TTAABBLLEE O

1. INTRODUCTION ....................................................................................................... 2

2. SAFETY INSTRUCTION ............................................................................................. 3

3. TRANSMITTER ILLUSTRATION

3.1 Alpha 3000 External Assembly ......................................................................... 4

3.2 Alpha 3000 Internal Assembly ......................................................................... 5

4. RECEIVER ILLUSTRATION

4.1 External Assembly ............................................................................................... 6

4.2 Alpha 3000 Internal Assembly ......................................................................... 7

5. OUTPUT CONTACT DIAG RAM

Alpha 3000 Output Contact ............................................................................. 8

6. SYSTEM CONFIGURATIONS

OFF CC

ONNTTEENNTTSS

O

Page

6.1 Jumper Settings ................................................................................................... 9

6.2 Security ID Code Settings ..................................................................................... 10

6.3 Pushbutton Contact Settings ................................................................................. 11

6.4 Voltage Settings ..................................................................................................... 11

7. RECEIVER INSTALLATION

7.1 Preparation For Installation ................................................................................... 12

7.2 Step By Step Installation ....................................................................................... 12

7.3 System Testing ....................................................................................................... 13

8. TRANSMITTER OPERATION ................................................................................... 14

9. TROUBLE SHOOTING ............................................................................................... 15

10. SYSTEM SPECIFICATION ......................................................................................... 16

11. PARTS LIST ................................................................................................................. 17

1

11.. IINNTTRROODDUUCCTTIIOONN

The Alpha 3000 System is a highly reliable industrial radio remote control system. The

versatile features of the Alpha 3000 system permit its use in many different remote control

applications that required 3-step control. The system can be used to control factory cranes,

multiple hoists, trolleys, mining equipment, building construction equipment, automatic

control systems, and many others.

The Alpha 3000 Radio Remote Control System incorporates numerous redundant safety

circuits that guaranty maximum security and ensure the system is resistant to outside

interference. The major features of the Alpha 3000 system are as follow:

* The system uses advanced microprocessors with highly evolved software that has

redundant error checking and correcting capabilities to ensure 100% error-free

transmission, decoding, and control of all output relays. This highly evolved software

includes CRC (cyclical redundancy check codes) and Hamming Codes (error recovery).

* To insure maximum operating safety, the Alpha 3000 system incorporates numerous

safety features. Some of these built-in safety features include transmitter pushbutton

self-diagnosing, transmitter low -voltage detection and warning, receiver self-diagnosing,

and MAIN deactivation when the system is in sleep mode.

* The transmitter encoder and receiver decoder both utilize advanced microprocessor

control. The availability of 65,536 sets of unique ID codes will ensure that only

commands from the matching control transmitter can be carried out without any

interference from other radio systems.

* For added safety, the system also incorporates special Safety MAIN Relay. If the Safety

MAIN Relay is defective (fails to open or close during operation), it will signal the

system to shut down immediately to avoid the possibility of any accidents occurring.

* Water -resistant transmitter and receiver enclosures.

The Alpha 3000 Radio Remote Control System consists of a water-resistant handheld

transmitter and receiver. The transmitter casing is molded using industrial strength composite

materials which are impervious to dust, water, oil, acids, alkaline, heat and sunlight as well as

being resistant to deformation due to long term use in harsh environments. The industry’s best

3-step pushbuttons are also constructed from industrial strength composite materials with a

minimum of up to one million press cycles. For power savings, the transmitter is designed

with an ultra high efficiency power saving circuit that requires only four “AA” size alkaline

batteries for more than 200 hours of continuos operation between replacements.

2

22.. SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONN

The Alpha 3000 system is relatively simple to use, however, it is very important to observe the

proper safety procedures before, during, and after operation. When used properly our Alpha

3000 radio remote controls will enhance safety, productivity and efficiency in the workplace.

The following procedures should be strictly followed:

1. Check the transmitter casing and pushbuttons daily. Should any damage that could

inhibit the proper operation of the transmitter be found the unit should be immediately

removed from service.

2. The transmitter voltage should be checked on a daily basis. If the voltage is low (red

status light blinking, refer to section 8 on page 14), the four “AA” alkaline batteries

should be replaced.

