Follett VU155M Service Manual

VU155 Series

Ice and Beverage Dispensers

Order parts online

www.follettice.com

Installation, Operation and Service Manual

Service numbers above B50000

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

00119636R08

Table of contents

Welcome to Follett Corporation

Important cautions

Specications

Installation

Installing dispenser in counter

Field wiring diagrams

Installing optional ice machine

Connecting beverage lines

Operation

How the dispenser works

Cleaning

Service

Dispense chute cover removal

Auger motor assembly removal

Gate assembly removal

Auger and auger tube removal

Dispenser wheel removal

Wiring diagrams

Troubleshooting

Replacement parts

3

3

4

6

6

7

7

8

8

8

9

11

11

11

11

11

11

12

13

15

2

Welcome to Follett

!

VU155B8LP

Model series

Beverage cooling

B – Integral beverage cooling

M – No beverage cooling

N – Ice and water only

Tower side (facing unit)

L – Left hand side

R – Right hand side

Ice and valve actuation

P – Pushbutton

L – Lever

Number of valves

0 (N series only), 8 or 10

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and

outstanding after-the-sale support. To ensure that this dispenser delivers that same degree of service, we ask that

you take a moment to review this manual before beginning the installation of the dispenser. Should you have any

questions or require technical help at any point, please call our technical service group at (877) 612-5806 or

+1 (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling

of a claim, if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

information about the type and capacity of Follett ice dispensing equipment. Following is an explanation of the

different model numbers in the VU155 series.

Important cautions

For indoor use only.

Storage area of dispenser contains mechanical, moving parts. Keep hands and arms clear of

this area at all times. If access to this area is required, power to unit must be disconnected rst.

Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

Always disconnect power before cleaning or servicing the dispenser.

Failure to remove all sanitizer may result in health hazard.

Follett manual load dispensers can accommodate most cube/cubelet ices up to 1" square, or Follett

compressed nugget ice. Crushed, ake, bagged, nugget or congealed ice cannot be used. Use of these

ices can jam dispenser and void warranty. Separate any “waffle-like” sections of cubes before adding

to dispenser. For ice compatibility questions, please call Follett customer service at

(877) 612-5806 or +1 (610) 252-7301.

3

Specications

Electrical

Each ice machine and dispenser require a separate circuit with electrical disconnect within 10 ft (6 m). Equipment

ground required. Standard electrical – 115V, 60Hz, 1 phase. Maximum dispenser fuse – 15 amps. For ice machine

circuit requirements, refer to the ice machine specication sheet.

Model Dispenser

number amperage

VU155M series 2.4 amps

(no integral beverage cooling)

VU155B series 4.4 amps

(integral beverage cooling)

Plumbing

Dispenser 3/4" PVC pipe nipple for bin drain

3/4" PVC pipe nipple for drain pan drain

1" ID hose for beverage bath drain

Beverage connections

1/4" ID syrup beverage hose

3/8" ID carbonated water beverage hose

3/8" ID plain water beverage hose

Note: Drains should be hard piped and insulated. Maintain at least 1/4" per foot (6 mm per 304 mm run)

slope on drain line run.

Water disconnect within 10 feet (3 m) of dispenser is suggested for automatic load units.

Follett recommends use of a Follett water lter system (part# 00130229) on ice machines

connected to automatic ll dispensers.

Ice machine Refer to detailed specications in ice machine installation manual packed with ice machine

