Page 1

MCD425A/W, R425A/W, MFD425A/W, P425A/W

Ice Machines

Operation and Service Manual

MCD425A/W_S

R425A/W

P425A/W

MCD425A/W_T

MFD425A/W_T

Following installation, please forward this manual

totheappropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01033646R03

Page 2

2 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 3

Contents

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before you begin ............................................................................ 4

Specications .............................................................................. 5

Electrical ................................................................................ 5

Plumbing ................................................................................ 5

Ambient ................................................................................. 5

Water usage (water-cooled condenser only) .................................................... 5

Dimensions and clearances ................................................................. 6

Operation .................................................................................. 7

Cleaning/descaling and sanitizing ............................................................ 7

Weekly ................................................................................. 7

Monthly ................................................................................. 7

Semi-Annually (more often if conditions dictate) ................................................. 7

Service .................................................................................... 9

Ice machine Operation (all models) ........................................................... 9

Water system ........................................................................... 10

Electrical system ..........................................................................11

Technical specications (all models) ......................................................... 13

Electrical control system schematic .......................................................... 14

Electrical control system operation ........................................................... 15

Refrigeration system (all models) ............................................................ 24

Replacement parts ......................................................................... 27

Replacement ice machine ordering matrix ..................................................... 27

Air-cooled skins assembly (MCD425A_S, R425A) .............................................. 28

Water-cooled skins assembly (MCD425W_S, R425W) ........................................... 29

Louvered docking station (MCD425A/W_T) .................................................... 30

Electrical components ....................................................................31

Evaporator ............................................................................. 32

Air-cooled ice machines ................................................................... 34

Water-cooled ice machines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 3

Page 4

Welcome to Follett

!

MCD425ABT

Application

V – Vision

B – Bin

H – Harmony

Configuration

S – RIDE

®

T – top-mount

Ice machine capacity and refrigerant

400 – 425 lbs (193 kg)/day, R404A

Ice machine series

Nugget ice machine

Voltage

D – 115V 60Hz

Condenser type

A – air-cooled

W – water-cooled

MCD – RIDE model installation, Vision

™

ice and beverage dispensers and top installation, Follett ice storage bins

R – Remote installation, Symphony

™

ice and water dispensers

P – Replacement icemaker, Symphony ice and water dispensers

Flake ice machine

MFD – Top installation, Follett ice storage bins

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers that same degree of service, we ask that you review

the installation portion of this manual before beginning to install the unit. Our instructions are designed to help you

achieve a trouble-free installation. Should you have any questions or require technical help at any time, please call

our technical service group at (877) 612-5086 or +1 (610) 252-7301.

Note: To expedite assistance, all correspondence or communication MUST include the model number, serial number

and complete and detailed explanation of the problem.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage

is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling of a claim,

if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

information about the type and capacity of Follett equipment. Following is an explanation of the different model

numbers in the 425 series.

Important cautions

Moving parts. Do not operate with front cover removed.

Hot parts. Do not operate with cover removed.

To reduce risk of shock disconnect power before servicing.

Most ice machine cleaners contain citric or phosphoric acid, which can cause skin irritation. Read caution label

on product and follow instructions carefully.

Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

4 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 5

Specications

Electrical

§ Each ice machine and dispenser require a separate circuit with electrical disconnect within 10 ft (6 m).

§ Equipment ground required.

§ Standard electrical – 115 V, 60 Hz, 1 phase.

§ Connect to a dedicated 15A circuit.

§ Maximum ice machine amperage – 11A each.

§ Cord and plug provided on ice machine.

Plumbing

§ 3/8" FPT water inlet

§ 3/4" MPT drain

§ 3/8" FPT condenser inlet (water-cooled condenser only)

§ 3/8" FPT condenser drain (water-cooled condenser only)

Notes:

§ Slope to drain of 1/4" per foot (6 mm per 30.4 cm run) with a 1/2" min. is recommended.

§ Water shut-off recommended within 10 feet (3 m), drain to be hard piped and insulated.

§ Separate drains for ice machine and condenser. To prevent back ow, do NOT connect drains.

§ Follett recommends a Follett water lter system be installed in the ice machine inlet water line (standard capacity

#00130229, high capacity #00978957, carbonless high capacity #01050442).

Ambient

Air temperature* 100 F/38 C max. 50 F/10 C min. (best performance below 80 F/27 C)

†

Water temperature

90 F/32 C max. 45 F/10 C min. (best performance below 70 F/21 C)

Water pressure 70 psi max. (482 kPA) 10 psi min. (68 kPA)

Condenser water

90 F/32.2 C max. 45 F/7.2 C min

temperature

Condenser water

125 psi (862 kPA) max. 10 psi (68 kPA) min.

pressure

*

Ambient air temperature is measured at the air-cooled condenser coil inlet.

†

Ambient water temperature is measured in the ice machine reservoir.

Water usage (water-cooled condenser only)

§ 0.25 gpm @ 50 F (10 C)

§ 0.5 gpm @ 70 F (21 C)

§ 1.25 gpm @ 90 F (32 C)

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 5

Page 6

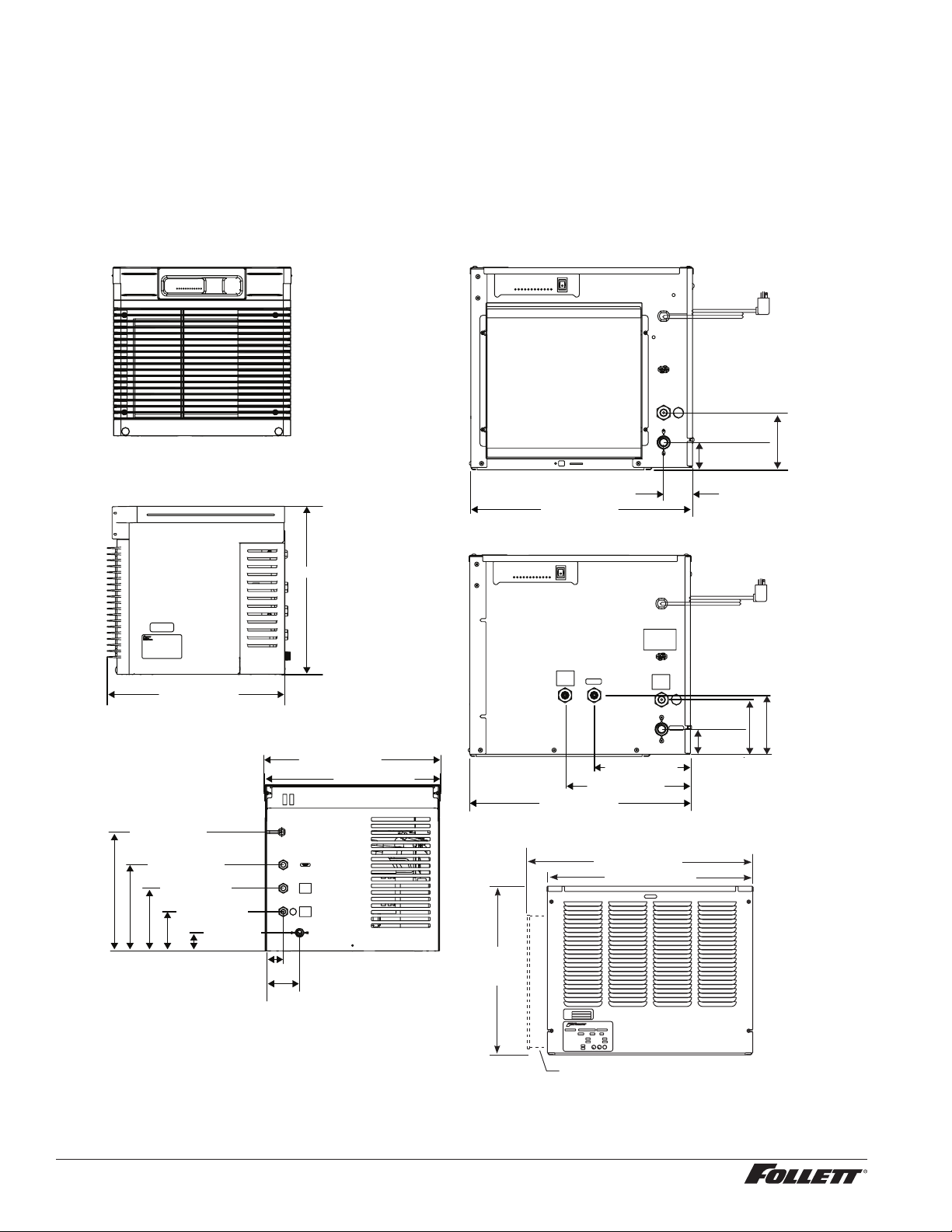

Dimensions and clearances

§ Entire front of ice machine must be clear of obstructions/connections to allow removal.

§ 12" (30.5 cm) clearance above ice machine for service.

§ 6" (15.3 cm) minimum clearance between exhaust side of ice machine and any adjacent equipment.

§ MCD425A & R425A – 18" (45.7 cm) minimum, 10 ft (3 m) maximum clearance between discharge and air

intake grilles.

