Food Warming Equipment Company HLC-1W6-7H-7-DRN Service Manual

Specification Page: 4-6

PROJECT: MODEL: QUANTITY: ITEM NO:

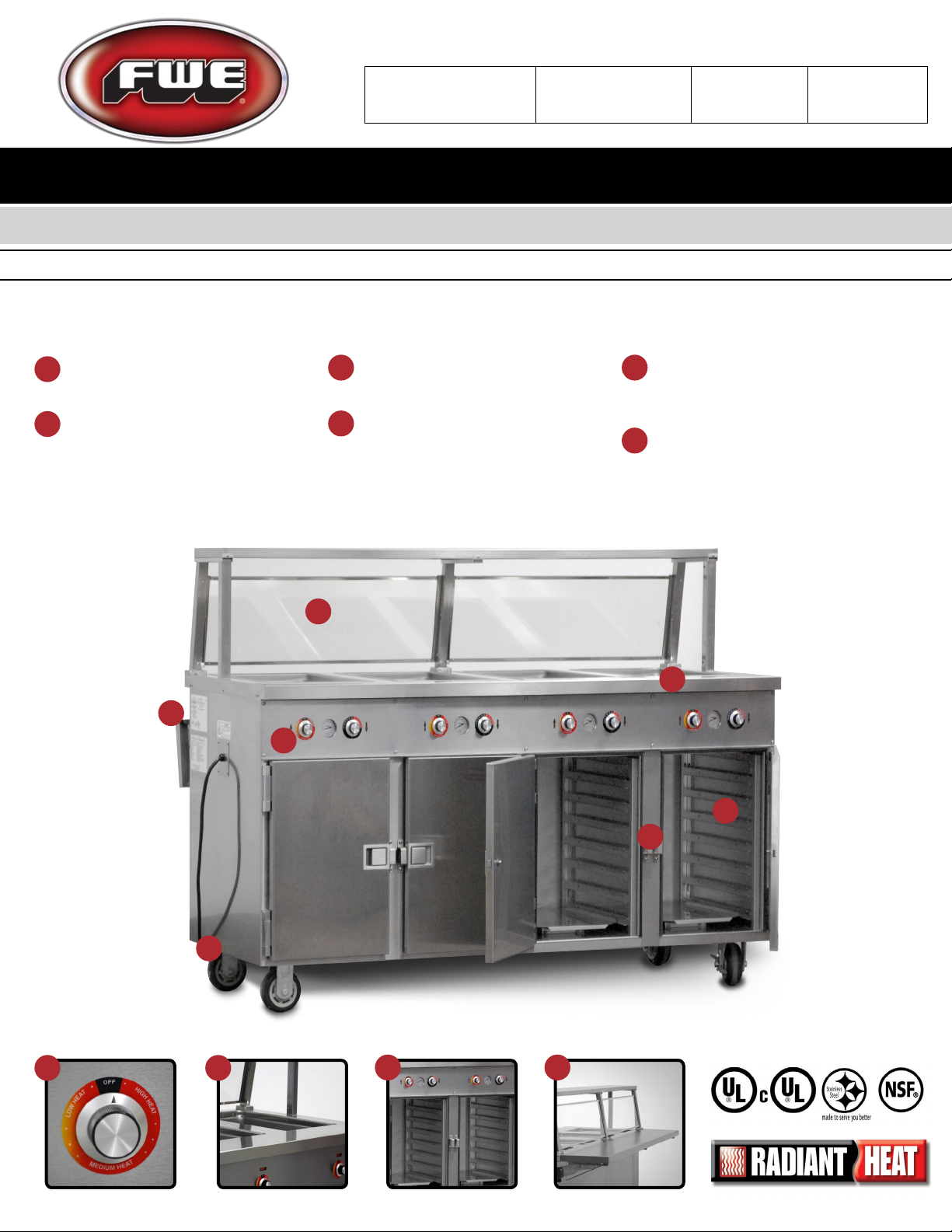

TRAY LINE HEATED HOLDING CABINETS

Serving Wells and Compartments for 12" x 20" pans and GN Containers

RADIANT “HLC-W” SERIES

Heavy-duty, mobile server takes the food whenever and wherever you need it to go!

Heated serving wells and heated holding

1

compartments keep rells close at hand!

