Page 1

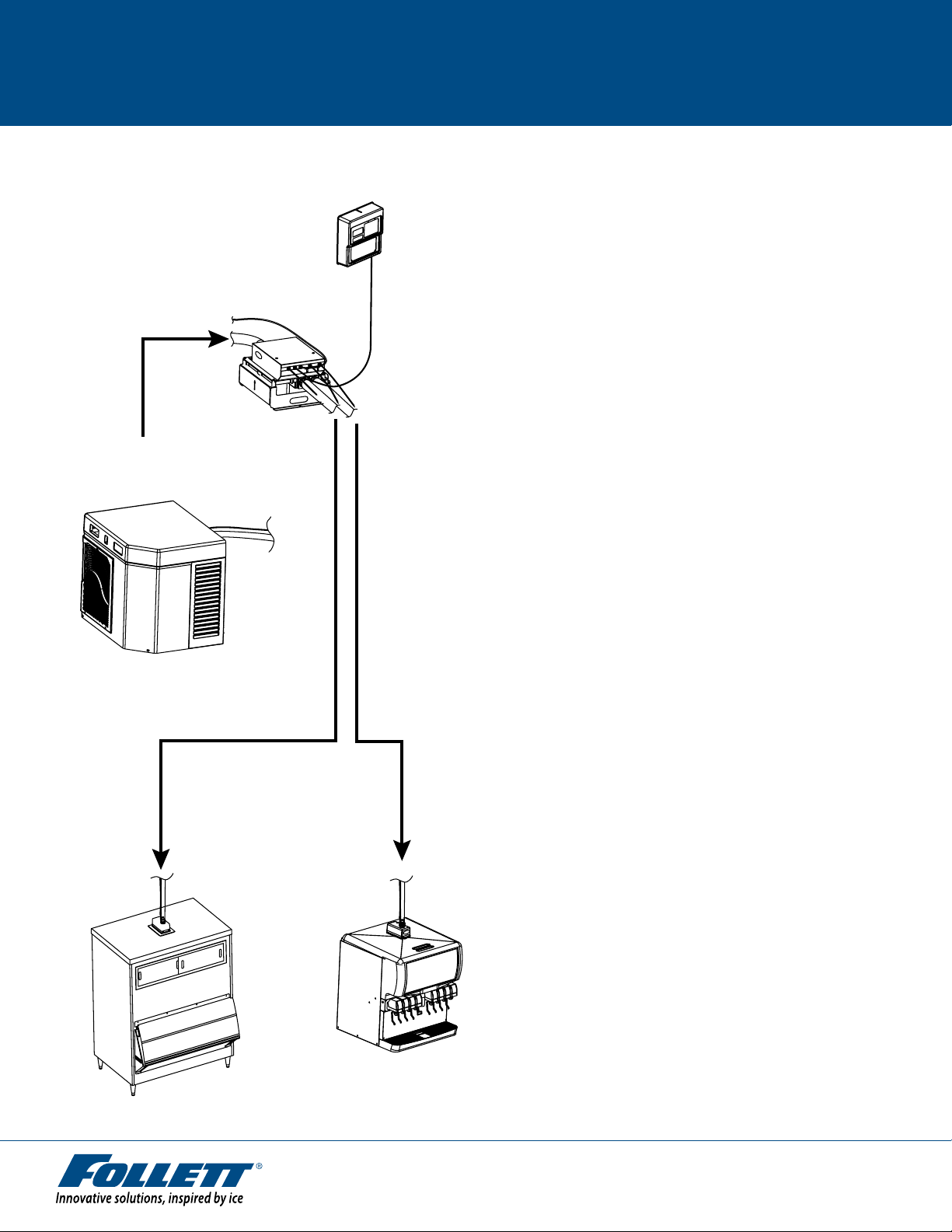

Ice Manager

Ice Manager

™

diverter valve system

IMDV-2

Series

Ice Manager

Diverter Valve

(1) Horizon

Chewblet® Ice Icemaker

(purchased separately)

™

Control Panel

The Ice Manager diverter valve system automatically delivers ice

from ONE Follett Horizon

or bins. The system includes a control panel, diverter valve, and

components to connect two ice storage units chosen.

_____________________________________________________

™

icemaker to TWO separate dispensers

Satellite-ll™ ice through a tube capability

• Deliver ice automatically through a tube to where you need it,

instead of manually transporting

• Reduce handling to provide more sanitary ice and prevent

safety issues for employees and customers

• Install icemaker and diverter valve up to 75' (23 m) away from

the bin

• Create a more aesthetically appealing dining area with less

heat and noise around your customers

Flexibility with a wide choice of bins and dispensers

• Follett ice storage bins, Ice Transport Systems (ITS), and

Ice•DevIce

• Follett Vision

• Countertop ice and beverage dispensers manufactured by

others (see approved list on page 2)

• Other ice storage containers (contact factory)

™

ice storage and dispensing systems

™

low-prole ice and beverage dispensers

Efficient use of equipment

• Fill two bins or dispensers with only one icemaker

• Reduce the number of icemakers in your operation, or

eliminate manual lling

• Keep one machine running more efficiently instead of two

machines that may idle frequently

• Service and maintain only one machine instead of two.