MCD425A/W_T

MFD425A/W_T

Front view — top mount

Side view — top mount

21.29" (54.1 cm)

MCD425A/W_S

R425A/W

Front view — air-cooled

2.5" (6.4 cm)

18.88" (48 cm)

Front view — water-cooled

C

F

B

4.81"

(12.0 cm)

A

2.31" (5.7 cm)

C

22.49" (57.1 cm)

Back view — top mount

15.22" (38.7 cm)

11.03" (28.0 cm)

8.03" (20.4 cm)

5.03" (12.8 cm)

2.34" (6 cm)

A – 3/4" MPT drain

B – 3/8" FPT water inlet

C – Electrical cord

2.32"

(5.9 cm)

CONDENSER

OUTLET

22.69" (57.6 cm)

C

E

D

22.46" (57.1 cm)

18.88" (48 cm)

Side view — air-cooled and water-cooled

E

8.25" (20.9 cm)

10.62" (27.0 cm)

22.75" (57.8 cm)

20.75" (52.7 cm)

D

B

A

17.00"

4.40" (11.2 cm)

(43.2 cm)

RIDE model air-cooled units only

D – 3/8" FPT condenser inlet

E – 3/8" FPT condenser drain

F – Bin signal connection (DO NOT APPLY VOLTAGE!)

F

B

A

4.81"

(12.0 cm)

2.31"

(5.7 cm)

5.25"

(13.3 cm)

6 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 7

Operation

Cleaning/descaling and sanitizing

Follett ice machines and dispensers, and their associated cleaning and sanitizing procedures, are designed for

use with potable water sources. The presence, or suspected presence, of infectious agents may call for additional

measures, including the replacement of components and more comprehensive disinfection measures. Follett

recommends that these cleaning and sanitizing procedures be reviewed with the appropriate infectious agent subject

matter experts to assure complete remediation.

Periodic cleaning/descaling and sanitizing of Follett’s ice machine system is required to ensure peak performance

and delivery of clean, sanitary ice. The recommended cleaning procedures that follow should be performed at least

as frequently as recommended and more often if environmental conditions dictate.

Cleaning of the condenser can usually be performed by facility personnel. Cleaning/descaling and sanitizing of

the ice machine system should be performed by your facility’s trained maintenance staff or a Follett authorized

service agent. Regardless of who performs the cleaning, it is the operator’s responsibility to see that this cleaning is

performed according to the schedule below. Service problems resulting from lack of preventive maintenance will not

be covered under the Follett warranty.

Symphony Plus Frequency

Drain Line weekly

Drain Pan/Drip Pan weekly

Exterior, Water Station Tube as needed

Condenser monthly (air-cooled only)

Ice Machine semi-annually

Transport Tube semi-annually

* Ice machine must be sanitized prior to start-up.

Weekly

The exterior may be cleaned with a stainless cleaner such as 3M* Stainless Steel Cleaner & Polish or equivalent.

* 3M is a trademark of 3M Company.

Monthly

Condenser (air-cooled ice machine only)

1. Use a vacuum cleaner or stiff brush to carefully clean condenser coils of lint and debris to ensure optimal

performance.

2. When reinstalling counter panels in front of RIDE model ice machines, be sure that ventilation louvers line

up with condenser air duct.

Semi-Annually (more often if conditions dictate)

§ A cleaning/descaling and sanitizing procedure should always include both the ice machine and bin/dispenser.

§ Icemaking system can be cleaned/descaled in place.

Cleaning & Sanitizing Tool Checklist

§ (2) 1.5 gallon (or larger) plastic buckets

§ (2) clean cloths

§ Sanitary gloves

§ Safety glasses

§ (2) Sani-Sponge™ (P/N 00131524 - single sponge)

§ (1 ) Packet of SafeCLEAN™ (P/N 00132001 - 24 packets)

§ 1.6 oz. of Nu-Calgon IMS-II or IMS-III Sanitizer (P/N 00979674 - 16 . oz. bottle)

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 7

Page 8

CAUTION!

§ Wear rubber gloves and safety goggles (or face shield) when handling cleaner or sanitizer mixtures.

§ Use only Follett approved cleaners.

§ It is a violation of Federal law to use the Cleaning or Sanitizing solution in a manner inconsistent with their

labeling.

§ Do not use solvents, abrasive cleaners, metal scrapers or sharp objects to clean any part of the dispenser.

Cleaning Solution: Mix cleaning solution of 1 gal. (3.8 L) 100 F (38 C) water and 7 oz. (198 g) (one 7 oz. packet) of

Follett SafeCLEAN ice machine cleaner/descaler (P/N 00132001).

Sanitizing Solution: Mix a sanitizing solution of 1 gal. (3.8 L) 100 F (38 C) water and 1.6 oz. (47 ml) Nu-Calgon IMS-II or

IMS-III Sanitizer (P/N 00979674).

Cleaning/descaling procedure

Note: Check drains and drain cup to ensure they are open and owing freely.

1. If ice machine was running recently, ensure that the evaporator is completely free of ice before proceeding.

If there is ice in the evaporator, complete steps 2-7 using only hot water to remove the ice then begin

Cleaning/Descaling Procedure again.

2. Remove front or top cover.

3. Disconnect bin signal cable from ice machine electrical box.

4. Press CLEAN switch. The MAINTENANCE light will turn on and the machine will drain. Wait for the LOW

WATER light to turn on.

5. Remove lid from cleaning cup and ll (about 1 quart) until cleaning solution completely lls the reservoir.

Place lid back on cup.

6. CLEANER FULL light will turn on and machine will start cleaning cycle then rinse three times; this process

takes approximately 15 minutes.

7. When machine is nished cleaning, the MAINTENANCE light will turn off.

Sanitizing Procedure

8. Press CLEAN switch. The MAINTENANCE light and LOW WATER light will turn on.

9. Fill cleaning cup with sanitizing solution until completely lls the reservoir. Place lid back on cup. Save

remainder of sanitizing solution.

10. CLEANER FULL light will turn on and machine will start sanitizing cycle then rinse three times; this

process takes approximately 15 minutes.

11. When machine is nished rinsing, the MAINTENANCE light will turn off. Remove top bearing insulation and

nozzle insulation, then loosen phillips-head screw on nozzle connected to evaporator. Remove nozzle from

evaporator side only, leave other side of nozzle connected to transport tube.

12. Place one Sani-Sponge in remaining sanitizing solution.

13. Insert the sponge soaked in sanitizing solution into nozzle then insert a dry sponge into the nozzle.

14. Replace nozzle onto evaporator and tighten screw. Ensure drain is connected to reservoir and vent tubes

are connected to evaporator drain pan.

15. Reconnect bin signal cable. Wait for ice to push sponges through transport tube.

16. Collect sponges from ice storage bin.

1 7. Replace front or top cover.

18. After 10 minutes, dispense all ice and discard.

19. Clean/descale and sanitize dispenser/bin.

8 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 9

Service

Ice machine Operation (all models)

Follett’s ice machine consists of four distinct functional systems:

§ Harvesting system

§ Water system

§ Electrical control system

§ Refrigeration system

These four systems work together to accomplish the production and harvesting of ice. A problem in any one of these

systems will result in improper operation of the entire ice production cycle. When troubleshooting the ice machine,

it is important to analyze the entire system operation to determine which system is not functioning properly, then

pinpoint the component within that system that is malfunctioning. Determine what corrective action must be taken

before making any adjustments or replacing any components.