Soft, radiant, uniform heat that gently

2

surrounds food to provide a better

appearance, taste and longer holding time

6

Each well and heated compartment is

3

controlled separately for added versatility

Made for mobile applications - FWE

4

cabinets are fully constructed of stainless

steel, with a one piece tubular welded base

frame, and designed to absorb vibration and

shock during transport

Stainless steel xed rack assembly

5

accommodates 12" x 20" pans and GN

containers

6

Customize with versatile service line optional

accessories, such as a sneeze guard and tray

slide shelf

*Two year limited warranty

6

3

2

5

3

4

Shown with optional Sneeze Guard and Tray Slide Shelf

2 3

Radiant Heat Controls Separately Controlled Wells Separately Controlled Compartments

3 6

HLC-4W6-7H-28-DRN

Optional Sneeze Guard &

Tray Slide Shelf

PROJECT: MODEL: QUANTITY: ITEM NO:

TRAY LINE HEATED

SPECIFICATIONS:

▲

6′

5′

4′

“H”

3′

2′

1′

▲

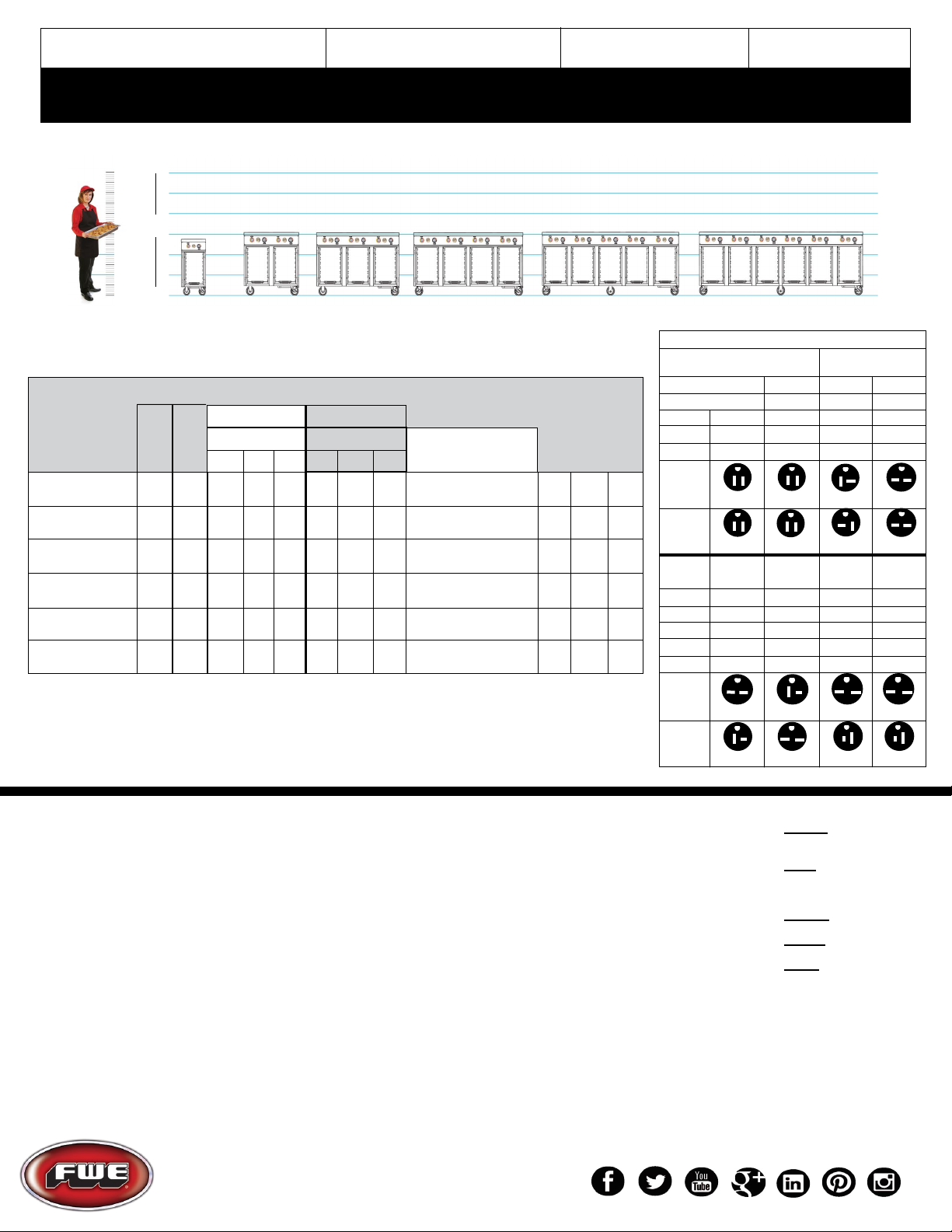

HLC-2W6-7H-14-DRN HLC-1W6-7H-7-DRN HLC-3W6-7H-21-DRN HLC-4W6-7H-28-DRN HLC-5W6-7H-35-DRN HLC-6W6-7H-42-DRN

CAPACITIES OF

MODEL

NUMBER

HLC-1W6-7H-7-DRN

HLC-2W6

-

7H-14-DRN

HLC-3W6-7H-21-DRN

-

HLC-4W6

HLC-5W6-7H-35-DRN

HLC-6W6-7H-42-DRN

[A] Combinations of deep and shallow pans may be used with varying capacities.

[B] Custom pan spacings are available to increase the capacity of the deeper pans:12″ x 20″ x 4″, 12″ x 20″ x 6″, GN 1/1-100

and GN 1/1-150 containers.

Custom Configurations are available to vary number of heated and ambient sections. Consult factory.

7H-28-DRN

DEPTH

OF

WELL

6.5″

(165)

6.5″

(165)

6.5″

(165)

6.5″

(165)

6.5″

(165)

6.5″

(165)

2.625″

NUMBER

OF

DEPTH

WELLS

2.5″ 4″ 6″

7 3[B] 2[B] 7 3[B] 2[B]

1

14 6[B] 4[B] 14 6[B] 4[B]

2

21 9

3

28 12

4

35 15

