Page 1

Features

Horizon Elite

1010 series - up to 978 lb (444 kg) in 24 hours

1410 series - up to 1372 lb (623 kg) in 24 hours

- automatically transport ice through a tube with RIDE

technology from up to 75' (22.8 m) away

- chewable, compressed nugget ice is preferred

overcubes

- ice dispenses reliably from ice and beveragedispensers

- available with approximately 1.00" (2.54 cm) long

standard Chewblet ice or optional 3/8" (0.95 cm) long

Micro Chewblet

- quiet production without noisy harvest cycles

Revolutionary, scale inhibiting design

- produces ice that has 15% the TDS of the incoming

water for optimum dispensing and long life in drinks

- quarantines and regularly expels scale producing

dissolved solids to dramatically reduce scalebuildup

- increases time between descaling and reduces or

eliminates the need for expensive scale treatment

- saves 35% water compared to comparable cubers

- meets 2018 Department of Energy regulations

- three phase models ENERGY STAR

Durable, attractive ice machine

- regular bearing inspection or replacement is

notrequired

- upgraded, easy-to-read LED operating status and

diagnosticdisplay

Designed with sanitation in mind

- Agion

key ice and water contact components

- floatless, sealed design inhibits formation of biofilms

- semi-automatic cleaning and sanitizing system

Warranty

- 3 years parts and labor, 5 years compressor parts

Certifications

1

™

ice

®

certified

®

silver-based antimicrobial product protection of

Horizon Elite

remote 1010, 1410 series Chewblet® ice machine

Short form specification:

Ice machine to be a Follett® Horizon Elite ice machine model

______________ [Insert size/series,condenser type and installation/

mounting, from model number guide] capable of producing compressed

nugget ice using an ecient, sanitary horizontal evaporator/auger system

and delivering ice by a flexible wire reinforced transport tube to

ice storage bin, ice and water dispenser, ice and beverage dispenser,

drop-in dispenser or Ice Manager™ diverter valve system, slide-out

evaporator with utility docking station, front-mounted unit status display,

®

evaporator water inlet at harvest end with automatic flush while producing

ice, and semi-automatic cleaning and sanitizing system, plus all the features

listed below and mounting/performance-enhancing accessories checked.

Model configurations

For use with ¹ Install/mount Condenser V/Hz/Ph

top mount

ice storage bin

RIDE

Follett Vision™

undercounter

ice & beverage

dispenser

Cornelius PR150

undercounter

ice & beverage

dispenser

countertop ice

& beverage

dispenser

(by others)

drop-in

dispenser

(by others)

Ice Manager

diverter

valve system

1

Ordered separately

2

Not compatible with Micro Chewblet ice

3

Requires top kit (see page 5 for part number)

4

For three phase remote condensing unit, replace third character (D) with F

e.g. HCF1010RBT

5

For Micro Chewblet ice, replace second character (C) with an M

e.g. HMD1010RBT

RIDE

RIDE

2

top mount

RIDE

RIDE

RIDE

with 115/60/1 4HCD1010RBT HCD1410RBT

without 115/60/1 HCD1010NBT HCD1410NBT

with 115/60/1 4HCD1010RBS HCD1410RBS

without 115/60/1 HCD1010NBS HCD1410NBS

with 115/60/1 4HCD1010RVS HCD1410RVS

without 115/60/1 HCD1010NVS HCD1410NVS

with 115/60/1 4HCD1010RPS HCD1410RPS

without 115/60/1 HCD1010NPS HCD1410NPS

with 115/60/1 4HCD1010RHT HCD1410RHT

3

without 115/60/1 HCD1010NHT HCD1410NHT

with 115/60/1 4HCD1010RHS HCD1410RHS

without 115/60/1 HCD1010NHS HCD1410NHS

with 115/60/1 4HCD1010RJS HCD1410RJS

without 115/60/1 HCD1010NJS HCD1410NJS

with 115/60/1 4HCD1010RMS HCD1410RMS

without 115/60/1 HCD1010NMS HCD1410NMS

Item number

1010 series

5

Item number

1410 series

™

5

1

Independent third party studies. Contact Follett for details.