3. The red mushroom type emergency stop button (EMS) should be checked at the

beginning of each shift to ensure it is in proper working order and the Stop command is

being received.

4. In the event of an emergency, depress the emergency stop button (EMS) immediately to

disengage the receiver MAIN and the transmitter power. Then turned the power “off”

from the main power source to the crane or equipment.

5. The transmitter power key switch should be pulled “off” aft er each use and should never

leave the transmitter in the power “on” position when the unit is unattended.

6. Do not use the same channel and ID code as any other system in use at the same facility

or within 600 feet.

7. Ensure the shoulder strap is worn at all time during operation to avoid accidental damage

to the transmitter.

8. Never operate a crane or equipment with two transmitter units at the same time with the

same channel and ID code.

FCC ID: LZ6ALPHA3000MODEL

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions; (1) this device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operations.

3

33.. TTRRAANNSSMMIITTTTEERR IILLLLUUSSTTRRAATTIIOONN

33..11 AAllpphhaa 33000000 EExxtteerrnnaall AAsssseemmbbllyy

1

2

3

4

5

6

7

15

8

9

10

11

12

16

13

17

14

(Front Few) (Back View)

1. Transmitter Unit 9. Pushbutton #1 (Up)

2. Status LED Display* 10. Pushbutton #3 (East)

3. Spare Power Key Switch 11. Pushbutton #5 (North)

4. Pushbutton #2 (Down) 12. START/AUX Pushbutton

5. Pushbutton #4 (West) 13. System Information

6. Pushbutton #6 (South) 14. Shoulder Strap Ring

7. Emergency Stop (EMS) 15. FCC/IC Label

8. Power Key Switch 16. Battery Cover

17. Warning Label

* Please refer to page14 for Transmitter Status LED information

4

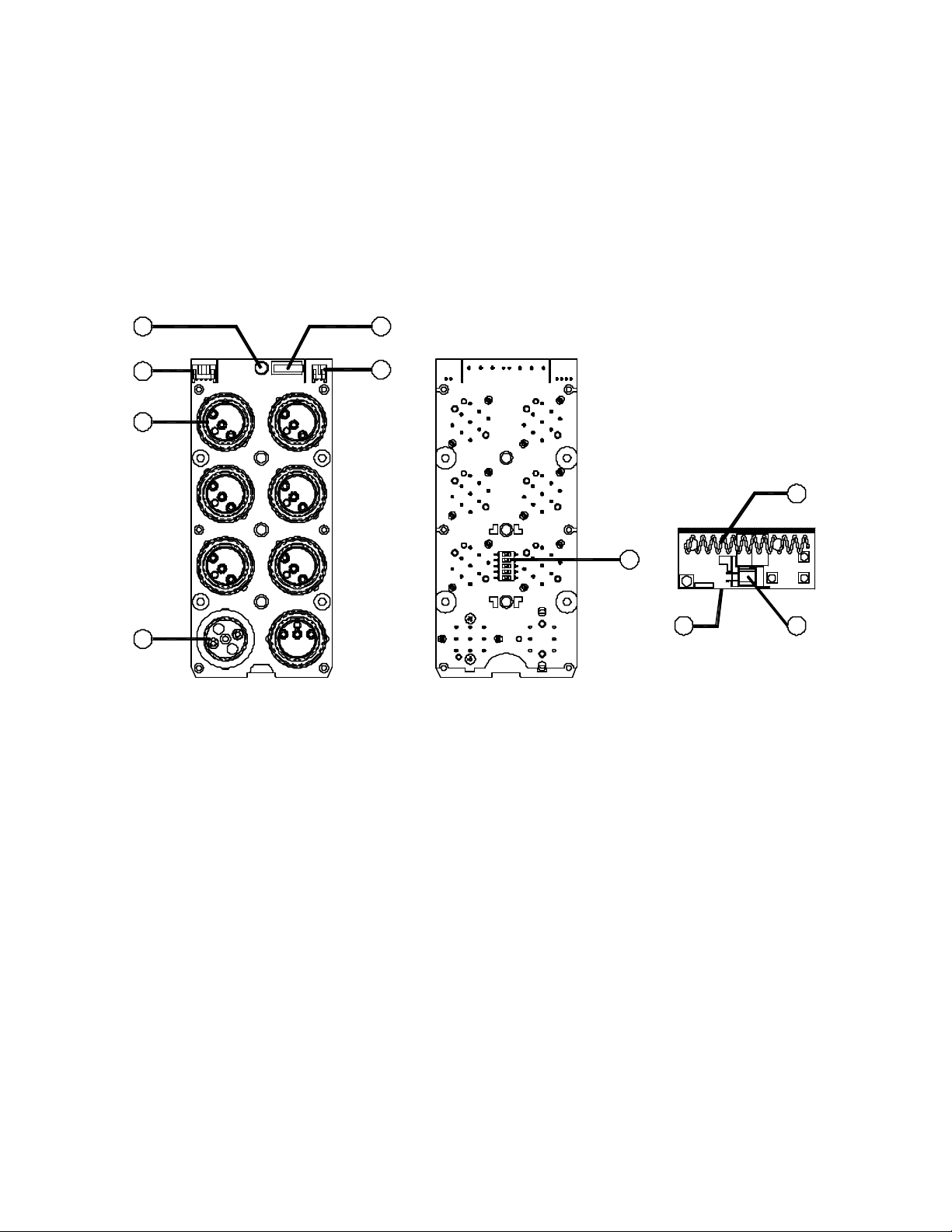

33..22 AAllpphhaa 33000000 IInntteerrnnaall AAsssseemmbbllyy

1

2

3

4

5

6

8

7

109

(Front View) (Back View) (RF Board)