(2) Ice Storage Units

(purchased separately)

Any combination of bins or dispensers

Lane 1

Factory-arranged installation and start-up

• Turn-key system installation with factory-trained installers

• Full operational demonstration to end-user

Lane 2

JOB: ______________________________________________

ITEM: _____________________________________________

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

Page 2

Ice Manager

™

diverter valve system

IMDV-2

Series

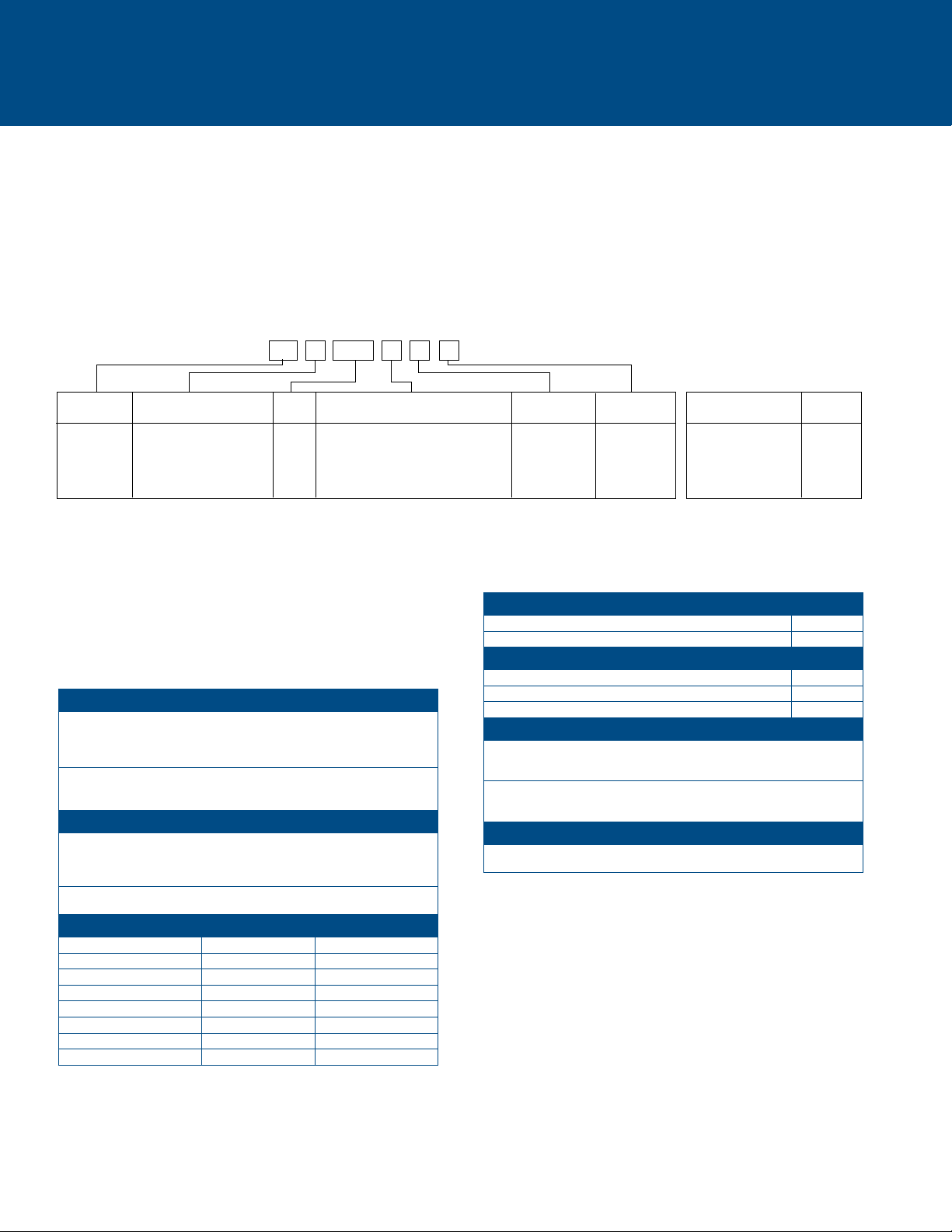

Conguring the Ice Manager diverter valve system

1. Select Horizon icemaker model

Using the model conguration table below, determine the Horizon icemaker to order that will best suit your needs. For more specications

on Horizon icemaker models see form# 3810, 3815, 3311. Existing Horizon icemakers may be retrotted to integrate with the Ice Manager

diverter valve system. Based on model# and serial#, determine the retrot kit to order using the table below.