2

Disclaimer: Antimicrobial protection is limited to the treated components and does not treat water or ice.

Job

Item

801 Church Lane | Easton, PA 18040, USA

1.800.523.9361 | 1.610.252.7301 | follettice.com

Page 2

Accessories

C7

C6

Top kit for ice and beverage dispensers (page 5)

Water filters (refer to form# 9905)

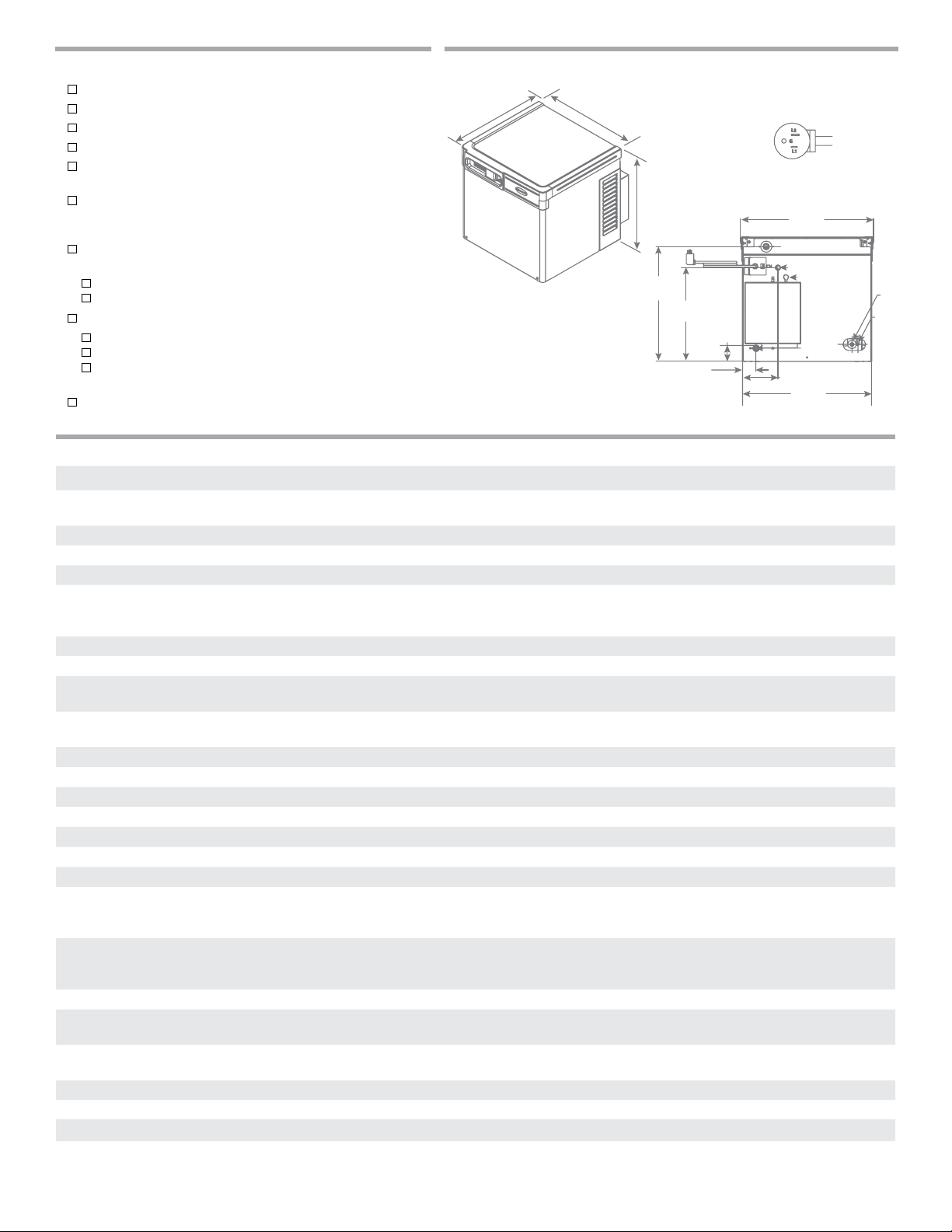

Dimensional drawing

D1

W1

C1

Wall mount bracket (item# 00997098 )