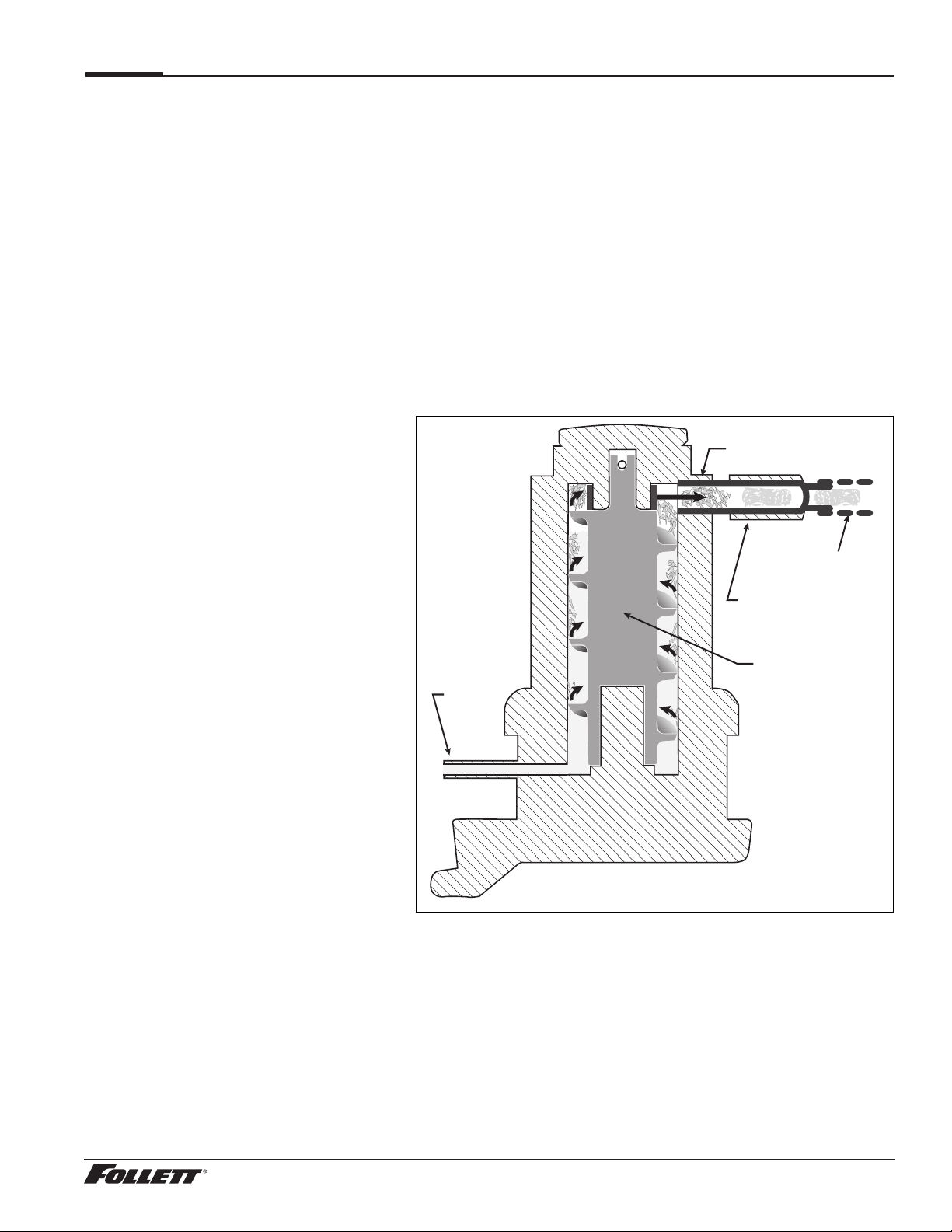

The icemaking process

The Maestro Plus ice machine uses a stainless steel jacketed evaporator and operates on a continuous freezing

cycle. Water is supplied to the evaporator from the water reservoir where the water level is controlled by a oat valve.

This valve also shuts off the water supply when the ice machine is not running.

When the ice machine is running, a layer

of ice forms on the interior surface of the

evaporator. This ice is continuously removed

by a slowly rotating (12RPM) auger. The

auger carries the ice upward into the cavity

formed by the top bearing housing and the

compression loop, where it is compressed to

remove excess water. When the ice reaches

the desired hardness it rotates within the

cavity and is forced through a discharge

port and compression nozzle and into the

ice transport tube. The discharge tube and

compression nozzle are slightly restricted to

further compress the ice and produce the

desired hardness.

A solid state control board located in the

electrical box of the ice machine controls

the normal operation of the ice machine

and monitors gearmotor torque. This control

board will shut down the ice machine should

an over-torque condition occur. It is very

important that you familiarize yourself with

the operational sequences detailed in this

manual before attempting to service the ice

machine.

water

inlet

evaporator

port

ice transport tube

compression nozzle

auger

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 9

Page 10

Water system

B

A

C

D

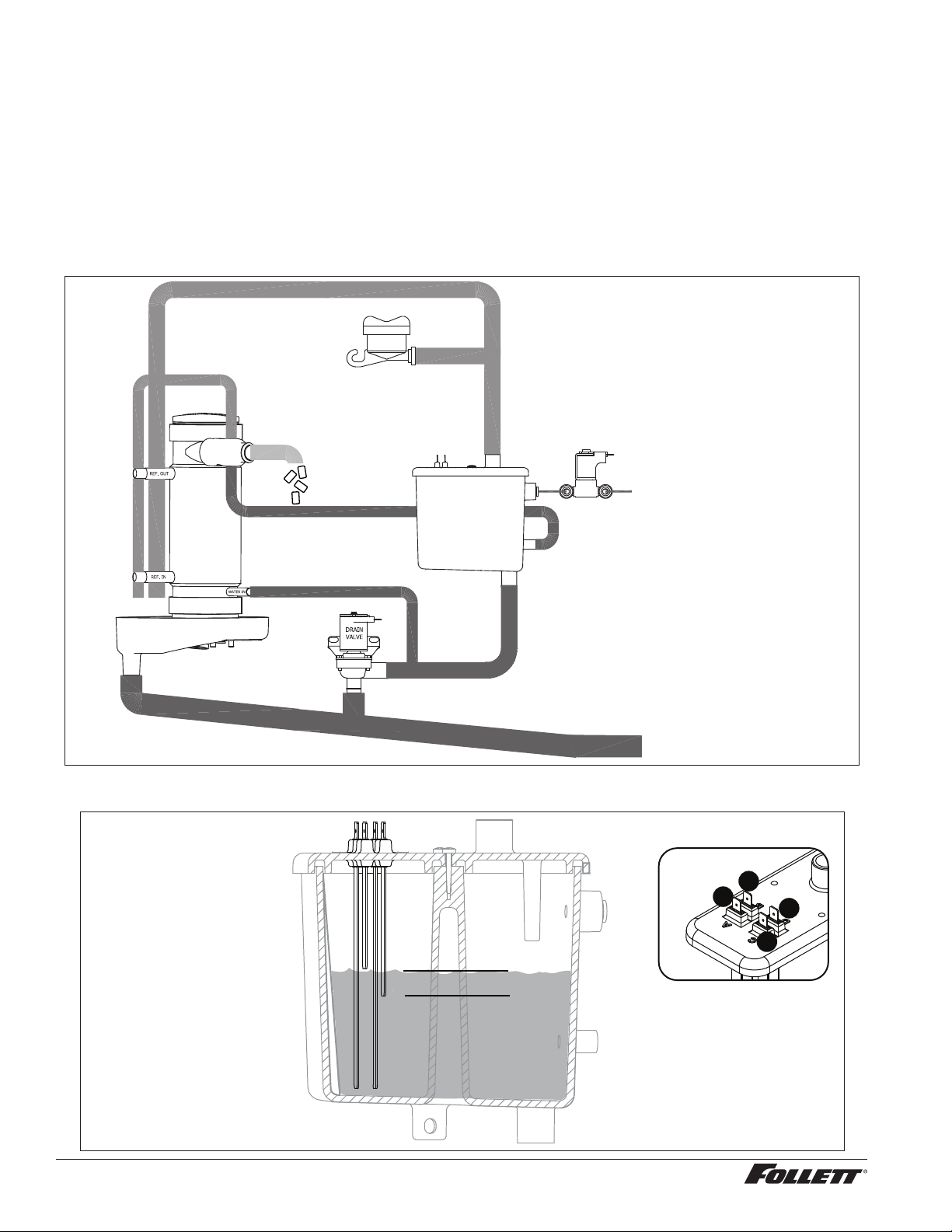

The water level in the evaporator is controlled by a ll solenoid (Fig 1) and level detecting sensors. Water sensing

rods (Fig. 2) extend down into the reservoir at the end of the evaporator assembly. The system works via electrical

conductivity as follows:

One of the longest probes is a common. When water is between any of the other probes and the common, the

PC board will sense the activation. During normal operation, the water level rises and falls between the Normal

High and Normal Low sensors. As water is consumed to make ice, the level will fall until the Normal Low sensor is

exposed, triggering the water feed solenoid on. Water will ll until the Normal High sensor is activated.

Note: The potable water dissolved solids content must be greater than 10 ppm for the water control system to

function properly. If using reverse osmosis water ltration system, ensure T.D.S level is greater than 10 ppm.

Fig. 1 Water system diagram

VENT

CLEANING CUP

RESERVOIR FILL

ICE

NOZZLE

SOLENOID

EVAPORATOR

DRAIN PAN

DRAIN

Fig. 2 Water level diagram

A ALARM LOW (RED)

B COMMON (BLACK)

C NORMAL HIGH (ORANGE)

D NORMAL LOW (YELLOW)

WATER

RESERVOIR

WATER SUPPLY

3/8" FPT, 45-90 F (7-32 C)

10-70 PSI (69-483 KPA)

