Food Warming Equipment Company UFS-10-GN Service Manual

Specification Page: S11–5 GN

PROJECT: MODEL: QUANTITY: ITEM NO:

MOBILE FREEZERSi

Banquet Trolleys Sized to Fit Covered Plates and Gastro-Norm

“UFS SERIES”

Specifically designed

engineered f

or transport

applications for banquets,

hotels, convention centers,

institutions, and satellite

operations.

TM

RECALL

TEMP

SETTINGS

MASTER

ON/OFF

FACTORY PRESET AT 15°F (-9.4°C)

UFS-10-GN

Built like no other freezer available, these units address

the most demanding and punishing environments.

Stationary or reach-in units are

while FWE’s construction absorbs vibration and shock

during transport.

Our forced air “COLD-TEMP” system maintains a

balanced temperature which gently circulates the cold

air evenly throughout the cabinet.

Exclusive “Food Sentry” easy-to-use controls offer

the ultimate performance and accurate cabinet

temperatures. Continuously intuitive self-defrosting

cold system

convenient and user friendly.

The versatile “UFS” GN Rack holds 12'' x 20'' pans,

Gastro-Norm, and shelves provided for covered plates.

Mobile freezers have the same high quality features and

construction that have made FWE the “Choice of the

Professionals.”

with on demand override

not

made to be moved –

make operation

DIGITAL

ADJUSTABLE

TEMP

DISPLAY

FREEZER: 5°F TO 32°F

TEMP

“ON” and

“CYCLE”

INDICATOR

LIGHTS

◊

FACTORY PRESET AT 15°F (-9.4°C).

-15°C TO 0°C

Exclusive “Food Sentry” recessed

electronic controls with digital display

◊

“Cold-Temp” system with automatic

Smart Defrost

◊

All stainless steel

◊

All welded construction - no rivets

◊

Tubular stainless steel welded base frame

◊

Full extension bumper

◊

Heavy-duty polyurethane casters

◊

Heavy-duty hinges

◊

Positive close door latch

◊

Heavy-duty push bar handles

◊

Gasket sealed doors

◊

Fully insulated throughout

◊

Removable rack fits GN pans and shelves

◊

Two year limited warranty

ON DEMAND

MANUAL DEFROST

WITH INDICATOR LIGHT

ADJUSTABLE TEMP

5°F TO 32°F (-15°C TO 0°C):

with manual override

Mobile Refrigeration

Section 11

U

®

L

L

®

Stainless

Steel

made to serve you better

NSF

®

U

C

PROJECT: MODEL: QUANTITY: ITEM NO:

MOBILE FREEZERS

SPECIFICATIONS:

▲

"W"

▲

6'

5'

4'

3'

2'

1'

(180cm)

(150cm)

(120cm)

(90cm)

(60cm)

(30cm)

▲

TOP

"D"

▼

▲

"H"