1. Status LED Display 6. Battery Power Connector

2. RF-to-Encoder Board Connector 7. ID Code Dip-switch

3. 3-Speed Pushbuttons 8. Antenna

4. Emergency St op Button (EMS) 9. Transmitting RF Board

5. Power ON/OFF Micro-Switch 10. Quartz Crystal

5

44.. RREECCEEIIVVEERR IILLLLUUSSTTRRAATTIIOONN

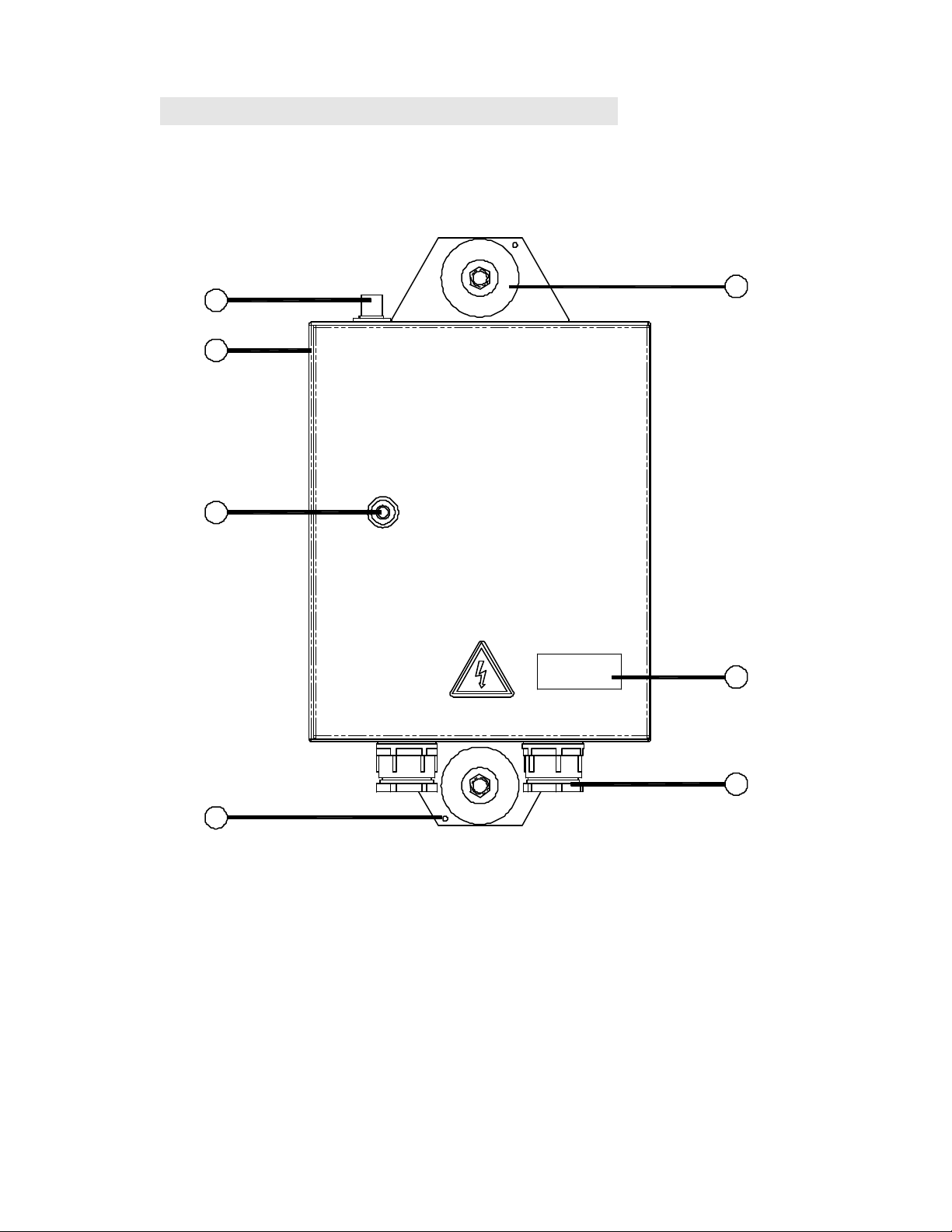

44..11 EExxtteerrnnaall AAsssseemmbbllyy

1

5

2

3

6

4

7

1. Antenna mount 4. External Grounding Hole

2. Receiver Enclosure 5. Shock Absorber

3. Key Lock 6. System Information

7. Cable Gland / Cord Grip

6

44..22 AAllpphhaa 33000000 IInntteerrnnaall AAsssseemmbbllyy

1

2

3

4

5

6

7

8

10

11

12

N3

U3

U2

+

+

D1U1

D3

D2

E2

E3

+

+

W1E1

W2

W3

9

N2

+

+

S1N1

S3

S2

~

Z1

~

ID

13

14

15

16

1. Antenna Seat 9. Bottom Relay Board

2. Receiving RF Module 10. Power Transformer

3. Decoder Module 11. Input Voltage Selector Seat

4. Decoder Module Power Display 12. Contact Relay LED Display

5. Receiver Status LED Display* 13. Terminal Block

6. SQ Status LED Display* 14. Power Fuses (1.0A)

7. Power (AC) LED Display 15. AC Power Input

8. Upper Relay Board 16. MAIN Safety Contact Relay

* Please refer to page 15 for Receiver and SQ display information