WASTE WATER DRAIN

3/4" FPT

C

NORMAL OPERATING RANGE

D

A

B

10 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 11

Electrical system

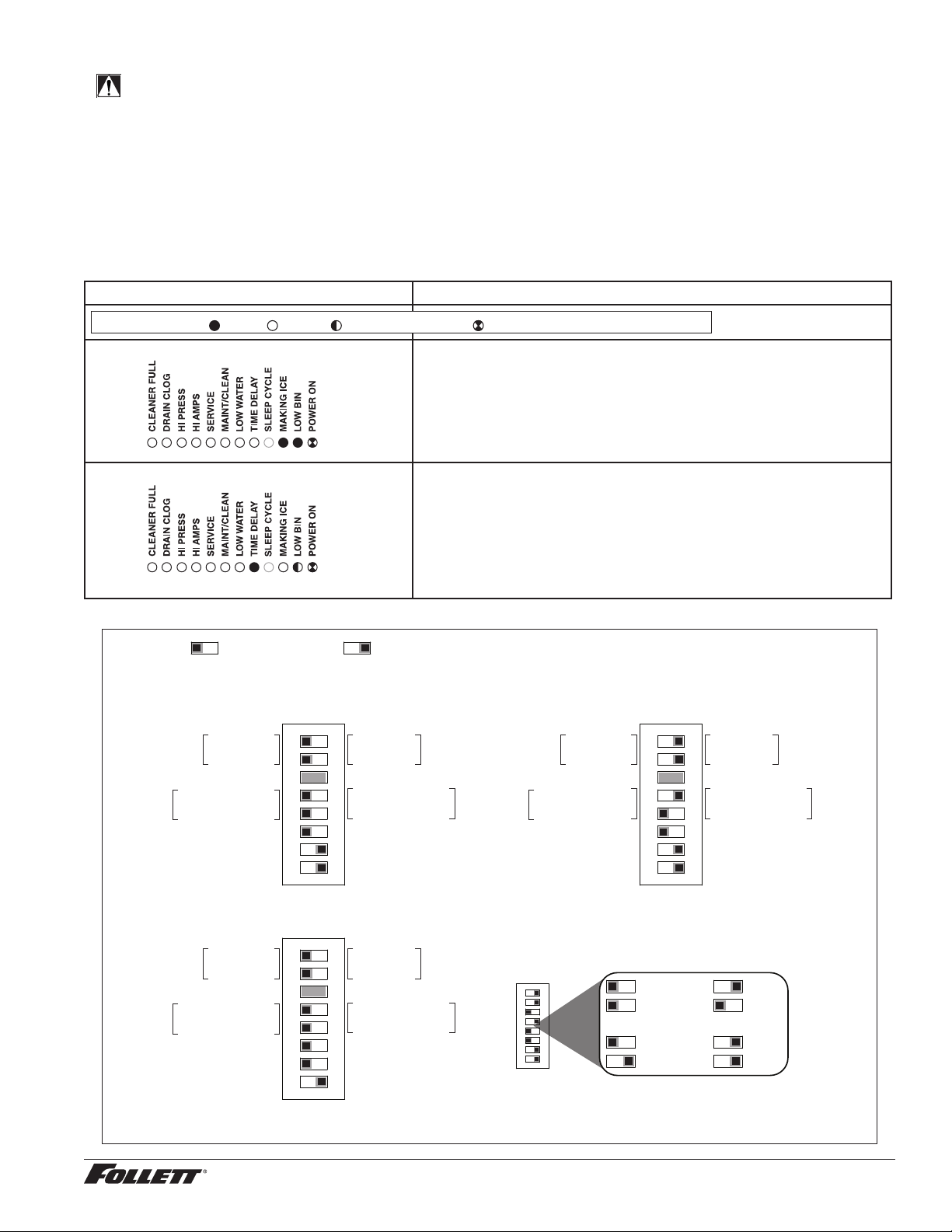

FLASHINGON or OFF

Legend:

OFFON

ATTENTION!

To prevent circuit breaker overload, wait 15 minutes before restarting this unit. This allows the compressor

to equalize and the evaporator to thaw.

Normal control board operation

The PC board indicator lights provide all the information necessary to determine the machine's status. Green

indicator lights generally represent “go” or normal operation; Yellow indicators represent normal off conditions; Red

indicators generally represent alarm conditions, some of which will lock the machine off.

A ashing green light labeled POWER indicates power to the machine. All other normal operation status indicators

are covered as follows:

Ice machine disposition Operating conditions

1. Ice machine is making ice. 1. Normal running.

2. Ice machine is not making ice.

DIP Switch Settings

OFF POSITION ON POSITION

MCD425A/W_T, MCD425A/W_S, R425A/W

OFF ON

Sleep cycle

disabled

Not used

Sleep cycle

dispense duration

20 min. time delay

Flush disabled

Maint. timer ON

Replacement P425A/W installed in Symphony dispenser

OFF ON

Sleep cycle

disabled

Not used

Sleep cycle

dispense duration

20 min. time delay

Flush disabled

Maint. timer ON

1 2 3 4 5 6 7 8

Sleep cycle

enabled

Not used

Sleep cycle

dispense duration

60 min. time delay

Flush enabled

Maint. timer OFF

1 2 3 4 5 6 7 8

Sleep cycle

enabled

Not used

Sleep cycle

dispense duration

60 min. time delay

Flush enabled*

Maint. timer OFF

2. Normal time delay. When the bin lls with ice, the LOW BIN

light goes out momentarily and the refrigeration and auger

drive systems immediately shut down. (Note: The fan motor

will continue to run for 10 minutes to cool condenser) The TIME

DELAY light comes on, initiating the time delay period. When

the time delay expires, the machine will restart provided that the

LOW BIN light is on.

425A/W installed in Symphony Plus

25/50/110 CI, CT, or FB

OFF ON

1 2 3 4 5 6 7 8

Sleep cycle

disabled

Not used

Sleep cycle

dispense duration

20 min. time delay

Flush disabled

Maint. timer ON

Sleep cycle dispense duration

OFF ON

1 2 3 4 5 6 7 8

4 5 4 5

35 s

15 s

Sleep cycle

enabled

Not used

Sleep cycle

dispense duration

60 min. time delay

Flush enabled

Maint. timer OFF

4 5 4 5

5 s

60 s

* Flush can be enabled on Symphony CT and FB models. Flush should be disabled on Symphony CI units due to risk of internal leak if

drain line is blocked. All Symphony Plus models should be set to Flush enabled.

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 11

Page 12

Relay/triac output indication

Each relay on the board has an indicator light associated with its output. For example, when the relay for the water

feed solenoid is energized, the adjacent indicator light glows green.

Flushing logic

Off cycle: At the completion of off-cycle time delay, the machine checks for a cumulative one (1) hour of ice making

time since the last off-cycle ush. If the cumulative ice making time exceeds one (1) hour, the machine will open

the drain valve for 60 seconds to drain the evaporator in its entirety. It will then rell with water, ush again and rell,

and begin making ice. If the ice making time is less than 1 hour, the machine will start and begin making ice without

draining the evaporator.

Error faults

The Maestro Plus PC board monitors various operating parameters including high pressure, auger gearmotor

amperage limits, clogged drain, and low water alarm conditions. There are two types of errors namely “hard” or “soft”.

A hard error is one that shuts the machine off and will not allow restart until the reset button is pressed. Even cycling

power will not reset a hard error. A soft error can either be automatically reset should the condition rectify, or if power

is cycled. Should an error occur, consult the troubleshooting guide in this manual or a Follett service technician.

Soft errors:

Note: For all soft errors, the ice machine will remain off for 1 hour.

LO WATER: During operation, the water level cycles between the normal low and normal high sensors. Should the

water be shut off to a running machine, a soft error will occur. The error sequence is as follows: During operation,

the water level falls to the normal low sensor, and when it does the water feed solenoid is energized. If water is not

detected at the normal low sensor within 10 seconds, a soft error will occur. The machine will shut down and TIME

DELAY and LOW WATER LEDs will be lit. After time delay, the solenoid will energize and remain energized until the

water level is sufficient for restart.

HI PRESSURE: Should the refrigeration pressure rise above 425 psi, the machine will shut down and the TIME

DELAY and HIGH PRESSURE will be illuminated. After the time delay, and if the pressure has fallen back below the

reset point of 295 psi, the machine will restart and the TIME DELAY and HIGH PRESSURE will clear.

HI AMPS: The PC board monitors the amperage of the auger motor. Should the gear motor experience current draw

above the allowable 3A limit or no current draw (0A), the machine will shut down and the TIME DELAY and HI AMP

will be illuminated. After the time delay the machine will restart and the TIME DELAY and HI AMP will clear.

Hard error:

HI AMPS: If a second hi-amp error occurs within 1 hour of the initial hi-amp error, the ice machine will shut off and

the reset on the board must be pressed to clear the error. If a second hi-amp has occurred, the HI AMP LED only will

be illuminated.

DRAIN CLOG: The drain clog sensor, located in the evaporator drain pan will detect the presence of water just below

the top edge of the pan. If water does not properly ow out of the internal or external drain lines it will backup into the

drain pan (especially during a self-ushing purge cycle). Pressing the reset button will restart the ice machine.