▲

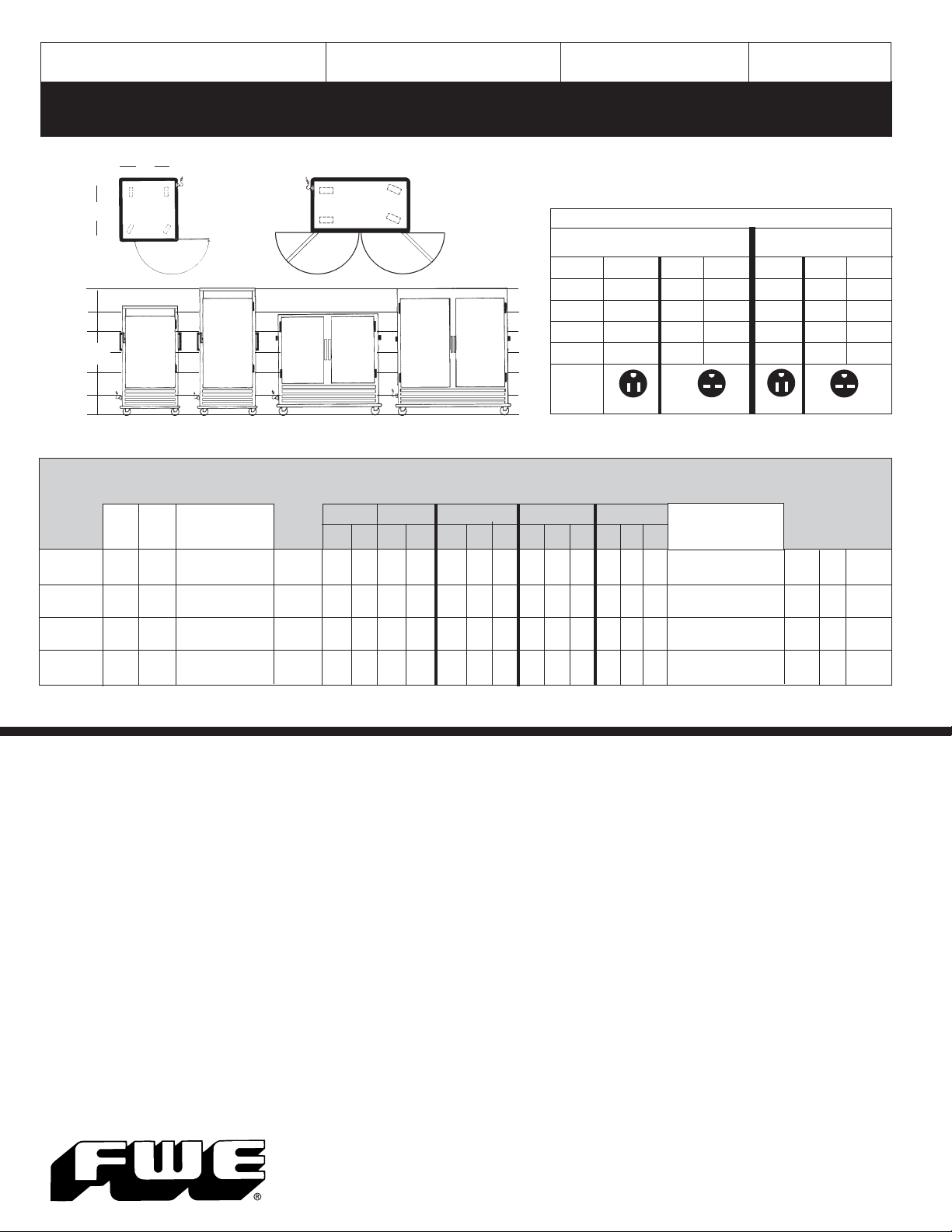

UFS-8-GN UFS-10-GN UFS-14-GN UFS-20-GN

DOOR SWING:

28" (711mm)

TOP

DOOR SWING:

28" (711mm)

Sized to fit covered plates and GN pans

ELECTRICAL DATA

Single Door Units

VOLTS 120 208 220 120 208 220

WATTS 900 780 780 1020 1020 1020

AMPS 7.5 3.75 3.6 8.5 4.9 4.7

HERTZ 50/60 50/60 50/60 50/60 50/60 50/60

PHASE Single Single Single Single Single Single

NEMA

PLUG

Dedicated circuit.

5-15P

G

G

6-15P

Double Door Units

5-15P

G

G

6-15P

NUMBER OF COVERED PLATES

PLATE DIAMETER AND HEIGHT

COVER & PLATE

HEIGHT

80mm67

mm

32 40

48 60

48 64

96 120

:

12'' x 20'' PANS GN 1/1PANS GN 2/1PANS

2.5'' 4'' 6'' 65 100 150 65 100 150

12 8 24

24

14 10 30

30

20 12 40

40

28 20 60

60

COLD-TEMP SYSTEM / CONTROLS. Continuously

intuitive defrost system with on demand defrost and

override. Self contained evaporator coil with thermal

expansion valve, heavy-duty circulation fans, de-ice

controls, condensation lines and stainless steel pan.

Condensing unit with 1/3 HP Hi-torque air cooled

compressor and filter drier. System uses environmentally safe non-CFC 404A refrigerant FOR MAXIMUM

PERFORMANCE. Controls shall include an easy to

read digital display of cabinet temperature (with recall

capability of temperature set point and actual cabinet

temperature), master ON/OFF button with power

indicator light, cooling cycle indicator light, ON

DEMAND DEFROST with defrost cycle indicator light.

