Food Warming Equipment Company ETC-1520-20 Specifications

Home Page

Product Overview

Specification Page: S8–2

PROJECT: MODEL: QUANTITY: ITEM NO:

Quick Link Directory

❏ Non-Heated

❏ Non-Insulated

❏ Adjustable

Upright

Assembly

FITS PATIENT TRAYS:

ENCLOSED TRAY CABINETSi

For 15" x 20", 14" x 18", or 18" x 26" Size Patient Trays

“ETC PATIENT TRAY SERIES 2”

15" x 20"

14" x 18"

18" x 26"

Rugged patient tray

transports in sanitary

stainless steel Easy to maintain and

non-electrical!

Patient Tray Delivery

Section 8

TM

ETC-1520-32

FWE’s heavy-duty patient tray cabinets are fully

enclosed and designed for fast tray access. Built

for mobility, FWE’s unibody construction keeps

the cabinet balanced and stable during transport.

One piece rack and upright assembly make it

easy and sturdy to transport various size trays.

Serve hot and cold foods together using pellet

systems, insulated, or disposable containers.

Complete meals can be prepared ahead of time,

then easily transported to serving location. Our

internal frame construction is designed to endure

the most rigorous operations and environments,

eliminating cabinet torquing during transport,

assuring FWE cabinets last longer than any

other –

Durable stainless steel takes the abuse of transport

applications and allows for sanitary maintenance.

Casters are mounted to reinforcement plates

for added durability and take the impact over

thresholds. Built tough from stainless steel

for continuous demanding use, FWE is the

“Choice of Professionals”.

period!

ETC-1520-16

◊

All stainless steel

◊

All welded construction - no rivets

◊

Tubular stainless steel welded base frame

◊

Full extension bumper

◊

Heavy-duty polyurethane casters

◊

Heavy-duty lift-off hinges

◊

Positive close door latch

◊

Heavy-duty tubular push bar handles

◊

Doors lie flush when open

◊

Insulated door(s)

◊

Pitched center drain

◊

Removable and adjustable tray slides

◊

Two year limited warranty

Stainless

Steel

made to serve you better

NSF

®

PROJECT: MODEL: QUANTITY: ITEM NO:

Series 2

SPECIFICATIONS:

ENCLOSED TRAY CABINETS

Patient Trays

▲

"W"

▲

▲

"D"

▼

6'

▲

5'

4'

3'

"H"

2'

1'

