Food Warming Equipment Company RH-B-12 Specifications

Home Page

Product Overview

Specification Page: S7–2

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

RETHERMALIZATION CABINETS

Rethermalization and Holding Ovens for Baskets

“RH-B SERIES”

CONTROL PANEL IS E-Z TO USE:

USE LIKE STANDARD OVEN OR

STORE & RETRIEVE UP TO

12 PRESET MENU SELECTIONS

RH-B-32

Discover quality food

from FWE rethermalization

cabinets with easy-to-use,

up-front controls

TM

Rethermalization

Section 7

RH-B-12

Serve high quality food quickly, safely and

effortlessly with FWE’s “RH-B Series”!

Now you can provide the best possible food

flavor with FWE’s Retherm and Hold technology,

without the overcooking and dehydration

associated with other Retherm cabinets.

The “RH-B Series” is designed especially to

accommodate baskets. The Retherm heat system

heats evenly and automatically switches from

Retherm mode to a lower holding temperature.

If product quality and safety are the

primary goals of your Cook-to-Inventory

food program, FWE Rethermalization

cabinets are the clear choice for high

performance and dependability.

Venting may be required.

Local codes prevail.

RH-B-24

◊

Separate temperature displays for

Retherm and Holding modes

◊

Switches automatically

from Retherm to Hold mode

◊

Preset 12 menu selections

◊

All stainless steel

◊

All welded construction - no rivets

◊

Welded base frame

◊

Polyurethane casters

◊

Easy-to-use, eye-level controls

◊

Heavy-duty door latch & hinges

◊

Gasketless door

◊

Fully insulated throughout

◊

Two year

C US

ANSI NSF 4

Comm. Cooking

Equipment

limited warranty

U

®

L

U

C

L

®

Stainless

made to serve you better

Steel

PROJECT: MODEL: QUANTITY: ITEM NO:

RETHERMALIZATION AND HOLDING OVENS

SPECIFICATIONS:

For baskets

6'

▲

5'

4'

3'

"H"

2'

1'

