Fomotech TWISTER2XA5000 User Manual

TTAABBLLEE OOFF CCOONNTTEENNTTSS

Page

1. INTRODUCTION ....................................................................................................... 2

2. SAFETY INSTRUCTIONS ......................................................................................... 3

3. SYSTEM FUNCTIONS ............................................................................................. 4~6

4. TRANSMITTER OUTLINE

4.1 TRANSMITTER BOX ....................................................................................... 7

4.2 DETAI LED PARTS ............................................................................................. 7

4.3 ENCODER BOARD AND PLL MODULE ....................................................... 8

4.4 CHARGE, BATTERY AND WAIST BELT ....................................................... 8

5. RECEIVER OUTLINE

5.1 RECEIVER BOX ............................................................................................... 9

5.2 DETAILED PARTS ............................................................................................. 9

5.3 SHOCK ABSORBERS ....................................................................................... 10

5.4 RX MODULE CARD, DECODER CARD,

RELAY CARD, POWER SUPPLY CARD ......................................................... 10~12

6. SYSTEM SETTINGS

6.1 TRANSMIITTER ID CODE SETTINGS ........................................................... 13

6.2 TRANSMITTER FREQUENCY CHANNEL SETTINGS ............................... 13

6.3 TRANSMITTER SPECIAL FUNCTIONS SETTINGS ..................................... 13

6.4 FREQUENCY CHANNEL TABLE ................................................................... 14

6.5 RECEIVER LCD OUTLINE ............................................................................... 15

6.6 RECEIVER ID CODE AND FREQUENCY CHANNEL SETTINGS ............... 16

7. RECEIVER SYSTEM STATUS DISPLAYS ............................................................... 17~18

8. RECEIVER INSTALLATION

8.1 PREPARATION ................................................................................................. 19

8.2 STEP BY STEP INSTALLATION ..................................................................... 19

8.3 SYSTEM TESTING ........................................................................................... 20

9 OPERATING INSTRUCTION

9.1 POWER “ON” THE SYSTEM ........................................................................... 21

9.2 TRANSMITTER SYSTEM STATUS DISPLAYS ............................................... 21~22

10. BATTERY CHARGING ............................................................................................. 23

11. SYSTEM SPECIFICATIONS ..................................................................................... 24~25

1

11.. IINNTTRROODDUUCCTTIIOONN

The Twister 2X is a highly sophisticated industrial radio control system. The versatile

features of the Twister 2X permits a wide range of industrial applications. The Twister 2X

industrial radio control system can be used to control all types of cranes, building

construction equipment, automatic control systems, mining equipment, and many others.

The Twister 2X incorporates numerous safety circuits that guaranty maximum security and

ensure the system is resistant to other radio interference. The major features of the Twister

2X industrial radio control system is as follow:

* Highly evolved software that have redundant error checking and correcting capabilities

to ensure 100% error-free transmission, decoding, and control of output relays. These

software designs include CRC (Cyclical Redundancy Check Code) and Hamming

Codes (Error Recovery).

* The encoding system utilizes an advanced microprocessor for 100% error -free data

transmission. The availability of 65,536 sets of unique security ID codes will ensure

that only commands from the matching control transmitter can be carried out without

any interference from other radio systems.

* The decoding system utilizes dual advanced microprocessors, which ensures 100%

error-free calculation, bit checking, and correction of incoming transmitted data.

* The system also utilizes an additional central microprocessor for data comparison and

cross checking between the two decoding microprocessors to ensure 100% error-free

decoding and control of all output relays. When faults are detected via this central

microprocessor, for maximum safety, the entire system will be shutdown within 0.50

second to avoid any undesired crane movements.

* The system utilizes PLL synthesized RF for means of data transmission. It allows the

user to select from a wide range of frequency channels best suited for the environment.

The frequency channel is selected via a dip-switch in the transmitter unit and LCD

control panel in the receiver box. The receiver system also has the ability to auto scan

from a wide range of frequency channels. The receiver system will search and locked

on to the intended matching transmitter unit.

* Optional dual advanced receiving system for optimum receiving capability.

* The Twister 2X systems are equipped with numerous self-diagnosing features.

These include transmitter low voltage detection warning system automatic

shutdown, faulty pushbutton and joystick contact switches detection, faulty MAIN

contact relay detection, faulty relay boards detection, faulty EEPROM detection,

faulty PLL synthesizes RE unit detection, and incorrect security ID code detection.

2

22.. SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS

The Twister 2X system is relatively simple to use. However, it is very important to observe

the proper safety procedures during ope ration. When use properly the Twister 2X systems

will enhance productivity and efficiency in the workplace.

The following instructions should be strictly followed:

1. Make a daily check of the transmitter casing, joysticks, and pushbuttons. Should it

appear that anything could inhibit the proper operation of the transmitter unit, it should

be immediately removed from service.

