Food Warming Equipment Company HLC-10 Specifications

Home Page

Product Overview

Specification Page: S4–2

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

MOBILE HANDY LINE COMPARTMENTS

For 12" x 20" and Gastro-Norm 1/1 Bulk Food Pans

“HLC SERIES”

Shown with Full-View Lexan Door

and Edgemount Latch optional accessories.

Natural radiant heat keeps

foods oven fresh longer

and prevent product

dehydration and shrinkage.

Handy Line Compartments

Section 4

HLC-8L

TM

HLC-10

FWE’s natural convection heat/humidity

system provides a soft radiant heat

throughout the cabinet, perfect for

holding pre-cooked foods for either

short or prolonged periods of time.

Serve appetizing food presentations

from these units that help you produce

consistent and better tasting foods.

Hold and serve the best possible foods

with FWE’s Mobile Pan Servers.

Designed to accommodate 12" x 20"

and GN 1/1 pans, these small holding

cabinets do not require forced air

movement. FWE’s unique pan slide

racks are one piece die stamped

stainless steel, providing greater

hygiene and strength. The front edges

are relieved for easy loading and

the pair of racks are removable

for easy cleaning.

HLC-7

◊

All stainless steel

◊

Welded construction - no rivets

◊

Tubular stainless steel welded base frame

◊

Heavy-duty polyurethane casters

◊

Recessed up-front controls

◊

Heavy-duty door hinges

◊

Positive close door latch

◊

Stainless steel lift handles

◊

Individually controlled compartments

◊

Hi-temp door gasket

◊

Fully insulated throughout

◊

Stainless steel pan slides

◊

Two year limited warranty

U

®

L

U

C

L

®

Stainless

Steel

made to serve you better

NSF

®

PROJECT: MODEL: QUANTITY: ITEM NO:

MOBILE HANDY LINE COMPARTMENTS

SPECIFICATIONS:

▲

▲

"W"

▲

TOP

"D"

▼

4'

▲

3'

2'

"H"

1'

▼

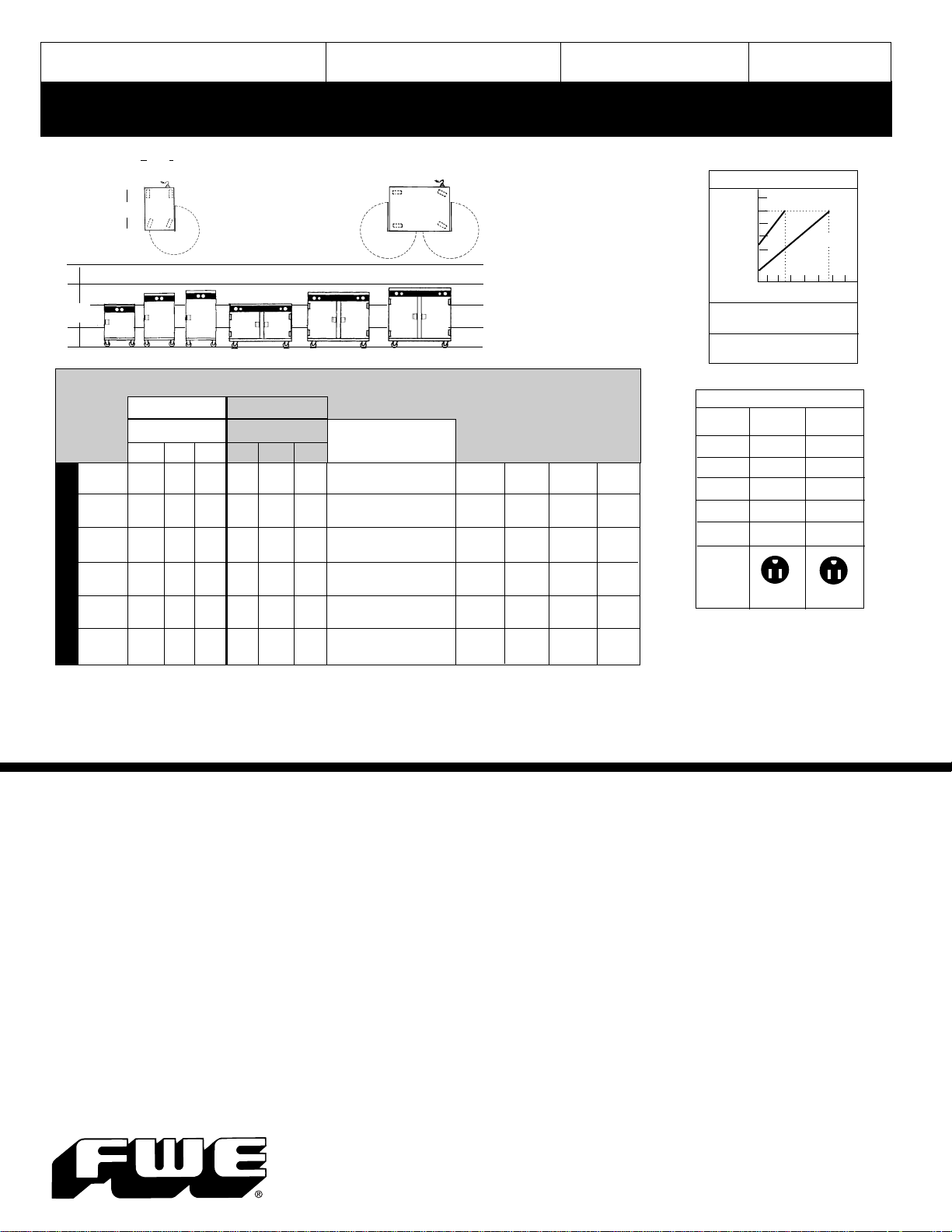

HLC-5 HLC-7 HLC-8 HLC-10 HLC-14 HLC-16

CAPACITIES OF

2.625''

