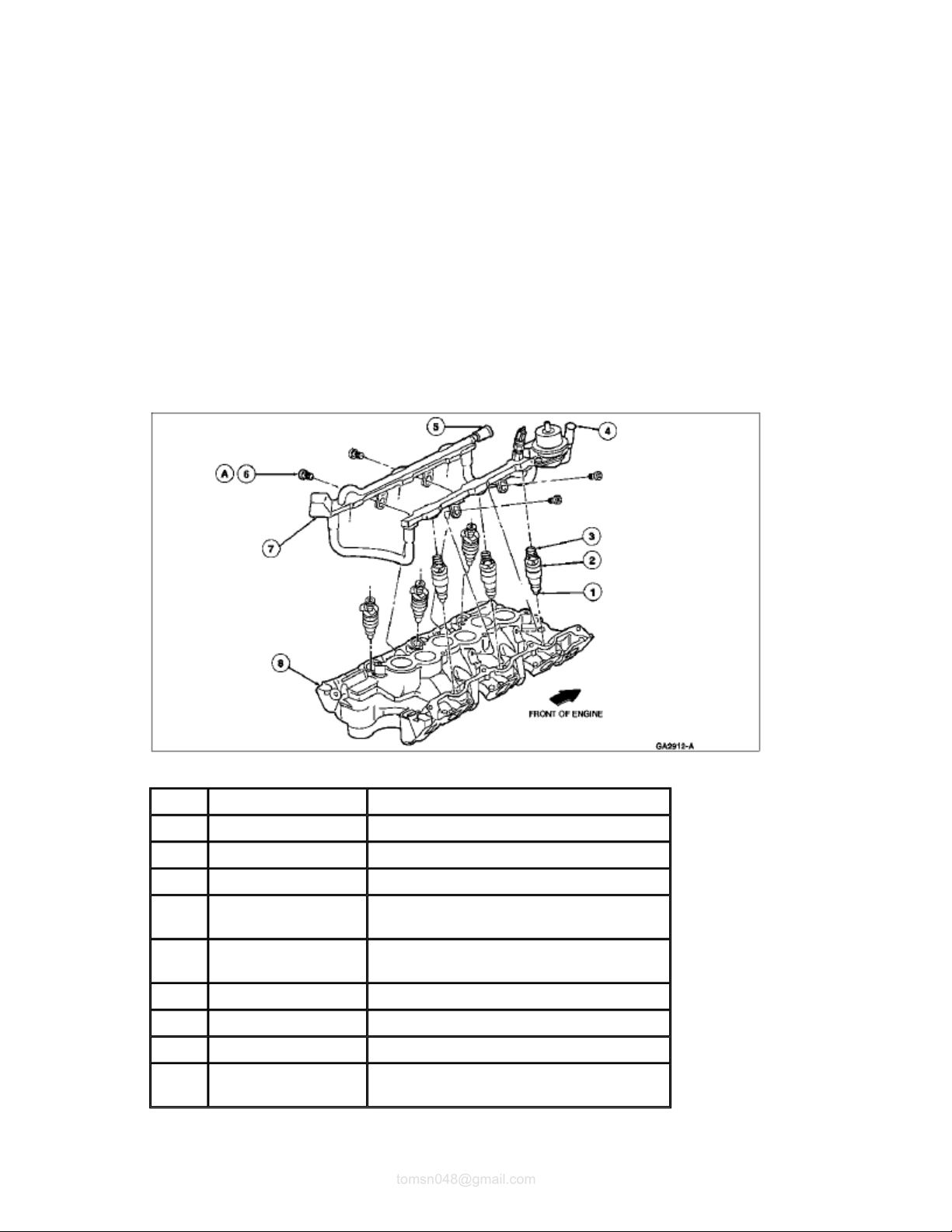

Valve Cover Installation, Ranger

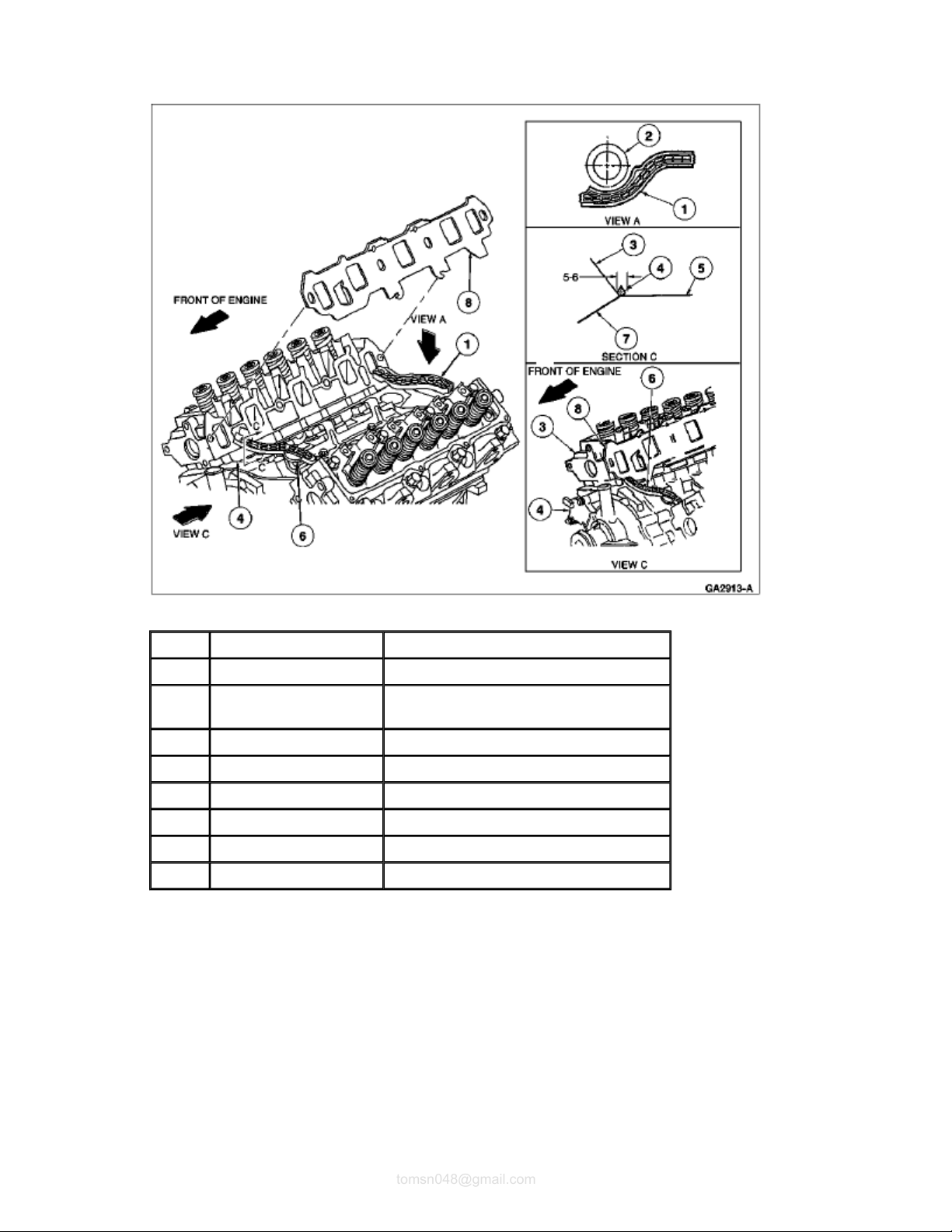

Part Number Description

1 6582 Valve Cover (RH)

2 N803298-S Screw and Washer

3 N803262-S Stud

4 6582 Valve Cover (LH)

5 ESE-

M4G195-B

6 9424 Intake Manifold

7 6049 Cylinder Head

8 6584 Valve Cover Gasket

9 6049 Cylinder Head

10 — Intersection of Head and Intake Manifold Must Be

A — Tighten to 10-14 Nm

Sealer

Flush to Within ± 1mm

(0.04 In.). Gasket Must Not Protrude Above Highest

Surface.

Page 4

Page

4

of 41997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B14.HTM~gen~ref.HTM

tomsn048@gmail.com

(7-10 Lb-Ft)

B — 4-6mm (.15-.23 In.)

Page 5

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 11997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B15.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Rocker Arm

Refer to Valve Tappet, Hydraulic In-Vehicle Service for removal and installation of the rocker arms. Perform

only the steps necessary to remove the rocker arms.

Page 6

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 61997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B16.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Valve Tappet, Hydraulic

NOTE: Before replacing a tappet for noisy operation,

make sure the noise is not caused by improper

valve-to-rocker arm clearance or by worn rocker arms or push rods. Refer to Section 03-00 .

Removal

1. NOTE: On 3.0L Aerostar it is necessary to remove the engine (6007) from the vehicle to

perform this procedure. Refer to Engine Assembly, Aerostar , Removal and Installation, in this

section.

Disconnect ground cable at battery and set aside.

2. Drain engine cooling system.

3. Remove PCV closure hose from valve cover (6582) and air cleaner outlet tube.

4. Remove air cleaner outlet tube from throttle body (9E926) and engine air cleaner (ACL) (9600).

5. WARNING: COVER THE VALVE WITH A SHOP RAG TO PREVENT ACCIDENTAL FUEL

SPRAY INTO THE EYES.

Carefully relieve fuel pressure at fuel supply manifold fuel pressure relief valve as outlined in Section

03-04B .

6. Remove fuel tube clips. Disconnect fuel lines as outlined in Section 03-04B .

7. Mark location of vacuum lines and remove.

8. Disconnect electrical connectors of:

Intake air temperature sensor (IAT sensor) (12A697)

Idle air control valve (IAC valve) (9F715)

Engine coolant temperature sensor (ECT sensor) (12A648)

Camshaft position sensor (12A112)

Ignition coil

Radio ignition interference capacitor (18801)

Water temperature indicator sender unit (10884)

EGR pressure sensor, if equipped

EGR vacuum regulator control, if equipped

9. Disconnect upper radiator hose from thermostat housing. After loosening hose clamp, use a twisting

motion on hose to loosen from housing.

Page 7

10. Remove ignition coil and bracket assembly (two nuts) from top of throttle body and pencil brace at

rag in the tappet valley to catch any gasket material. After scraping, carefully lift cloth from tappet

Page

2

of 61997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B16.HTM~gen~ref.HTM

tomsn048@gmail.com

exhaust manifold.

11. Remove throttle body, refer to Section 03-04B .

12. Disconnect fuel injector harness retaining standoffs from inboard rocker arm cover studs. Carefully

disconnect electrical connections to each fuel injector and remove fuel charging wiring (9D930) from

engine.

13. Disconnect heater water hoses at engine.

14. Remove spark plug wire set (12281) from spark plugs (12405) by using a twisting motion on the

rubber boot. Remove harness retaining standoffs from rocker arm cover studs.

15. Remove valve covers as outlined in this section.

16. NOTE: Intake manifold (9424) may be removed with fuel injection supply manifold (9F792) and

fuel injectors in place.

Remove intake manifold retaining bolts using a Torx® head socket. Before attempting to remove

intake manifold, break the seal between the manifold and cylinder blocks (6010). Wedge a large

screwdriver or similar heavy-duty tool between the intake manifold and the cylinder blocks. Pry

upward on the tool using the lug on top of the engine front cover (6019) as a leverage point. Removal

of generator (GEN) (10300) may be required for this step. Use care to prevent damage to machined

surfaces.

17. Loosen rocker arm bolt of the valve tappet (6500) to be replaced enough to allow the rocker arm

(6564) to be lifted off the push rod (6565) and rotated to one side.

18. Remove push rods. If more than one is removed, identify each push rod's location. The push rods

should be installed in their original location and position during reassembly.

19. Loosen roller tappet guide plate retainer bolts (2). Remove tappet guide plate retainer from tappet

valley.

20. Remove valve tappet guide plate (6K512) from valve tappets by lifting straight up.

21. NOTE: If the valve tappets are stuck in the bore(s) due to excessive varnish or gum deposits, it

may be necessary to use a claw-type tool to aid removal. Work the valve tappet in and out of

the lifter bore to loosen it from the deposits.

To remove, grasp valve tappet and pull in line with bore.

nstallation

I

NOTE: Lightly oil all bolt and stud threads before installation.

1. CAUTION: Aluminum components gouge easily, which may result in gasket leaks.

Always use care when scraping aluminum gasket surfaces.

Clean mating gasket surfaces of intake manifold and cylinder head (6049). Lay a clean cloth or shop

Page 8

valley preventing any particles to enter oil drain holes or cylinder head. Use a suitable solvent to

Page

3

of 61997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B16.HTM~gen~ref.HTM

tomsn048@gmail.com

remove old rubber sealant.