2. The transmitter voltage should be checked on a daily basis. If the voltage is low, the

battery pack should be recharged or replaced.

3. The emergency stop pushbutton (EMS) should be checked at the beginning of each shift

to ensure they are in the proper working order.

4. In the event of an emergency, activate the emergency stop pushbutton immediately.

Then turned the power “off” from the main power source of the equipment.

5. The power switch should be turned “off” after use and should never left the power “on”

when the unit is unattended.

6. Do not use the same RF channel and ID code as any other unit in use at the same

facility (within 300 -meter range / 900 feet).

7. Ensure the waist belt is worn at all time during operation to avoid accidental dropping.

8. Never operate a crane or equipment with two (2) transmitter units at the same time with

same RF channel and ID code.

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operations.

Changes or Modifications not expressly approved by the party responsible

for compliance could void the users’ authority to operate the device.

3

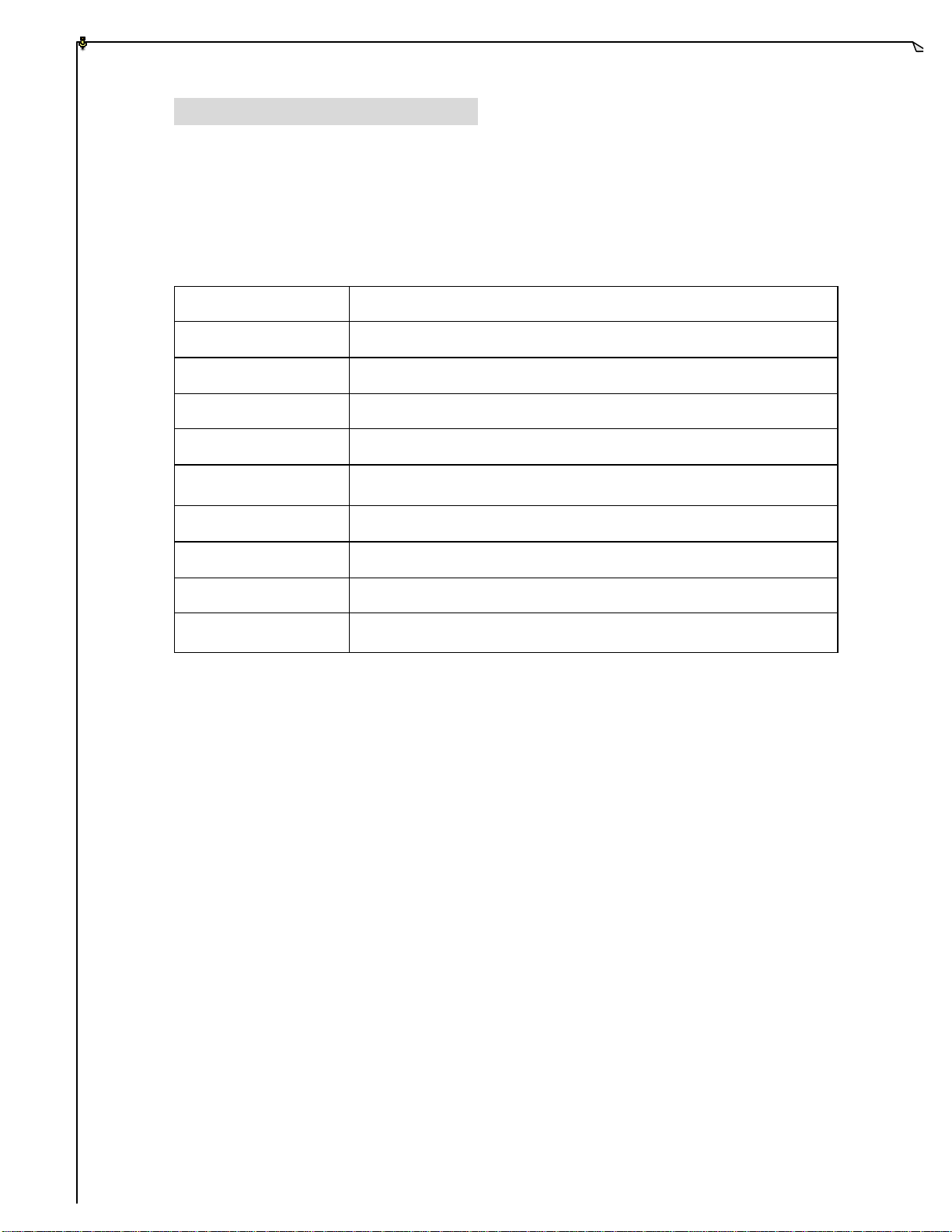

33.. SSYYSSTTEEMM FFUUNNCCTTIIOONNSS

TTrraannssmmiitttteerr JJooyyssttiicckk

Each transmitter unit is equipped with up to two (2) joysticks with single or double axis per

joystick. Please see the table below for different joystick settings:

TYPE FUNCTION

Linear (step -less)

1-Speed No acceleration.

