Food Warming Equipment Company ETC-1826-14PH Specifications

Home Page

Product Overview

Specification Page: S5–4

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

PROOFER/HEATER ETC CABINETS

Proofing Module for 18" x 26" Trays and Pans

“ETC-1826-PH SERIES”

❏ Non-Insulated Cabinet

❏ Insulated Door

❏ Removable Proofer/Heater Module

❏ 18" x 26" Tray Rack, Fixed Spacings

REMOVABLE

With removable water pan

secured by strap that doubles as handle

ETC-1826-9PH

Economy, non-insulated

cabinet with E-Z removable

proofer/heater module.

Proofer/Heater Cabinets

Section 5

TM

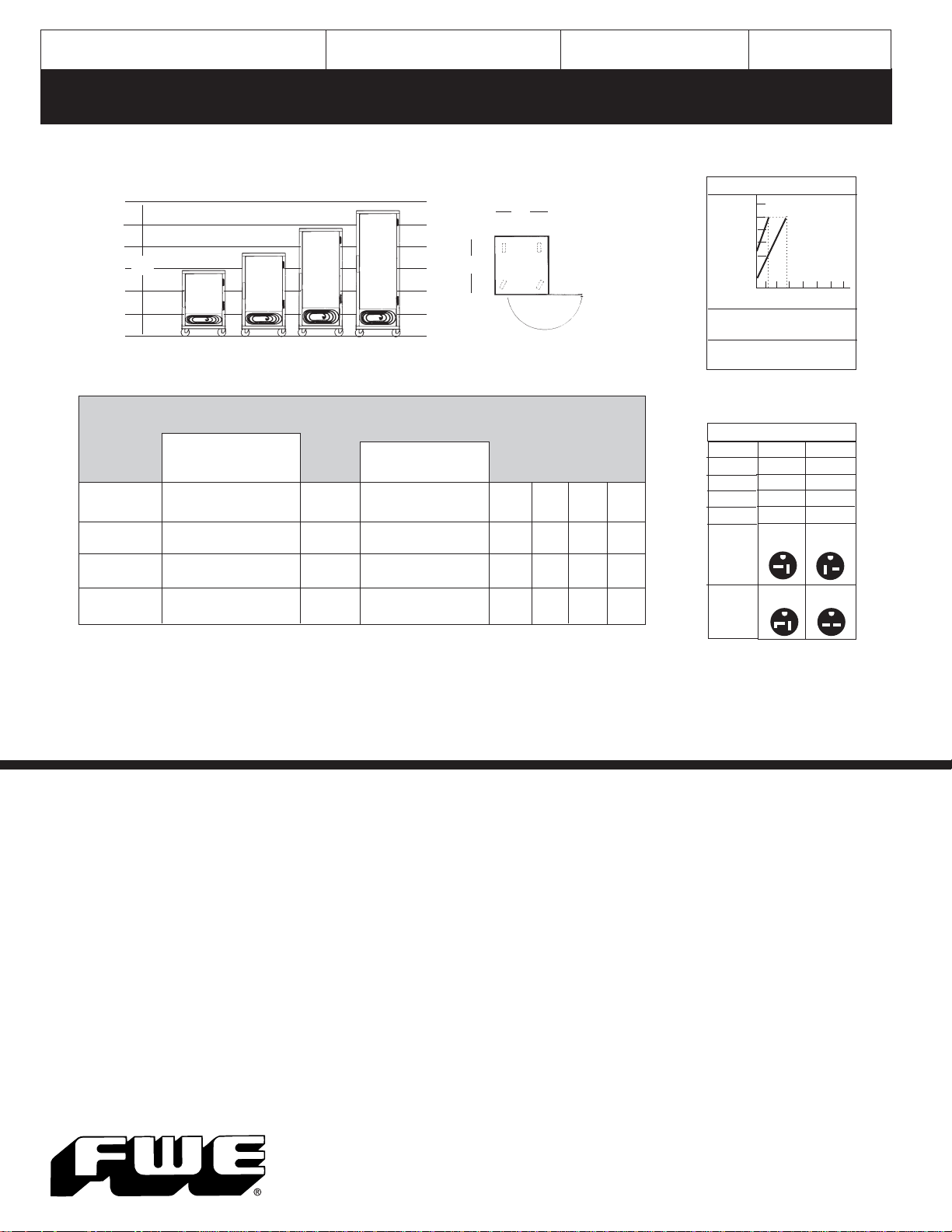

Thermometer

Heat control

REMOVABLE

PROOFER/HEATER

MODULE

Where non-insulated units are required

and/or a Removable Heat System is desired,

FWE offers this self-contained heat system.

The amount of warmed moisture in the

cabinet is regulated by the control dial with

settings marked “Low” to “High”. The cabinet

temperature is regulated by the control dial

with settings from 90°F to 190°F. To “Proof”,

add water to the water pan at the Medium

High setting and maintain the cabinet at 95°F.

If dry heat is needed for other holding

applications,

be used either wet or dry – unlike other

competitive products

Durable stainless steel takes the abuse of

transport applications and allows for sanitary

maintenance. Casters are mounted to

reinforcement plates for added durability

and take the impact over thresholds.

Built tough from stainless steel for

continuous demanding use.

it does not harm the unit to

.

Main Power

On/Off Switchr

Humidity control

Cord winding brackets

◊

Removable proofer/heater system

◊

Separate controls for heat and humidity

◊

All stainless steel

◊