2. Lubricate valve tappets and bore with Engine Assembly Lubricant D9AZ-19579-D or equivalent

meeting Ford specification ESR-M99C80-A.

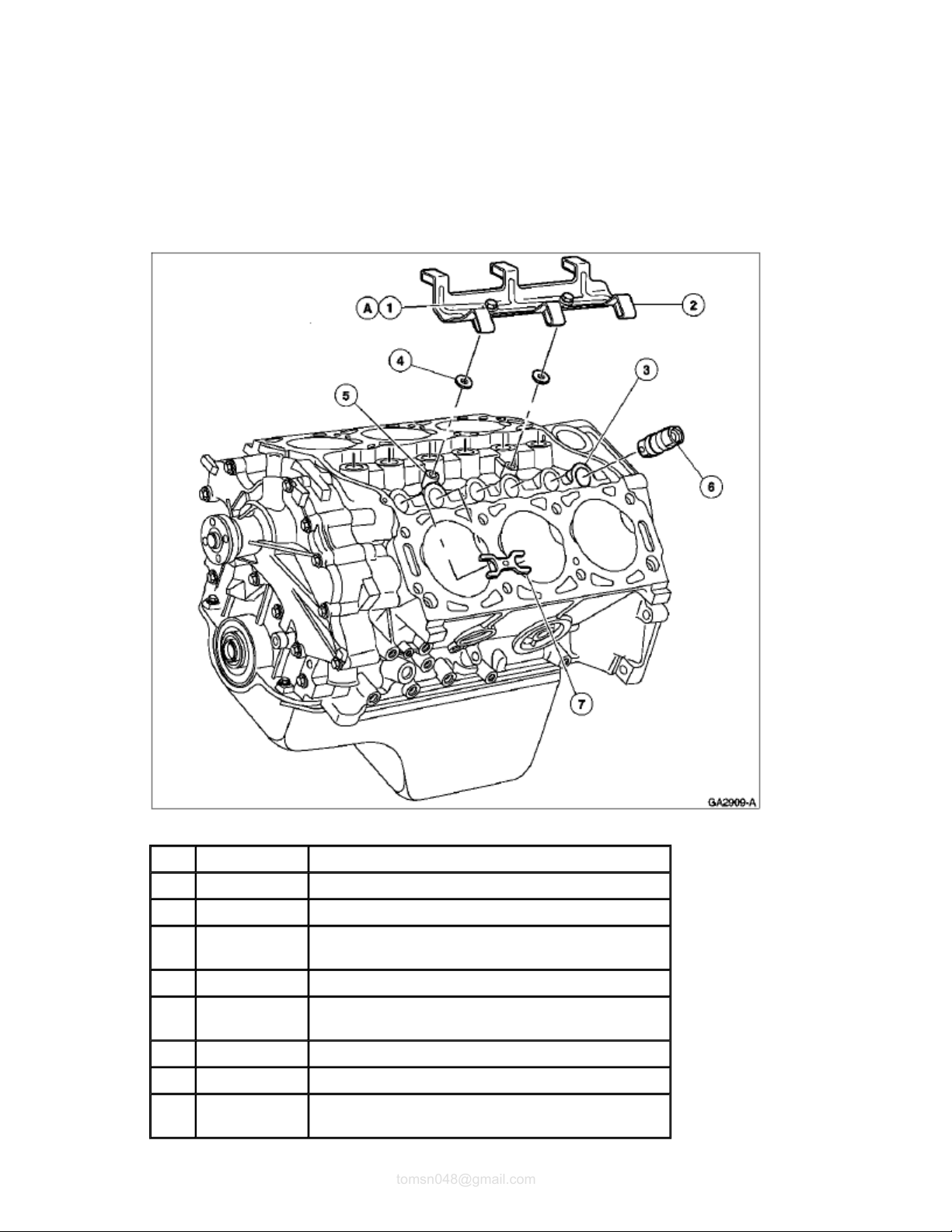

Item Part Number Description

1 — Bolt (Part of 6K564)

2 6K564 Tappet Guide Plate and Retainer

3 — Cylinder Block Assembly Tappet Bore

(Part of 6010)

4 — Washer (Part of 6K564)

5 — Cylinder Block Assembly Guide Plate Retainer

(Part of 6010)

6 6500 Valve Tappet

7 6K512 Valve Tappet Guide Plate

A — Tighten to 10-14 Nm

(7-10 Lb-Ft)

Page 9

3. Install valve tappet into bore.

in rocker arm and lifter sockets prior to final

-

tightening.

Page

4

of 61997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B16.HTM~gen~ref.HTM

tomsn048@gmail.com

4. NOTE: Install plate with the word "UP" and button visible.

Align valve tappet flats. Install valve tappet guide plate.

5. Install tappet guide plate retainer over valve tappet guide plates. Retainer orientation is not important.

Hand-start two retaining bolts. Tighten bolts to 10-14 Nm (7-10 lb-ft).

6. Apply a 5-6mm drop of Silicone Rubber D6AZ-19562-AA or -BA or equivalent meeting Ford

specification ESB-M4G92-A or ESE-M4G195-A to intersection of cylinder block and cylinder head

assembly at four corners as shown in the illustration under Intake Manifold in this section.

7. Position intake manifold gaskets (9439) onto cylinder heads. Align the intake gasket locking tabs to

the provisions on the cylinder head gaskets as shown in the illustration.

8. Install front and rear intake manifold seals as shown in the illustration under Intake Manifold in this

section. Secure with retaining features.

9. Lower intake manifold into position aligning manifold bolt holes to those in the cylinder head. Use

care to prevent disturbing the rubber sealer which can cause sealing voids. Install bolts 1, 2, 3 and 4

and hand-snug. Install remaining bolts and tighten in a two-step process. Tighten in numerical

sequence to 15 Nm (11 lb-ft), then again to 26-32 Nm (19-24 lb-ft).

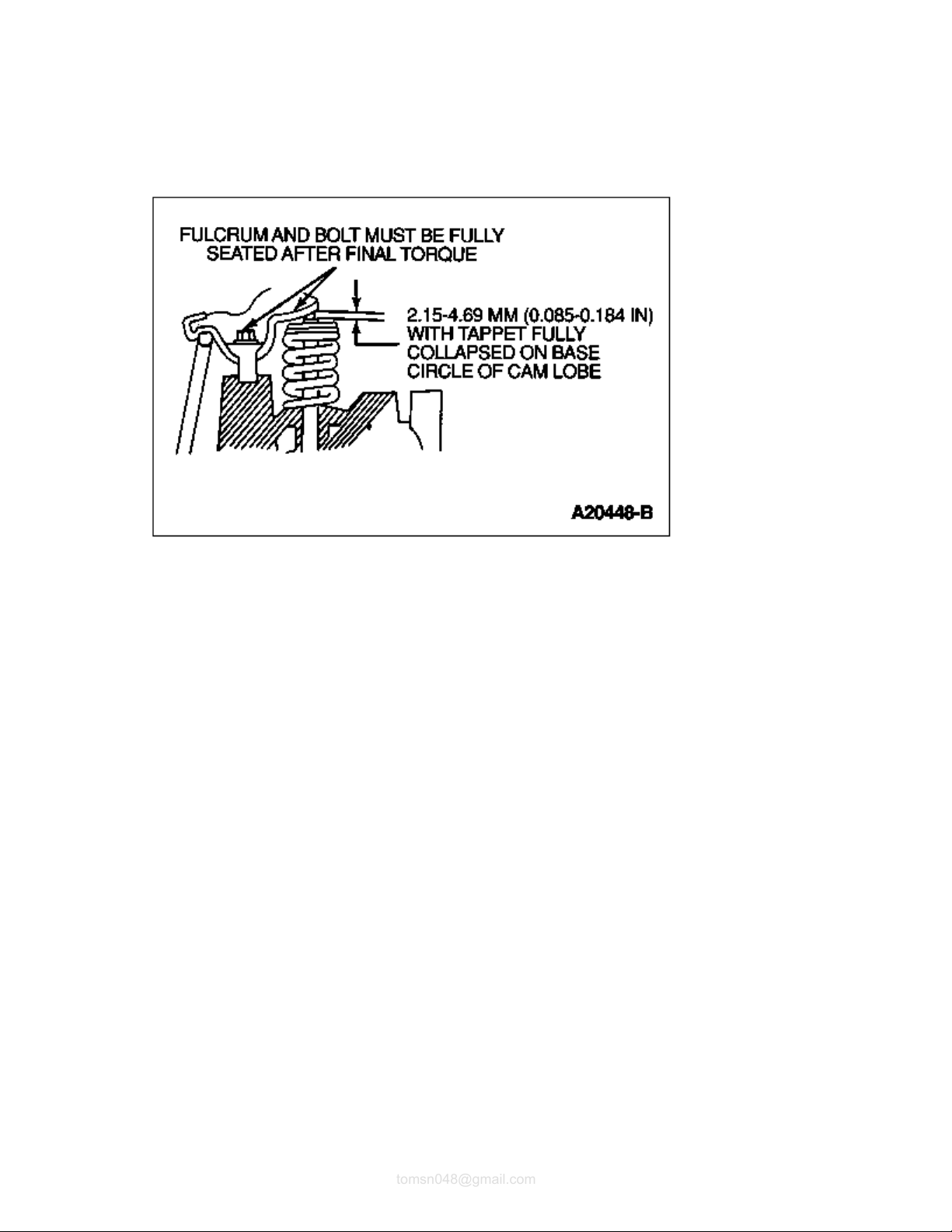

10. NOTE: Rocker arm must be fully seated into cylinder head and push rod must be fully seated

Page 10

Apply ESE-M2C39-F oil to removed push rods and rocker arms. Install push rods. Move rocker arms

adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the

Page

5

of 61997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B16.HTM~gen~ref.HTM

tomsn048@gmail.com

into position with push rod and snug rocker arm bolts. Rotate crankshaft (6303) to position camshaft

lobe(s) straight down and away from push rods. Tighten rocker arm bolt to 11 Nm (8 lb-ft) to seat

rocker arm into cylinder head. Final-tighten bolt to 26-38 Nm (19-28 lb-ft).

11. Install valve covers as outlined in this section.

12. Install fuel charging wiring to each fuel injector. Secure with standoffs to inboard rocker arm cover

studs.

13. Install throttle body assembly and new intake manifold upper gasket (9H486) as outlined in Section

03-04B . Install ignition coil and bracket assembly (Ranger only). Tighten retaining nuts to 16-20 Nm

(12-15 lb-ft).

14. Install spark plug wire set and bracket RH and/or spark plug wire set LH. Install wire harness

standoffs to rocker arm cover studs and connect wires to spark plugs and ignition coil.

15. Install fuel lines to fuel injection supply manifold as outlined in Section 03-04B .

16. Install fuel tube clips.

17. Install upper radiator hose and heater water hoses. Tighten hose clamps securely.

18. Connect vacuum lines to premarked locations.

19. Connect electrical connections of:

Intake air temperature sensor

Idle air control valve (IAC valve)

Engine coolant temperature sensor

Distributor

Ignition coil

Radio ignition interference capacitor

Water temperature indicator sender unit

EGR pressure sensor, if equipped

EGR vacuum regulator control, if equipped

Refer to Section 18-01 for further information.

20. NOTE: Engine coolant is corrosive to all engine bearing material. Replacing oil after removal

of a coolant carrying component prevents failure later.

Fill and bleed cooling system with specified coolant and proper mixture.

21. Replace crankcase oil and filter.

22. Install air cleaner outlet tube to throttle body and engine air cleaner. Tighten retaining clamps to 1.9

Nm (17 lb-in).

23. Install PCV closure hose to valve cover and air cleaner outlet tube.

24. NOTE: When the battery has been disconnected and reconnected, some abnormal drive

symptoms may occur while the powertrain control module (PCM) (12A650) relearns its

Page 11

strategy.

Page

6

of 61997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B16.HTM~gen~ref.HTM

tomsn048@gmail.com

Connect ground cable at battery.

25. Start engine and check for coolant, oil fuel and vacuum leaks.

26. Verify and correct default base initial engine timing to 10 degrees BTDC. Refer to the Powertrain

Control/Emissions Diagnosis Manual.

Page 12

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Intake Manifold

Upper

Refer to Section 03

-04B for throttle body removal and installation procedures.

Lower

Removal

1. Disconnect ground cable at battery and set aside.

2. Drain engine cooling system.

3. Remove PCV closure hose from valve cover (6582) and air cleaner outlet tube.

4. Remove air cleaner outlet tube from throttle body (9E926) and engine air cleaner (ACL) (9600).

5. CAUTION: Cover the fuel pressure relief valve with a shop rag to prevent accidental fuel

spray into the eyes.

