Food Warming Equipment Company HLC-2W6-1-DRN Service Manual

Home Page

Product Overview

Specification Page: S4–7

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

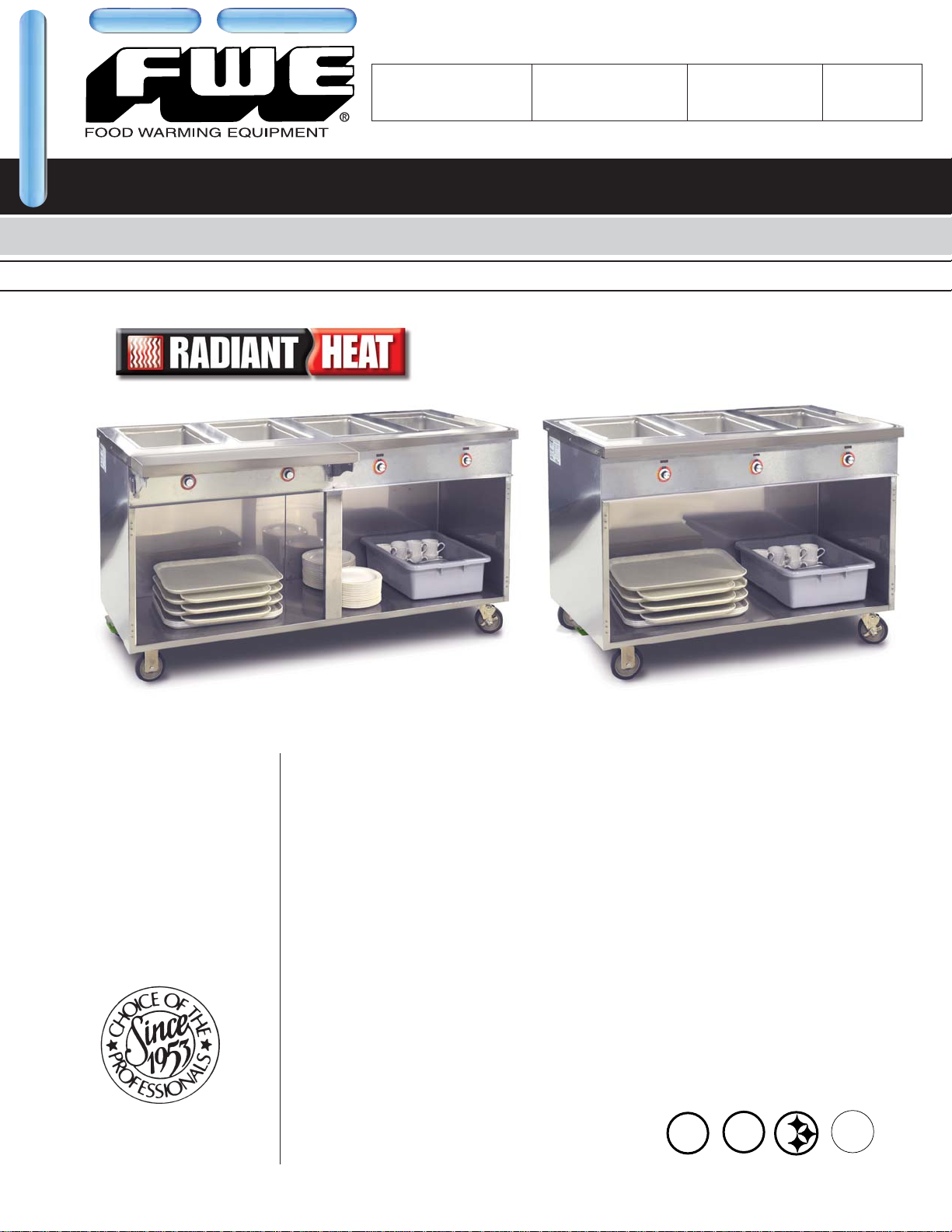

HANDY LINE SERVING WELLS

Serving Wells for 12" x 20" and GN 1/1 Bulk Food Pans

“HLC-W SERIES” OPEN BASE

Open base with

individually controlled

heated wells.

Customize with

versatile serving line

optional accessories!

Handy Line Compartments

Section 4

HLC-4W6-1-DRN

Shown with drop down half-shelf (or 2-well length)

TM

optional accessory.

Built stronger to last longer – these multi-well

serving steam table lines are completely

mobile on rugged poly casters. This instant

serving line to be operational when and

where you need it.

Available from a double well unit up to a

serving line of four (4) wells. Each well

accommodates up to a 12" x 20" x 6" or

a Gastr Norm 1/1-150 mm pan.

