Fomotech ALPHA510SERIES Users Manual

TTAABBLLEE O

OFF CC

ONNTTEENNTTSS

O

Page

1

1.

INTRODUCTION

The Alpha 580 is highly reliable industrial remote control system. The versatile features of the

Alpha 580 permit its use in many different remote control applications. The system can be used

to control cranes, hoists, trolleys, mining equipment, building construction equipment,

automatic control systems, and many others.

The Alpha 580 radio control system incorporates numerous redundant safety circuits that

guaranty maximum security and ensure the system is resistant to outside interference. The

major features of the Alpha 580 are as follow:

* The system uses advanced microprocessors which utilizes highly evolved software that

have redundant error checking and correcting capabilities to ensure 100 % error-free

transmission, decoding, and control of the output relays. These highly evolved software

include CRC (Cyclic Redundancy Check codes) and Hamming Codes.

* To insure maximum operating safety, the Alpha 500 series incorporate many safety features.

Some of these safety features include receiver self-diagnosing, transmitter pushbutton

self-diagnosing, transmitter low voltage detection/warning, and transmitter/receiver auto

shutdown after 1 minute of transmitter low voltage warning.

* The encoder/decoder system utilizes advanced microprocessor. The availability of 32,768

sets of unique ID codes will ensure that only commands from the matching control

transmitter can be carried out without any interference from other radio systems. A special

programmable integrated circuit is used to insure the unit can not simultaneously command

conflicting movements.

* Full SMT design for system stability.

The Alpha 580 radio control system consists of a transmitter handheld, and a receiver unit. The

transmitter casing is molded using an industrial strength composite material which is impervious

to dust, water, oil, acids, alkaline, heat, sunlight, and as well as being resistant to deformation

due to long term use in harsh environments. The pushbuttons are also constructed from

industrial strength composite material with a minimum of up to one million cycles. For power

saving, the transmitter unit uses special high efficiency power saving circuits that requires only

two “AA” alkaline batteries (UM-3).

2.

SAFETY INSTRUCTION

The Alpha 580 system is relatively simple to use. However, it is very important to observe the

proper safety procedures during operation. When use properly the Alpha 580 system will

enhance productivity and efficiency in the workplace.

The following instructions should be strictly followed:

1. Make a daily check of the transmitter casing and pushbuttons. Should it appear that

anything could inhibit the proper operation of the transmitter unit, it should be immediately

removed from service.

2. The transmitter voltage should be checked on a daily basis. If the voltage is low, the two

"AA" alkaline batteries should be replaced.

3. The emergency stop pushbutton (EMS) should be checked at the beginning of each shift to

ensure they are in the proper working order.

4. In the event of an emergency, activate the emergency stop pushbutton immediately. Then

turned the power “off” from the main power source of the equipment.

5. The power switch should be turned “off” after use and should never left the power “on”

when the unit is unattended.

6. Do not use the same RF channel and ID code as any other unit in use at the same facility.

7. Ensure the wrist strap is worn at all time during operation to avoid accidental dropping.

8. Never operate a crane or equipment with two (2) transmitter units at the same time with

same RF channel and ID code.

3

3.