7

5.

OUTPUT CONTACT DIAGRAM

AAllpphhaa 33000000 OOuuttppuutt CCoonnttaacctt

U2

U3

+

U1 D1

+

D2

D3

E1 W1

UPPER RELAY BOARD

E2

W2

E3

+

W3

+

N1 S1

N2

N3

+

+

S2

S3

Z1

BOTTOM RELAY BOARD

MAIN

ID

Note: Z1 represents START/AUX output contact.

Terminal Block and Common Shorting Pin Assembly

Common shorting pin illustrated above can be used rather than “daisy chaining” wiring

for the common.

8

66.. SSYYSSTTEEMM CCOONNFFIIGGUURRAATTIIOONNSS

66..11 JJuummppeerr SSeettttiinnggss

There are numerous functions that can be set via jumpers located inside the decoder module.

Please see the diagram and chart below on how to set these functions.

Manufacture Setting

JUMP

JP1

JP2

JP3

Open

Short

Open

Short Sleep mode deactivated wit h receiver MAIN stays on constantly.

Open

Short Pushbutton 1 ~ 6 non-interlocked with single speed contact.

Open

After inserting the transmitter power key switch, or after EMS reset, press

START/AUX pushbutton to activate the receiver MAIN.

Insert the transmitter power key switch will immediate ly activates the

receiver MAIN. After EMS reset, re-insert the power key switch to

reactivate the receiver MAIN.

