Food Warming Equipment Company HLC-SL1826-5 Service Manual

Home Page

Product Overview

Specification Page: S4–4a

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

HANDY LINE COMPARTMENTS

Side-Load Design for 18" x 26" Trays Fits Compactly Under the Counter

“HLC-SL1826 SERIES”

Shown with Lexan Door and

larger casters optional accessories.

Keep foods oven fresh

longer and prevent

product dehydration

and shrinkage.

TM

Handy Line Compartments

Section 4

HLC-SL1826-5L

Shown with 18'' x 26'' Tray and Wire Shelves.

Cabinet mounted with 2'' casters.

Side-Load

access and quick reference of inventory.

Convenient

makes these units perfect for a wide

variety of applications.

FWE’s natural convection heat system

allows a soft heat to radiate throughout

the cabinet, perfect for holding

pre-cooked foods for either short or

prolonged periods of time.

These small holding cabinets do not

require forced air movement. Stainless

steel interior walls and removable tray

slide assembly allow this unit to be

easily wiped clean.

Perfect for schools, hotels and QSR

in both under counter or counter top

applications.

18" x 26" trays for easy

under-counter height

HLC-SL1826-8

◊

All stainless steel

◊

Welded construction - no rivets

◊

Welded base frame

◊

Cool-to-touch exterior

◊

Easy-to-use controls

◊

Recessed controls

◊

Full grip door latch

◊

Heavy-duty door hinges

◊

Fully insulated throughout

◊

Hi-temp door gasket

◊

Sanitary tray slides

◊

Polyurethane casters

◊

Two year limited warranty

U

L

®

L

®

Stainless

Steel

made to serve you better

NSF

®

U

C

PROJECT: MODEL: QUANTITY: ITEM NO:

HANDY LINE COMPARTMENTS

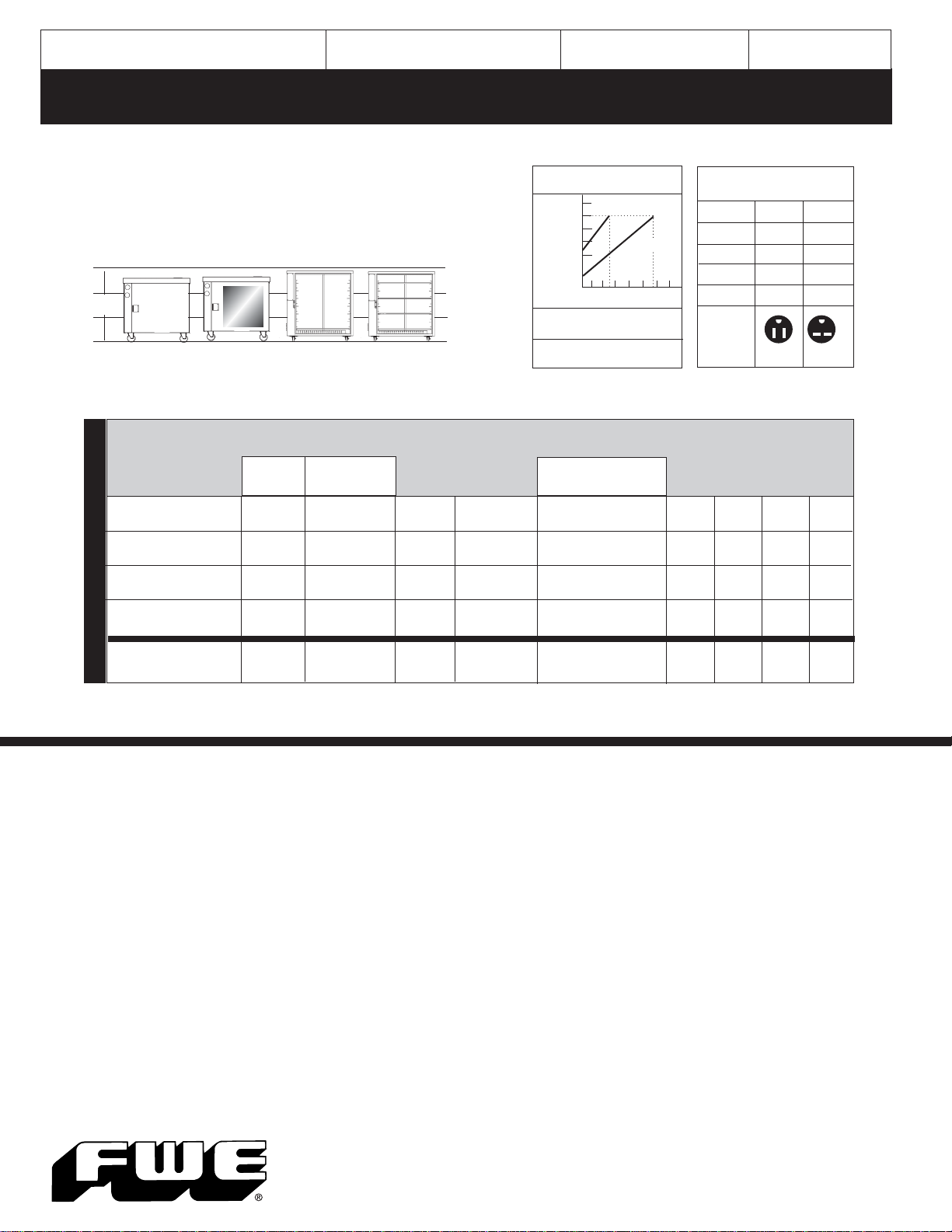

SPECIFICATIONS:

