Food Warming Equipment Company PTS-40-8HA Service Manual

Home Page

Product Overview

pdf file: Specification Page: S9–2

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

❏ Heated

Section:

Built-in

Heat System

❏ Ambient

Section:

Eutectic

Cold Plates

PRISONER TRAY SERVERSi

Serve Hot & Cold Trays Out of One Cabinet

CORRECTIONAL “PTS-HA SERIES”

HOLD,

TRANSPORT,

AND

SERVE

PTS-40-8HA

(Trays and beverage dispenser not included.)

“Correctional Quality” –

Designed to hold,

transport, and serve

both hot and cold trays

efficiently while

providing beverage urn

work surface!

TM

FWE Heated/ Ambient Prisoner Tray Servers allow

you to serve hot and cold foods from the same

two-section cabinet, separated by a thermal

insulated wall assuring even temperatures in both

sections. The heat system is built into the cabinet to

prevent tampering and reduce maintenance and

cleaning costs. Clean up is effortless. The controls

are tamper resistant and feature a full range

thermostat adjustable to actual temperature

(90°F -190°F) so they are easy to see and operate.

Cold plates keep trays of cold foods chilled and

ready to serve in the ambient section. The addition

of guard rails and beverage urn angles to the top of

unit make beverage service fast and easy. Inmate

populations are served quickly, efficiently, and at

less cost.

We don’t just add a “security package” to a catalog

item

- the PTS-HA Series is specifically designed

to withstand the correctional environment. Our

cabinets are built tough with an 18-gauge stainless

steel exterior, welded construction and our exclusive

tubular stainless steel base frame. The PTS-HA

Series includes abuse resistant features such as

tamper resistant screws, locking security latches

and protected controls. From minimum to maximum

security, a wide range of other prison accessory

packages are available to tailor each unit to your

institutions’ special needs.

◊

18-gauge stainless steel exterior

◊

Top mount beverage container angles

◊

Two (2) eutectic cold plates for ambient section

◊

“Maxi-Guard” locking security latch for each door

◊

Tamper resistant fasteners throughout

◊

Super-duty extra-wide 6”polyurethane casters

◊

Heavy-duty 12-gauge stainless steel hinges

◊

Flush-in door, positive close paddle latch

◊

Tubular stainless steel push bars welded to the body

◊

One piece stainless steel rack assembly

◊

Recessed thermometer with security cover

◊

Thermostat knob retention strap

◊

Built-in heat system with protected controls

◊

Full range thermostat adjustable to

actual

temperature (90°F -190°F)

◊

All stainless steel

◊

All welded construction - no rivets

(extra welds at critical points)

◊

Tubular stainless steel welded base frame

◊

Full extension bumper

◊

Hi-temp door gasket

◊

Fully insulated throughout

◊

One year parts, six months labor limited warranty

Correctional Security Units

Section 9

Of course, as with all FWE cabinets, standard

models can be modified to accommodate other

tray sizes and spacings.

PROJECT: MODEL: QUANTITY: ITEM NO:

SPECIFICATIONS:

6'

▲

5'

4'

3'

"H"

2'

1'