Horizon icemaker model: ____________________ Serial# (if existing Horizon icemaker): ____________________

Horizon 1000 & 1400 Series Icemaker Model Number Configurations

for use with Ice Manager Diverter Valve System

A M SC 1000HC

Icemaker Voltage Series Condenser

HC Horizon

Chewblet

C 208-230/60/1

(self-contained only)

D Low side 115/60/1

Condenser 208-230/60/1

(remote condensing only)

A Air-cooled, self-contained

1000

W Water-cooled, self-contained

1400

R Air-cooled, remote condensing unit

N Air-cooled, no condensing unit for

connection to parallel rack system

2. Select two dispensers or bins to be lled

Choose two approved units for ice storage. If exact model is not

known, note type of unit. Lane 1 is the primary lane and should

be assigned to bin or dispenser with highest demand.

Lane 1: ___________________________________

Lane 2: ___________________________________

If desired unit is not listed below, contact factory.

Follett Ice Transport and Storage

New Follett ice storage bin or transport system model.

See form# B300 for models. When ordering bin, specify bin top to be cut for

Ice Manager diverter valve system. If icemaker will be top mounted on bin,

see Step 3.

Existing Follett ice storage bin or transport system model.

Requires replacement top cut for Ice Manager diverter valve system. See

form# 4025 for item #'s. If icemaker will be top mounted on bin, see Step 3.

Follett Vision Ice and Beverage Dispensers

New Follett Vision 155 & 300 ice and beverage dispenser model. VU155N

models are available via Special Quote Request (SQR).

See form# 4025 for models. Order Vision with VUIMDVKIT to be configured

for Ice Manager diverter valve system.

Existing Vision 155 serial# must be greater than B50001.

Existing Vision 300 serial# must be greater than B50005.

Ice & Beverage Dispensers*

Cornelius ED/DF150 Series Lancer 4500-22N Servend MD250

Cornelius ED/DF175 Series Lancer 4500-30N Servend MDH300

Cornelius ED/DF200 Series Lancer FS-22N Servend MDH302

Cornelius ED/DF250 Series Lancer FS-30N Servend MDH402

Cornelius ED/DF300 Series Lancer FS-44N Servend SV175

Cornelius IDC215 Servend MD150 Servend SV200

Cornelius IDC255 Servend MD175 Servend SV250

Cornelius Flavor Fusion Servend MD200

* Consult with dispenser provider to be sure the dispenser is ready

to dispense nugget ice.

Horizon Retrofit Kits

Application Configuration

M Ice Manager S Satellite-fill

Horizon Model#

HCC prior to C43650

HCD prior to C43650

Models after C43650

Order

Part #

00185181

00185272

00191965

3. Choose Horizon icemaker mounting option

Mounting option: __________________________________

Wall Mount Bracket Part #

HCC1000 AMS, WMS and HCD1000 & 1400 RMS, NMS 00128587

HCC1400 AMS, WMS 00133934

Machine Stand Part #

HCC1000 AMS, WMS 00128553

HCC1400 AMS, WMS 00133926

HCD1000 & 1400 RMS, NMS 00128561

Follett Bin - Top Mount

New bin, see form# B300 for models.

When ordering bin, specify bin top to be cut for Ice Manager diverter valve

system and icemaker.

Existing bin, see form# 4025 for bin top listing.

Requires replacement top cut for Ice Manager diverter valve system and

icemaker when ordering.

Other

Specify what Horizon icemaker will be mounted on.

+ See drawings on page 3 for min. bin width and required clearances.

+

+

+

Page 3

Ice Manager

™

diverter valve system

IMDV-2

Series

4. Evaluate site for location of equipment

Lane 1 and Lane 2 dispensers or bins

• Refer to dispenser or bin specications for required

clearances

• See drawings below for required clearances for Ice Manager

diverter valve system

Follett Horizon icemaker

• 10' (3 m) max. distance from Horizon icemaker to diverter

valve

• See spec sheets 3810, 3815 and 3311 for utility requirements

and dimensions

Diverter valve

• 8' (2.4 m) max. distance from diverter valve module to electric

outlet

75' (23 m) max. distance from diverter valve to Lane 1 and

•

Lane 2 dispensers or bins

• Drain required, 15' (4.6 m) drain tube provided

Control panel

5. Determine length of ice transport tubes

Lane 1: (approx. length): ____________________

Lane 2: (approx. length): ____________________

Use the following guidelines to determine length of the ice

transport tube run from the diverter valve to each bin or dispenser.