Ice machine stand, height-adjustable (item# 00997080)

Timer to control one or two ice machines

(item# 00967625)

Longer ice transport tube, specify length: ___ ft/m in

5'/1.5 m increments (10'/3 m provided as standard for

RIDE models) (item#00174896)

Insulated refrigeration lines (not pre-charged) for

1010R and1410R

35' (11 m) (item#00193227)

50' (50 m) (Item# 01262328)

SafeCLEAN Plus™ ice machine cleaner

1 x 8 oz (237 ml) bottle(item#01147826)

6 x 8 oz (237 ml) bottles(item#01149954)

Carton of 24 x 8 oz (237 ml) bottles

(item#01149962)

SaniSponge™, 24 sanitary sponges (item# 01075431)

H1

19.59"

(49.76 cm)

(40.64 cm)

C1

16.00"

2.28"

(5.79 cm)

2.73"

(6.93 cm)

Back View

22.69"

(57.6 cm)

C2

C3

C5

C4

6.04"

(15.34 cm)

22.00"

(55.9 cm)

Specification, evaporator unit

Horizon Elite 1010 series Horizon Elite 1410 series

W1 Width 22.70" (57.7 cm)

Fits on 22.00" wide dispensers

D1 Depth 22.50" (57.1 cm) 24.50" (62.2 cm)

H1 Height 21.25" (53.9 cm) 21.25" (53.9 cm)

Clearance top, left and right–1.00"(2.54 cm) top, left and right–1.00"(2.54 cm)

C1 Electrical

115 V/60/1

5 amps, requires dedicated

15 amp circuit,

6' (1.8 m) cord, NEMA 5-15 plug

Operating power 0.6 kW 0.6 kW

C2 Ice transport tube see page 7 for details see page 7 for details

C3 Water inlet 3/8" OD push-in water inlet –

internalconnection

C4 Drain

3/4" MPT, 1" drain required

see page 7

for details

C5 Ice bin signal cord for Vision applications only for Vision applications only

C6 Liquid line 3/8" 3/8"

C7 Suction line 5/8" 5/8"

Air temperature 50 -100 F (10 - 38 C) 50 -100 F (10 - 38 C)

Water temperature 45 - 90 F (7 - 32 C) 45 - 90 F (7 - 32 C)

Potable water pressure 10 - 70 psi (69 - 483 kPa) 10 - 70 psi (69 - 483 kPa)

Ice production see ice production chart on page 8 see ice production chart on page 8

Energy consumption

90 F (32 C) air,

70 F (21C) water

single phase – 4.68 kWh

three phase – 3.57 kWh

per 100lb(45.4 kg) ice

Water consumption 12.0 gal (47 L) of potable water per 100lb

(45.4kg) ofice (per AHRI test standards).

12.4 gal (46.9 L) at lowTDS flush setting

Refrigerant R404a R404a

BTU/hr (Kcal/hr) at 0 F (-18 C) evaporator,

7,700 (1,940) 10,000 (2,520)

90F (32C) ambient air

Rack systems EPR valve - set to

0 F (-18 C) 0 F (-18 C)

EPR valve to be supplied by installer

Approximate ship weight 195 lb (88 kg) 205 lb (93 kg)

Approximate net weight 185 lb (84 kg) 195 lb (88 kg)

NOTE: For indoor use only. Outdoor installation of low side is not recommended and will void warranty.