Carefully relieve fuel pressure at fuel pressure relief valve as outlined in Section 03

-04B .

6. Remove fuel tube clips. Disconnect fuel supply and return lines as outlined in Section 03-04B .

7. Mark location of vacuum lines and remove.

8. Disconnect electrical connectors of:

Intake air temperature sensor (IAT sensor) (12A697)

Idle air control valve (IAC valve) (9F715)

Engine coolant temperature sensor (ECT sensor) (12A648)

Camshaft position sensor (12A112)

Ignition coil

Radio ignition interference capacitor (18801)

Water temperature indicator sender unit (10884)

EGR pressure sensor, if equipped

EGR vacuum regulator control, if equipped

Refer to Section 18-01 for further information.

Page 13

15.

Remove valve covers as outlined in this section.

Page

2

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

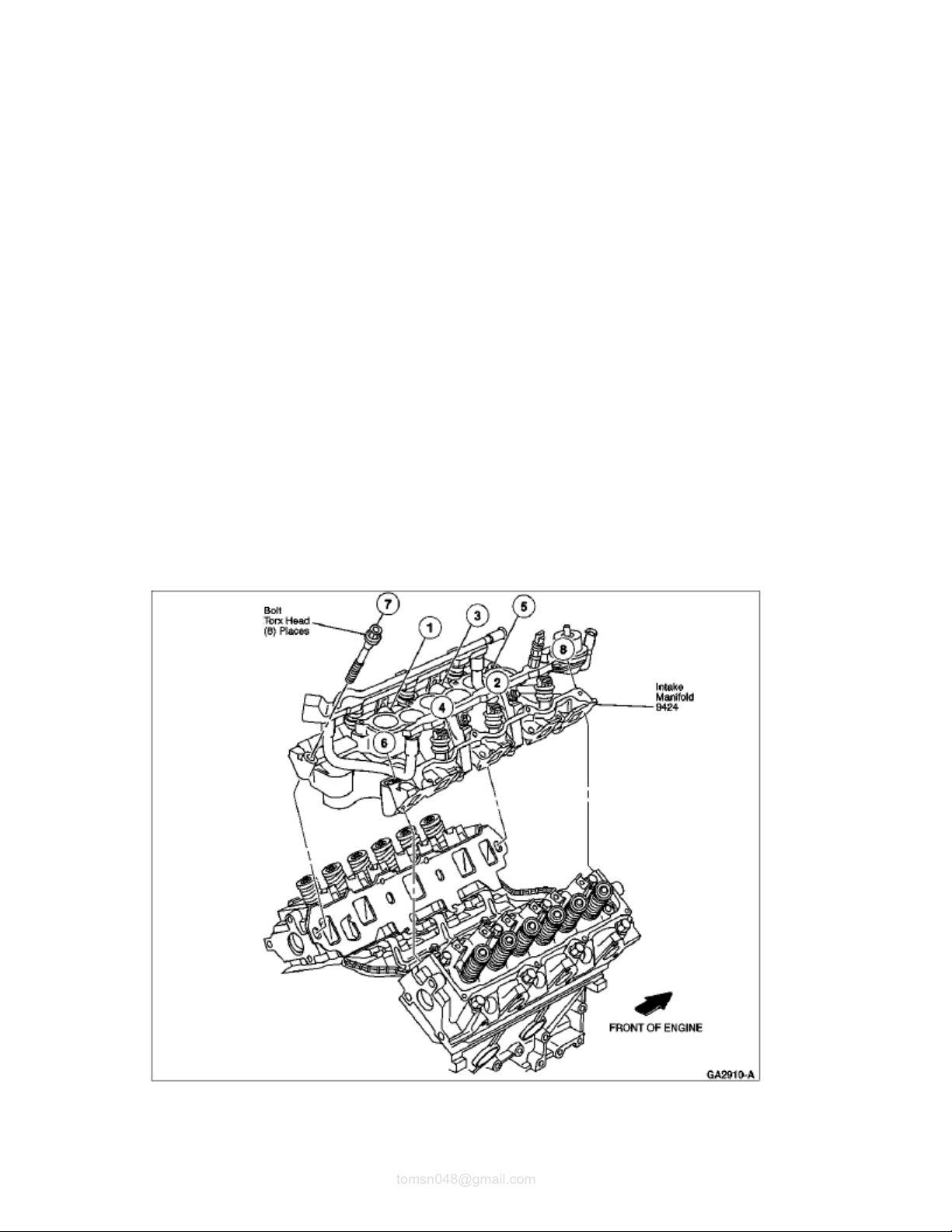

Item Part Number Description

1 12A648 Engine Coolant Temperature Sensor(Ranger)

2 124648 Engine Coolant Temperature Sensor (Aerostar)

3 9424 Intake Manifold

4 806344 Heater Elbow

5 18599 Hot Water Heater Elbow Connection

6 10884 Water Temperature Indicator Sender Unit

A — Tighten to 16-24 Nm

(12-17 Lb-Ft)

9. Disconnect upper radiator hose from thermostat housing connection. After loosening hose clamp, use

a twisting motion on hose to loosen from housing.

10. Remove ignition coil and bracket assembly (two nuts) from top of throttle body and pencil brace at

exhaust manifold.

11. Remove throttle body as outlined in Section 03

12. Disconnect fuel charging wiring retaining standoffs from inboard rocker arm cover studs. Carefully

disconnect electrical connections to each fuel injector and remove harness from engine.

13. Disconnect heater water hoses.

14. Remove spark plug wire set (12281) from spark plugs (12405) by using a twisting motion on the

rubber boot. Remove harness retaining standoffs from rocker arm cover studs.

-04B .

Page 14

16. Loosen cylinder No. 3 intake valve rocker arm bolt and rotate rocker arm (6564) off push rod (6565)

Page

3

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

and away from top of valve stem. Remove push rod.

NOTE: Intake manifold (9424) may be removed with fuel injector and fuel injection supply manifolds

(9F792) in place.

17. Remove intake manifold retaining bolts using a Torx® head socket. Before attempting to remove

intake manifold, break the seal between the intake manifold and cylinder blocks (6010). Wedge a

large screwdriver or similar heavy-duty tool between the manifold and the block. Pry upward on the

tool using the lug on top of the front cover as a leverage point. Removal of generator (GEN) (10300)

may be required for this step. Use care to prevent damage to machined surfaces.

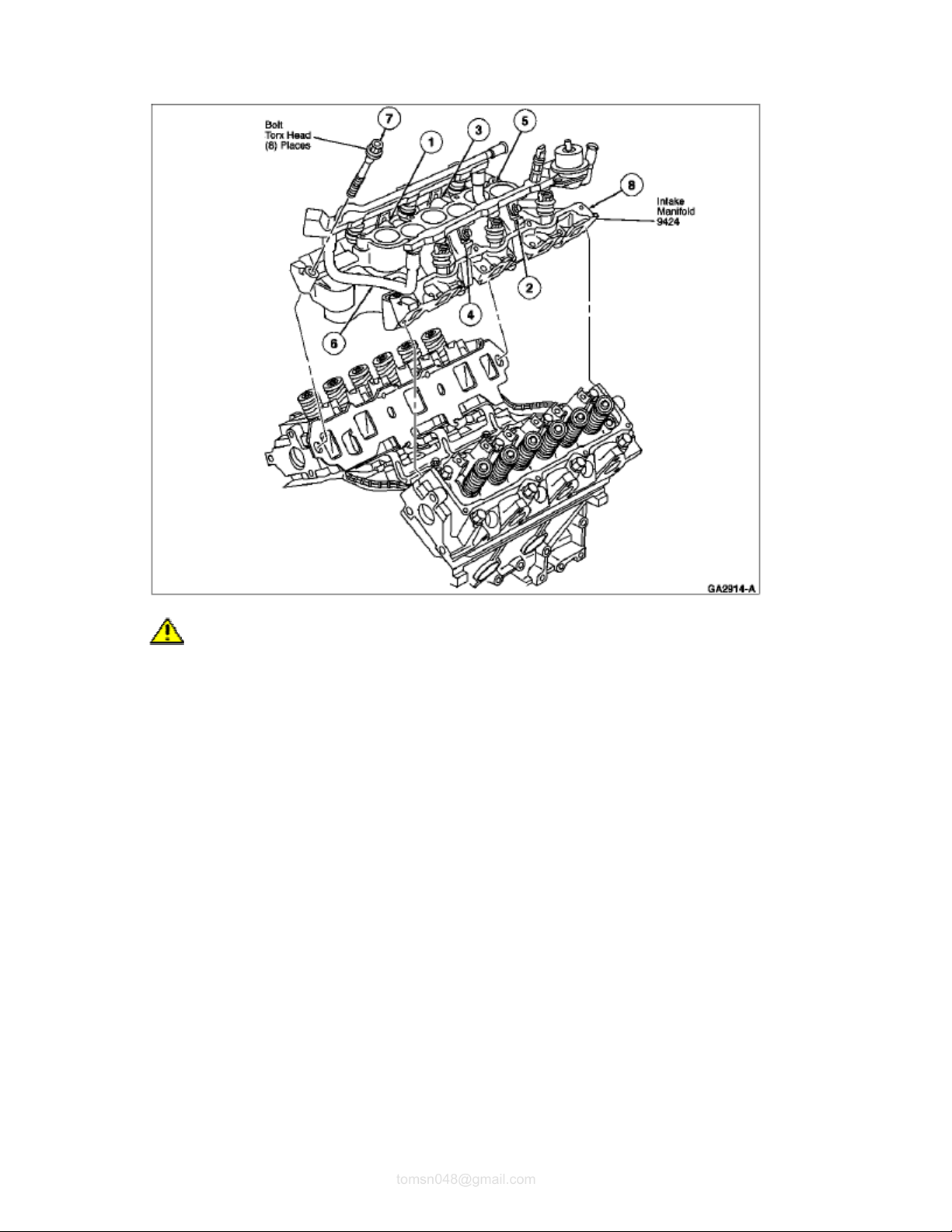

Fuel Rail and Injectors to Intake Manifold, Installation

Item Part Number Description

1 — Outlet End (Part of 9F593)

2 9F593 Fuel Injector

3 — Inlet End (Part of 9F593)

4 — Black Shipping Cap

(Part of 9F593)

5 — Green Shipping Cap

(Part of 9F593)

6 N802353-S100 Bolt

7 9F792 Fuel Injection Supply Manifold

8 9424 Intake Manifold

A — Tighten to 8-12 Nm

(71-106 Lb-In)

Page 15

Page

4

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

Installation

NOTE: Lightly oil all retaining bolt and stud threads before installation.

CAUTION: Aluminum components gouge easily which may cause gasket to leak. Always use

care when scraping aluminum gasket surfaces.

1. Clean mating gasket surfaces of intake manifold and cylinder blocks. Lay a clean cloth or shop rag in

the tappet valley to catch any gasket material. After scraping, carefully lift cloth from tappet valley

preventing any particles from entering oil drain holes or cylinder head. Use a suitable solvent to

remove old rubber sealant.

2. If installing new intake manifold, transfer:

Fuel injectors

Fuel injection supply manifold

Engine coolant temperature sensor

Water thermostat (8575)

Water thermostat housing

Hot water heater elbow connection (18599) by-pass fitting (18599).