2-Speed Shared acceleration relay.

2-Speed Separate acceleration relay.

2-Speed

3-Speed Shared acceleration relay.

4-Speed Shared acceleration relay.

5-Speed Shared acceleration relay.

0-Speed Contact Relay

Note A: When 2nd speed contact relay is activated, the 1st speed contact relay will be

deactivated.

Separate acceleration relay / 1st and 2nd speed relay interlocked (refer

to note A).

0-speed (neutral position) can also be equipped with contact relay for

connection to crane’s braking system.

4

TTrraannssmmiitttteerr PPuusshhbbuuttttoonnss

There are many different types of pushbuttons and switches available for the Twister 2X; please

refer to the chart below.

TYPE FUNCTION

1-Step Pushbutton Standard non-toggled pushbutton

2-Step Pushbutton Standard non-toggled pushbutton

Mechanical Toggle Pushbutton Standard toggled pushbutton

Electronic Toggle Pushbutton Resets itself when the transmitter unit is turned “off”

Rocker Switch 0-T (refer to note 1 & 2)

Rocker Switch 0-R (refer to note 1)

Rocker Switch R-0 (refer to note 1)

Rocker Switch T -0-T (refer to note 1 & 2)

Rocker Switch R-0-T (refer to note 1 & 2)

Rocker Switch T -0-R (refer to note 1 & 2)

Rocker Switch R-0-R (refer to note 1)

Selector Switch 0-T (refer to note 1 & 2)

Selector Switch 0-R (refer to note 1)

Selector Switch T -0-T (refer to note 1 & 2)

Selector Switch T -0-R (refer to note 1 & 2)

Selector Switch R-0-T (refer to note 1 & 2)

Selector Switch R-0-R (refer to note 1)

ON / OFF Pushbuttons

Note 1: 0 Original position.

T Maintain position (toggled).

R Retract to the 0-position (non-toggled).

Note 2: Pushbuttons, rocker switches, and selector switches with T (toggled) settings can

also have their contact relay in the receiver to stay a ctivated even if the transmitter

unit is turned “off”.

2 pushbuttons per set / interlocked / will reset to “off”

position when transmitter unit is turned “off”

5

EEmmeerrggeennccyy SSttoopp BBuuttttoonn ((EEMMSS))

In case of an emergency, press the Emergency Stop Button will immediately deactivates the

transmitter unit and the receiver MAIN Contact Relay.

PPoowweerr KKeeyy SSwwiittcchh

Key switch for activating the power of the transmitter unit (please refer to Fig. 2 on page 7).

SSttaarrtt PPuusshhbbuuttttoonn

After turning “on” the transmitter unit via power key switch, press the START pushbutton

will activate the receiver MAIN. After resetting the emergency stop button, pressing the

START pushbutton will also activate the receiver MAIN.

RReemmoovvaabbllee RReellaayy CCaarrddss

The special designed relay cards with main motherboard for future system expandability and

replacements.

AAuuttoo SSccaannnniinngg RReecceeiivveerr

When the transmitter unit’s frequency channel is changed, the receiver unit will search and

locked on to the intended matching transmitter unit.

OOppttiioonnaall FFeeaattuurreess

1. Pitch and Catch Mode – This feature allows two operators controlling one crane system

from opposite ends of a long travel.

2. Tandem Mode – This feature allows two operators controlling two crane systems

independently or one operator controlling two crane systems simultaneously.

3. Random Access – This function allows for up to eight operators randomly accessing

eight crane systems via an eight-position selector switch.

6

44.. TTRRAANNSSMMIITTTTEERR OOUUTTLLIINNEE

44..11

TTrraannssmmiitttteerr BBooxx

(Fig. 1)

44..22

DDeettaaiilleedd PPaarrttss

1. Power Status LED Display

2. Signal Status LED Display

3. Information Plate (engraved)

4. Left Joystick Rubber Boot

5. Right Joystick Rubber Boot

6. START Pushbutton

7. AUX/RES Pushbutton

8. AUX/RES Pushbutton

9. AUX/RES Pushbutton

10. Emergency Stop Button (EMS)

11. Power Key Switch (removable)

12. Battery Contact

13. System Information

14. Battery slot

MODEL

:

CHANNEL A B C

:

VOLTAGE

(Fig. 2)

:

BAND

:

POWER

:

S/NO.