12 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 13

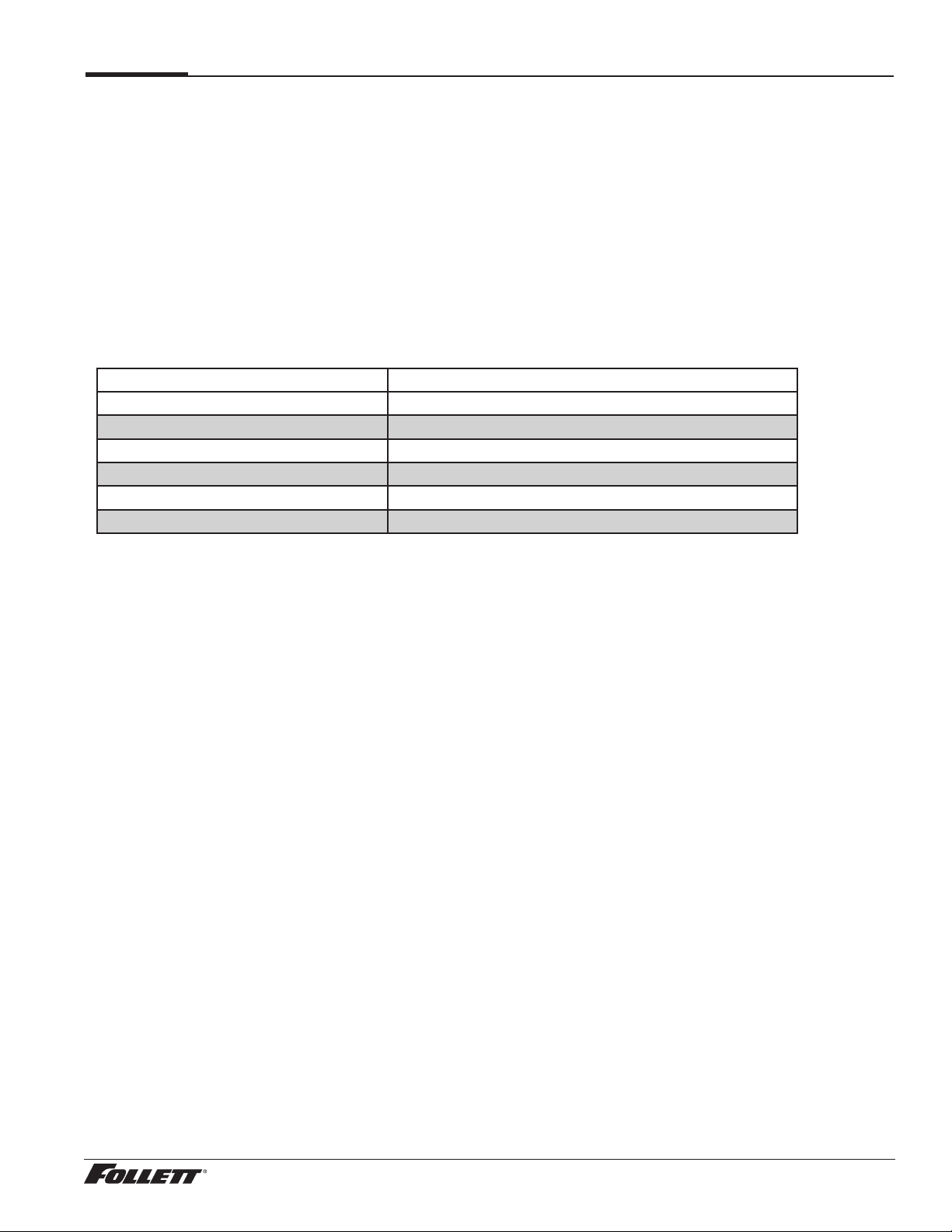

Technical specications (all models)

condenser

filter dryer

thermostatic

expansion

valve

evaporator

high side

service port

low side

service port

high pressure

switch

compressor

high

pressure

vapor

low

pressure

vapor

high

pressure

liquid

low

pressure

liquid

Refrigeration system diagram

Refrigeration pressure data

§ Water regulating valve is factory set at 300 (±10) PSIG head pressure.

§ Readings within 10% of table values should be considered normal.

Compressor data

Locked rotor amps 58.8A

Compressor current draw

Air-cooled

Ambient air temperature 60 F/15.6 C 70 F/21.1 C 80 F/26.7 C 90 F/32.2 C 100 F/37.8 C

Amperage 6.3A 6.5A 6.7A 6.9A 7.1A

High-side pressure (psi) 190 220 250 290 330

Low-side pressure (psi) 27 29 31 33 36

Water-cooled

Water temperature at oat 50 F/10 C 60 F/15.6 C 70 F/21.1 C 80 F/26.7 C 90 F/32.2 C

5.6A 5.6A 5.7A 5.8A 5.8A

Water-cooled Ice Machine Refrigeration Pressure

Discharge Pressure/Suction Pressure

Condenser inlet water temperature ˚F/˚C

˚F/˚C

50/10

70/21

90/32

Ice machine inlet water

temperature ˚F/˚C

Gearmotor data Split-Phase PSC (permanent split capacitor)

Gearmotor current 1.8A-1.9A (nominal) 0.8A-0.9A (nominal)

Locked rotor amps 14A 7A-14A (temperature dependent)

50/10

280/27

280/27

280/27

70/21

285/29

285/29

285/29

90/32

290/31

290/31

290/31

psi

psi

psi

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 13

Page 14

Air-Cooled ice machine capacity/24hrs.

Ambient Air Temperature F/C

F 60 70 80 90 100

C 16 21 27 32 38

50 460 425 390 355 320 lbs.

10 208 193 177 161 145 kg.

60 437.5 405 372.5 340 307.5 lbs.

16 198 184 169 154 139 kg.

70 415 385 355 325 295 lbs.

21 188 175 161 147 134 kg.

80 405 375 345 315 285 lbs.

27 184 170 156 142 129 kg.

90 395 365 335 305 275 lbs.

Inlet Water Temperature F/C

32 179 166 152 138 125 kg.

Note: Nominal values - actual production may vary by ±10%.

Electrical control system schematic

L1

L2/N

GND

DISP

BLACK #26

WHITE #25

GRN-YEL #24

BLACK #23

Water-Cooled ice machine capacity/24hrs.

Condenser Water Temperature F/C

F 50 60 70 80 90 100

C 10 16 21 27 32 38

50 486 465 443 422 400 389 lbs.

10 220 2 11 201 191 181 176 kg.

60 464 445 425 406 386 367 lbs.

16 210 202 193 184 175 166 kg.

70 443 425 408 390 372 358 lbs.

21 201 193 185 177 169 162 kg.

80 422 406 389 373 356 340 lbs.

27 191 184 176 169 161 154 kg.

90 400 385 371 356 341 326 lbs.

Inlet Water Temperature F/C

32 181 175 168 161 155 148 kg.

BLACK #23

BLACK #51

BIN

CONTACT

CLOSURE

WHITE #52

RED #54

BLACK #51

ORANGE #55

BLACK #56

GREEN #53

1 2 3 4 5 6 7 8 9

WHITE #62

WHITE #64

BLACK #61

BLACK #65

BLACK #66

GREEN #63

GREEN #67

2

5

6

1

4

C1 RUN

BLACK #66

BLACK #69

BLACK #68

BLACK #69

GREEN #57

BLACK #58

BLACK #59

COMPRESSOR

ELECTRICAL

BLACK #71

BOX

O.L.

C2 START

COMPRESSOR

P2

N N N N N N N N N

D37

P5

P4

DRAIN CLOG

SENSOR

T1

GRN #17

A B C D

BLACK #01

L1 L1L1

P1

P6

P21

P20

P19

P3

P22

RED #16

WHITE #121

WHITE #13

BROWN #14

BLACK #122

#15

FEED VALVE

#04

#05

FAN

DRAIN VALVE

BLUE #07

BLUE

BLACK

WHITE

START

RELAY

4

CAPACITOR

2

BLACK

YELLOW

3

BLACK

YELLOW

START

START

RUN

BLACK #51

WHITE #52

GREEN #53

COMP.

BLACK

WHITE

C

S

R

SPLIT-PHASE

RUN

PSC MOTOR

D17

D48

T.O.L.

T.O.L.

D19D22D21D20

CURRENT SENS

T2

OR

BLUE

K3

AUGER

WATER SENSOR

D18

RESERVOIR

ICE AUX WATER AUX

P15

P16

HI PRS

P14

P10

SERIAL COMM

P17

WATER LEVELS

BIN RS485

P11

P12

P18

P17

WATER LEVELS

VIOLET

BLACK

RED

ORANGE

YELLOW

BLACK

S2

P12

P13

P14

PRESS

D16

BIN

HI PRS

HIGH

MODEL SELECT

P9

2

1

PROGRAM

RESET

P7

P11

P

K1

6

5

RS485 UI

P8

CLEAN SAFE

COMPRESSOR

S1

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

MAINT.

CLEAN

14 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 15

Electrical control system operation

The P425A/W, MCD425A/W_S and R425A/W wiring diagrams which follow illustrate the circuitry of Follett ice

machines used with ice dispensers. Both normal operation of the ice machine (Stages 1–6) and non-normal

diagnostic sequences showing torque-out (Stages 7–10) for use in troubleshooting ice machine problems are

shown.

Circuitry notes

When the ice machine is used with a dispenser it receives power from the main power supply. Disconnect the

power source before performing service. When performing electrical service, always use a meter to determine

whether or not the components being serviced are energized.

§ High pressure cutout opens at 425 PSI and closes at 287 PSI (auto reset).

§ The bin signal input to the control board in the 425A/W ice machine must only be initiated by contact closure. Do

not supply power. To run the ice machine in the workshop, use the bin signal jumper (P/N 01069095).

Note: The operation stage descriptions that follow are based on the unit containing the split-phase gear

motor.

Normal operation – Stage 1

Power is supplied to L1 of the control board, the POWER LED light begins ashing. The ice level bin thermostat in

the dispenser is closed and calling for ice, supplying contact closure to the control board. The LOW BIN LED will

be on. The control board will now go through the start-up sequence. The board checks the water sensors (located

in the reservoir) for continuity between the common probe (B) and the high probe (C). If continuity is not sensed,

the water ll valve (P21) is energized.

Capacitor

YELLOW

NO CONNECT

BLACK

OR

T.O.L.

RED

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Drain Clog Sensor

Run

2

5

Compressor

Electrical Box

Fill

Valve

Start

1

Bin T-Stat

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

L1

P22

AUGER

Ice Dispense Input

N

BLACK

P6

P21

P20

P19

P3

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

Clean Switch

High

Pressure

Switch

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 15

Page 16

Normal operation – Stage 2

When continuity is seen between B and C, the water valve de-energizes, the AUGER output (P4) comes on along

with the MAKING ICE LED. The auger gearmotor’s start windings are energized through a current style start relay

that is pulled in by the initial high current draw of the gearmotor.

PSC: Start winding

energized through

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

capacitor.

Capacitor

YELLOW

NO CONNECT

OR

BLACK

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

Drain

Valve

Fill

Valve

Drain Clog Sensor

Bin T-Stat

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

P6

P21

P20

P19

P3

P22

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

Clean Switch

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

Normal operation – Stage 3

After the initial high current draw drops off, the gearmotor start relay contacts open, dropping out the start winding.

The condenser fan output (P3) comes on 0.5 seconds later.

PSC: Start

windings stay

energized.

