Food Warming Equipment Company UHST-28-B Service Manual

Home Page

Product Overview

Specification Page: S7–4

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

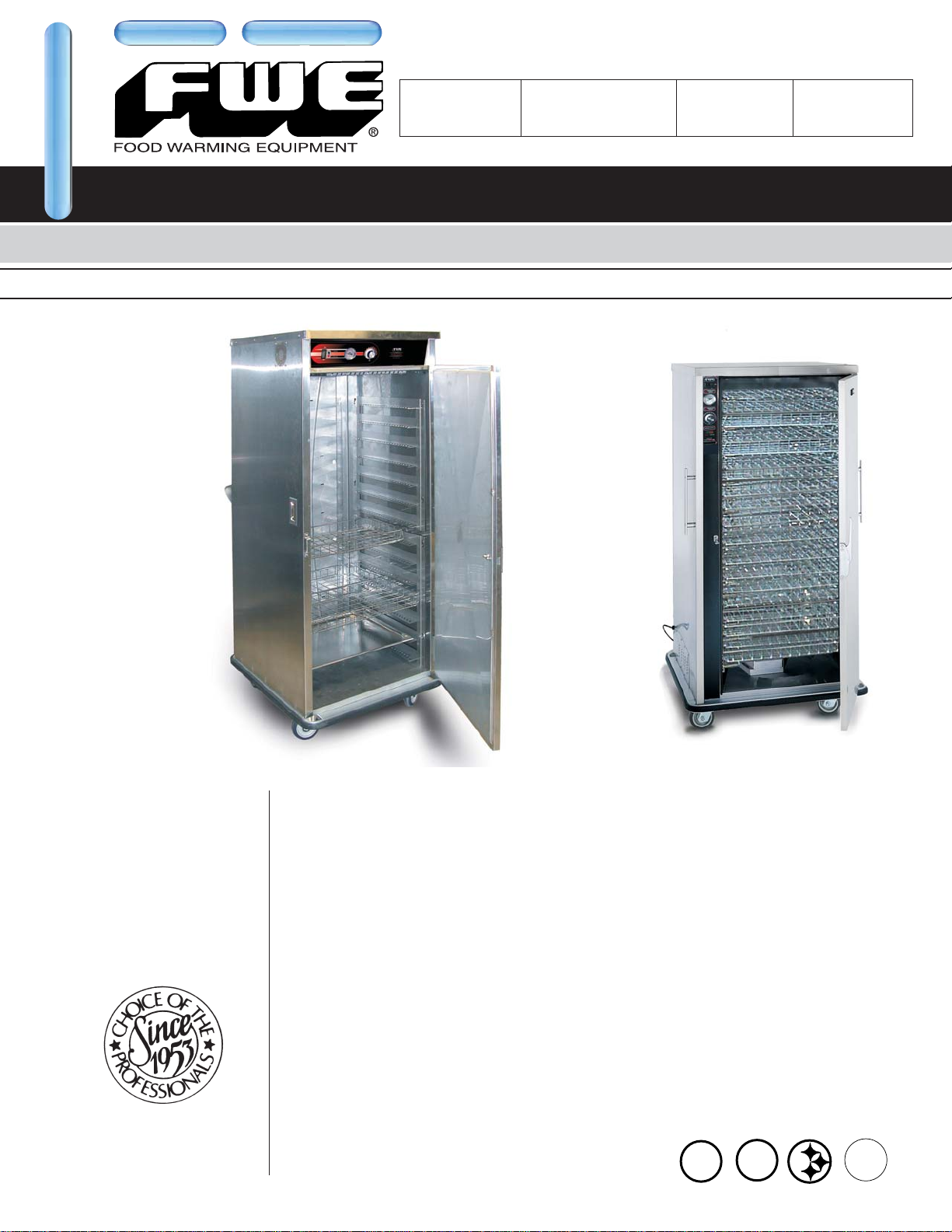

HEATED HOLDING FOR WIRE BASKETS

Available in Top Mount or Humi-Temp Heat Systems

“BASKET HOLDING SERIES”

High capacity heated

holding cabinet to

compliment your

speed-line operation.