▼

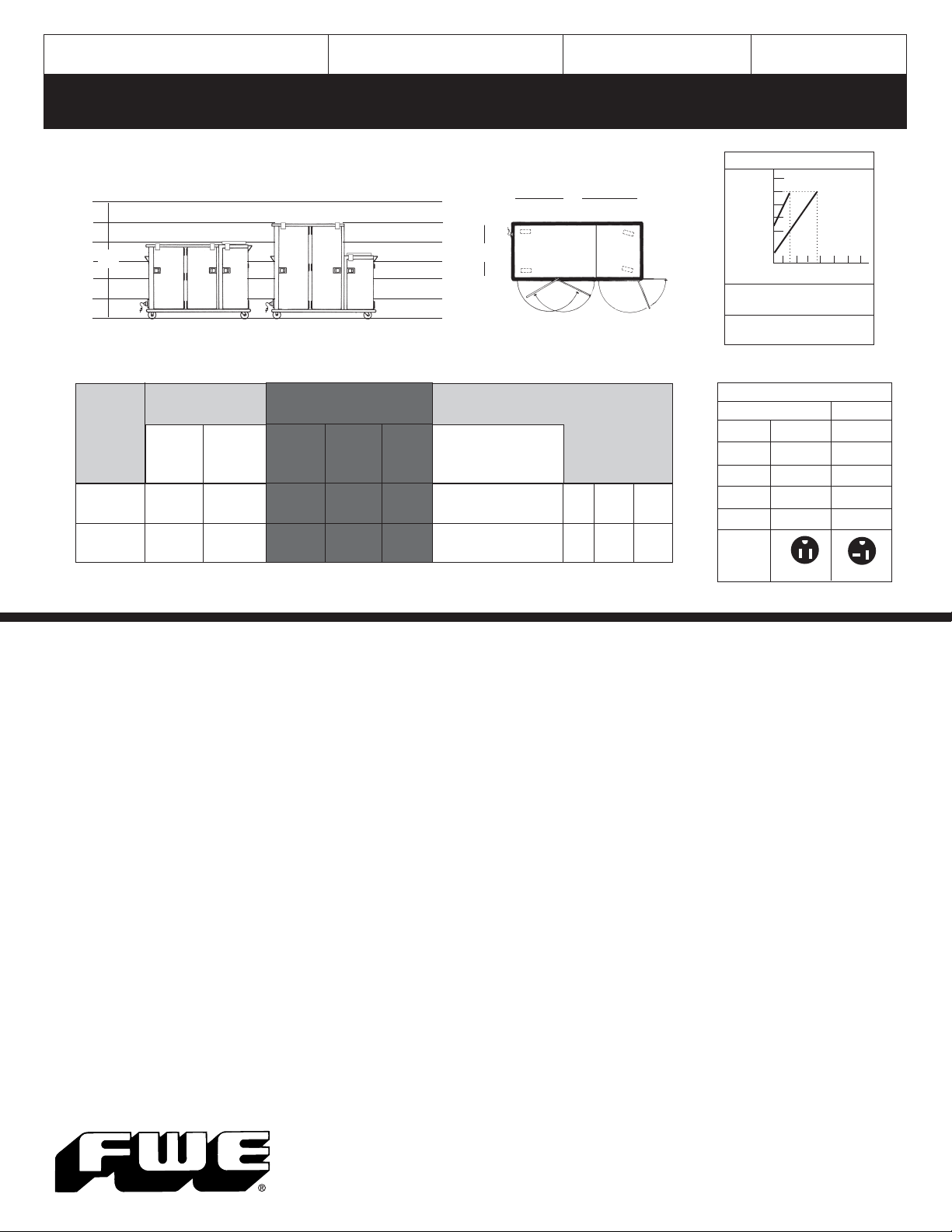

PTS-40-8HA PTS-60-8HA

HEATED SECTION

15.5"x 11.5

"

10"x 14

"

MODEL

NUMBER

PTS-40-8HA

PTS-60-8HA

[A]

Standard tray spacing 3". Each pair of tray slides accommodates two (2) trays.

[B]

Standard tray spacing 4". Each pair of tray slides accommodates two (2) trays.

Compartmented

Trays

40 [A]

60 [A]

Compartmented

[A]

Tray s

40 [A]

60 [A]

15.5"x 11.5

Compartmented

[A]

AMBIENT SECTION

10"x 14

"

"

Compartmented

Tray s

Tray s

16 [B]

16 [B]

[B]

[B]

16 [B]

16 [B]

PRISONER TRAY SERVERS

OVERALL EXTERIOR DIMENSIONS IN. (mm)

15"x 20

"

Tray s

4"Spacings

HIGH

@

"H"

49

8

(1168)

61

8

(1549)

"

"

▲

"D"

▼

DEEP

"D"

29.25

(743)

29.25

(743)

▲

"

"

"W"

TOP

DOOR SWING: 21.25"

NO.

WIDE

OF

"W"

DOORS

69

"

69

3

"

3

(1753)

(1753)

▲

CLASS 100

SHIP WT .

CASTER

LBS.

SIZE

(KG)

430

6

"

(195)

650

6

"

(295)

Compartment

Tray s

* PERFORMANCE VALUES

RECOVERY

190°

T

170°

•

150°

E

130°

110°

M

70°

P

PREHEAT

RECOVERY

*Values are for smaller model listed.

ELECTRICAL DATA

PTS-40-8HA PTS-60-8HA

VOLTS 120 120

WATTS 1412 1794

AMPS 11.7 14.95

HERTZ 50/60 50/60

PHASE Single Single

NEMA

PLUG

Dedicated circuit.

•

PREHEAT

TIME

5 10 15 20 25 30 35

75°F to 170°F

APPROX. 18.8 MIN.

120°F to 170°F

APPROX. 7.2 MIN.