Capacitor

YELLOW

BLACK

NO CONNECT

OR

T.O.L.

RED

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Drain Clog Sensor

Run

2

5

Compressor

Electrical Box

Fill

Valve

Start

1

Bin T-Stat

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

Ice Dispense Input

N

BLACK

P6

P21

P20

P19

P3

P22

P4

P15

HI PRS

1 2 3 4 5 6 7 8

WATER LEVELS

BIN

COMPRESSOR

RESET

P11

Clean Switch

High

Pressure

Switch

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

16 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 17

Normal operation – Stage 4

Water Sensors

One second (1 s) after the fan comes on, the COMPRESSOR output comes on. The compressor circuit uses both

run and start capacitors along with a potential start relay. The start capacitor in energized through the normally

closed contacts of the start relay.

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

Drain

Valve

Fill

Valve

N

L1

RED

BROWN

BLACK

BLUE

L1

P6

P3

P22

AUGER

P21

P20

P19

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

A B C D

Drain Clog Sensor

Bin T-Stat

Clean Switch

Normal operation – Stage 5

As the compressor comes up to normal running speed, its start winding generates a voltage potential across the

relay’s coil. This energizes the coil to open the contact and drop out the start capacitor.

The ice machine is now in a normal ice making mode. The ice machine will produce ice until the bin level control

in the ice dispenser is satised.

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

OR

BLACK

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

Drain

Valve

Fill

Valve

N

L1

RED

BROWN

BLACK

BLUE

L1

P22

AUGER

P6

P21

P20

P19

P3

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

A B C D

Clean Switch

Water Sensors

Drain Clog Sensor

Bin T-Stat

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 17

Page 18

Normal operation – Stage 6

Once the bin thermostat control opens, the LOW BIN LED goes out. The compressor and gear motor outputs turn

off, the MAKING ICE LED goes out and the TIME DELAY LED comes on. .

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

Drain

Valve

Fill

Valve

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

P6

P21

P20

P19

P3

P22

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

A B C D

Clean Switch

Water Sensors

Drain Clog Sensor

Bin T-Stat

Normal operation – Stage 7

The fan motor continues for 10 minutes before shutting off. The TIME DELAY LED remains on for 20 minutes.

The ice machine will not start while the TIME DELAY LED is on. To restart the ice machine for troubleshooting

purposes, depress the reset button to clear the control board.

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

3

R

4

2

BLACK YELLOW

S

C

Gearmotor

Drain

Valve

Fill

Valve

N

L1

L1

RED

BROWN

BLACK

BLUE

AUGER

A B C D

Bin T-Stat

Water Sensors

Drain Clog Sensor

18 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

P6

P21

P20

P19

P3

P22

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

COMPRESSOR

Clean Switch

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

Page 19

Normal operation – Stage 8

When the dwell time of 20 minutes has expired, the TIME DELAY LED goes off. If 5 seconds of ice has been

dispensed and the SLEEP CYCLE LED (Symphony Plus only) is off, the ice machine will go through the normal

start-up sequence when the bin level control signals the control board for ice.

Capacitor

YELLOW

NO CONNECT

BLACK

OR

T.O.L.

RED

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Drain Clog Sensor

Run

2

5

Compressor

Electrical Box

Fill

Valve

Start

1

Bin T-Stat

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

Ice Dispense Input

N

BLACK

P6

P21

P20

P19

P3

P22

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

WATER LEVELS

BIN

Pressure

Switch

COMPRESSOR

P11

Clean Switch

High

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

Quiet Night/Sleep cycle (Symphony Plus only)

The board monitors ice dispensing through a line voltage input to P15. If the ice dispense has not be initiated for

more than 5 seconds during the 20 minute time delay, the SLEEP CYCLE LED comes on. The machine will stay

off for 12 hours unless 5 seconds of dispensing is seen. After 12 hours, the SLEEP CYCLE LED goes out and the

ice making will resume if the bin thermostat is closed. The sleep cycle dispense duration is adjustable using the

DIP switches on the control board.

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 19

Page 20

Self-ushing (when enabled)

Water Sensors

At the completion of the 20 minute time delay, the machine checks for a cumulative one hour of ice making time

since the last off-cycle ush. If the cumulative ice making time exceeds one hour, the machine will energize the

drain valve P19 for 60 seconds to drain the evaporator. It will then rell with water, ush again, rell and begin

making ice if the LOW BIN LED is on. If the ice making time is less than 1 hour, the machine will start and begin

making ice without draining the evaporator.

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

3

R

C

A B C D

4

2

BLACK YELLOW

S

Gearmotor

Drain

Valve

Fill

Valve

Drain Clog Sensor

Bin T-Stat

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

P6

P21

P20

P19

P3

P22

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

Clean Switch

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

Diagnostic Stages

High gearmotor amps – Stage 1

The HI AMPS error and TIME DELAY LEDs are on indicating that the control board has sensed an over-torque

condition at the P4 terminal (more than 3 amps from the gearmotor) or no current draw (0A) and shut the ice

machine down (strike one). The HI AMPS and TIME DELAY LEDs will remain on for 60 minutes after an over-

torque condition has occurred. The ice machine will remain off as long as these two LEDs are on. After the

60 minute time delay, these LED lights turn off, and the control board will try to go through a normal start-up

sequence.

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

Drain

Valve

Fill

Valve

Drain Clog Sensor

Bin T-Stat

N

L1

L1

RED

BROWN

BLACK

BLUE

AUGER

20 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

P6

P21

P20

P19

P3

P22

N

BLACK

WATER LEVELS

P4

P15

HI PRS

BIN

1 2 3 4 5 6 7 8

RESET

P11

Clean Switch

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

Page 21

High gearmotor amps – Stage 2

If the restart is successful the board will continue to monitor the current draw on P4 for 60 minutes looking for

a second high amps (above 3A) occurrence. If the ice machine runs without problems for 60 minutes and no

additional torque errors occur, the ice machine will continue normal operation.

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

T.O.L.

RED

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Run

2

5

Compressor

Electrical Box

Fill

Valve

Start

1

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

AUGER

L1

P6

P21

P20

P19

P3

P22

Ice Dispense Input

N

P15

BLACK

HI PRS

WATER LEVELS

P4

1 2 3 4 5 6 7 8

RESET

BIN

COMPRESSOR

P11

High

Pressure

Switch

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

A B C D

Clean Switch

Water Sensors

Drain Clog Sensor

Bin T-Stat

High gearmotor amps – Stage 3

If a second occurrence happens during the 60 minute monitoring period, the HI AMPS LED will come on again

and shut the machine down (strike two). The HI AMPS LED (wihout the TIME DELAY LED) will indicate to the

technician that two consecutive over-torque situations have occurred. The ice machine is shut down at this time

and locked out. It will not restart unless the manual reset button is depressed while power is on.

Capacitor

YELLOW

NO CONNECT

BLACK

OR

T.O.L.

RED

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Drain Clog Sensor

Run

2

5

Compressor

Electrical Box

Fill

Valve

1

Start

Bin T-Stat

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

Ice Dispense Input

N

BLACK

P6

P21

P20

P19

P3

WATER LEVELS

P22

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

High

Pressure

Switch

COMPRESSOR

Clean Switch

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 21

Page 22

Loss of water

During operation, the water level cycles between the normal low (D) and normal high (C) water probes - the ll

valve (P21) cycling on and off. If continuity is not detected between the common probe (B) and normal low (D)

within 10 seconds, the LOW WATER and TIME DELAY LEDs will come on and the machine will shut down for

the one hour time delay period. After the time delay, the ll valve will re-energize and wait for continuity between

the common probe and normal high before restarting. LOW WATER LED will remain ON until the water level is

satised.

T.O.L.

RED

R

S

C

Compressor

Start

Relay

WHITE

Run

2

5

Compressor

Electrical Box

Start

1

Fan

WHITE

Ice Dispense Input

High

Pressure

Switch

Capacitor

YELLOW

NO CONNECT

BLACK

OR

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

Drain

Valve

Fill

Valve

Drain Clog Sensor

Bin T-Stat

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

P6

P21

P20

P19

P3

P22

N

BLACK

WATER LEVELS

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

Clean Switch

POWER

LOW BIN

MAKING ICE

COMPRESSOR

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

22 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 23

High refrigerant pressure

Should the refrigeration pressure rise above 425 psi, the high pressure switch contacts will open. The board sees

the open circuit and the HIGH PRESSURE and TIME DELAY LEDs will come on, the machine shuts down. After

the one hour time delay, the machine will attempt to restart. If the pressure has fallen below the reset point of 295

psi and the board see the contacts closed, the machine will resume normal operation. If the contacts are still open

after the restart, the board will again go into HIGH PRESSURE and TIME DELAY, cycling until contact closure is

seen.

Capacitor

YELLOW

NO CONNECT

BLACK

OR

T.O.L.

RED

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Drain Clog Sensor

Run

2

5

Compressor

Electrical Box

Fill

Valve

Start

1

Bin T-Stat

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

Ice Dispense Input

N

BLACK

P6

P21

P20

P19

P3

P22

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

WATER LEVELS

BIN

Pressure

Switch

COMPRESSOR

P11

Clean Switch

High

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

Drain clog

If continuity is seen between the two drain clog sensor probes, the DRAIN CLOG LED will come on and the

machine will shut down. The machine will not restart unless the manual reset button is depressed while power is

on.

Capacitor

YELLOW

NO CONNECT

BLACK

OR

T.O.L.