Coolant temperature sending unit

3. Apply a 5-6mm drop of Silicone Rubber D6AZ-19562-AA or -BA or equivalent meeting Ford

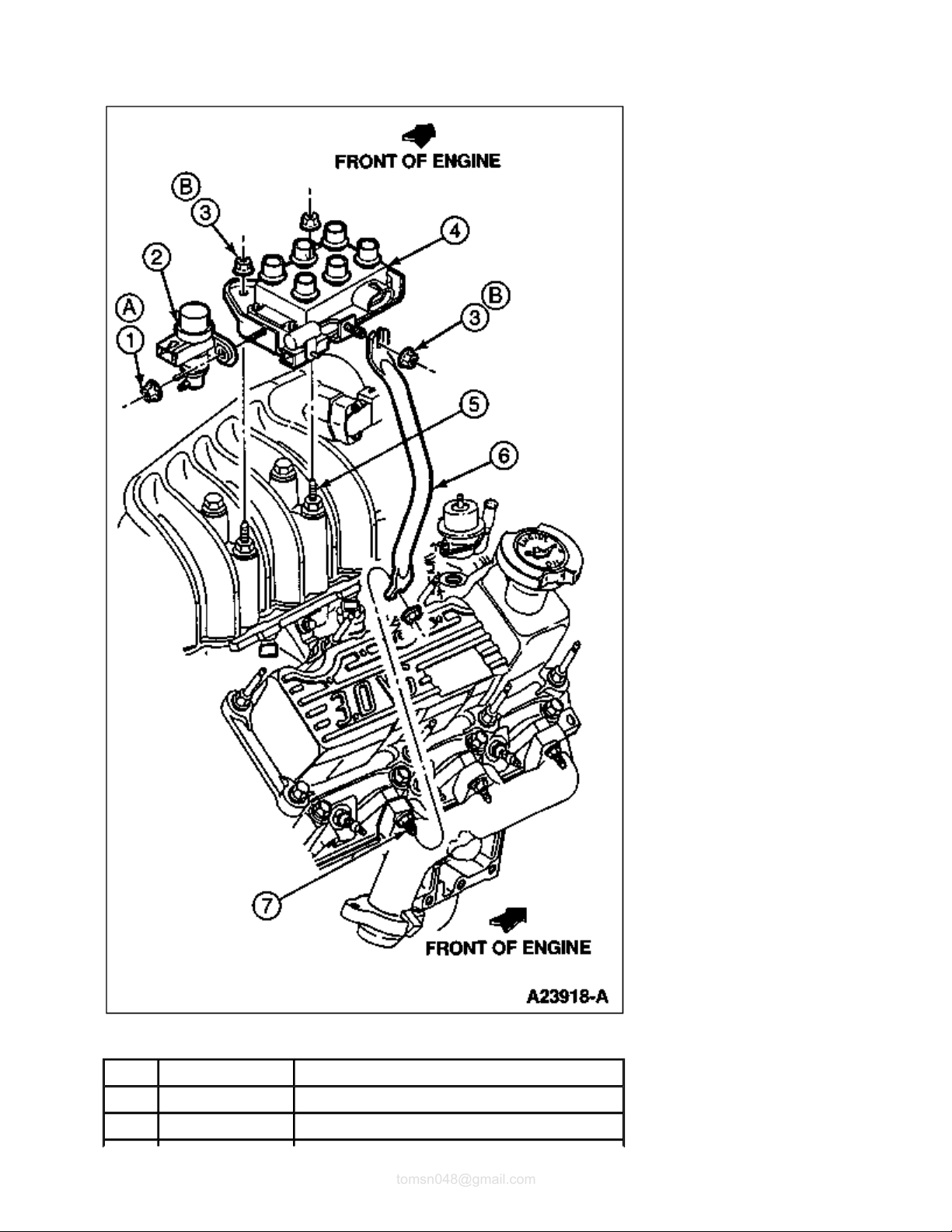

specification ESB-M4G92-A or ESE-M4G195-A to intersection of cylinder blocks and cylinder head

(6049) at four corners as shown in the illustration.

4. Position intake manifold gaskets (9439) onto cylinder heads. Align the intake gasket locking tabs to

the provisions on the cylinder head gaskets as shown in the illustration.

Intake Manifold Gasket, Installation

Page 16

Page

5

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 9A424 Seal, Intake Manifold, Rear

2 — Distributor Hole

(Part of Cylinder Block)

3 6049 Cylinder Head

4 ESE-M4G195-B Sealer (4 places)

5 6010 Cylinder Blocks

6 9A424 Seal, Intake Manifold, Front

7 6051 Head Gasket

8 9439 Intake Manifold Gasket

5. Install front and rear intake manifold seals as shown in the illustration. Secure with retaining features.

6. Lower intake manifold into position aligning manifold bolt holes to those in the cylinder head. Use

care to prevent disturbing the rubber sealer which can cause sealing voids. Install bolts 1, 2, 3 and 4

and hand-snug. Install remaining bolts and tighten in a two-step process. Tighten in numerical

sequence to 15 Nm (11 lb-ft), then again to 26-32 Nm (19-24 lb-ft).

Intake Manifold Bolt Torquing Sequence

Page 17

Page

6

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

7. CAUTION: If a new distributor or camshaft position sensor is installed, be sure to add the

rest of the pint of Engine Assembly Lubricant D9AZ-19579-D or equivalent meeting Ford

specification ESR-M99C80-A to the engine oil by pouring it through the distributor hole onto

the cam drive gear. Run engine at idle for five minutes before driving vehicle.

Dip entire distributor or camshaft position sensor drive gear in Engine Assembly Lubricant D9AZ19579-D or equivalent meeting Ford specification ESR-M99C80-A.

8. NOTE: Rocker arm fulcrum must be fully seated into cylinder head and push rod must be fully

seated in rocker arm and lifter sockets prior to final tightening.

Apply Engine Assembly Lubricant D9AZ-19579-D or equivalent meeting Ford specification ESRM99C80-A to cylinder No. 3 intake valve push rod and rocker arm. Install push rod. Move rocker arm

into position with push rod and snug rocker arm bolt. Rotate crankshaft (6303) to position camshaft

lobe straight down and away from valve tappet (6500). Tighten retaining bolt to 11 Nm (8 lb-ft) to seat

rocker arm fulcrum into cylinder head. Final-tighten bolt to 26-38 Nm (19-28 lb-ft) in any position.

9. Install valve covers as outlined in this section.

10. Install fuel charging wiring (9D930) to each fuel injector. Secure with standoffs to inboard rocker arm

cover studs.

Ignition Coil Installation

Page 18

Page

7

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 — Nut (Part of 12A310)

2 9J472 EGR Vacuum Regulator Bracket

Page 19

3 — Nut (Part of 12A310)

Page

8

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

4 12A310 Ignition Coil and Bracket Assembly

5 — Stud (Part of 9E926)

6 12N004 Ignition Coil Mounting Bracket

7 — Exhaust Manifold Stud

(Part of 9430)

A — Tighten to 8-12 Nm

(6-9 Lb-Ft)

B — Tighten to 16-20 Nm

(12-15 Lb-Ft)

11. Installthrottle body and newintake manifold gasketas outlined in Section 03-04B . Install coil and

bracket assembly (Ranger only). Tighten retaining nuts to 16-20 Nm (12-15 lb-ft).

12. Install wire harness standoffs to rocker arm cover studs and connect wires to spark plug and ignition

coil.

13. Install fuel supply and return lines to fuel injection supply manifold as outlined in Section 03-04B .

14. Install fuel tube clips.

15. Install upper radiator hose and heater water hoses. Tighten hose clamps securely.

16. Connect vacuum lines to premarked locations.

17. Connect electrical connections of:

Radio ignition interference capacitor

Idle air control valve

Engine coolant temperature sensor

Distributor

Ignition coil

Radio ignition interference capacitor

Water temperature indicator sender unit

EGR pressure sensor, if equipped

EGR vacuum regulator control, if equipped

Refer to Section 18-01 for further information.

18. NOTE: Engine coolant is corrosive to all engine bearing material. Replacing oil after removal

of a coolant carrying component prevents failure later.

Fill and bleed cooling system with specified coolant and proper mixture.

19. Replace crankcase oil and oil filter.

20. Install air cleaner outlet tube to throttle body and MAF sensor (12B579). Tighten retaining clamps to

1.9 Nm (17 lb-in).

21. Install closure hose to valve cover and air cleaner outlet tube.

Page 20

22. NOTE: When the battery has been disconnected and reconnected, some abnormal drive

Page

9

of 91997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B17.HTM~gen~ref.HTM

tomsn048@gmail.com

symptoms may occur while the powertrain control module (PCM) (12A650) relearns its

adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the

strategy.

Connect ground cable at battery.

23. Start engine (6007) and check for coolant, oil, fuel and vacuum leaks.

24. Verify and correct default base initial engine timing to 10 degrees BTDC. Refer to the Powertrain

Control/Emissions Diagnosis Manual. Tighten retaining bolt to 19-30 Nm (14-22 lb-ft).

Page 21

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Cylinder Head(s)

Removal

1. NOTE: On 3.0L Aerostar it is necessary to remove the engine (6007) from the vehicle to

perform this procedure. Refer to Engine Assembly, Aerostar

section.

Disconnect ground cable at battery and set aside.

2. Drain cooling system. Refer to Section 03-03 .

3. Remove:

Engine air cleaner outlet tube

Engine air cleaner

PCV closure hose

, Removal and Installation, in this

4. Remove throttle body (9E926) as outlined in Section 03-04B .

5. Remove engine oil filler adapter (Aerostar only).

6. Disconnect fuel lines as outlined in Section 03

-04B .

7. Mark vacuum line location and remove lines.

8. Disconnect upper radiator hose and heater water hoses and move out of the way.

9. Disconnect spark plug wires from spark plugs with a turning motion and remove spark plug wire

separators from valve cover retaining pins.

10. Remove ignition coil and bracket from top of throttle body and pencil at exhaust manifold.

11. Remove spark plugs (12405) and bring number one piston to top dead center of the compression

stroke.

12. Remove intake manifold (9424) as outlined.

13. Remove engine accessory drive belt (8620).

14. On Ranger only:

a. Recover refrigerant from A/C system. Refer to Section 12

-00 .

b. Disconnect liquid line at condenser and suction hose from accumulator.

c. Plug or cap all openings in the air conditioning system to keep dirt, foreign material and excess

moisture out of the system.

d. Remove 4 bolts securing A/C compressor to power steering pump support bracket and remove

A/C compressor and hoses assembly from vehicle.

Page 22

15. If left cylinder head is being removed, perform the following:

Page

2

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

a. Remove fuel line retaining bracket from stud bolt on left side of power steering pump support

bracket and remove stud bolt.

b. Loosen lower bolt on left side of power steering pump support bracket two or three turns, but

DO NOT REMOVE.

c. Remove three bolts securing power steering pump support bracket to front of left cylinder head

and carefully allow power steering pump and bracket to tilt forward.

d. Remove engine oil level indicator tube attaching nut from exhaust manifold stud. Remove oil

level indicator tube from exhaust manifold.

16. If right cylinder head (6049) is being removed, perform the following:

a. Disconnect wiring from generator.

b. Remove three generator bracket and adjusting arm retaining bolts. Remove generator/bracket

assembly from vehicle.

17. Remove exhaust inlet pipe or pipes and exhaust manifolds (9430) and exhaust manifold.

18. Loosen rocker arm bolts and remove rocker arm assemblies. Identify the location of each assembly.

The rocker arm assemblies must be installed in their original location during reassembly.

19. Remove push rods (6565). Identify the position of each rod. The push rods should be installed in their

original position during reassembly.

20. Remove cylinder head retaining bolts.

21. Remove cylinder heads.

22. Remove head gaskets (6051) and discard.

nstallation

I

NOTE: Lightly oil all bolt and threads before installation. Always use new bolts when installing a

cylinder head.

1. CAUTION: Aluminum components gouge easily. Gouges in aluminum components will

cause gaskets to leak.

Lay a clean shop rag in lifter valley to catch any gasket particles. Clean cylinder head, intake manifold

and cylinder head to block gasket surfaces. After scraping, lift cloth so no gasket material falls into

lifter valley. If the cylinder head was removed for a head gasket replacement, check the flatness of

the cylinder head and block gasket surfaces. Refer to Section 03-00 .