All welded construction - no rivets

◊

Tubular stainless steel welded base frame

◊

Heavy-duty polyurethane casters

◊

Removable, oversized humidity reservoir

◊

Heavy-duty hinges

◊

Positive close door latch

◊

Hi-temp door gasket

◊

Removable tray rack assembly

at fixed 3" spacings

◊

Recessed hand grips

◊

Insulated door

◊

Two year limited warranty

Stainless

U

®

L

U

®

C

L

Steel

made to serve you better

NSF

®

PROJECT: MODEL: QUANTITY: ITEM NO:

SPECIFICATIONS:

6'

▲

5'

4'

"H"

3'

2'

1'

▼

ETC-1826-5PH ETC-1826-9PH ETC-1826-14PH ETC-1826-17PH

Under Counter

CAPACITIES

MODEL

NUMBER

ETC-1826-5PH

Under Counter

ETC-1826-9PH

ETC-1826-14PH

ETC-1826-17PH

[A]

Tray rack assembly accommodates: (1) 18" x 26" tray and / or pan or (1) Baguette/French Bread Form 18" x 26" .

•

Dutch Doors [add “D”] are 2 half size doors available on the full-size models.†

•

See-thru Lexan Door [add “L”] is available on all model sizes.

Removable Proofer/Heat System:

Overall exterior dimensions: Height: 6" (152mm) / Depth: 19" (483mm) / Width: 18.25" (540mm) / Weight: 23 lbs (10kg)

3"FIXED SPACING

TRAY / PAN CAPACITY

5 - 18'' x 26'' trays / pans

9 - 18'' x 26'' trays / pans

14 - 18'' x 26'' trays / pans

†

17 - 18'' x 26'' trays / pans

†

[A]

18"x 26

"

BAGUETTE

FRENCH BREAD

FORMS

5

9

14

17

OVERALL EXTERIOR

DIMENSIONS IN. (mm)

HIGH

DEEP

"H"

"D"

33.5''

30.25''

(768)

(851)

44.5''

30.25''

(1130)

(768)

60.5''

30.25''

(768)

(1537)

69.25''

30.25''

(768)

(1759)

PROOFER/HEATER ETC CABINETS

"W"

▲

▲

TOP

"D"

▼

NO. OF

WIDE

DOORS

"W"

22''

(559)

22''

(559)

22''

(559)

22''

(559)

1 5''

1 5''

1 5''

1 5''

▲

DOOR SWING:

22.25"

Consult Factory for

SHIPPING CLASS

SHIP WT .

CASTER

LBS.