22.70" (57.7 cm)

Fits on 22.00" wide dispensers

5 amps, requires dedicated

15 amp circuit,

6' (1.8 m) cord, NEMA 5-15 plug

3/8" OD push-in water inlet –

internalconnection

3/4" MPT, 1" drain required

see page 7

for details

single phase – 4.63 kWh

three phase – 3.34 kWh

per 100lb(45.4 kg) ice

12.5 gal (47 L) of potable water per 100lb

(45.4kg) of ice (per AHRI test standards).

12.3 gal (46.5 L) at lowTDS flush setting

2

Form# 7035

Remote 1010, 1410 series ice machine

Page 3

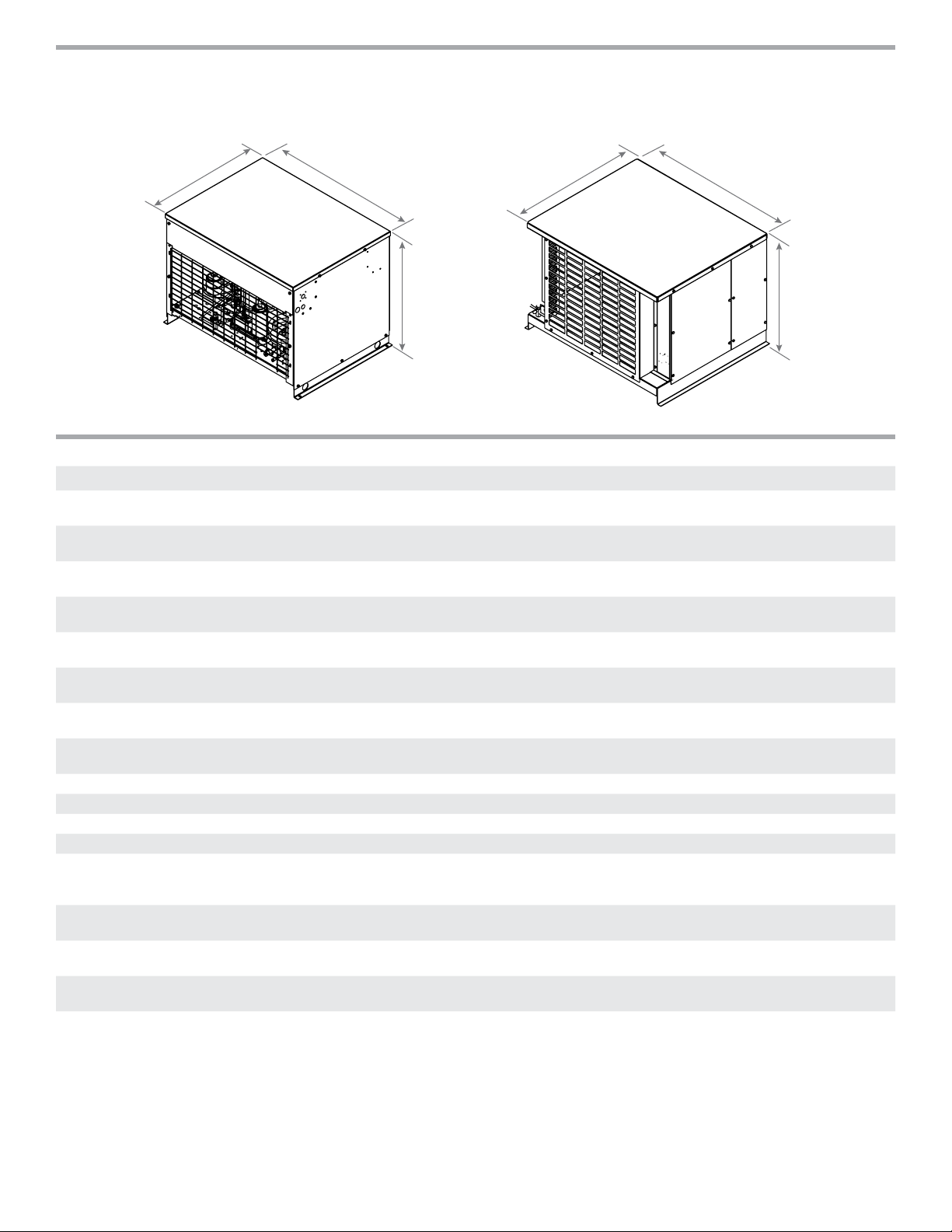

1010/1410 single phase

1410 three phase

Dimensional drawing

1010 three phase

D1

W1

H1

D1

W1

H1

Specification, condenser unit

Horizon Elite 1010 series Horizon Elite 1410 series

W1 Width 36.25" (91.4 cm) – all models 36.25" (90.1 cm) – single phase

37.75" (95.9 cm) – three phase

D1 Depth 25.50" (64.8 cm) – all models 25.50" (64.8 cm) – single phase

28.25" (71.6 cm) – three phase

H1 Height 26.10" (66.3 cm) – all models 26.10" (66.3 cm) – single phase

19.75" (50.2 cm) – three phase

Electrical single phase – 208-230/60/1

three phase – 208-230/60/3

Operating power single phase – 2.4 kW

three phase – 2.2 kW

Minimum circuit ampacity single phase – 10.7 A

three phase – 9.9 A

Maximum overcurrent protection single phase – 15 A

three phase – 15 A

Outdoor condensing unit operating limits

(air temperature)

Maximum refrigerant line run length 100' (30.5 m) 100' (30.5 m)

Maximum line rise above evaporator 35' (10.7 m) 35' (10.7 m)

Evaporator mounting above condenser 15' (4.6 m) 15' (4.6 m)

Maximum refrigeration line drop without oil trap 15' (4.6 m) 15' (4.6 m)

Refrigerant charge 12.5 lb required at installation 12.5 lb – single phase

Approximate ship weight 260 lb (118 kg) 270 lb (122 kg) – single phase

Approximate net weight 250 lb (114 kg) 260 lb (118 kg) – single phase

NOTE:

1. The entire liquid line should be insulated separately from the suction line.

min -20 F (-29 C)

max 120 F (49 C)

single phase – 208-230/60/1

three phase – 208-230/60/3

single phase – 4.2 kW

three phase – 3.0 kW

single phase – 19.3 A

three phase – 15 A

single phase – 30 A

three phase – 15 A

min -20 F (-29 C)

max 120 F (49 C)

8.5 lb – three phase

required at installation

230 lb (104 kg) – three phase

210 lb (95 kg) – three phase

Remote 1010, 1410 series ice machine

Form# 7035

3

Page 4

1 – Locating the ice machine

Horizon Elite remote Chewblet ice machines allow top-mounting or mounting in a base cabinet, on a wall or on a floor stand up to

75'(22.8 m) from the dispenser or ice bin with RIDE technology. In-cabinet mounting (RIDE applications) require special attention to

service access, unit ventilation and ice tube runs (seepages 5-7).

Top mounting – ice and beverage

dispensers (by others)

RIDE model – Follett low-profile

Vision and Cornelius PR150 ice and

beverage dispensers

Top mount on Follett ice storage bins

Important specifier notes Important specifier notes Important specifier notes

1. Dispenser must be compatible with nugget ice.

See page 5 for compatible ice and beverage

dispenser models and top kitnumbers.

2. Verify ceiling or soffit height to ensure sufficient

top clearance.

RIDE model – ice and beverage

dispensers (by others)

1. See page 5 for critical clearance requirements.

2. Ice transport tube ships with Vision ice and

beverage dispenser (Vision applications only).

3. Ice transport tube ships with Horizon Elite

icemachine for Cornelius dispensers.

RIDE model – drop-in beverage

dispensers (by others)

1. See form# B300 for bin sizing.

2. Verify ceiling or soffit height to ensure

topclearance.

3. Locate floor sink or grate and drains in front of

storage bin.

4. Do not position bin drain lines to block

Ice•DevIce

™

bin cart.