4

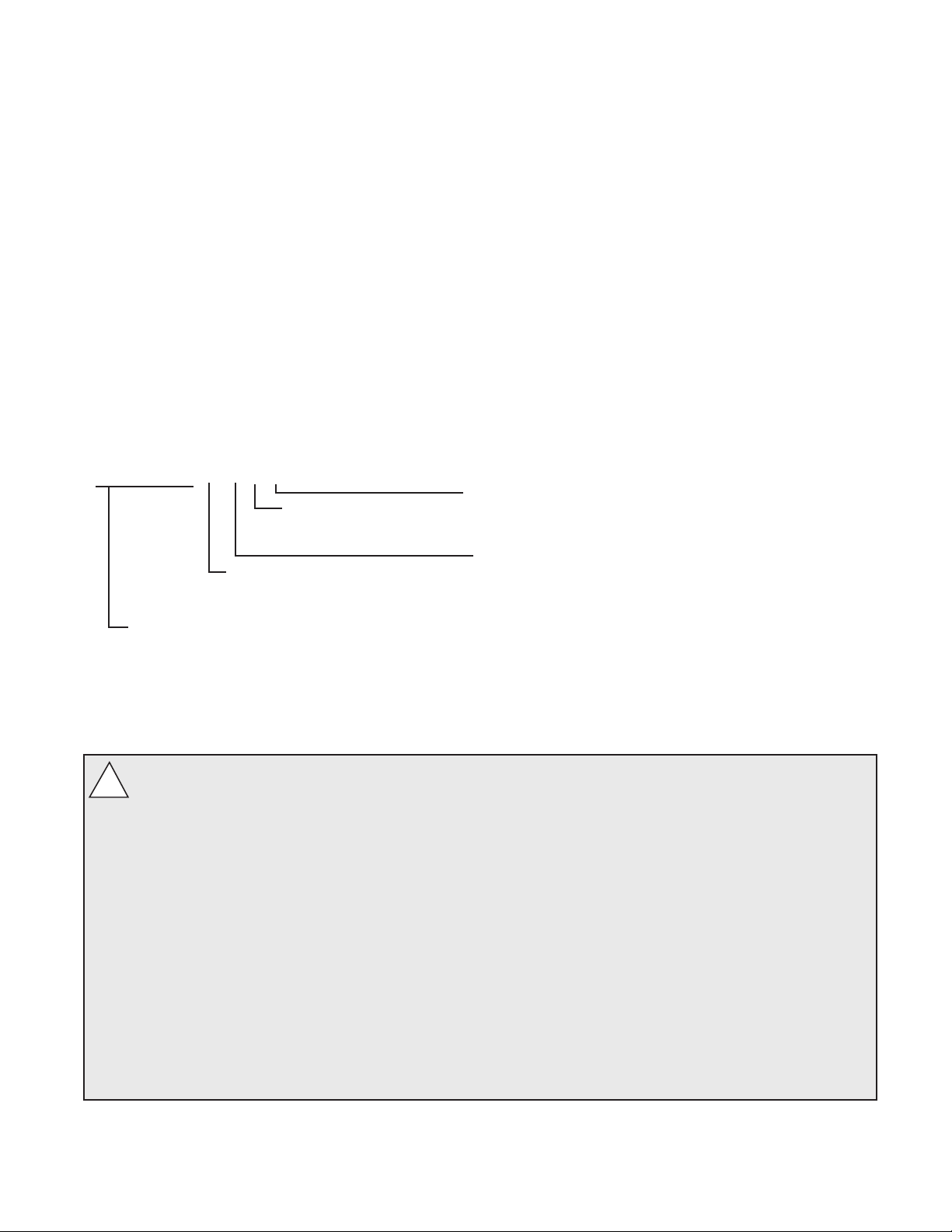

Dimensions and clearances

Required clearances

51" (1295 mm) minimum above counter for installation if dispenser will be dropped into counter

36" (915 mm) minimum above counter for all units after installation for auger cleaning and servicing

12" (305 mm) minimum on side opposite ice chute for service

12" (305 mm) minimum on ice chute side if ice transport tube enters this side

12" (305 mm) minimum between dispenser side(s) and optional ice machine(s)

Front View

37.25"

(947mm)

(10 valve unit)

31.25"

(794mm)

21.75"

(553mm)

counter top

49.75"

(1264mm)

beverage line

Side View

ice transport

tube entrance

2.8125"

(71mm)

3.5"

(889mm)

18.5"

(470mm)

ice

transport

tube

27.375"

(696mm)

3/4"

PVC

slip

joint

drain

beverage lines

beverage waterbath

overflow (1" ID hose)

3/4 PVC

drain pan

drain

3/4 PVC

slip joint

drain

6"

(153mm)

air break*

electrical

connections

Manual load unit

28"

(712mm)

*DO NOT CONNECT

AIR BREAK TO

DRAIN SYSTEM

8.75"

(223mm)