Rethermalization

Section 7

TM

UHST-28B

with fixed spacings

FWE’s Universal “Wire Speed Basket” cabinet was

specifically designed to provide needed capacity and

holding performance to operations using wire speed

baskets. From retherm to speed-line operations, these

units address the common requirement for additional

flexibility and back-up holding of finished products in

13" x 26" or 18" x 26" wire baskets, as well as flexibility

to accommodate 18" x 26" and GN 2/1 sheet pans.

FWE’s heat system eliminates hot and cold spots

by gently circulating air throughout the interior of the

cabinet keeping the food fresh and hot for hours.

The heat system is built

cleaning effortless, reducing maintenance and

cleaning costs. Controls are protected and up front

at eye level convenience, easy to see and operate.

Built tough using stainless steel throughout, the

welded construction and exclusive tubular stainless

steel base frame ensure that FWE’s cabinets will

withstand the most demanding use. Make your choice

FWE . . . the “Choice of the Professionals”.

into

the cabinet to make

UHS-24-B

with adjustable spacings

◊

Easy-to-use controls

◊

All stainless steel

◊

All welded construction - no rivets

◊

Tubular stainless steel welded base frame

◊

Full extension bumper

◊

Heavy-duty polyurethane casters

◊

Heavy-duty hinges

◊

Positive close door latch

◊

Fully insulated throughout

◊

Removable stainless steel rack assembly

with fixed spacings for baskets and trays or

adjustable universal tray slides

◊

Two year limited warranty

U

®

L

U

C

L

®

Stainless

Steel

made to serve you better

NSF

®

PROJECT: MODEL: QUANTITY: ITEM NO:

SPECIFICATIONS:

▲

6'

5'

4'

"H"

3'

2'

1'