RED

Start

Relay

4

2

3

BLACK YELLOW

R

S

C

Gearmotor

A B C D

Water Sensors

R

S

C

Compressor

Start

Relay

WHITE

Drain

Valve

Drain Clog Sensor

Run

2

5

Compressor

Electrical Box

Fill

Valve

Start

1

Bin T-Stat

Fan

WHITE

N

L1

RED

BROWN

BLACK

BLUE

L1

AUGER

Ice Dispense Input

N

BLACK

P6

P21

P20

P19

P3

WATER LEVELS

P22

P4

P15

HI PRS

1 2 3 4 5 6 7 8

RESET

P11

BIN

High

Pressure

Switch

COMPRESSOR

Clean Switch

POWER

LOW BIN

MAKING ICE

SLEEP CYCLE

TIME DELAY

LOW WATER

MAINTENANCE

SERVICE

HI AMPS

HI PRESSURE

DRAIN CLOG

CLEANER FULL

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 23

Page 24

Refrigeration system (all models)

All service on refrigeration systems must be performed in accordance with all federal, state and local laws. It is the

responsibility of the technician to ensure that these requirements are met. Recharging ice machine to other than

factory specications will void the warranty.

R404A ice machine charge specications

Model Charge Refrigerant type

MCD425A, MFD425A, R425A, P425A (air-cooled) 15 oz. (425 g) R404A

MCD425W, MFD425W, R425W, P425W (water-cooled) 9 oz. (255 g) R404A

Refrigerant replacement requirements

1. Non-contaminated refrigerant removed from any Follett refrigeration system can be recycled and returned

to the same system after completing repairs. Recycled refrigerant must be stored in a clean, approved

storage container. If additional refrigerant is required, virgin or reclaimed refrigerant that meets ARI

standard 700-88 must be used.

2. In the event of system contamination (for example, a compressor burn out, refrigerant leak, presence of

non-condensibles or moisture), the system must be repaired, evacuated and recharged using virgin or

reclaimed refrigerant that meets ARI standard 700-88.

3. Follett Corporation does not approve of recovered refrigerants. Improper refrigeration servicing

procedures will void the factory warranty.

Evacuation

Evacuate the system to a level of 500 microns. When the 500 micron level is reached, close valves and both

manifold and shut down the vacuum pump. Allow the system to sit for approximately 20 minutes. During this period

the system pressure should not rise. If the system pressure rises and stabilizes there is moisture in the system and

further evacuation is needed. If the pressure continues to rise check the system for leaks.

Ice capacity test

Ice machine production capacity can only be determined by weighing ice produced in a specic time period.

Replace all panels on ice machine.

1. Run ice machine for at least 15 minutes.

2. Weigh and record weight of container used to catch ice.

3. Catch ice for 15 or 20 minutes.

4. Weigh harvested ice and record total weight.

5. Subtract weight of container from total weight.

6. Convert fractions of pounds to decimal equivalents (ex. 6 lb 8 oz. = 6.5 lb).

7. Calculate production using following formula:

1440 min. x wt. of ice produced

= Production capacity/24 hr. period

Total test time in minutes

8. Calculated amount per 24 hours should be checked against rated capacity for same ambient and water

temperatures in Ice Production Tables.

24 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 25

Evaporator disassembly

Note: The upper bearing, lower bearing and auger assemblies must be replaced as assemblies. The bottom and

top bearing assemblies cannot be eld assembled to factory specications.

1. Press CLEAN switch.

2. Wait for LOW WATER light to illuminate.

3. Turn OFF power.

4. Remove top bearing insulation and

compression nozzle insulation.

5. Disconnect vent and drain tube from nozzle.

6. Disconnect compression nozzle from

evaporator.

7. Disconnect evaporator water feed line.

8. Remove nut and upper v-band coupling from

top of evaporator.

9. Lift top bearing assembly straight up with a

slight rotating motion and remove.

10. Remove ice compression loop located at top of

auger.

11. Lift auger straight up and out of evaporator.

12. Remove nut and lower vee band coupling from

bottom of evaporator.

13. Lift evaporator to clear bottom bearing

assembly.

14. Loosen hex head bolt in side of mounting

base with 5/16 wrench and lift lower bearing

assembly.

15. Remove condensate shield.

16. Remove 4 Allen head machine screws holding

mounting base to gearbox.

Fig. 3

FLAKER COMPONENTS

COMPRESSION

LOOP 00124115

AUGER 00124123

Evaporator reassembly

1. Clean gearmotor boss, output shaft and shaft

well.

Fig. 4

Apply grease in well

2. Install drain pan and evaporator mounting

base.

3. Fill gear motor shaft well with food grade

grease (Fig. 4).

4. Install condensate shield and seat against

gear motor boss.

Evaporator drain pan and mounting base not shown for clarity.

5. Install bearing O ring in groove in evaporator

mounting base.

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 25

Page 26

6. Lower bottom bearing assembly into

evaporator mounting base.

7. While maintaining rm downward pressure

on bottom bearing assembly, tighten hex

head bolt with a 5/16 wrench.

8. Position evaporator over lower bearing

assembly and align grooves with pins in

bearing assembly.

9. Install vee band clamp and nut to 70 in/lb.

(Fig. 5).

Note: Clamp must be oriented as shown

in order for the insulation to be placed

properly.

10. Place auger in center of evaporator and

rotate to mate with drive pin.

11. Install ice compression loop, orienting loop.

12. Install upper bearing and seal assembly,

rotating bearing to slip pin into auger slot.

13. Install upper vee band clamp and nut to

70in/lb.

14. Install evaporator insulation.

15. Install compression nozzle and tubing.

16. Secure ice transport tube with clamp

(Fig.6.1).

Note: Clamp must be oriented as shown

in order for the insulation to be placed

properly.

Fig. 5

Fig. 6

2

4

3

1 7. Install compression nozzle insulation

(Fig.6.2).

18. Install vent and drain tube (Fig.6.3).

19. Install top bearing insulation (Fig.6.4).

Gearmotor replacement

1. Disassemble evaporator.

2. Disconnect the wire connectors.

3. Remove 4 screws holding gear motor

mounting plate to base of ice machine and

lift gearbox and motor clear of ice machine.

4. Remove machine screws holding mounting

plate to motor.

5. Install new motor in reverse order.

3

1

26 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 27

Replacement parts

Replacement ice machine ordering matrix

Dispenser models Replacement ice machine model

Dispensers with top mounted ice machines

50CT425A & 50HT425A P425A

50HT425W & 50HT425W P425W

25CT 425A & 25HT425A P425A

25CT425W & 25HT425W P425W

110CT425A P425A

110CT425W P425W

Dispensers with remote ice machines

25CR425A & 25HR425A R425A

25CR425W & 25HR425W R425W

50CR425A & 50HR425A R425A

50CR425W & 50HR425W R425W

110CR425A R425A

110CR425W R425W

All U150/VU155 series with air-cooled ice machines MCD425AVS

All U150/VU155 series with water-cooled ice machines MCD425W

All VU300 series with air-cooled ice machines MCD425A

All VU300 series with water-cooled ice machines MCD425W

Freestanding dispensers with ice machines in the base

25FB425A P425A

25FB425W P425W

50FB425A P425A

50FB425W P425W

110FB425A P425A

110FB425W P425W

Nugget ice machine on top of bin

MCD425ABT MCD425ABT*

MCD425WBT MCD425WBT*

Flake ice machine on top of bin

MFD425ABT MFD425ABT*

MFD425WBT MFD425WBT*

* New bin top required.

Ice machine cleaner/descaler

00132001 SafeCLEAN environmentally-friendly cleaner, carton of 24 x 7 oz packets

Ice machine sanitizer

00979674 Nu-Calgon IMS-II or IMS-III Sanitizer, 16 oz. bottle

00131524 Sponge, sanitary, each

Miscellaneous

Part # Description

501860 Condensate pump

502775 Oil, gearmotor, 1 pint

501111 Grease, Mobile FM 222, 14 oz tube

500377 Clamp, ice tube

501425 Grille

01075431 Sponge, sanitary, pack of 24

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 27

Page 28

Air-cooled skins assembly (MCD425A_S, R425A)

7

6

8

2

1

Reference # Description Part #

1 Gasket, duct 502781

2 Duct (including gasket) 01068188

3 Front panel 01068204

4 Spacer, base 01068220

5 Panel, right side 01068238

6 Panel, left side and rear (1 piece) 01068246

7 Bushing 01026152

8 Panel, top 01068253

9 Tube, drain 01016948

10 Fitting, water 01065375

11 Fitting, drain 00109728

3

4

10

11

9

5

28 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 29

Water-cooled skins assembly (MCD425W_S, R425W)

9

8

10

4

1

1

2

3

Reference # Description Part #

1 Fitting, condenser 00195966

2 Fitting, water 01065375

3 Fitting, drain 00109728

4 Panel, front 01068261

5 Spacer, base 01068220

6 Panel, right side 01068238

7 Tube, drain 01016948

8 Panel, left side and rear (1 piece) 01068246

9 Bushing 01026152

10 Panel, top 01068253

5

7

6

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 29

Page 30

Louvered docking station (MCD425A/W_T)