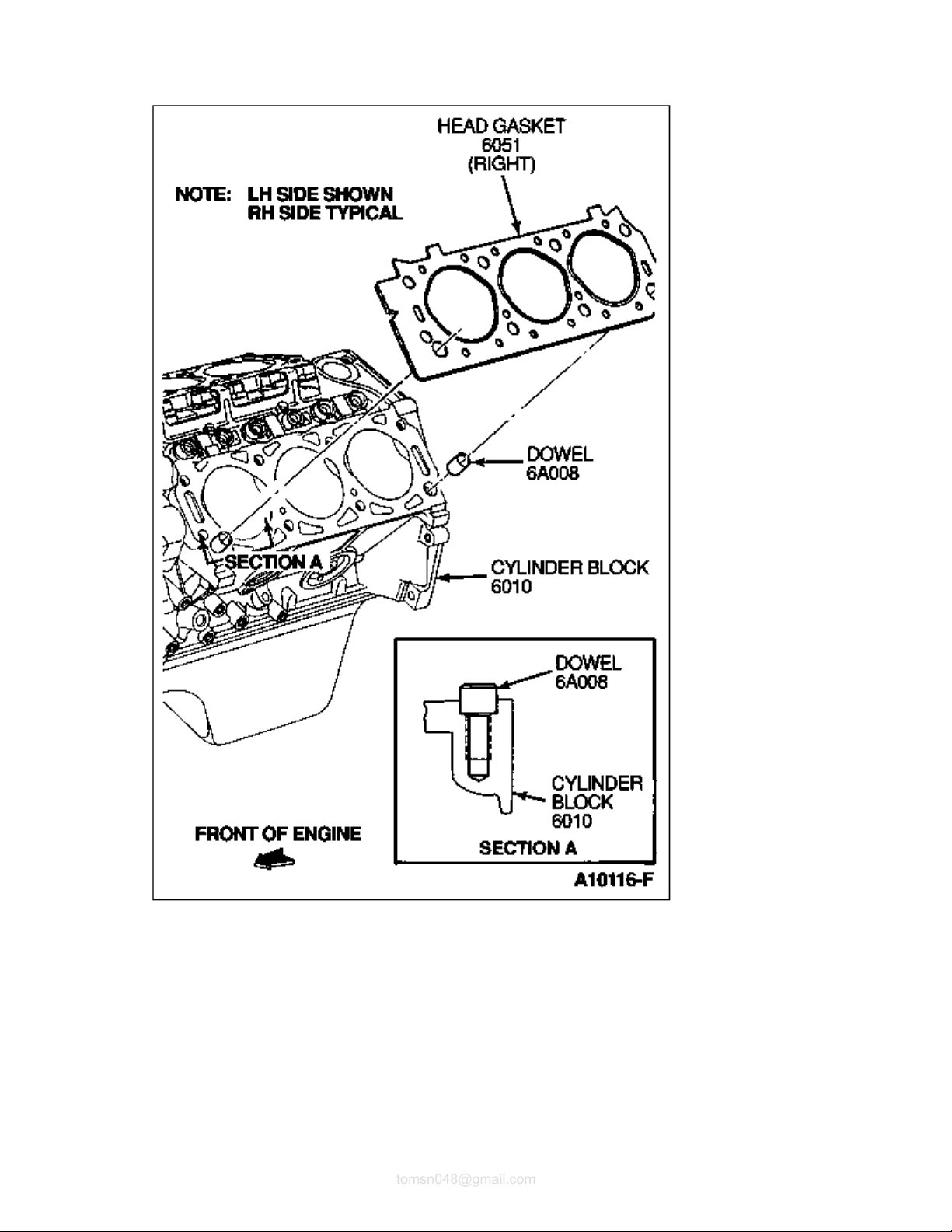

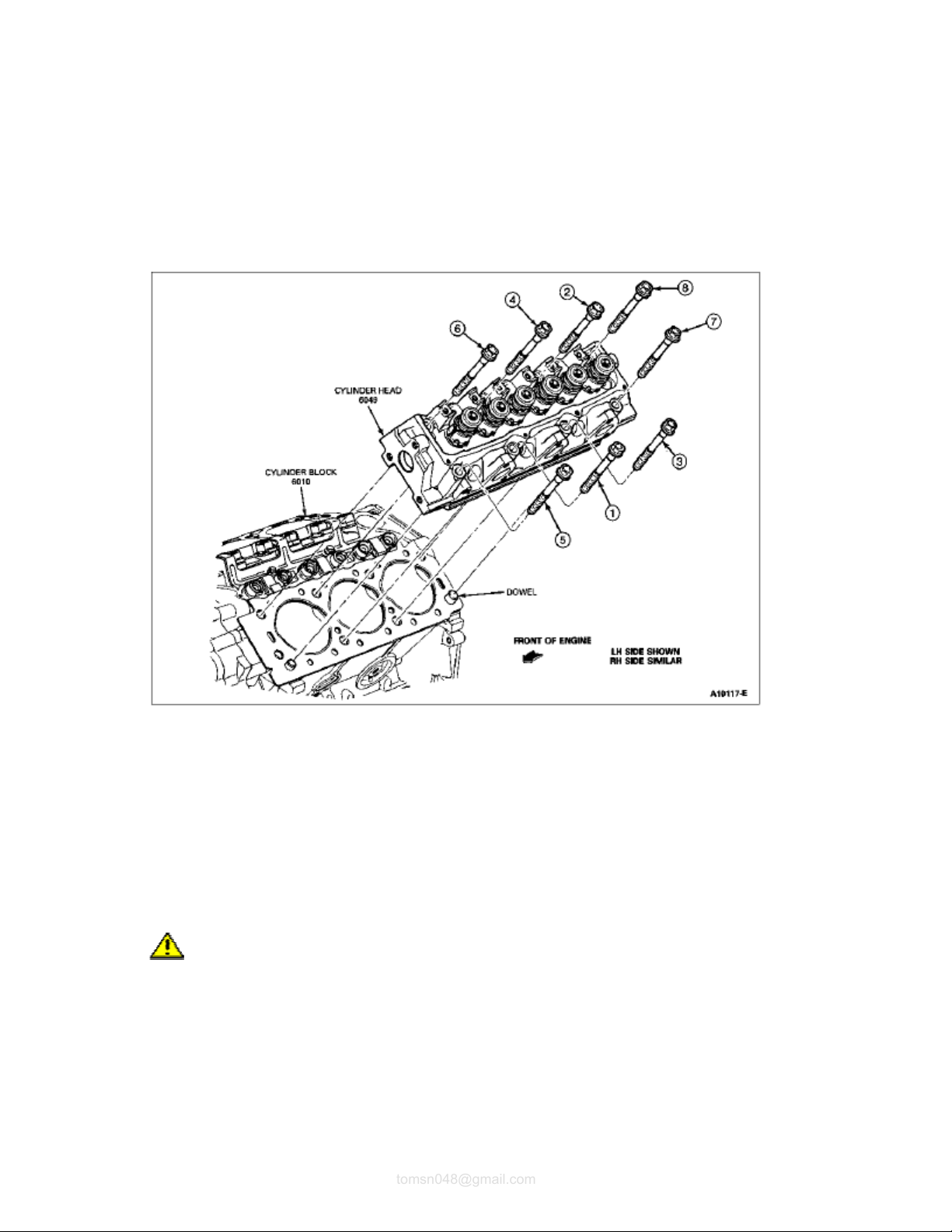

2. NOTE: Replace alignment dowels if damaged.

Position head gaskets on cylinder blocks (6010) using the dowels for alignment. Make sure gasket is

aligned as shown in the illustration.

Page 23

be checked for tightness if desired.

Page

3

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

3. Carefully position cylinder heads on cylinder blocks.

4. Install new cylinder head retaining bolts and hand tighten.

5. Tighten retaining bolts in sequence as illustrated to 80 Nm (59 lb-ft).

6. Back off all bolts a minimum of one full turn (360 degrees).

7. NOTE: When the cylinder head retaining bolts have been tightened using this procedure, it is

not necessary to retighten the bolts after extended engine operation. However, the bolts can

Page 24

Retighten the cylinder head retaining bolts in sequence in two tightening steps as follows:

required.

Page

4

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

45-55 Nm (33-41 lb-ft)

85-99 Nm (63-73 lb-ft)

Cylinder Head Assembly, Installation

8. Install intake manifold as outlined in this section.

9. Dip each push rod Engine Assembly Lubricant D9AZ-19579-D or equivalent meeting Ford

specification ESR-M99C80-A heavy engine oil. Install push rods in their original positions and

orientation.

10. Loosely install rocker arm assemblies in original locations. Apply Engine Assembly Lubricant D9AZ19579-D or equivalent meeting Ford specification ESR-M99C80-A heavy engine oil. Tighten rocker

arm fulcrum bolts to 10-12 Nm (8-10 lb/ft) while lifter is on base circle of corresponding cam lobe.

Final tighten rocker arm fulcrum bolts to 26-38 Nm (20-28 lb/ft).

11. CAUTION: Rocker arm fulcrum must be fully seated into cylinder head and push rods

must be fully seated in lifter and rocker arm sockets during final tightening.

NOTE: With number one piston at top dead center (TDC) of the exhaust stroke, you can tighten

intake rockers of cylinder numbers 1 and 4, and exhaust rockers of cylinder 2 and 5. With the

crankshaft rotated so number one piston is 135 degs. after top dead center (ATDC) of the

exhaust stroke, you can tighten intake rockers of cylinder numbers 2, 3, 5 and 6, and exhaust

rockers of cylinder numbers 1, 3, 4 and 6.

NOTE: If the original valve train components are being reused, a valve clearance check is not

Page 25

You must check rocker arm to valve tip clearance if a cam, lifters, push rods, rocker arms, rocker arm

Page

5

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

fulcrums or valves are replaced, or valves are ground.

12. Install valve covers as outlined in this section.

13. Install exhaust manifolds as outlined in this section. Tighten retaining bolts to 20-30 Nm (15-22 lb/ft).

Install inlet pipe retaining nuts, tighten to 39-42 Nm (30-32 lb/ft).

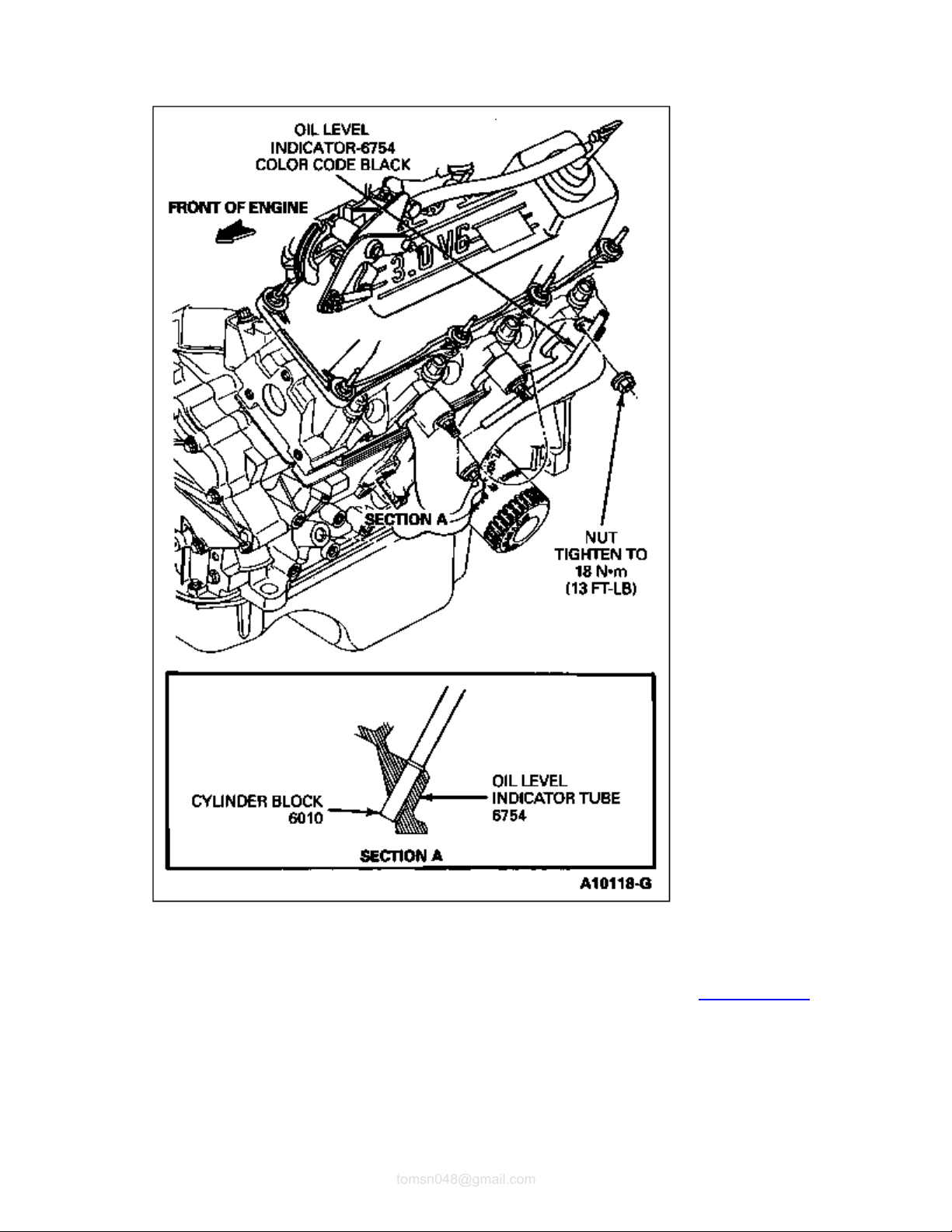

14. Apply Cup Plug Sealer meeting Ford specification ESE-M4621-A or equivalent to cylinder block.

Install oil level indicator tube into cylinder block. Oil level indicator tube must bottom out as illustrated.

Tighten oil level indicator tube retaining nut at exhaust manifold stud bolt to 16-20 Nm (12-14 lb/ft).