▼

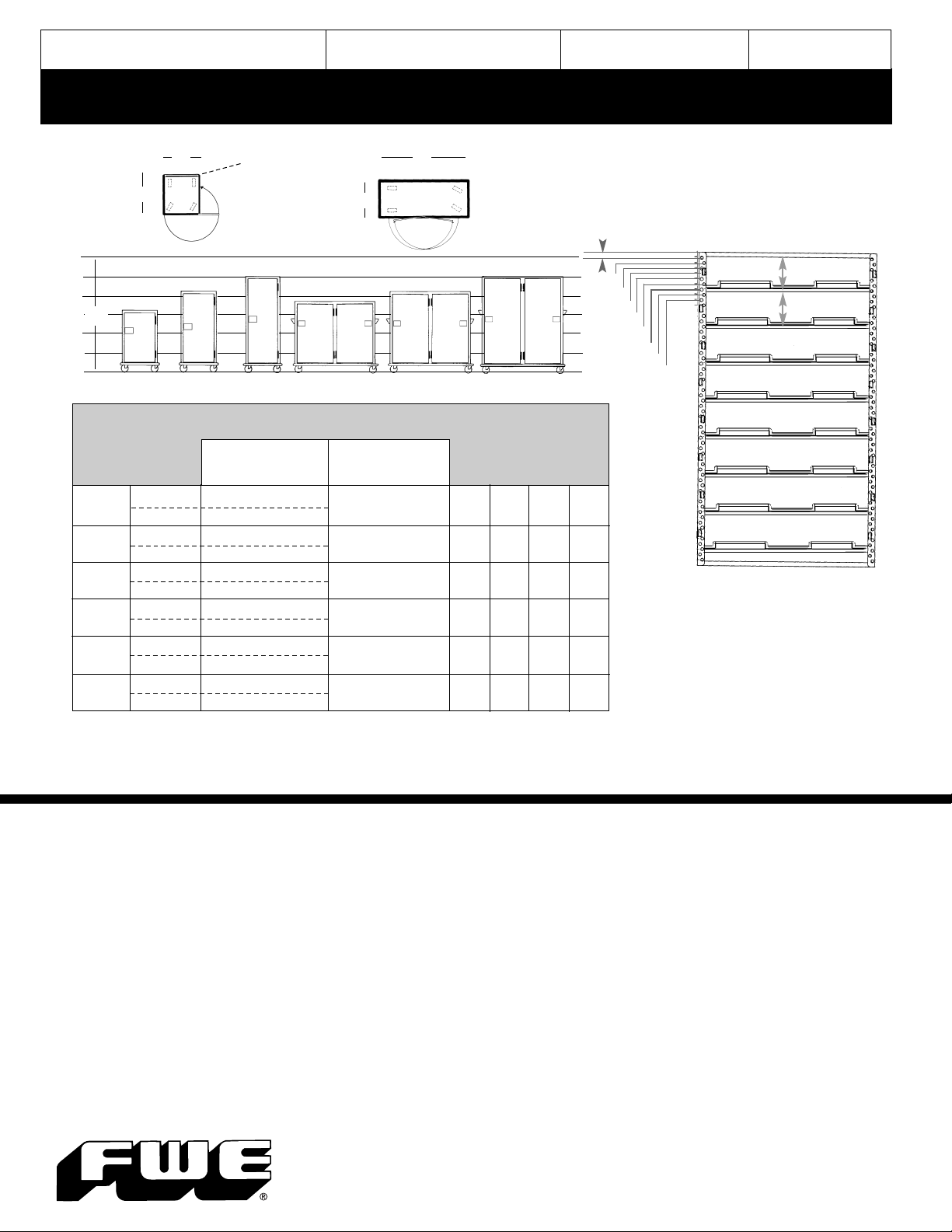

ETC-1520-10 ETC-1520-16 ETC-1520-20 ETC-1520-24 ETC-1520-32 ETC-1520-40

MODEL

NUMBER

ETC-1520-10

ETC-1520-16

ETC-1520-20

ETC-1520-24

ETC-1520-32

ETC-1520-40

[A]

Upright assembly accommodates 15'' x 20'', 14'' x 18'', or 18'' x 26'' trays by adjusting the position of the uprights on the alignment pins.

[B]

Model numbers are based on capacities of 15'' x 20'' Trays @ spacings of 5.25''.

Tray slides can be positioned at a choice of .75'' increments.

❏

See-thru Lexan Door [add “L”] displays cabinet contents for easy monitoring.

Pass-thru Door and Dutch Doors are not available on these model numbers.

TRAY SIZE

15x20 or 14x18

18 x 26

15x20 or 14x18

18 x 26

15x20 or 14x18

18 x 26

15x20 or 14x18

18 x 26

15x20 or 14x18

18 x 26

15x20 or 14x18

18 x 26

Handle

mounted

at rear

of unit on

single door

model

TRAY CAPACITIES

NUMBER OF TRAYS AT SPACINGS OF:

3.75" 4.5" 5.25"

14 10 10 8

755 4

22 18 16 14

11 9 8 7

28 22 20 16

14 11 10 8

32 28 24 20

16 14 12 10

44 36 32 28

22 18 16 14

56 44 40 32

28 22 20 16

[A]

OVERALL EXTERIOR DIMENSIONS IN. (mm)

HIGH

“H”

[B]

6.0"

37

(1257)

52

(1321)

62.6

(1590)

42.5

(1080)

52

(1321)

62.6

(1590)

▲

"D"

▼

"

"

"

"

"

"

▲

DEEP

“D”

35.25

(895)

35.25

(895)

35.25

(895)

35.25

(895)

35.25

(895)

35.25

(895)

TOP

"

"

"

"

"

"

"W"

29.5

(749)

29.5

(749)

29.5

(749)

52.75

(1340)

52.75

(1340)

52.75

(1340)

WIDE

“W”

"

"

"

"

"

"

▲

DOOR SWING: 20"

NO.