4

3

2

1

Reference # Description Part #

1 Louver, front 01006154

2 Cover, front 01068279

3 Tube, drain 01055185

4 Lovered docking station 01068287

30 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 31

Electrical components

1

3

4

Reference # Description Part #

1 Capacitor, run 00997759

2 Relay start, compressor, 115 V, 60 Hz 00997726

3 Board, control circuit, 115 V, 60 Hz 01064708

4 Switch, clean 00117036

Not shown Bin thermostat (MCD425A/WBT, MCD425A/WHT, MFD425A/WBT and

MFD425A/WHT only)

Not shown Board, stand off control (8 required) 00903005

Not shown Relay, power to contact closure 01020734

Not shown Jumper, bin signal 01069095

Not shown Cord and plug, power 01075589

Not shown Converter, bin signal, Vision 01067156

Not shown Relay, bin signal (power to contact closure) 01020734

2

500514

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 31

Page 32

Evaporator

FOOD SERVICE

23

HEALTHCARE

15

17

17

18

25

19

30

27

2

24

FLAKER

1

3

4

5

COMPONENTS

3

4

26

20

1

FLAKER

32

28

18

12

21

22

7

6

8

10

11

16

9

13

31

29

13

32 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 33

Evaporator

Reference # Description Part #

1 Coupling, vee band, includes nut 502735

2 Bearing assembly, top 502736

3 Loop, ice compression, beveled (see below for Flaker-specic components) 502110

4 Auger (see below for Flaker-specic components) 502737

5 Evaporator (includes insulation jacket, 502740) 01064658

6 O ring, bearing housing 500496

7 Bearing assembly, bottom (includes O rings and condensate shield) 502738

8 O ring, mounting base 501063

9 Shield, condensate 500744

10 Screw, Allen 1/4 20 x 1/2 (set of 4) 501080

11 Mounting base, evap. (includes 501063) 502733

12 Bolt, mounting base 502227

13 Gearbox and motor 502730

Not shown Mounting base, gearbox 01067693

15 Compression nozzle, with single drain 01064674

16 Drain pan, evaporator 00181990

17 Tube, compression nozzle vent 01027804

18 Tube, compression nozzle, single drain 01027416

Not shown Grease, Chevron SRI-2, 14 oz 501111

19 Bracket, vent hoses 01007087

20 Insulation jacket, evaporator 01049592

21 Relay, gearmotor (for split-phase motor only) 00142042

22 Cover, black plastic 01012228

23 Nozzle, compression, dual drain 01067446

24 O ring, top bearing 01064963

25 Tube, compression nozzle, dual drain 01033778

26 Sensor, overow 01039783

27 Insulation, top bearing 01049600

28 Insulation, compression nozzle, single drain 01049584

29 16 µF Capacitor (for PSC motor only) 01103142

30 Screw, compression nozzle 00956250

31 Cover, aluminum 01106376

Not shown O-ring, compression nozzle 00988097

Flaker-specic components

Reference # Description Part #

3 Loop, compression, notched 00124115

4 Auger (with paddle) 00124123

18 Tube, compression nozzle, single drain 01027416

32 Compression nozzle, aker 01067453

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 33

Page 34

Air-cooled ice machines

9

23

22

16

25

11

1

5

13

2

18

14

15

7

19

12

4

24

21

6

8

10

17

34 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

20

3

Page 35

Air-cooled ice machines

Reference # Description Part #

1 Drier 502724

2 Condenser coil, A/C 01067461

3 Reservoir mounting bracket, a/c 01072909

4 Reservoir assembly 01064682

5 Bracket, electrical box 01068170

6 Evaporator (see page 32 and 33 for complete breakdown) —

Not shown Tubing, polypropylene, reservoir supply (sold by foot) 502079

7 Valve, expansion, thermal 502726

8 Drain pan, evaporator 0018190

9 High pressure cutout 502732

10 Mounting bracket, gearbox 01067693

11 Gearbox & motor assembly, 115 V, 60 Hz 502730

12 Tubing, clean and vent 00998765

13 Fan blade 500474

14 Motor, fan, 115 V, 60 Hz 500672

15 Bracket, fan motor 01067107

Not shown Overload, compressor, 115 V, 60 Hz 01027572

16 Compressor, 115 V, 60 Hz 01065259

17 Tube, ll/purge - reservoir-solenoid-evaporator feed 01051192

Not shown Water inlet tting, brass 01065275

Not shown Fitting, reservoir, plastic 1/4" stem x 1/4" push-in 00121699

18 Jacket, insulation, TXV 502830

19 Bracket, ice tube entry 01067644

20 Solenoid, purge 00991216

21 Solenoid, ll 01082403

Not shown Tube, drain, MCD425AxT 01055185

Not shown Tube, drain, MCD425AxS 01016948

22 Tube, ice transport, MCD425A/WxT 01003532

23 Jacket, insulation, TXV bulb 00106534

24 Cup, cleaning 01065226

Not shown Gasket, reservoir 00990978

25 Capacitor, start 01026145

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 35

Page 36

Water-cooled ice machines

23

15

7

11

16

16

13

6

4

18

1

25

22

21

5

9

8

10

17

19

3

4

20

2

24

14

36 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 37

Water-cooled ice machines

Reference # Description Part #

1 Drier 502724

2 Valve, water regulating (includes Iso-washer) 500537

Not shown Iso-washer (for water regulating valve) 501810

3 Reservoir assembly 01064682

4 Reservoir mounting bracket 01068162

Not shown Tubing, polypropylene, reservoir supply (sold by foot) 502079

Not shown Fitting, reservoir, plastic 1/4" stem x 1/4" push-in 00121699

5 Evaporator (see page 32 and 33 for complete breakdown) —

6 Bracket, electrical box tower 01068121

7 Valve, expansion, thermal 502726

8 Drain pan, evaporator 00181990

9 Gearbox & motor assembly, 115 V, 60 Hz 502730

10 Mounting bracket, gearbox 01067693

11 Bracket, electrical box mounting 01068139

Not shown Overload compressor, 115 V, 60 Hz 01027572

12 Compressor, 115 V, 60 Hz 01065259

13 Coil, condenser 00195933

14 Tube, clean and vent 00998765

Not shown Water inlet tting, brass 01065275

15 High pressure cutout 502732

16 Ty-rap (2 required) 204584

17 Tube, ll/purge - reservoir-solenoid-evaporator feed 01051192

18 Bracket, ice tube entry 01067644

19 Solenoid, purge 00991216

20 Solenoid, ll 01082403

Not shown Tube, drain, 25/50CI 01054576

Not shown Tube, drain, MCD425AxT 01055185

Not shown Tube, drain, MCD425AxS 01016948

21 Tube, ice transport, MCD425A/WxT 01003532

22 Jacket, insulation, TXV 502830

23 Jacket, insulation, TXV bulb 00106534

24 Cup, cleaning 01065226

Not shown Bracket, ll solenoid 01072867

Not shown Gasket, reservoir 00990978

25 Capacitor, start 01026145

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 37

Page 38

Water treatment accessories for Symphony ice and water dispensers

Reference # Description Part #

Standard capacity lter system

Not shown Follett QC4-FL4S water lter system (includes FL4S primary cartridge and head, coarse

pre-lter and head, pressure gauge, ushing valve; assembled and installed on mounting

bracket), one per ice machine

Not shown Follett FL4S primary replacement cartridge 00130245

Not shown Water lter cartridge – primary, carton of 6 00954297

Not shown Everpure coarse pre-lter cartridge 00130211

Not shown Water pre-lter cartridge – pre-lter, carton of 12 00954305

High capacity lter system

Not shown High capacity water lter system (one per ice machine) 00978957

Not shown High capacity water lter cartridge – primary, single 00978965

Not shown High capacity water lter cartridge – primary, carton of 6 00978973

Not shown Water pre-lter cartridge – pre-lter, single 00130211

Not shown Water pre-lter cartridge – pre-lter, carton of 12 00954305

Carbonless high capacity lter system

Not shown Carbonless high capacity water lter system (one per ice machine) – Horizon™ and Mae-

stroPlus series ice machines

Not shown Carbonless high capacity water lter cartridge – primary, single 01050426

Not shown Carbonless high capacity water lter cartridge – primary, carton of 6 01050434

Not shown Water pre-lter cartridge – pre-lter, single 00130211

Not shown Water pre-lter cartridge – pre-lter, carton of 12 00954305

Other ltration

Not shown Claris hardness removal ltration system 00986059

Not shown Replacement lter for Claris system 00985127

Not shown Reverse osmosis system, 200 gallons per day 00986034

Not shown Replacement reverse osmosis cartridge 00985085

Not shown Replacement reverse osmosis pre-lter 00985077

Not shown Cleaning plug for reverse osmosis system 00985119

Not shown Cleaning cartridge for reverse osmosis system 00985101

Water pressure

Not shown Water pressure regulator (25 psi) 501781

00130229

01050442

Miscellaneous

Reference # Description Part #

Not shown Diverter plate (single agitator Cornelius dispensers and left-hand

307277

dispense chute on dual-agitator Cornelius dispensers)

Not shown Diverter plate (right-hand dispense chute on dual-agitator dispensers) 00996207

Not shown Diverter plate, Cornelius Flavor Fusion 01100825

38 MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines

Page 39

MCD425A/W, R425A/W, MFD425A/W, P425A/W Ice Machines 39

Page 40

SafeCLEAN, SensorSAFE, Maestro Plus, Symphony Plus, Quiet Night and Sani-Sponge are trademarks of Follett Corporation.

Follett and RIDE are registered trademarks of Follett Corporation, registered in US.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

© Follett Corporation 12/15

01033646R03

Loading...

Loading...