▼

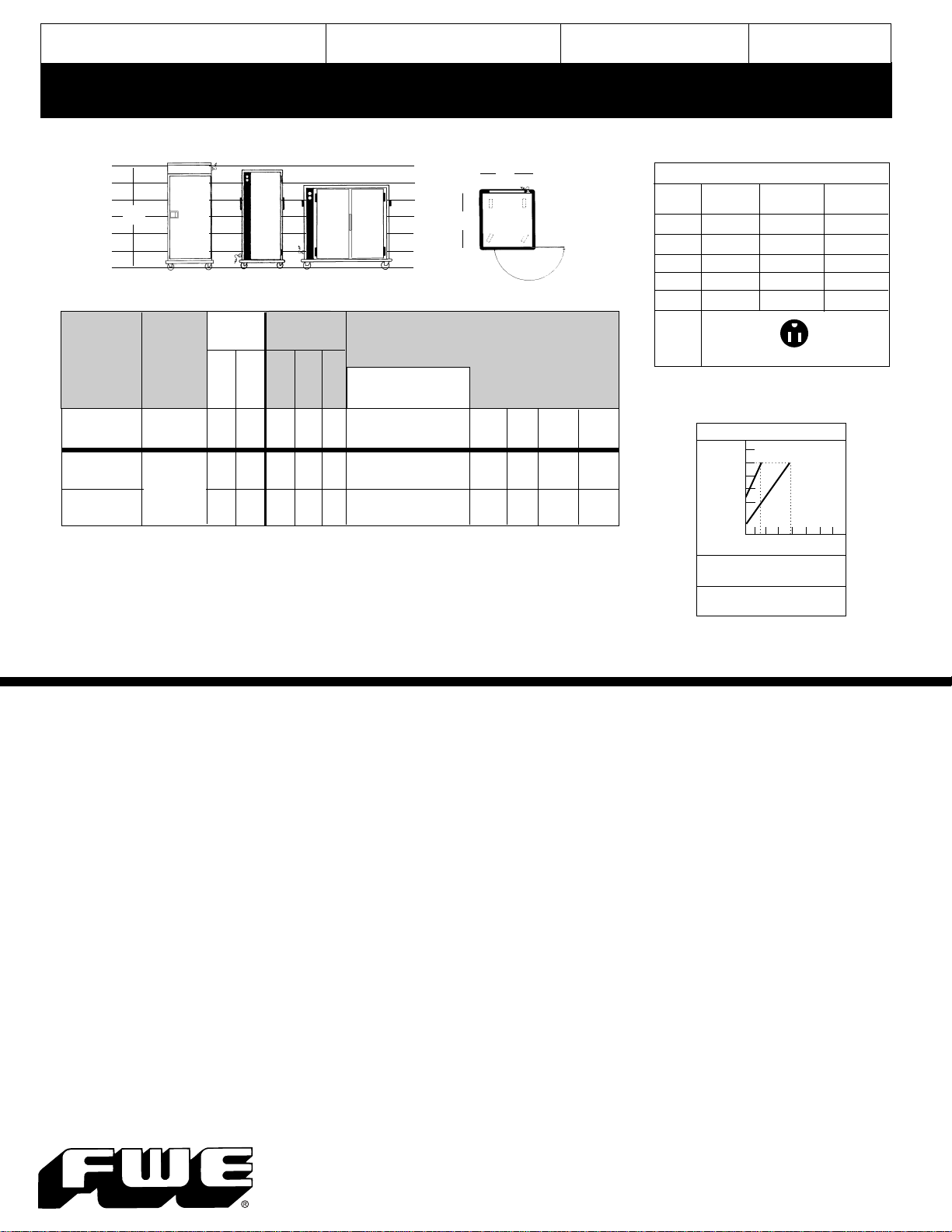

UHST-28B UHS-24B UHS-36B

Wire

Baskets

Trays and

Pans

OVERALL EXTERIOR

HEATED HOLDING FOR WIRE BASKETS

"W"

TOP

▲

DOOR

SWING: 30"

CLASS 100

▲

▲

"D"

▼

DIMENSIONS IN. (mm)

MODEL

NUMBER

UHST-28-B

Top Mount

UHS-24-B

Humi-Temp

UHS-36-B

Humi-Temp

All UHST-B Models have rear discharge heat distribution tunnel and are not available with Pass-thru Door.

UHS-B Tray-slides accommodate (2) baskets 13'' x 26'' or (1) basket 18'' x 26'', or (1) 18'' x 26'', (2) 14'' x 18'',

(2) 12'' x 18'', (2) 10'' x 20'' and (2) 12'' x 20” trays and/or pans.

Uprights punched on 1.5" centers. UHS Tray-slides are adjustable.

Dutch Doors are available.

CAPACITIES:

SPACINGS

4''

FIXED

(102)

4.5''

ADJUSTABLE

(114)

Add “D” for the Dutch Door optional accessory.

13'' x 26''

28 14

24 12

36 18

18'' x 26''

18'' x 26''

14 14 28

12 12 24

18 18 36

GN 2/1

12'' x 20''

HIGH

“H”

76''

(1930)

72.5''

(1842)

57''

(1448)

DEEP

“D”

35.25''

(895)

31''

(787)

33''

(838)

WIDE

“W”

32''

(813)

33.75''

(857)

66.25''

(1683)

NO. OF

DOORS

1

1

1

SHIP WT.

LBS.

CASTER

(KG)

SIZE

410

5''

(185)

385

5''

(174)

435

5''

(196)

CUBIC

FEET

(m3)

49.61

(1.61)

43.90

(1.24)

72.12

(2.04)

ELECTRICAL DATA

UHST-28-B

VOLTS 120 120 120

WATTS 1835 1685 1794

AMPS 15.3 14.0 14.95

HERTZ 50 / 60 50 / 60 50 / 60

PHASE Single Single Single

NEMA

PLUG

Dedicated circuit.

PERFORMANCE VALUES

T

190°

170°

E

150°

130°

M

110°

P

70°

PREHEAT

RECOVERY

UHS-24-B

5-15P

RECOVERY

•

•

5 10 15 20 25 30 35

75°F to 170°F

APPROX. 19.5 MIN

120°F to 170°F

APPROX. 7.7 MIN

UHS-36-B

G

PREHEAT

TIME

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 20-gauge polished

exterior, 22-gauge stainless steel interior with

easy-to-clean coved corners. Welded tubular

base frame shall be 1" square, heavy gauge

stainless steel tubing, with 10-gauge stainless

steel reinforcing plates at corners.