5

42 18

6

12″ x 20″

or

GN 1/1

FIXED SPACINGS

12″ x 20″

66.7mm

PANS

DEPTH

GN 1/1

65mm 100mm 150

[B] 6[B] 21 9[B] 6[B]

[B] 8[B] 28 12[B] 8[B]

[B] 10[B] 35 15[B] 10[B]

[B] 12[B] 42 18[B] 12[B]

PANS

[A]

FIXED SPACINGS

PANS

mm

OVERALL EXTERIOR

DIMENSIONS IN. (mm)

(Height Includes Casters)

HIGH

‘’H’’

35.25″

(895)

37″

(940)

37″

(940)

37″

(940)

37″

(940)

37″

(940)

DEEP

‘’D’’

27.5″

(698)

27.5″

(698)

27.5″

(698)

27.5″

(698)

29″

(737)

29″

(737)

WIDTH

*

‘’W’’

18.5″

*

(470)

34.25″

*

(870)

51.5″

(1308)

68.75″

(1746)

82″

(2083)

103.25″

(2623)

DOORS

CLASS 100

NO.

OF

CASTER

1

2

3

4

5

6

SIZE

3.5″

5″

5″

5″

5″

5″

SHIP WT.

LBS.

(KG)

190

(86)

280

(127)

440

( 2 0 0 )

615

( 2 7 9 )

750

( 3 4 0 )

850

( 3 8 6 )

HOLDING CABINETS

VOLTS

WATTS

AMPS

HERTZ

PHASE

PLUG

USA

PLUG

CANADA

VOLTS

WATTS

AMPS

HERTZ

PHASE

PLUG

USA

PLUG

CANADA

Dedicated circuit.

120

1000

8.3

50/60

Single

5-15P

5-15P

HLC-3W6-7H-

21-DRN

220-240

3570

14.9

50/60 50/60

Single

6-15P

6-20P 6-50P

ELECTRICAL DATA

HLC-1W6-7H-7-DRN

220-240

1190

5

50/60

Single

G

G

G

G

G

5-15P

G

5-15P

HLC-4W6-7H-

28-DRN

220-240

4760

19.8

50/60

Single

G

6-20P

G

6-30P

HLC-2W6-7H-14-DRN

120

220-240

G

G

G

G

2380

9.9

50/60

Single

6-15P

6-15P

HLC-6W6-7H-

42-DRN

220-240

7140

29.8

50/60

Single

6-30P

6-50P

2000

16.7

50/60

Single

5-20P

5-30P

HLC-5W6-7H-

35-DRN

220-240

5950

24.8

Single

6-30P

G

G

G

G

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 20-gauge polished

exterior, 22-gauge stainless steel interior with

easy-to-clean coved corners. Welded tubular base

frame shall be 1″ square, heavy gauge stainless steel

tubing, with 10-gauge stainless steel reinforcing stress

plates at corners.