Page 26

Page

6

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

15. Install fuel charging wiring (9D930) to fuel injectors and inboard rocker arm cover studs. Connect fuel

charging wiring to engine control sensor wiring (12A581) and secure with retaining features.

16. Install throttle body and new intake manifold gasket (9439) as outlined. Refer to Section 03-04B .

17. If left cylinder head was removed, perform the following:

a. Install three bolts securing power steering pump support bracket to front of left cylinder head,

finger tight only.

b. Install stud bolt at left side of power steering pump support bracket. Tighten all five bolts

securing power steering pump support bracket to engine block and cylinder head to 40-62 Nm

Page 27

(30-46 lb/ft).

strategy.

Page

7

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

c. Install fuel line retaining bracket to stud bolt on left side of power steering pump support

bracket and secure with nut. Tighten nut to 16-20 Nm (12-15 lb/ft).

18. If right cylinder head was removed, perform the following:

a. Install generator (GEN) (10300) and generator bracket assembly. Tighten three retaining bolts

to 48 Nm (35 lb-ft).

b. Install generator brace and tighten nuts to 26-35 Nm (20-25 lb-ft).

c. Connect generator voltage regulator wiring.

19. On Ranger only:

a. Position A/C compressor and hose assembly on power steering pump support bracket. Install

4 bolts securing A/C compressor to power steering pump support bracket and tighten four

fasteners to 21-29 Nm (15-21 lb/ft).

b. Remove plugs and caps from all openings in the air conditioning system.

c. Connect liquid line at condenser and suction hose to accumulator.

d. Evacuate and recharge A/C system. Refer to Section 12

20. Install engine accessory drive belt.

21. Install ignition coil and bracket assembly to throttle body stud bolts and pencil brace at exhaust

manifold. Tighten three nuts to 16-20 Nm (12-14 lb/ft).

-00 .

22. Connect fuel lines to fuel injection supply manifold (9F792) as outlined in Section 03-04A . Install fuel

tube clips.

23. Connect upper radiator hose and heater water hoses. Tighten hose clamps securely. Refer to Section

03-03 .

24. Connect vacuum lines to premarked locations.

25. Install engine oil filler adapter (Aerostar only).

26. NOTE: Engine coolant is corrosive to all engine bearing material. Replacing engine oil after

removal of a coolant-carrying component prevents failure later.

Drain and change engine oil.

27. Install air cleaner outlet tube to throttle body and engine air cleaner (ACL) (9600). Tighten clamps

securely. Refer to Section 03-12 .

28. Install closure hose at air cleaner outlet tube and valve cover (6582).

29. CAUTION: This engine has aluminum components and requires a special corrosion-

inhibiting coolant formulation to avoid radiator damage. Refer to Section 03-03 for coolant

specifications.

Fill and bleed cooling system.

30. NOTE: When the battery has been disconnected and reconnected, some abnormal drive

symptoms may occur while the powertrain control module (PCM) (12A650) relearns its

adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the

Page 28

Connect ground cable at battery.

Page

8

of 81997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B18.HTM~gen~ref.HTM

tomsn048@gmail.com

31. Start engine and check for coolant, fuel, oil, vacuum and exhaust leaks.

32. Verify base ignition timing as outlined.

33. Check and, if necessary, adjust speed control linkage.

Page 29

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

A

Vibration Damper and Seal Replacer

Page

1

of 31997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B19.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

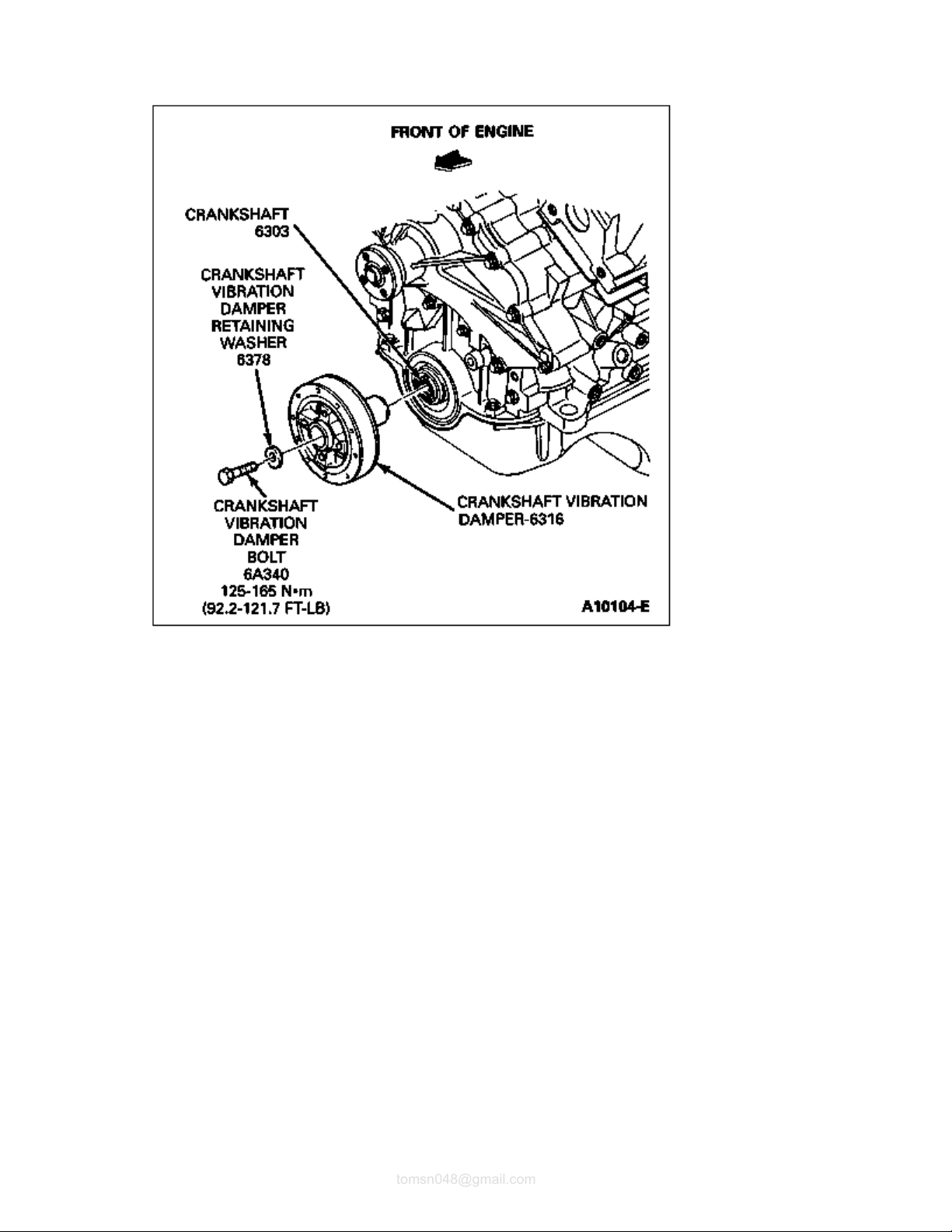

Crankshaft Pulley/Vibration Damper/Crankshaft Front Seal

SPECIAL SERVICE TOOL(S) REQUIRED

Description Tool Number

Front Cover Seal Replacer T70P-6B070Crankshaft Damper Remover T58P-6316-D

Vibration Damper Remover Adapter T82L-6316-B

T82L-6316-A

Removal

1. Disconnect ground cable at battery and set aside.

2. Remove air cleaner outlet tube assembly.

3. Remove drive belts.

4. Remove four pulley-to-damper retaining bolts.

5. Remove crankshaft pulley (6312).

6. Remove crankshaft vibration damper bolt and crankshaft vibration damper washer.

7. Remove crankshaft vibration damper from crankshaft (6303) using Crankshaft Damper Remover

T58P-6316-D and Vibration Damper Remover Adapter T82L-6316-B.

8. Pry crankshaft front seal (6700) from engine front cover (6019) with a flat-bladed screwdriver or other

similar tool. Use care to prevent damage to engine front cover and crankshaft.

Page 30

strategy.

Page

2

of 31997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B19.HTM~gen~ref.HTM

tomsn048@gmail.com

Installation

1. Inspect front cover and shaft seal surface of the crankshaft damper for damage, nicks, burrs or other

roughness which may cause the new seal to fail. Service or replace components as necessary.

2. Lubricate seal lip with clean engine oil and install crankshaft front seal using Vibration Damper and

Seal Replacer T82L-6316-A and Front Cover Seal Replacer T70P-6B070-A.

3. Coat crankshaft damper sealing surface with clean engine oil. Apply RTV F4AZ-19562-B or

equivalent meeting Ford specification WSE-M4G323-A1 using Rotunda Gasket Gun with Regulator

071-R0001 or equivalent to keyway of damper prior to installation. Install crankshaft vibration damper

using Vibration Damper and Seal Replacer T82L-6316-A. Install crankshaft vibration damper bolt and

crankshaft vibration damper washer and tighten to 125-165 Nm (92-122 lb-ft).

4. Position crankshaft pulley and install attaching bolts. Tighten attaching bolts to 32 Nm (24 lb-ft).

5. Install engine (6007) accessory drive belt (8620) and route as illustrated. Check to ensure drive belt is

riding in ribbed pulley correctly or early failure will result.

6. Install air cleaner outlet tube.

7. NOTE: When the battery has been disconnected and reconnected, some abnormal drive

symptoms may occur while the powertrain control module (PCM) (12A650) relearns its

adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the

Page 31

Connect ground cable at battery.

Page

3

of 31997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B19.HTM~gen~ref.HTM

tomsn048@gmail.com

8. Start engine and check for oil leaks.

Page 32

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Tool Number

Fan Clutch Holding Tool

Page

1

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Water Pump

SPECIAL SERVICE TOOL(S)

REQUIRED

Description

T84T-6312-C

Fan Clutch Nut Wrench T84T-6312-D

Removal

1. Disconnect ground cable at battery and set aside.

2. Remove engine air cleaner outlet tube.

3. CAUTION: Fan clutch has left-hand threads so nut must be turned clockwise to remove.

Loosen nut on fan clutch using Fan Clutch Holding Tool T84T-6312-C and Fan Clutch Nut Wrench

T84T-6312-D and remove fan blade and clutch assembly from water pump (8501).

4. Remove 2 screws holding fan shroud to radiator (8005). Remove fan blade and clutch assembly and

fan shroud together.

5. Drain cooling system.

6. Loosen, do not remove, 4 water pump pulley (8509) retaining screws.

7. Rotate engine drive belt tensioner clockwise and remove engine drive belt (8620).

8. Remove 4 water pump pulley retaining screws and water pump pulley.

9. Remove 3 electrical connectors at generator (GEN) (10300).

10. On Aerostar only, remove oil fill tube retaining nut at generator stud and lift tube from stud.

11. Remove 3 bolts retaining generator bracket to cylinder head (6049) and remove generator and

bracket as an assembly.

Engine Accessory Installation, 3.0L, Ranger

Page 33

Page

2

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 N606068-S2 Bolt

2 10300 Generator

3 10153 Generator Mounting Bracket

4 N806020-S2 Bolt

5 19703 A/C Compressor

6 6312 Crankshaft Pulley

7 3A674 Power Steering Pump

8 N807551-S100 Bolt

9 N807123-S2 Stud

10 N605805-S2 Bolt

11 2882 A/C Compressor Mounting Bracket

Page 34

12 N800199-S8M Bolt

Page

3

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

13 3A733 Power Steering Pump Pulley

14 6B209 Drive Belt Tensioner

15 N60608-S2 Bolt

16 N807124-S2 Bolt

17 3F671 Belt Adjuster

18 N802096-S2 Bolt

19 8509 Water Pump Pulley

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

B — Tighten to 21-29 Nm

(15-21 Lb-Ft)

C — Tighten to 53-72 Nm

(39-53 Lb-Ft)

12. Disconnect crank position sensor (CKP) wiring.

13. Remove heater water return hose at water pump.

14. Remove bypass hose from fitting at intake manifold (9424).

15. CAUTION: Use care not to damage the throttle linkage or fuel lines.

On Ranger only, remove 3 screws securing A/C compressor to power steering pump support bracket.

Using a piece of wood bridged from the top of the battery to the throttle body (9E926), suspend the

A/C compressor with a wire tie or other suitable material.

16. Using a Torx® 50 driver, remove enginedrive belt tensioner (6B209) assembly.

17. On Aerostar only, if equipped with auxiliary heater, remove screw retaining auxiliary heater tube

bracket at power steering pump support bracket.

18. Remove lower radiator hose at radiator and water pump.

19. Remove 5 screws retaining power steering pump support bracket to the engine (6007) and secure

power steering pump and bracket assembly toward battery tray.