After 5 minutes of transmitter non-usage the receiver MAIN

will be deactivated (sleep mode).

Pushbutton 1 ~ 6 interlocked.

No acceleration delay from 1st through 3rd speed.

JP4

Short Acceleration delay for up to 1 second from 1

Note: Every time when you change jumper settings you must first turn the receiver power “off” and then turn

it back “on” after setting so that they can be stored in memory.

9

st

through 3rd speed.

Press START/AUX

speed contact

JP1

JP1

Open

JP1

Short

JP2

JP2

Open

JP2

Short

JP3

JP3

Open

JP3

Short

Insert the transmitter

power key switch

Insert the transmitter

power key switch

After 5 minutes of transmitter non -usage Receiver MAIN deactivated

Receiver MAIN

activated

Receiver MAIN stays “on” constantly until the main power source of the system is turn “off”

Pushbutton 1 ~ 6 non-interlocked with single speed contact

Receiver MAIN

activated

or After EMS reset

Pushbutton 1 ~ 6 interlocked

or

After EMS

reset

Re-insert the transmitter

power key switch

START/AUX

Press

Receiver MAIN activated

Receiver MAIN

activated

JP4

JP4

Open

JP4

Short

1st speed

depressed

After 1

second

1st speed contact

relay engaged

No acceleration delay from 1st through 3rd speed

2nd speed

depressed

After 1

second

nd

2

relay engaged

3rd speed

depressed

After 1

second

3rd speed contact

relay engaged

66..22 SSeeccuurriittyy IIDD CCooddee SSeettttiinnggss

The ID code dip-switch is located on the backside of the encoder board (refer to item #7 on

page 5) and on the top of the decoder module (see below).

Example : ID code ? 10001100

Top Location ? “1”

Bottom Location ? “0”

10

66..33 PPuusshhbbuuttttoonn CCoonnttaacctt SSeettttiinnggss

The START/AUX pushbutton can be set either to normal or latching contact. This function

that can be set via an 8-position dip-switch located inside the decoder module (please refer to

the diagram below). By adjusting the dip setting either to the top or bottom slot will change

the contact form of the pushbutton (please refer to the chart below). Pus hbuttons are

numbered from right -to-left and from top-to-bottom.

DIP SWITCH

Alpha 3000

DIP1 ? “0” ? Pushbutton 7 (START/AUX) with normal momentary contact

“1” ? Pushbutton 7 (START/AUX) with toggle / latching contact

ID

Top position ? “1”

Bottom position ? “0”

66..44 VVoollttaaggee SSeettttiinnggss

There are four different voltage settings available inside the Alpha 3000 receiver enclosure

(bottom relay board), please select one that corresponds to the main power source of the crane

or equipment.

Input Voltage Range Accepted:

1) AC 110V ? From AC 100V ~ AC 120V

2) AC 220V ? From AC 220V ~ AC 240V

3) AC 380V ? From AC 380V ~ AC 400V

4) AC 415V ? From AC 415V ~ AC 440V

11

77.. RREECCEEIIVVEERR IINNSSTTAALLLLAATTIIOONN

77..11 PPrreeppaarraattiioonn FFoorr IInnssttaallllaattiioonn

1. Required Tools:

(1) Flat Head Screwdriver (-)

(2) Phillips Head Screwdriver (+)

(3) Multi-Meter

(4) Open End Wrench

(5) Power Drill with 10.5mm ~ 11mm Drill-Bit

2. Check to ensure that your receiver is not set to the same channel and ID code as any

other systems in operation at the same facility within 600 feet.

3. Prior to installation, make sure that the crane or equipment itself is working

properly.

4. Use a multi-meter to check the voltage source available and ensure that the receiver

voltage setting matches your power source.

5. Prior to installation, switch “off” the main power source to the crane or equipment.

77..22 SStteepp BByy SStteepp IInnssttaallllaattiioonn

1. The location selected should have the antenna visible from all areas where the

transmitter is to be used.

2. The location selected should not be exposed to high levels of electrical noise.

3. Ensure the selected location has adequate space to accommodate the receiver

enclosure.