power

bin signal

5

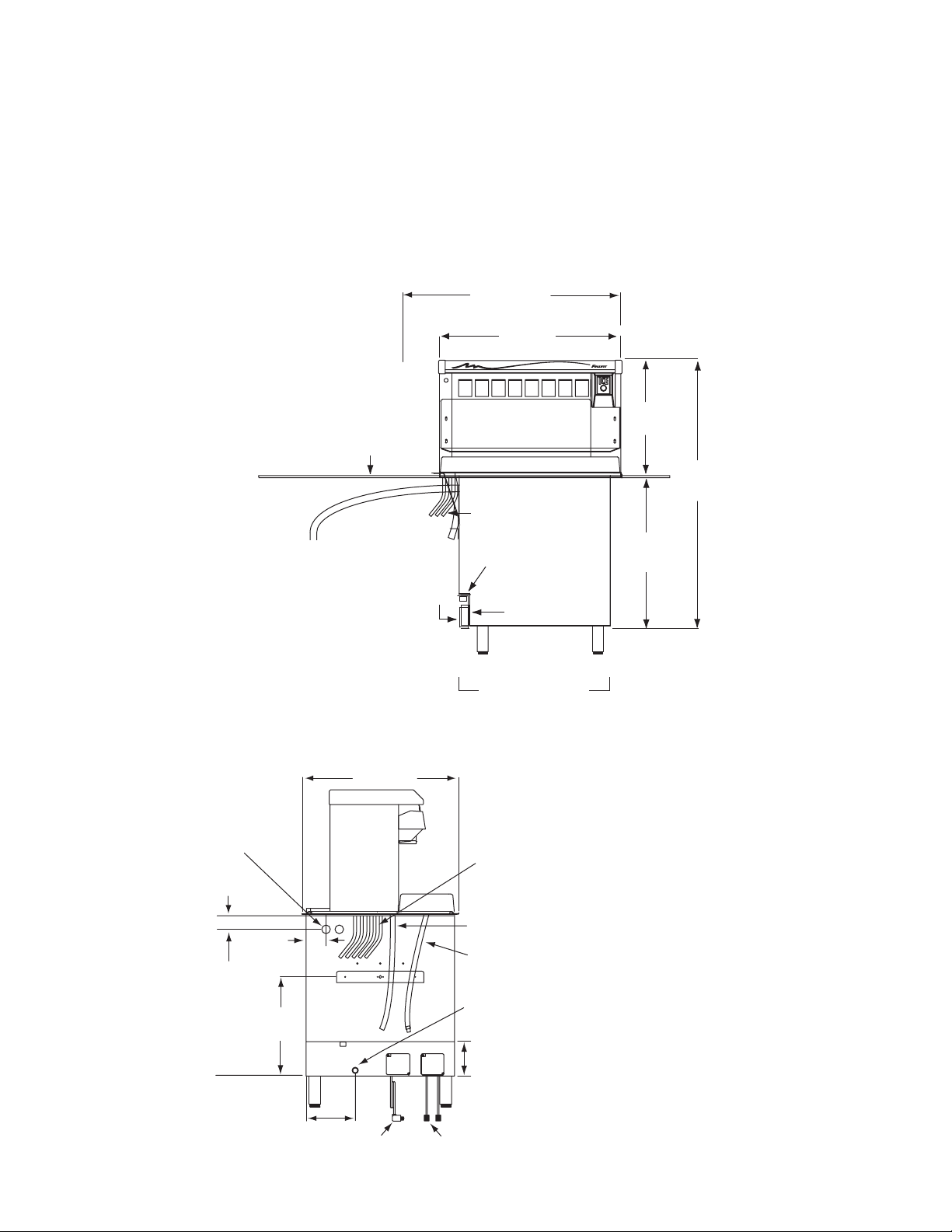

Installation

Bin thermostat capillary tube mounting

ice tube

retaining

bracket

thermostat

Front View, VU300

Front View, VU155

ice tube

Installing dispenser in counter

Note: All dispensers must be supported from below with supplied 6" – 9" (153 – 229 mm) adjustable leg accessory,

or equivalent. Do not hang dispenser on ange.

All dispensers must be installed level in both directions to ensure proper operation.