For cafeterias, buffets, schools, prisons

or buffet style applications in restaurants,

institutions, or other demanding environments,

customize your server with a drop down

shelf and sneeze guard to serve your

food oven fresh.

These open base units offer maximum

flexibility for serving applications, allowing

ample room for storage and transport to

make your foodservice complete.

HLC-3W6-1-DRN

◊

All stainless steel

◊

Welded construction - no rivets

◊

Tubular stainless steel welded base frame

◊

Heavy-duty polyurethane casters

◊

Recessed up-front controls

◊

Serving wells - use wet

◊

Well drain system with easy access valve

◊

Independently controlled wells

◊

Fully insulated wells

◊

Open bottom base

◊

Cool-to-touch exterior

◊

Two year limited warranty

U

®

L

U

C

L

®

Stainless

Steel

made to serve you better

NSF

®

PROJECT: MODEL: QUANTITY: ITEM NO:

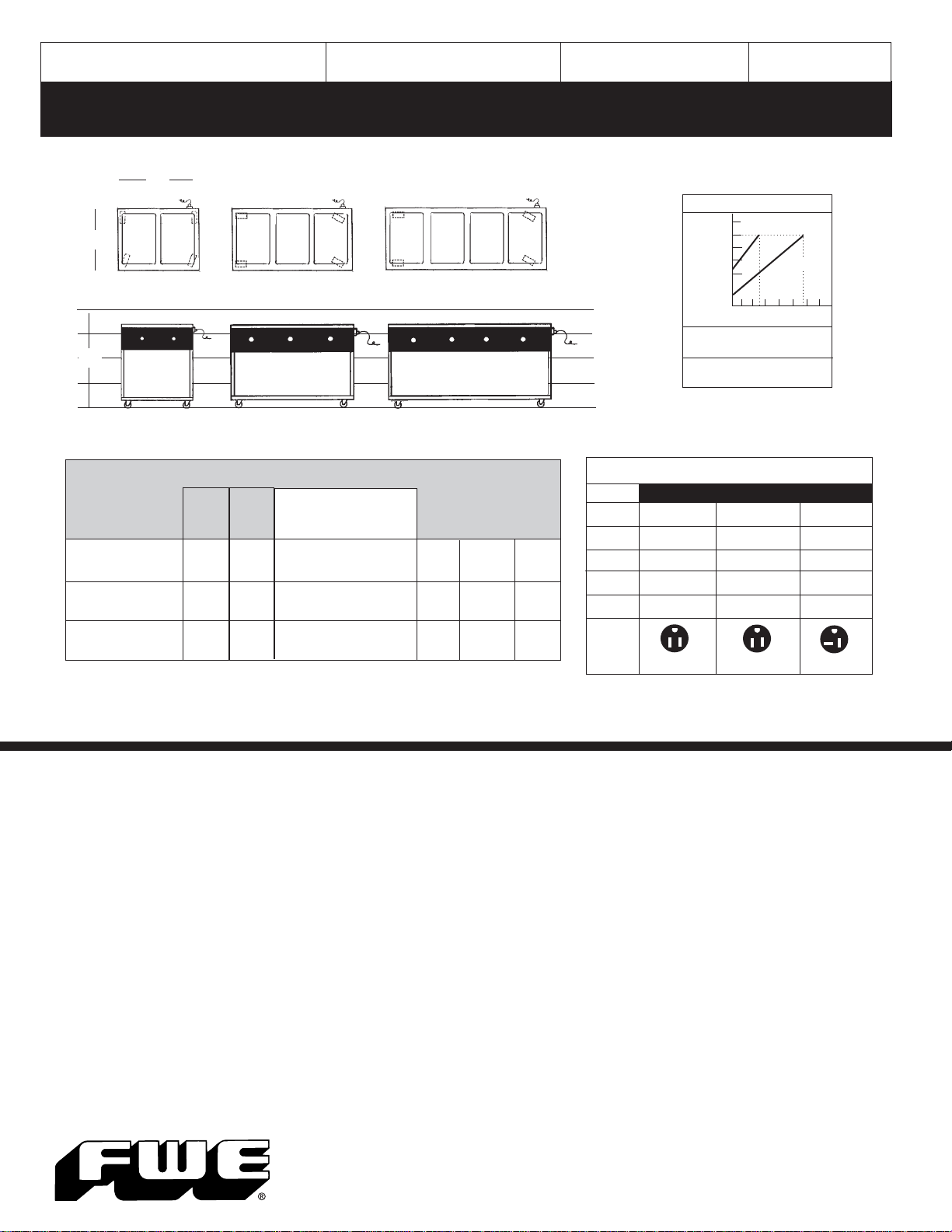

SERVING WELLS WITH OPEN BASE

SPECIFICATIONS:

For 12" x 20" and GN 1/1 Bulk Food Pans

"L"

▲

▲

▲

"D"

▼

4'

▲

3'

2'

"H"

1'

▼

HLC-2W6-1-DRN HLC-3W6-1-DRN HLC-4W6-1-DRN

WELL DESCRIPTION

MODEL

NUMBER

HLC-2W6-1-DRN

HLC-3W6-1-DRN

HLC-4W6-1-DRN

Note: Drop handles are standard on 2W units. If omitting drop handles, subtract 1.25" from overall

*

exterior length “L”. For optional accessory full perimeter bumper, add 5" to overall exterior length “L”.

DEPTH

OF

WELLS

6.5''

(165)

6.5''

(165)

6.5''

(165)

OVERALL EXTERIOR DIMENSIONS IN. (mm)

NUMBER

WELLS

OF

2

3

4

HIGH

''H''

37''

(940)

37''

(940)

37''

(940)

27.5''

(698)

27.5''

(698)

DEEP

''D''

27.5''

(698)

LONG

*

''L''

34.25''

(870)

51.5''

(1308)

68.75''

(1746)

SHIP WT.

CASTER

SIZE

5''

5''

(1256)

395

5''

(178)

205

(92)

280

CLASS 100

CUBIC

LBS.

(KG)

19.08

(.54)

28.69

(.81)

38.29

(1.08)

FEET

(m3)

PERFORMANCE VALUES

T

E

M

P

PREHEAT

RECOVERY

ELECTRICAL DATA

RECOVERY

190°

170°

150°

130°

110°

•

70°

5 10 15 20 25 30 35

75°F to 170°F

APPROX. 29 MIN.

120°F to 170°F

APPROX. 13 MIN.

•

PREHEAT

TIME

HLC-2W6-1 HLC-3W6-1 HLC-4W6-1

VOLTS 120 120 120

WATTS 1000 1500 2000

AMPS 8.3 12.5 16.6

HERTZ 50/60 50/60 50/60

PHASE Single Single Single

NEMA

PLUG

G

5-15P

5-15P

G

G

5-20P

Dedicated circuit.

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 18-gauge

polished exterior, 22-gauge stainless steel

interior with easy-to-clean coved corners.

Welded tubular base frame shall be 1" square,

heavy gauge stainless steel tubing, with

10-gauge stainless steel reinforcing stress

plates at corners.

INSULATION. “Ultra-Guard” UG-26 high

density fiberglass insulation throughout;

top, back, bottom, sides and door(s).

HANDLES. Heavy-duty stainless steel,

side-mounted lift handles on 2-well models.

CASTERS.

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be

secured to a 10-gauge stainless steel

reinforcing stress plate via welded in place

stainless steel studs. The reinforcing stress

plates shall be welded to the heavy gauge

tubular frame of the unit.

TOP MOUNT SERVING WELLS. Each well shall

be one piece stainless steel, deep drawn with

coved corners. Each well shall have ridge around

top perimeter. Each insulated, individually thermo

wrapped well shall have a separate adjustable

thermostat and indicating light. Top well depth

of 6.5" (165mm) is designed to be used wet.

Accomodates up to a 12" x 20" x 6" or

a GN 1/1-150.

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Maintenance free polyurethane tire

DRAIN. Each heated well connects to built-in

drain system with easy access external

shut-off valve.

ELECTRICAL CHARACTERISTICS. 3 wire

grounded 10 foot extension power cord and plug,

rear mounted for safety. See electrical data chart

above for amperage and receptacle configuration.

Dedicated circuit.

FWE Products are used by major

companies world-wide. We can modify,

design, or custom build equipment

to fit your special requirements.

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

Optional Accessories:

220 volt, 50/60 Hz, single phase

■

CE compliant

■

Cord winding brackets

■

Security panel for controls

■

Knob retention strap

■

Heat retention battery

■

Sliding doors

■

All swivel or larger casters

■

Full extension bumper

■

Push-pull bar

■

Tubular handles

■

Corner bumpers

■

Drop down shelf

■

Drop down side shelf

■

Drop down tray slide shelf

■

Cutting board

■

Under shelf for open base

■

Stainless steel top cover

■

Cold plate cartridge

■

Sneeze guard

■

FWE products may be covered under one or more of the

following U.S. patents: 288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©12E Food Warming Equipment Company. Inc.

Loading...

Loading...