▼

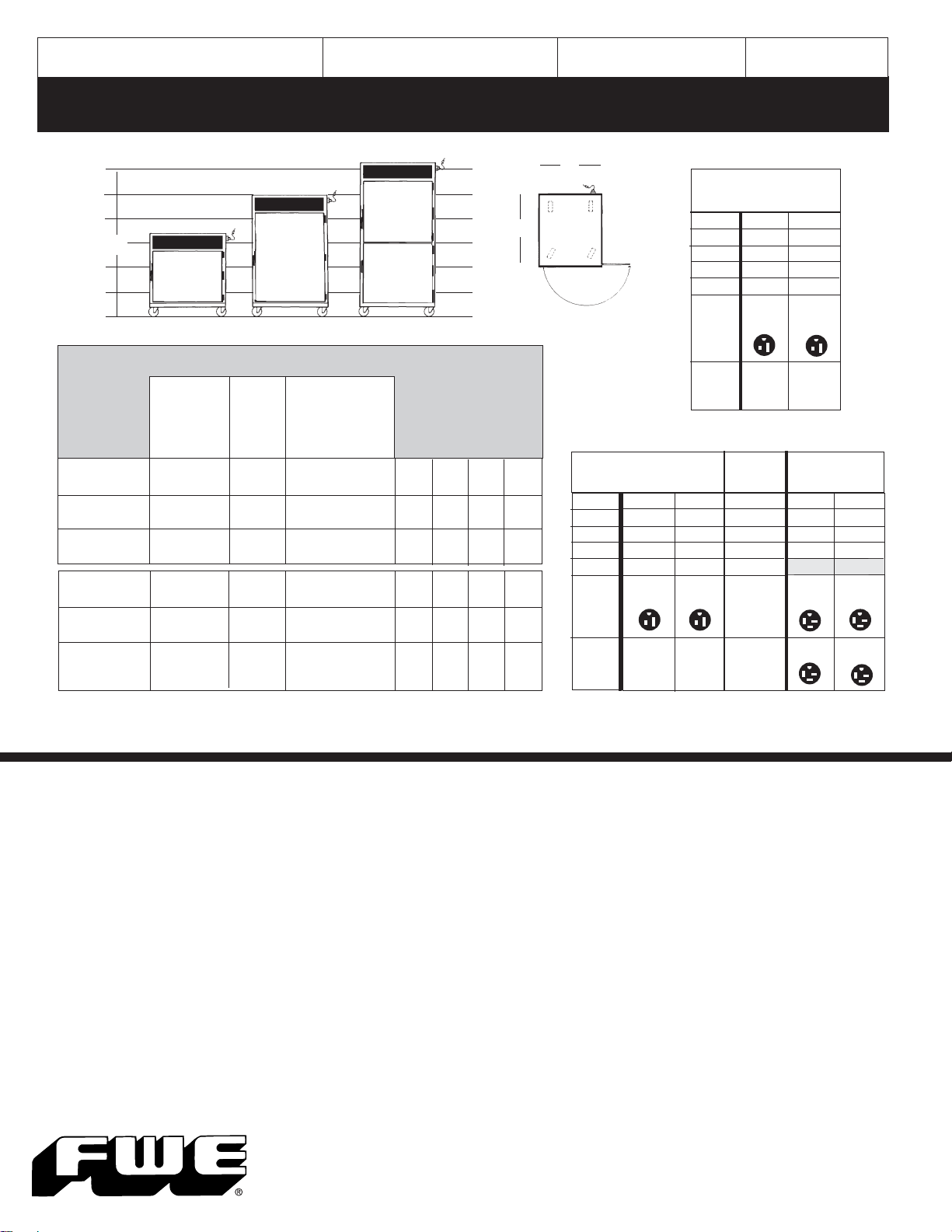

RH-B-12 RH-B-24 RH-B-32

CAPACITIES AT 3

13.5" x 26"

x 2.5''

MODEL

NUMBER

RH-B-12

RH-B-24

RH-B-32

RH-B-24 HO

THREE PHASE

RH-B-32 HO

THREE PHASE

RH-B-32 HO P

PASS-THRU

THREE PHASE

Unit standard with maximum 350°F (177°C) range. Specify if lower temperature is required.

HO refers to “High Output” wattage which provides increased heat and circulation for

dense or heavy-weight food product capacities.

WIRE BASKETS

2 Baskets Per Slide

12

24

32

24

32

32

"

SPACINGS (76MM)

TOTAL

MEALS:

10 PER

BASKET

120

240

320

240

320

320

OVERALL EXTERIOR

DIMENSIONS IN. (mm)

HIGH

"H"

40"

(1016)

61"

(1549

75"

(1905)

61"

(1549

75"

(1905)

75"

(1905)

DEEP

(952)

)

)

"D"

37.5"

37.5"

(952)

37.5"

(952)

37.5"

(952)

37.5"

(952)

40"

(1016)

WIDE

"W"

34.5"

(876)

34.5"

(876)

34.5"

(876)

34.5"

(876)

34.5"

(876)

34.5"

(876)

NO.

OF

DOORS

1

2

Dutch

2

Dutch

2

Dutch

2

Dutch

4

Dutch

CLASS 100

SHIP

WT.

CASTER

LBS.

SIZE

(KG)

286

5"

(130)

555

5"

(250)

660

5"

(297)

555

5"

(250)

660

5"

(297)

690

5"

(311)

▲

▲

"D"

▼

DOOR SWING: 25.5"

CUBIC

FEET

(m3)

29.94

(.85)

45.67

(1.29)

56.15

(1.59)

45.67

(1.29)

56.15

(1.59)

59.89

(1.7)

▲

"W"

TOP

ELECTRICAL DATA

Models RH-B-24, RH-B-32

VOLTS

WATTS

AMPS

HERTZ

PHASE

PLUG

USA

PLUG

CANADA

DEDICATED CIRCUIT.