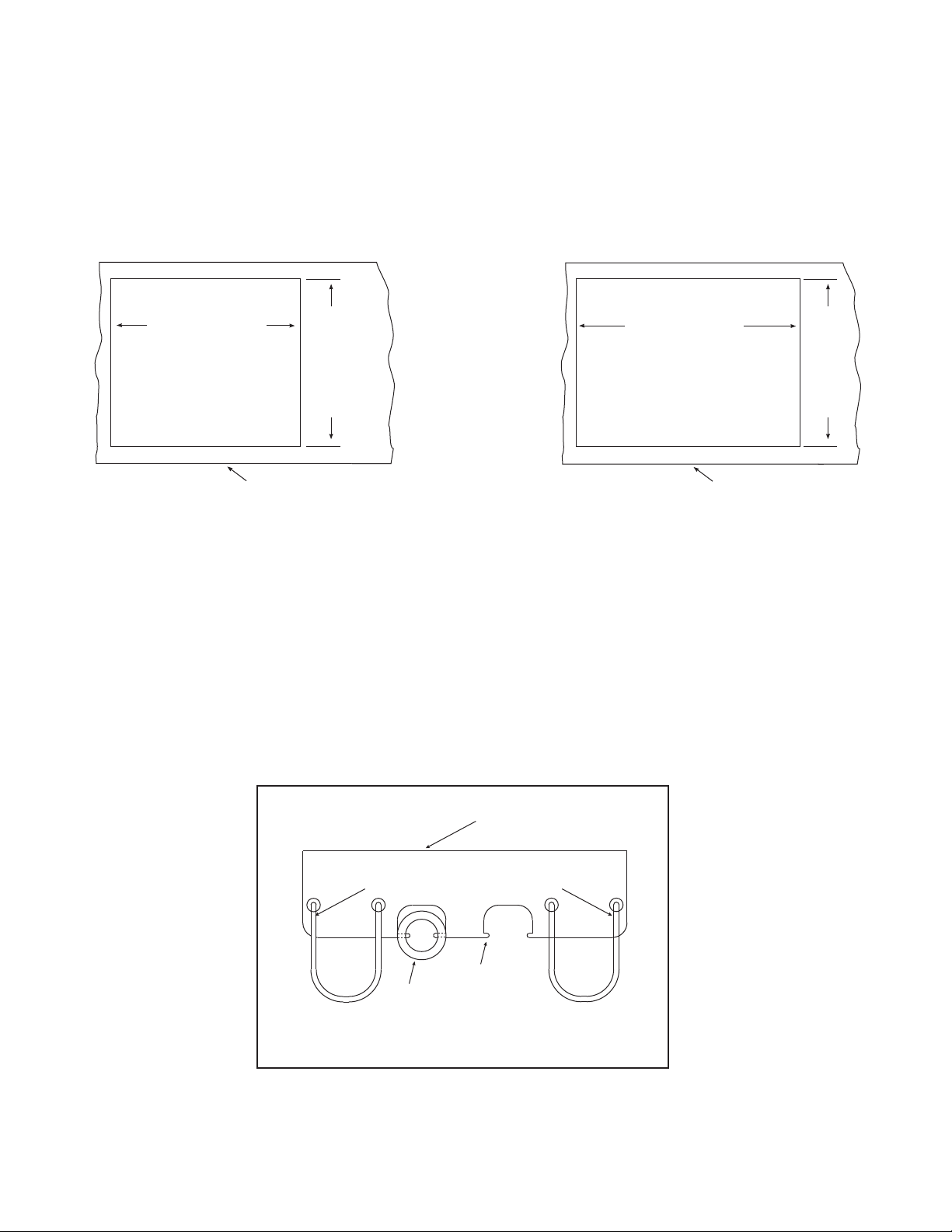

1. Check that dispenser location meets all requirements in this manual and cut counter as shown.

Plan View

units with up to 8 valves counter cut-out

units with 10 valves counter cut-out

Plan View

30.375"

(772mm)

+.125"

- .125"

+3 mm

- 3 mm

(667mm)

+3 mm

- 3 mm

front of counter

26.25"

+.125"

- .125"

36.375"

(924mm)

+.125"

- .125"

+3 mm

- 3 mm

front of counter

26.25"

+.125"

- .125"

(667mm)

+3 mm

- 3 mm

2. Place support blocks in cabinet to raise dispenser to a height of 12" (305 mm).

3. Place dispenser in counter onto support blocks.

4. Attach adjustable legs to dispenser.

5. Remove support blocks and lower dispenser feet to oor.

6. Adjust legs for 1/8" (4 mm) clearance between dispenser lip and countertop to verify there is no load on ange.

7. Apply a bead approximately 1/4" (6 mm) in diameter of NSF-listed silicone sealant (Dow Corning RTV-732 or

equivalent) around perimeter of dispenser where it meets counter. Smooth sealant to a 1/8" (4 mm) radius.

8. Install a PVC drain line with at least a 1/4" per foot (20 mm per 1 m) slope. Insulate drain line to prevent

condensation.

Note: Do not apply excessive heat if any sweating of ttings is necessary. Heat conduction through metal

may melt threads in plastic drain.

Do not reduce drain line size or tie drains together.

9. Make electrical connections in accordance with applicable wiring diagrams provided. Provide disconnects within

10 ft (3 m) of dispenser and ice machine for servicing.

ice tube

ice tube

retaining

bracket

thermostatthermostat

tabs in ice tube

retainer bracket

engage holes in ice

tube and hold tube

in place

6

Loading...

Loading...