SIZE

(KG)

165

12.90

(75)

(.36)

195

17.13

(88)

(.48)

235

23.30

(106)

(.66)

260

26.67

(117)

(.75)

CUBIC

FEET

(m3)

PERFORMANCE VALUES

T

190°

RECOVERY

170°

•

•

E

150°

130°

M

110°

P

70°

PREHEAT

RECOVERY

* Values are for mid-size model listed.

ELECTRICAL DATA

VOLTS

WATTS

AMPS

HERTZ

PHASE

PLUG

USA

PLUG

CANADA

Dedicated circuit

PREHEAT

TIME

5 10 15 20 25 30 35

75°F to 170°F

APPROX. 14 MIN.

120°F to 170°F

APPROX. 6 MIN.

120 220-240

2200 4270

18.3 17.8

50 / 60 50 / 60

Single Single

5-20P 6-20P

G

5-30P 6-30P

G

G

G

CONSTRUCTION. Heliarc welded, single unit

construction of 18-gauge stainless steel;

Welded tubular base frame shall be 1" square, heavy

gauge stainless steel tubing, with 10-gauge stainless

steel reinforcing plates at corners and fittings.

DOORS AND LATCHES. Flush mounted, stainless

steel insulated doors. High temperature gasket sealed;

gasket shall be cabinet mounted. Each door shall have

two (2) heavy-duty edgemount die cast hinges.

Door latch shall be edgemounted, full grip, and positive

closing. The hinge and latch mountings are reinforced

with stainless steel backing plates.

HANDLES. Full-size, form-fitting recessed hand grips

shall be mounted on each side of cabinet.

CASTERS.

Maintenance free polyurethane tire

casters in a configuration of two (2) rigid and

two (2) swivel with brake. Casters shall have a

reinforced yoke mounted to 10-gauge caster

plate. The caster mounting plate shall be secured

to a 10-gauge stainless steel reinforcing stress

plate via welded in place stainless steel studs.

The reinforcing stress plates shall be welded to

the heavy gauge tubular frame of the unit.

TRAY RACK ASSEMBLY. Unitized tray rack

assembly shall be heavy gauge stainless steel,

channels fixed in place at 3" spacings. Assemblies

are designed to accommodate one (1) 18" x 26" tray.

Removable stainless steel uprights shall easily

lift off heavy-duty stainless steel supports

without the use of tools.

REMOVABLE PROOFER/HEATER SYSTEM AND

CONTROLS. Forced air heating system shall be

completely removable for convenience and

sanitation. System shall include two (2) separate

long life Incoloy nickel-chromium alloy heating

elements; separate, adjustable controls shall be

provided for each function: One to control the

interior air temperature, and one to control the

interior air moisture with hydro immersion waterbath.

A stainless steel water reservoir shall be

Food Warming Equipment Company, Inc.

P.O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

removable for ease of cleaning/sanitation.

System shall have a Hi-Temp, self-lubricated,

impedance protected fan-cooled blower motor

for moist air distribution. Controls shall include

adjustable air temperature control (to 190°F.),

adjustable moisture control (Low to High),

20 amp ON/OFF power switch, operational

range thermometer.

ELECTRICAL CHARACTERISTICS.

3 wire grounded 10 foot extension power cord

and plug. See electrical data chart above for

amperage and receptacle configuration.

Dedicated circuit.

FWE Products are used by major

companies world-wide. We can

modify, design, or custom build

equipment to fit your special

requirements.

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

Optional Accessories:

CE compliant

■

Heat retention battery

■

Dutch doors

■

See-thru lexan door

■

Key locking door latch

■

Magnetic latch

■

Paddle latch

■

Padlocking transport latch

■

Left hand door hinging

■

Security packages

■

Full extension bumper

■

Corner bumpers

■

Heavy-duty push-pull handles

■

All swivel or larger casters

■

Door edge trim

■

Cold plate cartridge

■

Floorlock (requires 6" casters)

■

Extra tray slides

■

Custom tray

■

slide spacing

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10E Food Warming Equipment Company. Inc.

Loading...

Loading...