4. Make sure the receiver unit is in upright position (vertical).

5. The distance between the antenna and the control panel should be as far apart as

possible.

6. Drill two holes on the control panel (10.5mm). Refer to diagrams next page.

7. Tightened the bolt nuts provided.

8. Ensure AC ground is connected to the power input terminal block, otherwise chassis

ground should be connect to the chassis ground connection hole on the receiver

enclosure (refer to item #4 on page 6).

9. For syste m wiring, please refer to the output contact diagram on page 8.

10. Ensure all wiring is correct and safely secured and all screws are fastened.

12

77..33 SSyysstteemm TTeessttiinngg

1. Connect the power source to the receiver and test the MAIN relay output (EMS

button) and observe that it properly opens and closes the main line.

2. Test the operation of each function to ensure it corresponds to the transmitter

direction labels and/or the pendant it is replacing.

3. Test the limit switches on the crane and verify that they are working properly.

4. If your new remote control is replacing an existing pendant make sure it is

completely disconnected to prevent unwanted control commands.

5. If your new remote control is replacing an existing pendant make sure the

pushbutton is stored in a safe location where it will not interfere with remote

operation.

13

8.. TTRRAANNSSMMIITTTTEERR OOPPEERRAATTIIOONN

1. Batteries _ Make sure the four “AA” alkaline batteries are installed correctly, the labels

on the battery holder will tell you which side is “up” and which side is “down”. Use

2000mA alkaline type batteries for optimum operating time between replacements.

2. Start Up _ Insert the power key switch located on the top right hand side of the

transmitter unit (refer to diagram below). The Status LED on the face of the transmitter

will display a green light (type -1 below) for up to 2 seconds when the power key switch is

inserted. Do make sure the red EMS pushbutton is in elevated position when the

transmitter power key is inserted, by pulling it upward. Then depress t he START/AUX

pushbutton to activate the receiver MAIN (depending on JP1 setting on page 9). When

the pushbuttons are depressed, the transmitter status LED will display a blinking green

light (type -2 below) telling you that the command signals are being transmitted to the

receiver. After 5 minutes of transmitter non-usage (pushbuttons not depressed), the

receiver MAIN will be automatically deactivated (depending on JP2 setting on page 9).

To resume work, just depress the START/AUX pushbuttons.

3. Status Light Display (refer to item #2 on page 4).

TYPE LED DISPLAY INDICATION

1 Green “on” ? 2.0 seconds System power “on”

2

3

4

5

Green “on” ? 0.1 second

“off” ? 2.0 seconds

Red “on” ? 0.1 second

“off” ? 2.0 seconds

2 fast red blinks followed

by 2 seconds “off”

Red “on” ? 0.5 second

“off” ? 0.5 second

Pushbutton depressed with signal transmitted

Transmitter low -voltage warning

Pushbutton contact jammed or locked

Emergency Stop Button activated (depressed)

4. EMS & Restarting _ In case of an emergency, depressing the Red EMS pushbutton will

immediately deactivates the receiver MAIN contact relay. When EMS is activated, the

Status LED will display a red blinking lights that is “on” ? 0.5 second and “off” ? 0.5

second (refer to the chart above). To reactivate the system, just pull up the EMS

pushbutton and depress START/AUX (depending on JP1 setting on page 9).

5. Interlocking Pushbuttons _ The top three sets of motions (the first 6 pushbuttons) are

interlocked to its self so no conflicting commands can take place for safety purpose. For

example, depressing the hoist “UP” and “DOWN” pushbutton simultaneously will result

in no command being sent.

14

UD

99.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

Should the operator find the equipment not operating normally, please check the chart below

for simple trouble shooting tips.

PROBLEM POSSIBLE REASON SOLUTION

Transmitter does not

communicate to

receiver.

Transmitter does not

communicate to

receiver.

No power to the

receiver.

Outputs do not

operate correctly.

Receiver Status LED Display

TYPE

LED INDICATION PROBLEM AND SOLUTION

Transmitter and the receiver are

not on the same RF channel

(SQ not lit) or ID code.

Low or no transmitting power

from the transmitter unit.

Blown fuse or no input power

connection.

Receiver configuration and output

wiring is not set properly.