G

5-15P 5-20P

G

CONSTRUCTION. Heliarc welded, single

unit construction of type 304 stainless

steel; 18-gauge polished exterior,

20-gauge stainless steel interior with

easy-to-clean coved corners. Welded

tubular base frame shall be 1" square,

heavy gauge stainless steel tubing,

with 10-gauge stainless steel reinforcing

stress plates at corners.

INSULATION. “Ultra-Guard” UG-26 high

density fiberglass insulation throughout;

top, back, bottom, sides, doors.

PUSH BARS. Heavy-duty, 1" diameter

tubular stainless steel push handles.

Mountings welded in place and reinforced

with stainless steel channel to prevent

removal.

BUMPER. Solid 1-1/2" wide continuous

wraparound aluminum channel, bolted to

frame, with snap-in, non-marking replaceable vinyl cushion. Full perimeter bumper

extends beyond doors, handles, etc., for

added protection. Shall be continuous,

with corner cut-outs to facilitate cleaning.

DOORS AND LATCHES. Flush mounted,

stainless steel, insulated doors. When

opened, doors lie flush against side of

unit or another door to keep work aisles

unobstructed. Each door shall have

three (3) heavy-duty, 12-gauge stainless

steel hinges. Each door shall be equipped

with a positive closing, flush-in-door,

stainless steel paddle latch. The hinge

and latch mountings are reinforced with stainless

steel backing plates. Each door shall be provided

with padlock compatible (padlock not included)

transport/security latch.

CASTERS. 6" heavy-duty, extra-wide

polyurethane tire casters with Zerk grease

(lubrication) fittings in a configuration of

two (2) rigid, and two (2) swivel with brake.

Casters shall have a reinforced yoke welded

to 10-gauge caster mounting plate. The caster

mounting plate shall be secured to a 10-gauge

stainless steel reinforcing stress plate via welded

in place stainless steel studs. The reinforcing

stress plates shall be welded to the heavy

gauge tubular frame of the unit.

TRAY SLIDES. Fully welded, unitized tray slide

assemblies shall be heavy gauge stainless steel,

channels fixed-in-place at 3" spacings and shall

be capable of field adjustability to accommodate

two (2) 15.5" x 11.5" or two (2) 10" x 14" trays

per pair of tray slides. Unless specified

otherwise, assembly shall be factory adjusted to

accommodate 15.5" x 11.5" trays. Contact factory for special spacing and custom assembly is

available to accommodate other tray sizes.

AMBIENT SECTION. Compartment shall be

provided with two (2) eutectic cold plates. Top

section shall be reinforced with interior stainless

steel channels to support the weight of beverage

containers (containers not included). Two (2)

sets of 12-gauge beverage container angles

shall be fixed to the top of the section (specify

brand and model number of containers).

HEATING SYSTEM/CONTROLS. Heat system shall

be built-in to prevent tampering, loss, or damage.

System shall include an Incoloy nickel-chromium

alloy heating element, and Hi-Temp, self-lubricated,

impedance protected, fan-cooled blower motors.

Controls shall be end mounted, fully recessed and

shall include a full range thermostat adjustable to

actual temperature. Thermostat shall include

temperature scale marked in ten degree

increments (F/C) from 90° to 190°F (30° to 90°C).

An operational range thermometer, 20 amp ON/OFF

switch, power supply light and thermostat cycling

light are also included.

ABUSE RESISTANT FEATURES. Cabinet shall

have 12-gauge stainless steel thermostat knob

retention strap, and 1/4" thick Lexan cover over

Optional Accessories:

220 volt, 50/60 Hz, single phase

■

CE compliant

■

Heat retention battery

■

Cord winding brackets

■

Removable twist-lock cord and plug

■

High impact plexi-glass,

■

hinged control panel cover

Locking paddle latch

■

Rack hold down device

■

All swivel or larger casters

■

Top corner bumpers

■

Stainless steel bumper

■

Top perimeter guard rail

■

Tow bar

■

the thermometer. Both shall be attached with

tamper-proof fasteners to prevent unauthorized

removal. Cabinet shall have tamper-resistant

fasteners in all critical areas, and extra welds

throughout for added durability. Heavy-duty

1" diameter tubular stainless steel push handles

shall be welded in place and reinforced with

stainless steel channel to prevent removal.

Each door shall be provided with padlock compatible

(padlock not included) transport/security latch.

ELECTRICAL CHARACTERISTICS. 3 wire

grounded 10 foot extension power cord and plug,

side mounted for safety. Dedicated circuit.

FWE Products are used by major

companies world-wide. We can

modify, design, or custom build

equipment to fit your special

requirements.

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10C Food Warming Equipment Company. Inc.

Loading...

Loading...