FIXED SPACINGS

MODEL

NUMBER

HLC-5

HLC-7

HLC-8

HLC-10

HLC-14

UNDER COUNTER MODELS

HLC-16

DEPTH

12'' x 20''

2.5'' 4'' 6''

5 22 5 22

7 327 32

8 438 43

10 4410 44

14 6414 64

16 8616 86

DOOR SWING: 20"

12'' x 20''

or

GN 1/1

66.7mm

DEPTH

PANS

65mm100mm150

PANS

[A]

FIXED SPACINGS

GN 1/1

PANS

mm

24.75''

24.75''

HIGH

"H"

(629)

30''

(762)

33.5''

(821)

(629)

30''

(762)

33.5''

(821)

TOP

OVERALL EXTERIOR

DIMENSIONS IN. (mm)

WIDE

DEEP

"D"

27.5''

(698)

27.5''

(698)

27.5''

(698)

27.5''

(698)

27.5''

(698)

27.5''

(698)

18.25''

18.25''

18.25''

35.25''

35.25''

35.25''

"W"

(464)

(464)

(464)

(896)

(896)

(896)

*

NO. OF

DOORS

1

1

1

2

2

2

For 12" x 20" and GN 1/1 Bulk Food Pans

PERFORMANCE VALUES

CASTER

SHIP WT .

SIZE

105

"

3.5

(48)

115

3.5

"

(52)

3.5

"

(54)

165

3.5

"

(76)

180

3.5

"

(82)

3.5

"

(86)

CLASS 100

CUBIC

LBS.

FEET

(KG)

(m3)

7.19

(.20)

8.71

(.25)

9.44

120

(.27)

13.88

(.39)

16.83

(.48)

18.23

190

(.52)

T

E

M

P

PREHEAT

RECOVERY

VOLTS 120 120

WATTS 500 1000

AMPS 4.3 8.3

HERTZ 50/60 50/60

PHASE Single Single

NEMA

PLUG

Dedicated circuit.

RECOVERY

190°

170°

150°

130°

110°

70°

5 10 15 20 25 30 35

75°F to 170°F

APPROX. 29 MIN.

120°F to 170°F

APPROX. 13 MIN.

ELECTRICAL DATA

HLC-5, HLC-7 HLC-10, HLC-14

HLC-8 HLC-16

5-15P 5-15P

•

TIME

G

•

PREHEAT

G

[A] Combinations of deep and shallow pans may be used with varying capacities.

*Width Note: If omitting drop handles, subtract 1.25" (31 mm) from overall exterior width.

Pass-thru Door [add “P”] is available on all model sizes. Add 2.5" to depth dimension.

•

•

See-thru Lexan Door [add “L”] is available on all model sizes.

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 20-gauge polished

exterior, 22-gauge stainless steel interior with

easy-to-clean coved corners. Welded tubular

base frame shall be 1" square, heavy gauge

stainless steel tubing, with 10-gauge stainless

steel reinforcing stress plates at corners.

INSULATION. “Ultra-Guard” UG-26 high

density fiberglass insulation throughout; top,

back, bottom, sides and door(s).

HANDLES. Heavy-duty stainless steel,

side-mounted lift handles.

DOORS AND LATCHES. Flush mounted, double

pan, stainless steel doors shall have 1" thick

fiberglass insulation. High temperature door gasket

mounted on cabinet. Each door shall be equipped

with flush-in-door stainless steel paddle latch;

CASTERS. Maintenance free polyurethane tire

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be

secured to a 10-gauge stainless steel

reinforcing stress plate via welded in place

stainless steel studs. The reinforcing stress

plates shall be welded to the heavy gauge

tubular frame of the unit.

PAN SLIDES. Stainless steel racks shall be

one piece die stamped channel-type pan slides

at 2.625" (66.7 mm) spacings to accommodate

either deep or shallow 12" x 20" or GN 1/1 pans

(at varying capacities - see chart). Racks are

removable without tools for cleaning. Racks

shall lift off heavy-duty stainless steel supports.

positive closing. Each door shall have two (2)

heavy-duty lift-off hinges and allow 270° door swing.

FWE Products are used by major companies

world-wide. We can modify, design, or custom

build equipment to fit your special requirements.

HEATING SYSTEM/CONTROLS.

Radiant heat system shall include an

Incoloy nickel-chromium alloy heating

element. Removable stainless steel baffled

humidifier pan shall be provided. Controls

shall be up-front, recessed and shall include

a full range thermostat adjustable to actual

temperature.Thermostat shall include

temperature scale marked in ten degree

increments (F/C) from 90° to 190°F (30° to

90°C). An operational range thermometer,

power supply light and thermostat cycling

light are also included.

ELECTRICAL CHARACTERISTICS.

3 wire grounded 10 foot extension

power cord and plug, rear mounted for

safety. See electrical data chart above for

amperage and receptacle configuration.

Dedicated circuit.

Optional Accessories:

Electronic controls

■

Digital thermometer

■

220 volt, 50/60 Hz, single phase

■

CE complaint

■

Heat retention battery

■

See-thru Lexan door

■

Pass-thru door

■

Key locking door latch

■

Magnetic latch

■

Padlocking transport latch

■

Left hand door hinging

■

Security packages

■

All swivel or larger casters

■

Door edge trim

■

Tubular handle

■

Full extension bumper

■

Corner bumpers

■

Cold plate cartridge

■

Custom pan slide spacing

■

6" floor legs

■

4" counter legs

■

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10F Food Warming Equipment Company. Inc.

Loading...

Loading...