• Length of ice transport tube from diverter valve module

to each dispenser or bin can be specied in 5' (1.5 m)

increments from

• Max. vertical rise of ice transport tube – 10' (3 m)

• Horizontal run should be pitched so that melt water drains

back to diverter valve module. Run must have 1⁄4" per

foot pitch.

• No dips or traps in the tube run

*Lengths to include any bends and turns needed to connect components.

6. Site plan drawings

Installation may be performed by an authorized installer

contracted by Follett. Contact factory for details.

• 20' (1.8 m) max. distance from control panel to diverter valve

Required clearances for Ice Manager diverter valve system

10' - 75' (3 m - 23 m)*

Diverter valve

12" (305 mm)

clearance

6" (153 mm)

clearance

6" (153 mm)

clearance

Front View

mounting

bracket

Sensor distribution unit

(bins and ice and beverage dispensers only)

Front View Side View

12" (305 mm)

clearance

bin / dispenser top bin / dispenser top

Insulated transport tube

(Satellite-fill applications)

Front View Side View

6" (153 mm)

clearance

Side View

LANE 2

mounting

bracket

Top mount on a bin

(minimum bin width)

Front View

Y

X

LANE 1

4.125"

sensor

distribution

unit

min.

2" (51 mm)

clearance

Horizon X Y

icemaker icemaker width min. bin width

series inches (mm) inches (mm)

HCC1000 26.75 (680) 34.75 (883)

HCC1400 29.75 (756) 37.75 (959)

HCD1000/1400 19.50 (496) 26.50 (673)

Note: For 30" (762 mm) Follett bin, sensor distribution unit

may be placed behind icemaker.

(105 mm)

Horizon icemaker

min.

1" (26 mm)

clearance

min.

.5" (13 mm)

clearance

bin top

3" (77 mm) dia. hole required

to run tubing through walls

Page 4

Ice Manager

™

diverter valve system

IMDV-2

Series

Dimensions

Diverter valve with mounting bracket Control panel

Front View Side View Front View Side View

17.468"

(444 mm)

10.375"

(264 mm)

16"

(407 mm)

3/8" NPT

barbed drain fitting

Sensor distribution unit

(bins and ice and beverage dispensers only)

Front View Side View

3.5"

(89 mm)

4.125"

(105 mm)

7.75"

(197 mm)

13.625"

(346 mm)

LANE 2

LANE 1

12"

(305 mm)

Patents pending

3.75"

(96 mm)

12.5"

(318 mm)

Warranty

3 years parts and labor on all components.

Utilities

Electrical - 115 V, 60 Hz, 1 ph, 1.5 amps.

8' (2.4 m) cord and NEMA 5-15 plug provided. If local code

requires hard-wiring, separate disconnects also required.

Approximate shipping weight

Ice Manager with 50' (15.2 m) of ice transport tube (typical).

120 lb (54.4 kg)

Temperature requirements

Ice Manager components, including ice transport tube, must be

operated in ambient temperatures between 40 F and 120 F

(5 C and 49 C). Relative humidity not to exceed 55%.

Ice Manager diverter valve system components

Diverter valve – 8' (2.4 m) cord and plug, 15' (4.6 m) drain tubing

Control panel – 20' (6 m) cable to diverter valve

Lane 1 – insulated ice transport tube and sensor cable

‡

, and connection kit for ice storage unit used

valve

Lane 2 – insulated ice transport tube and sensor cable to diverter

‡

, and connection kit for ice storage unit used

valve

‡ Lengths to be specied by customer.

† Follett Vision ships with connection kit factory-installed (item# VUIMDVKIT).

†

†

to diverter

Specication

Ice Manager diverter valve system to be model IMDV-2.

System to direct ice delivery to two bins or dispensers

automatically, utilizing sonic sensors to control level of ice.

Icemaker to be Follett Horizon model _____________ .

Lane 1 to ll ____________________ ,

Lane 2 to ll ____________________ .

(ice and beverage dispenser, bin, drop-in, or Vision)

Horizon icemaker to be mounted on ___________________ .

(bin, wall mount bracket or machine stand)

System to include _____ feet of insulated ice transport tube

for Lane 1, and _____ feet of insulated ice transport tube for

Lane 2.* (75' (23 m) max. length for each lane)

Horizon icemaker and Ice Manager to be NSF, UL, and

cUL listed. System to be installed by Follett.

* Lengths to be conrmed on-site prior to shipment. Lengths to include any

bends and turns needed to connect components.

Horizon, Ice•DevIce, Ice Manager, Satellite-ll and Vision are trademarks of Follett Corporation.

Chewblet and Follett are registered trademarks of Follett Corporation, registered in the US.

Follett reserves the right to change specications at any time without obligation. Certications may vary depending on country of origin.

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

© Follett Corporation

Form #3265

02/11

Loading...

Loading...