:

m

RXWTX W

A

B C

9

8

7

6

5

4

3

V

2

MHz

1

0

7

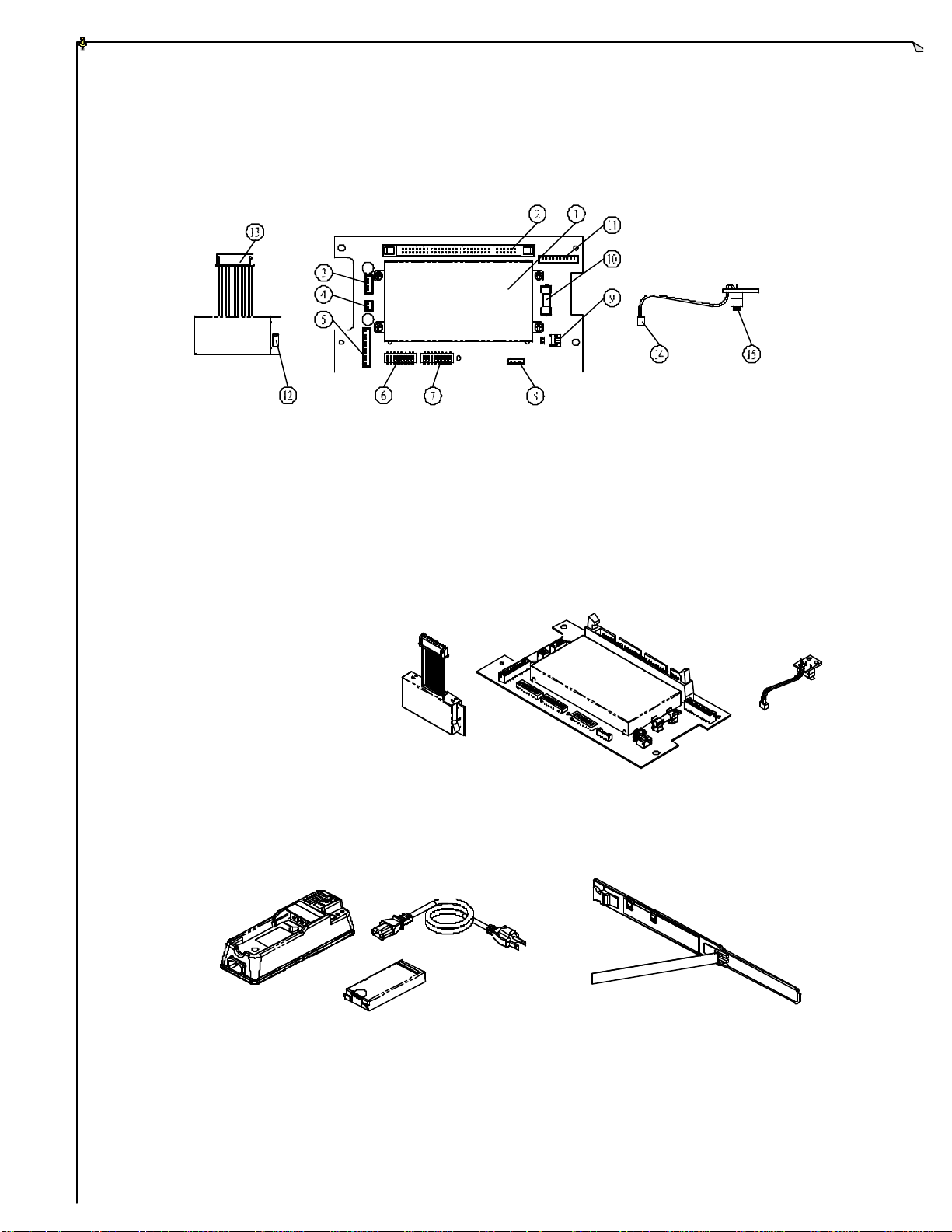

44..33 EEnnccooddeerr BBooaarrdd aanndd PPLLLL MMoodduullee

(Fig. 3)

1. Encoder Shield Plate 9. Power Key Switch Connector Port

2. Ribbon Type Connector Port 10. Power Fuse (0.25A)

3. Power Input Connector Port 11. Infrared Interface Port

4. Charger Connector Port 12. Antenna Port

5. TX Module Connector Port 13. TX module Connector

6. ID Code Dip-Switch 14. Power Key Switch Connector

7. Frequency Channel Dip-Switch 15. Power Key Switch

8. Programming Port

(Fig. 4)

44..44 IInntteelllliiggeenntt CChhaarrggeerr,, 660000mmAA BBaatttteerryy PPaacckk xx 22,,

p

WWaaiisstt BBeelltt,, aanndd SShhoouullddeerr SSttrraap

(Not Pictured)

(Fig. 5)

8

Loading...

Loading...