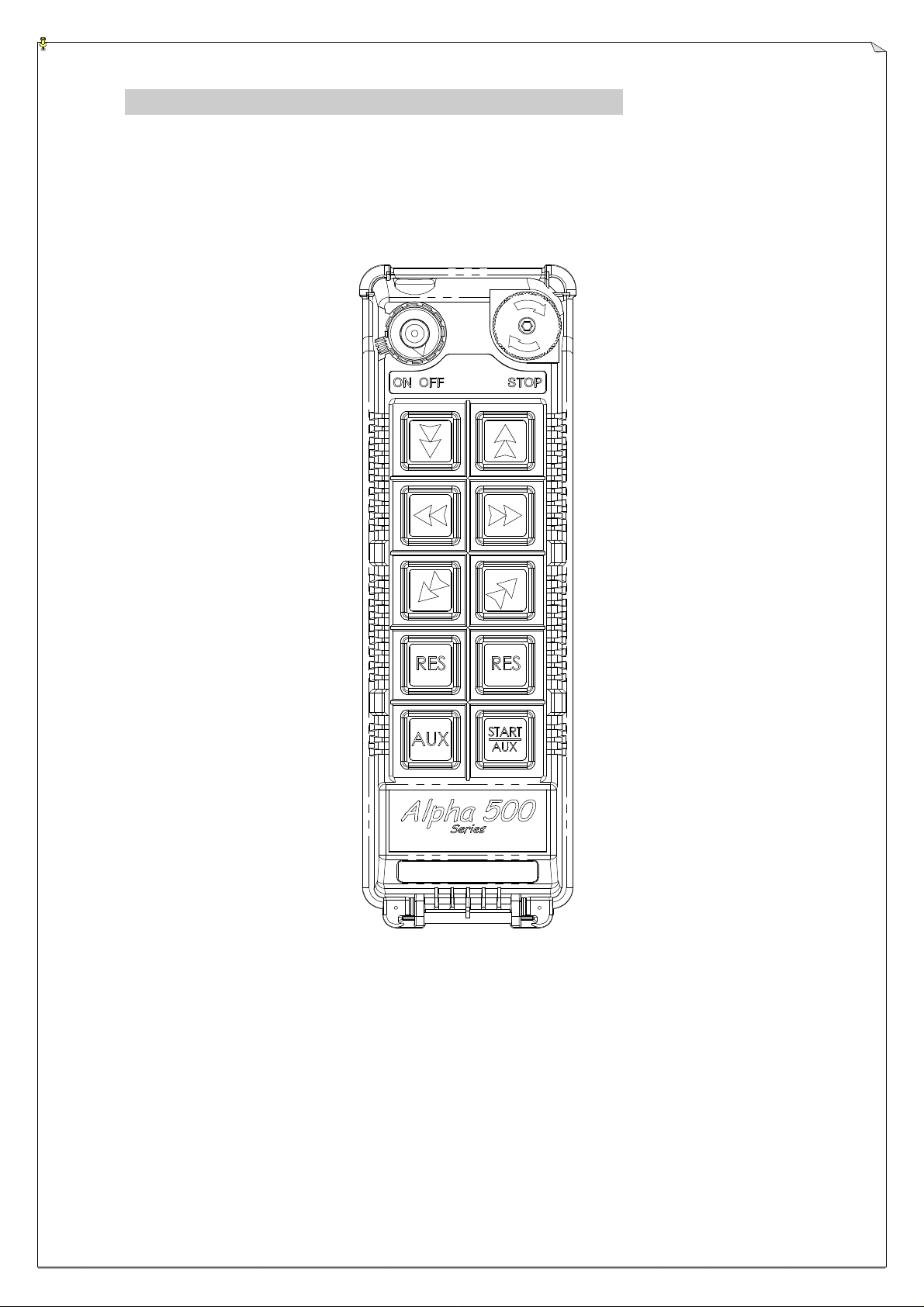

PUSHBUTTON CONFIGURATION

The Alpha 580 model can be configured from 3 to 5 motions with 2-speed pushbuttons and an

emergency stop button (EMS).

(Fig. 1) Pushbutton Placements

RES 2-Speed pushbuttons which can be used for the 4th motion or for any other

functions.

AUX 2-Speed pushbuttons which can be used for the 5th motion or for any other

functions.

4

4.

TRANSMITTER OUTLINE

4.1 External View

(Fig. 2) Front

View

1) Transmitter enclosure 8) Emergency Stop (EMS) 15) Battery Screws

2) Power switch (ON/OFF) 9) Pushbutton #1 16) Batter Cover/FCC ID

3) Pushbutton #2 10) Pushbutton #3

4) Pushbutton #4 11) Pushbuttons #5

5) Pushbutton #6 12) Pushbutton #7 (A1)

6) Pushbutton #8 (A2) 13) Pushbutton #9 (A3)

7) Pushbutton #10 (A4) 14) System Information

5

Loading...

Loading...