Ensure the correct transmitter is in

use. The labels on the receiver and

the transmitter will identify the RF

channel and ID code in use.

Turn on the transmitter and with

EMS elevated. If the status LED

shows blinking red lights or no

lights, then turn the power off and

replace the four batteries.

Ensure power input to the receiver

unit is correct. If power indicator

(AC) is not lit, please check the

receiver for any open fuse.

Please refer to section 5 and 6 to

ensure receiver is correctly wired

and configured for your application.

(refer to item #5 on page 7)

1

2

3

4

3 fast blinks followed by

OFF ? 2.0 seconds

2 fast blinks followed by

OFF ? 2.0 seconds

ON ? 0.1 second

OFF ? 2.0 seconds

ON ? 0.1 second

OFF ? 0.1 second

Defective MAIN contact relay.

Incorrect ID code setting.

Decoder on standby.

Transmitted signal decoded.

TYPE

1

2

SQ Status LED Display

LED INDICATION PROBLEM AND SOLUTION

ON ? 0.1 second

OFF ? 0.1 second

Blinking when pushbuttons are

not depressed.

(refer to item #6 on page 7)

Transmitted signal received by the receiver.

Other radio interference.

15

1100.. SSYYSSTTEEMM SSPPEECCIIFFIICCAATTIIOONN

Transmitter Unit

Frequency Range : 301MHz

Transmitting Range : 150 feet

Hamming Distance : ?6

Channel Spacing : 25KHz

Frequency Control : Quartz Crystals

Frequency Drift : < 5ppm @ -4? ~ 158?

Frequency Deviation : < 1ppm @ 77?

Spurious Emission : -50dB

Transmitting Power : 0.1mW

Emission : F1D

Antenna Impedance : 50 ohms

Enclosure : IP -66

Source Voltage : DC 6.0V

Current Drain : 8mA @ 6V

Operating Temp. : -4? ~ 158?

Dimension : 23cm x 7.8cm x 4.7cm

Weight (include batteries) : 21oz

Receiver Unit

Frequency Range : 301MHz

Modulation : Narrow Band FM

Frequency Control : Quartz Crystals

Frequency Drift : < 5ppm @ -4? ~ 158?

Frequency Deviation : < 1ppm @ 77?

Sensitivity : -118dBm

Antenna Impedance : 50ohms

Data Decoder Reference : Quartz Crystals

Responding Time : 64~100mS

Enclosure : IP -66

Standard Source Voltage : AC 120V/220V/380V/415V @ 50/60 Hz.

Power Consumption : 11VA

Operating Temp. : -4? ~ 158?

Output Contact Rating : 250V @ 10A

Dimension : 42.5cm x 24.5cm x 13cm

Weight (include antenna) : 17.68lb

16

1111.. PPAARRTTSS LLIISSTT

1. Transmitting RF Board TX-2005

2. Encoder Board EN-3000

3. Receiving RF Module RX-3000

4. Decoder Module DE-3000

5. Upper Rely Board RY -3000

6. Bottom Relay Board RY -3001

7. Transmitter Casing TC-3000

8. Receiver Enclosure RC-3000

9. Receiver Antenna (301MHz) ANT-301

10. Transformer (AC-110V/220V/380V/415V) SSB-1726

(AC-115V/208V/230V/460V) SSB-2213

11. 1-Step Pushbutton (Optional) PB-3001

2-Step Pushbutton (Optional) PB-3002

3-Step Pushbutton (Standard) PB-3003

12. Emergency Stop Button EMS-3000

13. Emergency Stop Red Cap RD-3000

14. Pushbutton Rubber Boot RB-3000

15. Pushbutton Compass Label DL-3000

16. Transmitter Power Key + Strap TK-3000

17. Receiver Panel Key RK-3000

18. Transmitter Battery Holder BH-3000

19. Transmitter Battery Cover BC-3000

20. Terminal Block TB-3000

21. Common Shorting Pin SP-3000

22. Cable Gland / Cord Grip CG-3000

23. Shock Absorber SA-3000

24. Transmitter Shoulder Strap SS-3000

25. Protective Vinyl Covering PC-3000

17

Loading...

Loading...