INSULATION. “Ultra-Guard” UG-26 high density

fiberglass insulation throughout; top, back,

bottom, sides, and door(s).

HANDLES. Flush-in-wall hand grips recess

mounted on each side of unit and heavy-duty,

1" diameter tubular stainless steel push handle

mounted at rear of unit.

BUMPER. Solid 1.5" wide continuous wraparound

aluminum channel, bolted to frame, with snap-in,

non-marking replaceable vinyl cushion. Full

perimeter bumper extends beyond doors, handles,

CASTERS. Maintenance free polyurethane tire

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be

secured to a 10-gauge stainless steel

reinforcing stress plate via welded in place

stainless steel studs. The reinforcing stress

plates shall be welded to the heavy gauge

tubular frame of the unit.

BASKET AND SHEET TRAY SLIDES.

Stainless steel racks shall be one piece die

stamped channel-type slides at 4" (101.6 mm)

spacings to accommodate 13.5" x 26" or

18" x 26" wire speed baskets as well as

18" x 26" or GN 2/1 sheet pans. Racks are

removable without tools for cleaning. Racks

shall lift off heavy-duty stainless steel supports.

etc., for added protection. Shall be continuous,

with corner cut-outs to facilitate cleaning.

DOORS AND LATCHES. Flush mounted, stainless

steel insulated and featuring a gasketless door.

Each door shall have three (3) heavy-duty

edgemount die cast hinges with flush-in-door

stainless steel paddle latch; positive closing.

The hinge and latch mountings are reinforced

with stainless steel backing plates.

UHST HEAT SYSTEM / CONTROLS.

Top mounted, forced air blower system shall

include two (2) Hi-Temp, self-lubricated,

impedance protected, fan-cooled blower

motors to distribute heat equally throughout

cabinet interior. Heating element shall be

located in top heat chamber separated from

food cabinet. Wall heat distribution tunnels

shall be vented for balanced air circulation.

Food Warming Equipment Company, Inc.

P. O. Box 1001

Crystal Lake, IL 60039-1001 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Controls shall be up-front, recessed and shall

include a full range thermostat adjustable to

actual temperature. Thermostat shall include

temperature scale marked in ten degree

increments (F/C) from 90° to 190°F (30° to

90°C). An operational range thermometer,

power supply light, thermostat cycling light,

and 20 amp ON/OFF switch are also

included.

UHS HEAT SYSTEM / CONTROLS.

Patented built-in “Humi-Temp” system shall

include an Incoloy nickel-chromium alloy

heating element and Hi-Temp, self-lubricated,

impedance protected fan-cooled blower

motor. Cabinet shall have humidifying

chamber and drawer style baffled humidifier

pan. Both shall be stainless steel and

removable. Controls shall be up-front,

recessed and shall include a full range

thermostat adjustable to actual temperature.

Thermostat shall include temperature scale

marked in ten degree increments (F/C) from

90° to 190°F (30° to 90°C). An operational

range thermometer, power supply light,

thermostat cycling light, and 20 amp

ON/OFF switch are also included.

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

ELECTRICAL CHARACTERISTICS.

3 wire grounded 10 foot extension power

cord and plug, side mounted for safety.

See chart above for electrical data.

Dedicated circuit.

Optional Accessories:

220 volt, 50/60 Hz, single phase

■

Food SentryTMelectronic controls

■

Key locking door latch

■

Padlocking transport latch

■

Left hand door hinging

■

Security packages

■

All swivel or larger casters

■

Door edge trim

■

Cold plate cartridge

■

Floorlock (requires 6" casters)

■

6" Adjustable legs

■

FWE Products are used by major

companies world-wide. We can

modify, design, or custom build

equipment to fit your special requirements.

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10F Food Warming Equipment Company. Inc.

Loading...

Loading...