20. Remove 12 water pump retaining bolts and note bolt location.

21. Remove water pump and discard old water pump gasket.

nstallation

I

NOTE: Lightly oil all bolts and stud threads before installation except those requiring special

sealant.

1. Clean gasket surfaces on engine front cover (6019) and water pump carefully. (Use care as

Page 35

aluminum gouges easily.)

Item

Page

4

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

2. Position a new gasket on water pump sealing surface using Gasket and Trim Adhesive D7AZ19B508-B or equivalent meeting Ford specification ESE-M2G52-A to hold gasket in position.

3. Install water pump on engine front cover and hand-tighten 12 attaching bolts. Refer to Engine Front

Cover in this section for tightening specifications.

4. Reinstall lower radiator hose at water pump and radiator and tighten clamps.

5. Reinstall power steering pump support bracket to engine and torque to (5 fasteners) (Ranger) 48-61

Nm (35-45 lb-ft) or (3 fasteners) (Aerostar) 40-54 Nm (30-40 lb-ft).

Power Steering Support Bracket — Aerostar

Part

Number Description

1 3A674 Power Steering Pump

2 3C511 Power Steering Pump Support

3 N800199-

S309

4 3A733 Power Steering Pump Pulley

5 6B209 Drive Belt Tensioner

6 N606068- Bolt

Bolt

Page 36

S309

Page

5

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

7 3F671 Power Steering Belt Idler Support

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

B — Pulley with Pull-Off Groove Facing Front, Flush with

End of Shaft + /- .25mm

(0.018 Inch)

C — Tighten to 30-50 Nm

(22-37 Lb-Ft)

Power Steering Support Bracket — Ranger

Item Part Number Description

1 6049 Cylinder Head

2 3A674 Power Steering Pump

3 N807123-S2 Stud

4 N605805-S2 Bolt

5 — Power Steering Bracket (Part of 3A674)

6 N800199 Bolt

7 3A733 Power Steering Pump Pulley

8 N606068-S2 Bolt

9 6B209 Drive Belt Tensioner

10 N807124-S2 Bolt

11 3F671 Power Steering Belt Idler Support

12 N807551-S100 Bolt (4 Places)

Page 37

13 N602098-S2 Screw and Washer

Page

6

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

14 8509 Water Pump Pulley

15 6312 Crankshaft Pulley

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

B — Tighten to 53-72 Nm

(39-53 Lb-Ft)

C — Tighten to 21-29 Nm

(16-21 Lb-Ft)

6. Reinstall engine accessory drive belt tensioner and torque to 35-45 Nm (27-33 lb-ft).

7. On Ranger only, install A/C compressor to steering pump support bracket with 3 bolts and torque to

22-28 Nm (17-21 lb-ft).

8. Reconnect bypass hose to fitting on intake manifold and tighten clamp.

9. Install heater water return hose at water pump fitting and tighten clamp.

10. On Aerostar only, if equipped with auxiliary heater, reinstall auxiliary heater tube bracket at power

steering pump support bracket and torque to 8-12 Nm (6-8 lb-ft).

11. Connect crank position sensor (CKP) wiring at sensor.

12. Reinstall generator and bracket assembly to right cylinder head with 3 bolts and torque to 40-54 Nm

(30-40 lb-ft).

Front End Accessory Drive, Upper — Aerostar

Page 38

Page

7

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 6049 Cylinder Head (RH)

2 N606068-S309 Bolt

3 N806209-S309 Stud

4 10A313 Generator Bracket

5 10300 Generator

6 N802827-S309 Nut

7 N606706-S309 Bolt

8 N606070-S309 Bolt

9 3F671 Power Steering Belt Idler Support

10 8680 Belt Idler Bracket

11 — A/C Compressor Bracket (Part of 19703)

12 N605801-S309 Bolt

13 19703 A/C Compressor

14 N806020-S309 Bolt

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

B — Tighten to 21-29 Nm

(16-21 Lb-Ft)

Front End Accessory Drive, Upper — Ranger

Page 39

Front End Accessory Drive, Drive Belt Routing

— Aerostar

Page

8

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 N606068-S2 Bolt

2 10300 Generator

3 10A313 Generator Bracket

4 N606065-S2 Bolt

5 6049 Cylinder Head (RH)

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

13. Reconnect 3 wiring connectors in generator.

14. Install oil fill tube bracket over stud at generator and torque retaining nut to 42-50 Nm (32-37 lb-ft).

15. Install water pump pulley on water pump hub and tighten bolts finger-tight.

16. Wrap engine accessory drive belt around all pulleys except generator. Rotate belt tensioner clockwise

and when belt clears, slip over alternator pulley.

Page 40

Front End Accessory Drive, Drive Belt Routing

— Ranger

Page

9

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 3F671 Power Steering Belt Idler Support

2 3A733 Power Steering Pump Pulley

3 6B209 Drive Belt Tensioner

4 8620 Drive Belt

5 6312 Crankshaft Pulley

6 8509 Water Pump Pulley

7 — Idler (Part of 8A620)

8 19703 A/C Compressor

9 10300 Generator

Page 41

Page

10

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 19703 A/C Compressor

2 3A733 Power Steering Pump Pulley

3 6B209 Drive Belt Tensioner

4 8620 Drive Belt

5 6312 Crankshaft Pulley

6 8509 Water Pump Pulley

7 10300 Generator

8 3F671 Power Steering Belt Idler Support

17. Torque water pump pulley bolts to 23-32 Nm (18-24 lb-ft).

18. Place radiator fan and clutch assembly in fan shroud and slide fan shroud into position. Lower edge

Page 42

of fan shroud should locate in clips at bottom of radiator. Secure top of fan shroud with 2 screws and

Page

11

of 111997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B20.HTM~gen~ref.HTM

tomsn048@gmail.com

torque to 6-8 Nm (53-71 lb-in).

19. CAUTION: Fan clutch has left-hand threads so nut must be turned clockwise to remove.

Install fan clutch on water pump hub and torque to 41-135 Nm (30-100 lb-ft) using Tool T84T-6312-C

and Fan Clutch Nut Wrench T84T-6312-D.

20. Reinstall engine air cleaner outlet tube and tighten clamps.

21. Fill engine cooling system to specified level. Refer to Section 03

22. Reconnect ground cable at battery.

23. Start vehicle and check for leaks. Allow engine to reach operating temperature and verify no fluid

leaks. Shut off engine, check and correct all fluid levels.

-03 .

Page 43

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Tool Number

Vibration Damper and Seal Replacer

Page

1

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Engine Front Cover

SPECIAL SERVICE TOOL(S) REQUIRED

Description

Fan Clutch Holding Tool T84T-6312-C

Fan Clutch Nut Wrench T84T-6312-D

T82L-6316-A

Vibration Damper Remover Adapter T82L-6316-B

Crankshaft Damper Remover T58P-6316-D

Removal

1. Disconnect ground cable at battery and set aside.

2. NOTE: Engine front cover (6019) can be removed with water pump (8501) installed. To perform

this operation, do not remove bolts 11 through 15 in the Fastener Location, Water Pump Front

Cover illustration.

Remove water pump as outlined in this section (if required).

3. Raise vehicle on hoist.

4. On Aerostar only, remove 4 screws holding A/C compressor (19703) to engine bracket and support

compressor to sidemember of engine compartment.

5. On Aerostar only, remove 3 screws securing A/C compressor bracket to cylinder blocks (6010) and 2

nuts in front at timing cover studs.

Engine Accessory Installation, 3.0L — Ranger

Page 44

Page

2

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 N606068-S2 Bolt

2 10300 Generator

3 10153 Generator Mounting Bracket

4 N806020-S2 Bolt

5 19703 A/C Compressor

6 6312 Crankshaft Pulley

7 3A674 Power Steering Pump

8 N807551-S100 Bolt

9 N807123-S2 Stud

10 N605805-S2 Bolt

11 2882 A/C Compressor Mounting Bracket

Page 45

12 N800199-S8M Bolt

Page

3

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

13 3A733 Power Steering Pump Pulley

14 6B209 Drive Belt Tensioner

15 N60608-S2 Bolt

16 N807124-S2 Bolt

17 3F671 Belt Adjuster

18 N802096-S2 Bolt

19 8509 Water Pump Pulley

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

B — Tighten to 21-29 Nm

(15-21 Lb-Ft)

C — Tighten to 53-72 Nm

(39-53 Lb-Ft)

Engine Accessory Installation, Upper— Aerostar

Item Part Number Description

1 6049 Cylinder Head (RH)

2 N606068-S309 Bolt

3 N806209-S309 Stud

4 10A313 Generator Bracket

Page 46

5 10300 Generator

Item

Page

4

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

6 N802827-S309 Nut

7 N606706-S309 Bolt

8 N606070-S309 Bolt

9 3F671 Power Steering Belt Idler Support

10 8680 Belt Idler Bracket

11 — A/C Compressor Bracket (Part of 19703)

12 N605801-S309 Bolt

13 19703 A/C Compressor

14 N806020-S309 Bolt

A — Tighten to 40-55 Nm

(30-41 Lb-Ft)

B — Tighten to 21-29 Nm

(16-21 Lb-Ft)

Engine Accessory Installation, Lower — Aerostar

Part

Number Description

1 3A674 Power Steering Pump

2 3C511 Power Steering Pump Support

3 N800199- Bolt

Page 47

S309

Page

5

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

4 3A733 Power Steering Pump Pulley

5 6B209 Drive Belt Tensioner

6 N606068-

S309

7 3F671 Power Steering Belt Idler Support

A — Tighten to 40-55 Nm

B — Pulley with Pull-Off Groove Facing Front, Flush with

C — Tighten to 30-50 Nm

6. Remove 4 screws retaining crankshaft pulley (6312) and remove pulley.

7. Remove bolt and washer retaining crankshaft damper to crankshaft.

8. Remove crankshaft vibration damper from crankshaft (6303) using Crankshaft Damper Remover

T58P-6316-D and Damper Remover Adapter T82L-6316-B.

9. Drain engine oil from crankcase.

10. Remove oil pan (6675) as outlined in this section and discard oil pan gasket (6710).

Bolt

(30-41 Lb-Ft)

End of Shaft + /- .25mm

(0.018 Inch)

(22-37 Lb-Ft)

11. Lower vehicle.

Fastener Location, Water Pump Front Cover

Page 48

Fastener and Hole No.

Ft

M8 x 1.25 x 72.25

30

22

M8 x 1.25 x 72.25

30

22

S8

30

22

S8

30

22

30

22

M8 x 1.25 x 104.3

30

22

S8

30

22

S8

30

22

S8

30

22

S2

30

22

Page

6

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

Fasteners

Part No. Size Nm Lb-

1

2

3

a

a

a

N804215

N804215

N804811-

2020-

M8 x 1.25 x 73.0 20-

151515-

4 N8048115 N804811 M8 x 1.25 x 73.0 206 N807515

7 N8048118 N8048119 N804811-

10 N606543-

M8 x 1.25 x 73.0 20-

20M8 x 1.25 x 73.0 20M8 x 1.25 x 73.0 20M8 x 1.25 x 70.0 20M8 x 1.25 x 52.0 20-

15151515151515-

Page 49

11 N804576-

S8

S8

S8

S8

S8

Page

7

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

M6 x 1.0 x 28.5 8-12 6-8

12 N80457613 N80457614 N80457615 N804576-

a

Apply Pipe Sealant with Teflon D8AZ-19554-A or equivalent meeting Ford specifications WSK-

M2G350-AZ and ESR-M18P7-A to fastener threads.

12. Remove remaining bolts in engine front cover and remove cover. Discard old engine front cover

gasket (6020).

13. Pry crankshaft front seal (6700) from engine front cover with a flat-blade screwdriver or similar tool.

Use care to prevent damage to engine front cover.

14. While timing cover is off, inspect timing chain and sprockets to ensure continued service as outlined

in Section 03

Installation

CAUTION: Aluminum components gouge easily, which may result in gasket leaks. Always use

care when servicing aluminum gasket surfaces.

-00 .

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

Engine Front Cover

NOTE: Lightly oil all bolt threads except those requiring special sealants.

1. If crankshaft front seal is to be replaced, follow instructions outlined in this section.

2. Clean gasket surfaces on cylinder blocks and engine front cover.

Page 50

3. Align new engine front cover gasket on cylinder blocks dowel pins. Note bolts that require pipe

Fastener and Hole No.

Ft

M8 x 1.25 x 72.25

30

22

M8 x 1.25 x 72.25

30

22

S8

30

22

S8

30

22

S8

30

22

M8 x 1.25 x 104.3

30

22

S8

30

22

Page

8

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

sealant on accompanying chart.