Adjustable temperature range from 5°F to 32°F

(-15°C to 0°C) factory preset at 15°F (-9.4°C).

ELECTRICAL CHARACTERISTICS.

3 wire grounded 10 foot extension power cord

and plug, side mounted for safety. See electrical

data chart above for amperage and receptacle

configuration. Dedicated circuit.

MODEL

NUMBER

UFS-8-GN

UFS-10-GN

UFS-14-GN

UFS-20-GN

Rail spacings are 3" (76.2mm).

All models are available with the Pass-thru Door [add “P”] and/or Dutch Doors [add “D”]. Dutch Door: 2 half size doors.

CONSTRUCTION. Heliarc welded, single

unit construction of stainless steel;

20-gauge polished exterior,

22-gauge stainless steel interior with

easy-to-clean coved corners. Welded

tubular base frame shall be 1" square,

heavy gauge stainless steel tubing, with

10-gauge stainless steel reinforcing stress

plates at corners.

INSULATION. “Ultra-Guard” UG-26 high

density fiberglass and foam insulation

throughout.

PUSH BAR HANDLES. Heavy-duty, solid

formed 1" x .375" thick; mounted at each

end of unit. Mountings reinforced with

stainless steel channel.

BUMPER. Solid 1.5" wide continuous

wraparound aluminum channel, bolted to

frame, with snap-in, non-marking replaceable vinyl cushion. Full perimeter bumper

extends beyond doors, handles, etc.,

for added protection. Shall be continuous,

MAXIUM

SHELVES

PROVIDED

POSITIONS

2

12

15

3

20

2

30

6

SHELF

533mm x 635mm

21

533mm x 635mm

21

533mm x 635mm

21

533mm x 635mm

SHELF SIZE

21"x 25

"

"

x 25

"

"

x 25

"

"

x 25

"

DOORS AND LATCHES. Flush mounted, stainless

steel insulated doors shall be gasket sealed. Each

door shall have two (2) heavy-duty edgemount die

cast hinges. Door latch shall be edgemounted,

full grip, and positive closing. The hinge and

latch mountings are reinforced with stainless

steel backing plates.

CASTERS. Maintenance free polyurethane tire

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be secured

to a 10-gauge stainless steel reinforcing stress

plate via welded in place stainless steel studs.

The reinforcing stress plates shall be welded

to the heavy gauge tubular frame of the unit.

RACK. Removable pair of one piece stainless

steel racks with fixed spacings of 3'' (76.2mm).

One piece rack is easy to remove without

the use of tools for cleaning.

SHELVES. Triple plated, welded rod-type shelves

shall be removable and adjustable.

267mm

267mm

267mm

267mm

PLATE

SIZE

10.5

10.5

10.5

10.5

PLATES STACKED

3.125'' 2.625''

80mm67

"

4

"

4

"

3

"

4

3.125'' 2.625''

mm

5

5

4

5

with corner cut-outs to facilitate cleaning.

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

12 8

14 10

20 12

28 20

12

15

20

30

64

75

10 6

14 10

OVERALL EXTERIOR

CLASS 110

DIMENSIONS IN. (mm)

NO.

DEEP

"D"

36.5"

(927)

36.5"

(927)

36.5"

(927)

36.5"

(927)

WIDE

"W"

34.5"

(876)

34.5"

(876)

64"

(1626)

64"

(1626)

OF

CASTER

DOORS

SIZE

1 6"

1 6"

2 6"

2 6"

HIGH

"H"

65.5"

(1664)

73.5"

(1867)

58.5"

(1486)

73.5"

(1867)

Optional Accessories:

CE compliant

■

Cold plate cartridge

■

Dutch doors

■

Pass-thru door

■

Glass door

■

Key locking door latch

■

Magnetic latch

■

Paddle latch

■

Padlocking transport latch

■

Left hand door hinging

■

Security packages

■

All swivel or larger casters

■

Door edge trim

■

Floorlock (requires 6" casters)

■

Extra shelves

■

Custom rail spacings

■

FWE Products are used by

major companies world-wide.

We can modify, design,

or custom build equipment

to fit your special

requirements.

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10A Food Warming Equipment Company. Inc.

SHIP WT .

LBS.

(KG)

380

(171)

420

(190)

550

(250)

670

(304)

Loading...

Loading...