Side Load Design For 18" x 26" trays

3'

▲

2'

"H"

1'

▼

HLC-SL1826-5 HLC-SL1826-5L HLC-SL1826-8 HLC-SL1826-8

Lexan

MODEL

NUMBER

HLC-SL1826-5

Side Load & Under Counter

HLC-SL1826-5L

Side Load & Under Counter

HLC-SL1826-5P

Side Load & Under Counter

UNDER COUNTER MODELS

HLC-SL1826-5LP

Side Load & Under Counter

HLC-SL1826-8

Side Load & Under Counter

18

"

x 26

Trays

5

5

5

5

7

CAPACITIES

"

Type of Tray

Spacings

Fixed at

3.75"Spacings

Fixed at

3.75

"

Spacings

Fixed at

"

Spacings

3.75

Fixed at

3.75

"

Spacings

Fixed at

3.75

"

Spacings

With 3 Shelves

Optional Accessories

18"x 26

Trays

6

6

6

6

8

"

Type of Tray

Spacings

Fixed at

"

Spacings

3

Fixed at

3

"

Spacings

Fixed at

"

Spacings

3

Fixed at

3

"

Spacings

Fixed at

3

"

Spacings

PERFORMANCE VALUES

T

E

M

P

PREHEAT

RECOVERY

RECOVERY

190°

170°

150°

130°

110°

•

70°

5 10 15 20 25 30 35

75°F to 170°F

APPROX. 29 MIN.

120°F to 170°F

APPROX. 13 MIN.

PREHEAT

TIME

DIMENSIONS IN. (mm)

DEEP

"D"

22

(559)

22

(559)

(616)

(616)

22

(559)

WIDE

"W"

32.5

"

(826)

"

32.5

(826)

32.5

"

(826)

32.5

"

(826)

32.5

"

(826)

HIGH

"H"

"

28

(711)

28

"

(711)

28

"

(711)

28

"

(711)

34

"

(864)

24.25

24.25

•

"

"

"

"

"

ELECTRICAL DATA

VOLTS 120 220

WATTS 1000 1000

AMPS 8.3 4.5

HERTZ 50 / 60 50 / 60

PHASE Single Single

NEMA

PLUG

G

5-15PG6-15P

Dedicated circuit.

CLASS 100

NO. OF

CASTER

DOORS

1

1

2

2

1

SIZE

"

2

2

"

2

"

2

"

"

2

SHIP WT .

LBS.

(KG)

155

(70)

165

(75)

175

(80)

175

(80)

175

(80)

CUBIC

FEET

(m3)

12.27

(.35)

12.27

(.35)

13.68

(.39)

13.68

(.39)

14

(.4)

Fixed spacings of 3.75" are standard. Specify other spacings at time of order.

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 20-gauge polished

exterior, 22-gauge stainless steel interior with

easy-to-clean coved corners. Welded tubular base

frame shall be 1"square, heavy gauge

stainless steel tubing, with 10-gauge stainless

steel reinforcing stress plates at corners.

INSULATION. “Ultra-Guard” UG-26 high

density fiberglass insulation throughout; top,

back, bottom, sides and door(s).

DOORS AND LATCHES. Flush mounted, double

pan, stainless steel doors shall have 1" thick

fiberglass insulation. High temperature door gasket

mounted on cabinet. Each door shall be equipped

with flush-in-door stainless steel paddle latch;

positive closing. Each door shall have two (2)

heavy-duty edgemount die cast hinges and are

field-reversible.

CASTERS.

Maintenance free polyurethane tire

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

secured to a 10-gauge stainless steel

reinforcing stress plate via welded in place

stainless steel studs. The reinforcing stress

plates shall be welded to the heavy gauge

tubular frame of the unit.

FIXED TRAY SLIDES. Removable pair of

one piece stainless steel racks with fixed

spacings of 3.75" are standard. Easy to

remove without the use of tools for cleaning.

HEATING SYSTEM/CONTROLS.

Radiant heat system shall include an Incoloy

nickel-chromium alloy heating element.

Removable stainless steel baffled humidifier

pan shall be provided. Controls shall be upfront,

recessed and shall include a full range

thermostat adjustable to actual temperature.

Thermostat shall include temperature scale

marked in ten degree increments (F/C) from

90°to 190°F (30°to 90°C). An operational

range thermometer, power supply light and

thermostat cycling light are also included.

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

ELECTRICAL CHARACTERISTICS.

3 wire grounded 10 foot extension

power cord and plug, rear mounted for

safety. See electrical data chart above for

amperage and receptacle configuration.

Dedicated circuit.

FWE Products are used by major

companies world-wide. We can

modify, design, or custom build

equipment to fit your special

requirements.

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

Optional Accessories:

Electronic controls

■

Digital thermometer

■

220 volt, 50/60 Hz, single phase

■

CE compliant

■

Heat retention battery

■

See-thru Lexan door

■

Pass-thru door

■

Key locking door latch

■

Magnetic latch

■

Padlocking transport latch

■

Left hand door hinging

■

Field-reversible doors

■

Security packages

■

All swivel or other casters

■

Door edge trim

■

Menu card holder

■

Push-pull bar

■

Tubular handles

■

Stainless steel lift handles

■

Full extension bumper

■

Corner bumpers

■

Cold plate cartridge

■

6" floor legs

■

4" counter legs

■

Wire shelves 18'' x 26''

■

Other fixed spacings

■

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

© 11-Food Warming Equipment Company. Inc.

Loading...

Loading...