CASTER

OF

SIZE

DOORS

1

1

1

2

2

2

Consult Factory for

SHIPPING CLASS

SHIP WT .

LBS.

(KG)

200

(90)

215

(97)

235

(106)

360

(162)

360

(162)

385

(174)

22.26

(.63)

31.29

(.89)

37.67

(1.07)

55.96

(1.58)

55.96

(1.58)

67.36

(1.91)

6

"

6

"

6

"

6

"

6

"

6

"

CUBIC

FEET

Tray Slides can be positioned at a choice

of .75" increments for greater flexibility.

Spacings at .75" increments

1.5"

2.25"

3.0"

3.75"

4.5"

5.25"

6.0"

6.75"

(m3)

Spacing the Tray Slides

to meet your capacities:

5.25" Spacing

5.25" Spacing

Side View of ETC-1520-16

FWE Products are used by major

companies world-wide. We can

modify, design, or custom build

equipment to fit your special

requirements.

CONSTRUCTION. Heliarc welded, single unit

construction of 18-gauge stainless steel.

Welded tubular base frame shall be 1" square,

heavy gauge stainless steel tubing, with

10-gauge stainless steel reinforcing

plates at corners and fittings.

PUSH BAR HANDLES. Heavy-duty, 1" diameter

tubular stainless steel push handles: One (1)

on single door units mounted on rear of unit,

two (2) on multi-door units mounted on each

end of unit. Mountings reinforced with stainless

steel channel.

BUMPER. Solid 1.5" wide continuous

wraparound aluminum channel, bolted to frame,

with snap-in, non-marking replaceable vinyl

cushion. Full perimeter bumper extends beyond

doors, handles, etc., for added protection.

Shall be continuous, with corner cut-outs

to facilitate cleaning.

DOORS AND LATCHES. Flush mounted,

stainless steel insulated doors. When opened

doors lie flush against side of unit or another

door to keep work aisles unobstructed. Each

door shall have two (2) heavy-duty, lift-off,

12-gauge stainless steel hinges. Each door

shall be equipped with a positive closing,

flush-in-door, stainless steel paddle latch.

The hinge and latch mountings are reinforced

with stainless steel backing plates.

CASTERS.

tire casters in a configuration of two (2) rigid

and two (2) swivel with brake. Casters shall

have a reinforced yoke mounted to 10-gauge

caster plate. The caster mounting plate shall

be secured to a 10-gauge stainless steel

reinforcing stress plate via welded in place

stainless steel studs. The reinforcing stress

plates shall be welded to the heavy gauge

tubular frame of the unit.

Food Warming Equipment Company, Inc.

P .O. Box 1001

Crystal Lake, IL 60039 USA

800-222-4393; 815-459-7500

Fax: 815-459-7989

TRAY SLIDES.

slides are nickel plated for greater

durability and sanitation. Fully

adjustable /

give secure bottom tray support. Removable

stainless steel uprights shall be punched on

.75" spacing for easy tray/pan adjustment,

and shall easily lift off heavy-duty, stainless

steel brackets without the use of tools.

Each upright assembly contains four (4)

Maintenance free polyurethane

sets of alignment holes that mount to fixed

top and bottom alignment pins welded to

cabinet floor and ceiling.

PITCHED DRAIN. Cabinet shall have a

pitched center drain to facilitate thorough

cleaning of interior.

Manufacturing Facilities:

7900 S. Route 31

Crystal Lake, IL 60014 USA

www.FWE.com sales@fweco.net

Welded rod-style tray

removable and designed to

FWE products may be covered under

one or more of the following U.S. patents:

288,299;238,300;3,952,609;4,192,991.

All specifications subject to change without notice.

©10G Food Warming Equipment Company. Inc.

Optional Accessories:

See-thru Lexan door

■

Key locking door latch

■

Padlocking transport latch

■

Door swing configuration

■

Security packages

■

All swivel or larger casters

■

Door edge trim

■

Cold plate cartridge

■

Menu card holder

■

Top guard rail (3 or 4 sided)

■

Beverage urn angles

■

Extra tray slides

■

Fixed-in-place tray slides

■

Loading...

Loading...