Fasteners

Part No. Size Nm Lb-

a

1

a

2

a

3

4 N8048115 N6059096 N807515

7 N804811-

N804215

N804215

N804811-

20-

20M8 x 1.25 x 73.0 20M8 x 1.25 x 73.0 20-

M8 x 1.25 x 73.0 20-

20M8 x 1.25 x 73.0 20-

15151515-

151515-

Page 51

8 N804811-

S8

30

22

S8

30

22

S2

30

22

S8

S8

S8

S8

S8

Page

9

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

M8 x 1.25 x 73.0 20-

15-

9 N80481110 N60654311 N80457612 N80457613 N80457614 N80457615 N804576-

a

Apply Pipe Sealant with Teflon D8AZ-19554-A or equivalent meeting Ford specifications WSK-

M2G350-AZ and ESR-M18P7-A to fastener threads.

4. Install engine front cover and attaching bolts. Refer to the previous illustration. Tighten bolts 1 through

10 to 20-30 Nm (15-22 lb-ft) and bolts 11 through 15 to 8-12 Nm (6-8 lb-ft).

5. Raise vehicle.

6. Install oil pan as outlined in this section.

7. Coat crankshaft vibration damper sealing surface with clean engine oil. Apply RTV or equivalent

meeting Ford specification ESE-M4G195-B, using Rotunda RTV Dispenser 021-00031, to keyway of

damper prior to installation. Install damper using Damper/Front Cover Seal Installer T82L-6316-A.

Install crankshaft pulley bolt (6A340) and crankshaft pulley retaining washer (6378) and torque to

125-165 Nm (94-123 lb-ft).

M8 x 1.25 x 70.0 20M8 x 1.25 x 52.0 20-

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

M6 x 1.0 x 28.5 8-12 6-8

1515-

8. Install crankshaft pulley and torque 4 screws to 53-70 Nm (40-52 lb-ft).

9. On Aerostar only, position A/C compressor bracket over 2 engine front cover studs and install 2 nuts

on engine front cover studs and 3 screws into engine block bosses. Torque all A/C compressor

bracket retainers to 41-54 Nm (31-40 lb-ft).

10. Detach A/C compressor from sidemember of engine compartment and secure to A/C compressor

bracket with 4 screws. Torque fasteners to 22-28 Nm (17-21 lb-ft).

11. Lower vehicle.

12. Install water pump as outlined in this section (if removed).

Page 52

Page

10

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B21.HTM~gen~ref.HTM

tomsn048@gmail.com

Page 53

Install timing chain sprocket bolt and crankshaft pulley retaining washer (6378). Tighten bolt to 55

-

70

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 31997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B22.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Timing Chain, Sprockets, Tensioners and Guides

Removal

1. Disconnect ground cable at battery and set aside.

2. Remove engine front cover (6019) as outlined in this section.

3. Rotate crankshaft (6303) until No. 1 piston (6108) is at top dead center (TDC) and the timing marks

are aligned as illustrated.

4. Check timing chain deflection for excessive wear as outlined in Section 03

5. Slide camshaft sprocket (6256), crankshaft sprocket (6306) and timing chain forward and remove as

an assembly.

6. Clean timing cover and oil pan sealing surfaces of all gasket material and silicone sealer.

-00 .

Installation

1. Clean and inspect all parts before installation.

2. Slide camshaft sprocket, crankshaft sprocket and timing chain on as an assembly with timing marks

aligned as illustrated.

3. NOTE: The timing chain sprocket bolt has a drilled oil passage for timing chain lubrication. If

damaged, do not replace with standard bolt. Clean oil passage with solvent.

Page 54

Nm (41-52 lb-ft). Lubricate chain and sprockets with engine oil.

10.

Install crankshaft vibration damper and crankshaft pulley as outlined in this section.

Page

2

of 31997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B22.HTM~gen~ref.HTM

tomsn048@gmail.com

Item Part Number Description

1 6279 Camshaft Sprocket Bolt

2 6256 Camshaft Sprocket

3 6306 Crankshaft Sprocket

4 6268 Timing Chain/Belt

5 6278 Camshaft Sprocket Washer

A — Tighten to 55-70 Nm

(41-52 Lb-Ft)

4. Inspect crankshaft front seal (6700) for burrs or cuts. If required, replace seal using Front Cover Seal

Installer T70P-6B070-A.

5. Position engine front cover gasket (6020) onto cylinder block alignment dowels.

6. Install engine front cover onto cylinder blocks (6010) using caution to not damage crankshaft front

seal.

7. Install retaining bolts and tighten as outlined in this section.

8. Install oil pan (6675) and new oil pan gasket (6710) as outlined in this section.

9. Install water pump (8501) if removed.

Page 55

11. Install front end accessory drive components as outlined. Refer to Section 03-05 for routing and

Page

3

of 31997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B22.HTM~gen~ref.HTM

tomsn048@gmail.com

tension of drive belt.

12. Fill crankcase with the correct viscosity and weight engine oil.

13. CAUTION: This engine has aluminum components and requires a special corrosion-

inhibiting coolant formulation to avoid radiator damage. Refer to Section 03-03 for coolant

specifications.

Fill and bleed cooling system.

14. NOTE: When the battery has been disconnected and reconnected, some abnormal drive

symptoms may occur while the powertrain control module (PCM) (12A650) relearns its

adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the

strategy.

Connect battery ground cable (14301).

15. Start engine (6007) and check for coolant, oil and exhaust leaks.

Page 56

NOTE: Lightly oil all retaining bolt and stud threads before installation except those specified for

Section 03-01B: Engine, 3.0L V-6 1997 Aerostar, Ranger Workshop Manual

Page

1

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B23.HTM~gen~ref.HTM

tomsn048@gmail.com

IN-VEHICLE SERVICE

Camshaft

Removal

1. NOTE: On 3.0L Aerostar it is necessary to remove the engine (6007) from the vehicle to

perform this procedure. Refer to Engine Assembly, Aerostar

section.

Disconnect ground cable at battery and set aside.

2. Rotate crankshaft (6303) so No. 1 piston is at 0 degrees at Top Dead Center (TDC) on the

compression stroke.

3. Remove radiator as outlined in Section 03-03 .

4. Recover A/C refrigerant and remove A/C condenser core as outlined in Section 12-00 .

5. Remove engine front cover (6019) and timing chain and sprockets as outlined in this section.

6. Remove intake manifold (9424) and valve covers (6582) as outlined in this section.

, Removal and Installation, in this

7. Loosen rocker arm bolts enough to allow the rocker arms (6564) to be lifted off the push rod (6565)

and rotated to one side.

8. Remove push rods. Identify each push rod's location. The push rods should be installed in their

original location and position during reassembly.

9. Loosen roller tappet guide plate retainer bolts (2). Remove tappet guide plate retainer from tappet

valley.

10. Remove valve tappet guide plates (6K512) from valve tappets (6500) by lifting straight up.

11. NOTE: If the valve tappets are stuck in the bores due to excessive varnish or gum deposits, it

may be necessary to use a claw-type tool to aid removal. Work the valve tappet up and down

in the bore to loosen it from the deposits.

Remove valve tappets by grasping each valve tappet and pulling in line with bore.

12. Remove the two camshaft thrust plate retaining bolts and camshaft thrust plate (6269).

13. CAUTION: Damage to camshaft bearings and/or camshaft can occur if camshaft is

allowed to drop on bearing surface or cylinder block.

Remove camshaft (6250) by pulling slowly toward front of engine keeping camshaft perfectly in line

with camshaft bores.

Installation

Page 57

special sealant.

Page

2

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B23.HTM~gen~ref.HTM

tomsn048@gmail.com

1. CAUTION: Aluminum components gouge easily which can cause gasket leaks. Always

use care when scraping aluminum gasket surfaces.

Clean mating gasket surfaces of intake manifold and cylinder head (6049). Lay a clean cloth or shop

rag in the tappet valley to catch any gasket material. After scraping, carefully lift cloth from tappet

valley preventing any particles from entering oil drain holes or cylinder head. Use a suitable solvent to

remove old rubber sealant. Clean gasket mating surfaces of engine front cover to cylinder block.

2. Inspect camshaft bearings for wear. Replace as outlined in this section.

3. Clean and inspect all components before installation.

4. Lubricate camshaft lobes, bearing surfaces, and distributor drive gear liberally with Engine Assembly

Lubricant D9AZ-19579-D or equivalent meeting Ford specification ESR-M99C80-A.

5. Slide camshaft through bearings into cylinder blocks (6010) remembering to keep camshaft perfectly

in line with front bearing.

6. Lubricate camshaft thrust plate with Engine Assembly Lubricant D9AZ-19579-D or equivalent meeting

Ford specification ESR-M99C80-A and install with two retaining bolts. Tighten bolts to 8-12 Nm (6-8

lb-ft).

Page 58

7. If installing a new camshaft, check end play as specified in Section 03-00 . If clearance is excessive,

Page

3

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B23.HTM~gen~ref.HTM

tomsn048@gmail.com

replace camshaft.

8. CAUTION: Do not replace camshaft sprocket bolt (6279) with a standard bolt or severe

engine damage will occur. This bolt is an oil carrying, precision component.

Lubricate timing chain and sprockets with Engine Assembly Lubricant D9AZ-19579-D or equivalent

meeting Ford specification ESR-M99C80-A and install as an assembly. Align marks as illustrated.

Inspect camshaft sprocket (6256) for blockage of drilled oil passages and clean as required. Install

camshaft sprocket bolt and washer and tighten to 50-70 Nm (37-52 lb-ft).

9. Lubricate valve tappets and bore with Engine Assembly Lubricant D9AZ-19579-D or equivalent

meeting Ford specification ESR-M99C80-A.

10. Install valve tappets into original bores.

11. NOTE: Install valve tappet guide plates with the word "UP" or button visible.

Aligning tappet flats, install valve tappet guide plates.

12. Install tappet guide plate and retainer (6K564) over valve tappet guide plates. (NOTE: Retainer

orientation is not important.) Hand-start two retaining bolts. Tighten bolts to 10-14 Nm (7-10 lb-ft).

13. Apply a 5-6mm drop of Silicone Rubber D6AZ-19562-AA or equivalent meeting Ford specification

ESB-M4G92-A or ESE-M4G195-A to intersection of cylinder block and cylinder head assembly at four

corners.

14. Position intake manifold gaskets (9439) on tocylinder heads. Align the intake gasket locking tabs to

the provisions on the head gaskets (6051).

15. Install front and rear intake manifold seals. Secure with retaining features.

16. Lower intake manifold into position aligning manifold bolt holes to those in the cylinder head. Use

care to prevent disturbing the rubber sealer which can cause sealing voids. Install bolts 1, 2, 3 and 4

and hand-snug. Install remaining bolts. Tighten in numerical sequence to 15 Nm (11 lb-ft), then again

to 26-32 Nm (19-24 lb-ft).

Page 59

Page

4

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B23.HTM~gen~ref.HTM

tomsn048@gmail.com

17. Completely coat camshaft position sensor gear teeth with Engine Assembly Lubricant D9AZ-19579-D

or equivalent meeting Ford specification ESR-M99C80-A.

18. CAUTION: If a new camshaft is installed, always add the rest of the pint of Engine

Assembly Lubricant D9AZ-19579-D or equivalent meeting Ford specification ESR-M99C80-A to

the engine oil by pouring it through the distributor hole onto the camshaft drive gear. Run

engine at idle for five minutes before driving vehicle.

Install camshaft position sensor. Refer to Section 03-14 .

19. Rotate engine socamshaft is in Position A, as shown, with camshaft sprocket timing mark and

crankshaft sprocket timing mark at top center.

20. NOTE: Lubricate each push rod, rocker arm, and rocker arm fulcrum with Engine Assembly

Lubricant D9AZ-19579-D or equivalent meeting Ford specification ESR-M99C80-A before

installing.

Install push rod, rocker arm, rocker arm fulcrum, and rocker arm bolt for valves:

Page 60

Cylinder No. 1 Intake

installing.

Page

5

of 101997 Aerostar/Ranger

2011

-04-27file://C:\TSO\tsocache\VDTOM_5368\SVK~us~en~file=SVK31B23.HTM~gen~ref.HTM

tomsn048@gmail.com

Cylinder No. 2 Exhaust

Cylinder No. 4 Intake

Cylinder No. 5 Exhaust

Tighten rocker arm bolts to 11 Nm (8 lb-ft).

21. For valves in above step, check rocker arm-to-valve clearance. Clearance should be 2.15-4.69mm

(0.084-0.184 in.).