208 220-240 220-240

10,250 11,570 13,355

49.3 48.2 55.7

50/60 50/60 50/60

Single Single Single

6-50P 6-50P

G

HARD

WIRE

ELECTRICAL DATA

Model RH-B-12

VOLTS 208 220-240

WATTS 8910 11,570

AMPS 42.9 48.2

HERTZ 50/60 50/60

PHASE Single Single

PLUG 6-50P 6-50P

USA

PLUG

CANADA

DEDICATED CIRCUIT.

G

HARD

WIRE

G

HARD

WIRE

OPTIONAL

UPGRADE

HARD

WIRE

HARD

WIRE

HARD

WIRE

RH-B-24-HO

RH-B-32-HO

208 220-240

11,590 15,140

32.2 36.5

50/60 50/60

Three Three

15-50P 15-50P

15-50P 15-50P

G

G

G

G

G

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 18-gauge

polished exterior, 18-gauge stainless steel

interior with easy-to-clean coved corners.

Welded tubular base frame shall be 1" square,

heavy gauge stainless steel tubing, with

10-gauge stainless steel reinforcing

plates at corners.

INSULATION. “Ultra-Guard” UG-26 high

density fiberglass insulation throughout;

top, back, bottom, sides, and door(s),

with a minimum of 2" and up to 4".

DOOR AND LATCH. Flush mounted, stainless

steel double pan stainless steel insulated

gasketless door(s). Heavy-duty edge mount

full grip magnetic door latch with heavy-duty

die-cast edgemount door hinges.

CASTERS. Maintenance free polyurethane tire

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be secured

to a 10-gauge stainless steel reinforcing stress

plate via welded in place stainless steel studs.

The reinforcing stress plates shall be welded

to the heavy gauge tubular frame of the unit.

BASKET SLIDES.

shall be one piece die stamped channel-type

basket slides at 3.5" spacings to accommodate

wire baskets. Racks are removable without

tools for cleaning. Racks shall lift off heavy-duty

stainless steel supports.

HEATING SYSTEM. Built-in heat system

includes multiple Incoloy sheathed heating

elements that provide fast heat up and

accurate temperature set points. In retherm

cycle, elements provide full power to assure

safe retherm times. When retherm time expires,

unit to automatically switch to hold mode

maintaining food quality and safe holding

temperatures. Unit contains internal cooling

fans and thermally protected blower motors,

safety switches and control panel is

temperature rise protected. Unique precision

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Stainless steel racks

venting baffle duct system for even, efficient heat

throughout the entire cabinet, in either retherm

or holding periods. Venting may be required.

Local codes prevail.

CONTROL PANEL. Automatic controls include

PREHEAT with override capability,

PAUSE feature, TIME counting and timer that

automatically switches from Retherm Cycle to

Hold Cycle. Adjustable RETHERM control up to

350°F (180°C) with adjustable HOLDING control

up to 190°F (90°C) and E-Z Recall of original set

points. Shall include ON / OFF switch. Actual

cabinet temperature reading is LED displayed

during each cycle. Unit can function by timer

or by probe (Probe ready; Probe not included).

Consult factory if lower temperature is required

for local codes.

ELECTRICAL CHARACTERISTICS.

See chart above for amperage. Dedicated circuit.

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.fweco.com sales@fweco.net

Optional Accessories:

All swivel or larger casters

■

Push - pull bar handles

■

Security panel for controls

■

Floorlock (requires 6" casters)

■

Menu card holder

■

Baskets

■

Product probe

■

Custom spacings

■

Controls to California Standard:

■

250°F Maximum Setting

FWE Products are used by major

companies world-wide. We can modify,

design, or custom build equipment to fit

your special requirements.

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10J Food Warming Equipment Company. Inc.

Loading...

Loading...