INSULATION. “Ultra-Guard” UG-26 high density

fiberglass insulation throughout; top, back, bottom, sides

and door(s).

HANDLES. Heavy-duty stainless steel, side mounted lift

handles on 1-well and 2-well models.

DOORS AND LATCHES. Flush mounted, double pan,

stainless steel doors shall have 1″ thick fiberglass

insulation. High temperature door gasket mounted on

cabinet. Each door shall be equipped with flush-in-door

stainless steel paddle latch; positive closing. Each

door shall have two (2) heavy-duty edgemount die cast

hinges.

CASTERS. Maintenance free polyurethane tire casters

in a configuration of two (2) rigid and two (2) swivel with

brake. HLC-5W6-7H-35-DRN and

HLC-6W6-7H-42-DRN shall have a six caster

configuration with two (2) rigid and four (4) swivel with

brake. Casters shall have a reinforced yoke mounted to

10-gauge caster plate. The caster mounting plate shall

be secured to a 10-gauge stainless steel reinforcing

stress plate via welded in place stainless steel studs.

The reinforcing stress plates shall be welded to the

heavy gauge tubular frame of the unit.

PAN SLIDES. Stainless steel racks shall be one piece

die stamped channel-type pan slides at 2.625″ (66.7

mm) spacings to accommodate either deep or shallow

12″ x 20″ or GN 1/1 pans (at varying capacities - see

chart). Racks are removable without tools for cleaning.

Racks shall lift off heavy-duty stainless steel supports.

HEATED COMPARTMENTS. Radiant heat system

shall include an Incoloy nickel-chromium alloy heating

element. Controls shall be up-front, recessed and shall

include a full range thermostat adjustable to actual

temperature. Thermostat shall include temperature scale

marked in ten degree increments (F/C) from 90° to

190°F (30° to 90°C). An operational range thermometer,

power supply light and thermostat cycling light are also

included.

TOP MOUNT SERVING WELLS. Each well shall be one

FOOD WARMING EQUIPMENT COMPANY, INC.

5599 HWY. 31 W. Portland, TN 37148

800.222.4393 | 815.459.7500 | Fax: 815.459.7989

www.FWE.com | sales@fwe.com

piece stainless steel, deep drawn with coved corners.

Each well shall have ridge around top perimeter. Each

insulated, individually thermo wrapped well shall have a

separate adjustable thermostat and indicating light. Top

well depth of 6.5″ (165mm) is designed to be used wet.

Accommodates up to a 12″ x 20″ x 6″ or a GN 1/1-150.

DRAIN. Each heated well connects to built-in drain

system with easy access external shut-off valve.

ELECTRICAL CHARACTERISTICS. 3 wire grounded

10 foot extension power cord and plug, rear mounted

for safety. See electrical data chart above for amperage

and receptacle configuration. Dedicated circuit.

INSTALLATION. Unit should not be installed in an

area where adverse environmental conditions are

present.

FWE products may be covered under one or more of the following

U.S. patents: 288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

© 15 Food Warming Equipment Company, Inc.

All rights reserved.

Errors subject to correction.

R.15.02

Optional Accessories

ELECTRIC

□

220 volt, 50/60 Hz, single phase

□

Heat retention battery

DOORS

□

Key locking door latch

□

Magnetic latch

□

Padlocking transport latch

SPACINGS

□

Custom pan slide spacing

CASTERS

□

All swivel or larger casters

EXTRAS

□

Security packages

□

Full extension bumper

□

Tubular handles

□

Corner bumpers

□

Drop down side shelf

□

Drop down tray slide shelf

□

Drop down stainless steel, wood

or polyethylene cutting board

□

Sneeze guard

□

Cord winding bracket

□

Stainless steel top cover

□

Humidity pan

Loading...

Loading...