Food Warming Equipment Company HDC-252-I Specifications

Home Page

Product Overview

Specification Page: S1–13

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

MOBILE HEATED DISH CABINETi

Heated Rotary Cabinet for 12" Plates

“HDC SERIES”

HDC-252-

I

HDC-252-

I

Shown with flip back top opened.

Up to 12" plates

can be stored,

heated, and held

in this insulated

and temperature

controlled dish dolly.

Banquet Cabinets

Section 1

TM

Profitability increases with satisfied customers and repeat customers –

and one way to accomplish this is by serving hot appetizing meals.

Compact, fully enclosed, heated rotary dish dolly stores and transports

up to 12" diameter clean dishes that are preheated prior to dish-up.

Adjustable / removable wire rods create four compartment segments

that help separate and protect plates while in storage. Additional rods

can be conveniently positioned to adjust to multiple plate sizes, which

increases the capacity of smaller plates - or to accommodate future

changes in your operation.

Ideal for hotel / resorts, banquet operations, cafeteria, buffet and

restaurant establishments, these heated rotary dish cabinets are

built stronger and perform better than any other on the market today –

period!

E-Z access rotating base, along with front door and flip-back

top access, allow for easy loading and unloading of all dishes.

The flip-back cover design allows the front door to be opened

even when the top is closed.

FWE’s design achieves unmatched results with faster heat-up times

and more consistent plate temperatures than any competitive model.

Fully insulated walls, adjustable up-front full range thermostat

100°F - 200°F (38°C - 93°C), and a high performance, split-baffle,

eight-sided rotating heat tube system that delivers a

top performance 360° air flow, all at a lower energy cost.

Low profile design conserves valuable floor space by conveniently

fitting under a 36” counter, along with all stainless steel construction that

includes heavy duty abuse resistant welded tubular base frame, heavy

duty polyurethane casters for easy mobility (even when fully loaded),

makes the

HDC-252

-I a true performer in any operation.

◊

Rotating stainless steel dish base

◊

Master on-off switch

◊

Separate control for temperature

◊

Range 100°F to 200°F

◊

Fully insulated walls and door

◊

Flip-back top for easy load and unload

◊

All stainless steel

◊

All welded construction - no rivets

◊

Welded base frame

◊

All swivel with brake polyurethane casters

◊

Heavy duty door latch & hinges

◊

Sanitary removable plate divider rods

◊

Cord winding brackets

◊

Two year limited warranty

U

®

L

U

C

L

®

Stainless

Steel

made to serve you better

NSF

®

PROJECT: MODEL: QUANTITY: ITEM NO:

SPECIFICATIONS:

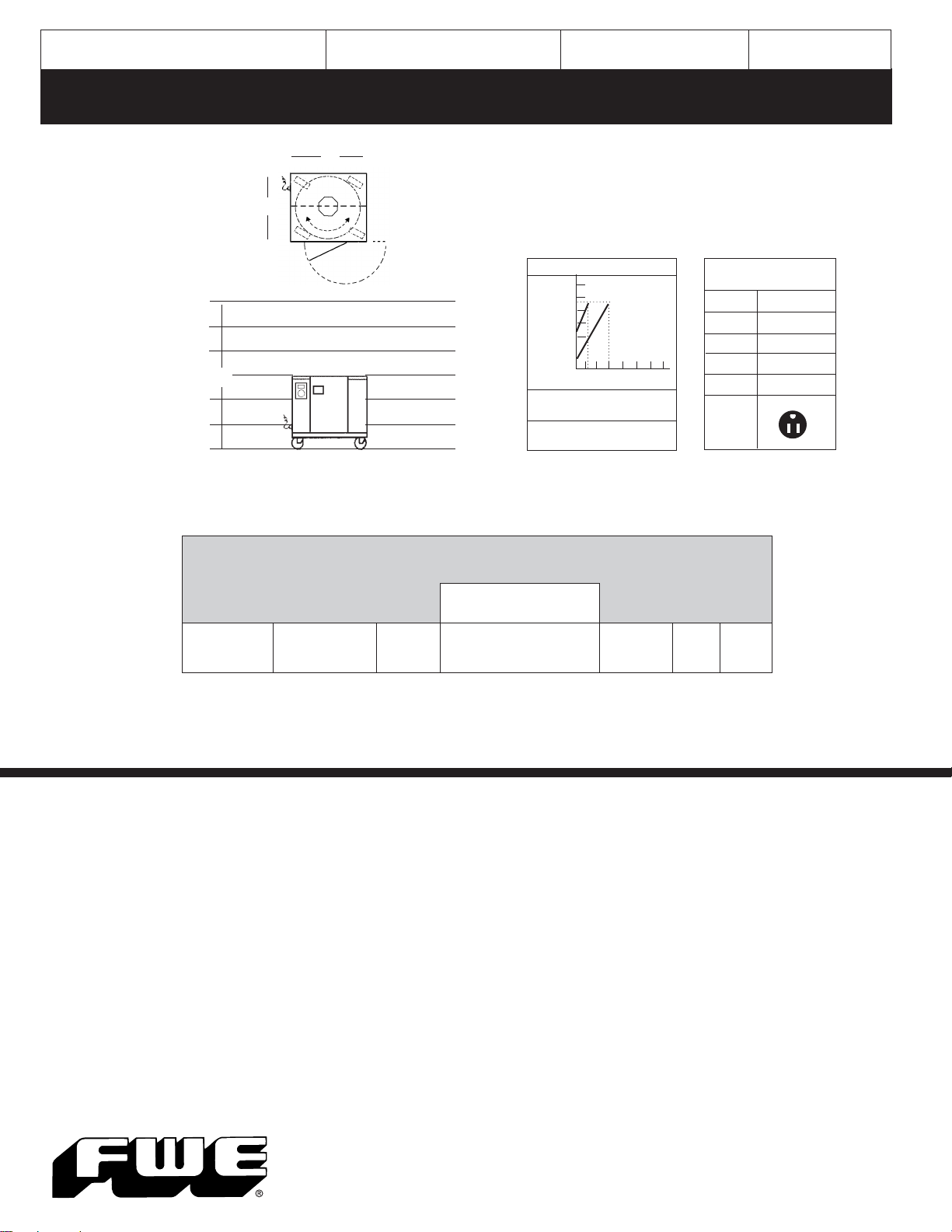

"W"

▲

▲

"D"

▼

6'

▲

5'

4'

3'

"H"

2'

1'

▼

HDC-252-I

(heated)

▲

“Top View”

HEATED DISH CABINET

DOOR SWING: 20"

PERFORMANCE VALUES

T

190°

RECOVERY

170°

E

150°

130°

M

110°

P

70°

PREHEAT

RECOVERY

•

•

PREHEAT

TIME

5 10 15 20 25 30 35

75°F to 160°F

APPROX. 15 MIN.

120°F to 160°F

APPROX. 6 MIN.

For up to

12" Dishes

ELECTRICAL DATA

VOLTS 120

WATTS 1550

AMPS 13

HERTZ 50 / 60

PHASE Single

NEMA

PLUG

5-15P

Dedicated circuit.

G

CAPACITY BASED ON 12'' PLATE:

MODEL

NUMBER

HDC-252-I

Heated

[A] Capacity depends upon height of plates from .572'' (14.53) to .345'' (8.76).

❏ Corner Bumpers: Cabinet Dimensions with Corner Bumpers: DEEP “D”: 35.5'' (902); WIDE “W”: 34'' (864).

CONSTRUCTION. Heliarc welded, single unit

construction of stainless steel; 20-gauge

polished exterior, 22-gauge stainless steel interior

with easy-to-clean coved corners. Welded tubular

base frame shall be 1" square, heavy gauge

stainless steel tubing, with 10-gauge stainless

steel reinforcing stress plates at corners.

INSULATION. “Ultra-Guard” UG-26 high density

fiberglass insulation throughout; top, back, bottom,

sides, and door(s).

DOORS AND LATCHES. Flush mounted,

stainless steel insulated doors with two (2)

heavy-duty 12-gauge stainless steel hinges.

Door latch shall be stainless steel flush-in-door,

paddle latch, and positive closing.

FLIP-BACK TOP. Top shall be mid-hinged to

allow easy top loading and unloading of dishes,

with top hand grip lift.

ROTATING DISH RACK. Cabinet shall include

rotating base for easy access for loading and

unloading of dishes.

12'' PLATE MAXIMUM

4 STACKS

152 to 252

[A]

PLATE DIVIDER SLIDES. Four (4) standard

welded rod-style plate slides are adjustable to

fit up to 12" plates standard and removable for

greater sanitation. Fully adjustable / removable

design to give secure plate alignment. Up to

four (4) additional dividers can be added to

accommodate or separate smaller size plates.

CASTERS.

tire casters in a configuration of four (4)

swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be

secured to a 10-gauge stainless steel

reinforcing stress plate via welded in place

stainless steel studs. The reinforcing stress

plates shall be welded to the heavy gauge

tubular frame of the unit.

OVERALL EXTERIOR DIMENSIONS IN. (mm)

WORKING

HEIGHT

21.75''

(552)

HIGH

"H"

33.5''

(851)

Maintenance free polyurethane

DEEP

"D"

33''

(838)

HEAT CONTROLS. Long life Incoloy nickel-chromium

alloy heating element; Hi-Temp, self-lubricated,

impedance protected fan-cooled blower motor for

heated air distribution. Controls shall be up-front

and shall include temperature sensor and master

ON / OFF 20 amp lighted power switch, adjustable

temperature control to 200°F (93°C).

ELECTRICAL CHARACTERISTICS.

3 wire grounded 10 foot extension power

cord and plug with cord winding brackets,

side mounted for safety.

amperage and receptacle configuration.

Dedicated circuit.

WIDE

"W"

31.5''

(800)

CASTER

SIZE

5"

all swivel casters

See chart above for

CLASS 100

SHIP

WT.

LBS.

(KG)

205

(94)

CUBIC

FEET

(m3)

19.23

(.54)

Optional Accessories:

Larger casters

■

Corner bumpers (set of 4)

■

Full perimeter bumper

■

Push - pull bar handles

■

220 volt, 50/60 Hz, single phase

■

FWE Products are used by major

companies world-wide. We can

modify, design, or custom build

equipment to fit your special

requirements.

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10D Food Warming Equipment Company. Inc.

Loading...

Loading...