RIDE model – Follett ice storage bins

Important specifier notes Important specifier notes Important specifier notes

1. Dispenser must be compatible with nugget

ice. Compatible dispensers include Cornelius

DB/ED/DF150/175, Lancer 4500-22N, FS-16N

and FS-44N, Servend MD150/175/200/250

SV150/175/200/250 and Follett Symphony Plus

110CM, as well as dispensers listed on page 5.

2. Top kit MSF30SC required with Coca-Cola Freestyle

7000. Top adapter 46412 and ice kit 46430 must

also be ordered from Coca-Cola. Top kit HSF26SC

required with Coca-Cola Freestyle 9100. Consult

with Coca-Cola and Follett to qualify application

prior to ordering.

3. RIDE application is approved only for PepsiSpire

3.0, 5.0 and 4.1 designed for top mount ice

machines and requires MSP24SC for 3.0 and

MSP30SC for 5.0 and 4.1, ordered separately. For

manual fill versions of PepsiSpire 3.0, 5.0 and

4.1, contact factory.

4. See page 5-6 for critical clearance requirements.

4

Form# 7035

1. Compatible with the following dispensers:

Cornelius 1522, 1722, 2323 and Lancer 2200,

2300, 23300.

2. Requires 12.00" (30.5 cm) of access space for

™

installation on transport tube side.

3. See page 5-6 for critical clearancerequirements.

1. See form# B300 for bin sizing.

2. Locate floor sink or grate and drains in front of

storage bin.

3. Do not position bin drain lines to block Ice•DevIce

bin cart.

Remote 1010, 1410 series ice machine

Page 5

1 – Locating the ice machine (continued)

Top mounting – compatible ice and beverage dispensers

Manufacturer Model Number

Freestyle 7000 30.10 (76.5) 33.11 (79.0) 47.00 (119.4) H22F30-F

Coca-Cola

dispensers

Freestyle 9000 25.50 (64.8) 35.50 (90.2) 73.75 (187.3) H22F24-F

Freestyle 9100 25.50 (64.8) 39.25 (99.7) 77.25 (196.2) H22F26-F

DB/ED/DF 200 series 30.00 (76.2) 30.00 (76.2) 34.38 (87.3) H22C30-F

DB/ED/DF 250 series 30.00 (76.2) 30.00 (76.2) 38.38 (97.5) H22C30-F

Cornelius

dispensers

DB/ED/DF 300 series 44.00 (111.8) 30.00 (76.2) 34.00 (86.4) H22C44-(F or B)

FlavorFusion/Overload 30.00 (76.2) 30.70 (78.0) 39.38 (100.0) H22C30-F-FF

IDC215 30.00 (76.2) 30.70 (78.0) 39.38 (100.0) H22C30-F-IDC

IDC255 and Pro Fast Gate 30.00 (76.2) 30.70 (78.0) 36.38 (92.4) H22C30-F-IDC

4500-30N 30.00 (76.2) 30.50 (77.5) 36.50 (92.7) H22L30-(F or B)

FS-22N 22.00 (55.9) 30.50 (77.5) 42.13 (107.0) H22L22-F

FS-30N 30.00 (76.2) 30.50 (77.5) 42.13 (107.0) H22L30-(F or B)

Lancer

dispensers

Bevariety 30.00 (76.2) 31.00 (78.7) 37.75 (95.9) H22L30-F-STP

Sensation 30" 30.00 (76.2) 31.00 (78.7) 38.25 (97.2) H22L30-F-STP

Sensation 44" 44.00 (111.8) 31.00 (78.7) 39.38 (100.0) H22L44-F-STP

Touchpoint 32.50 (82.55) 33.70 (85.6) 40.00 (101.6) H22L30-F-STP

Pepsi

dispensers

Servend

dispensers

Spire 3.0 27.00 (68.6) 35.00 (88.9) 38.12 (96.8) H22P24-F

Spire 5.0 / 4.1 30.50 (77.5) 36.00 (91.4) 42.75 (108.6) H22P30-F

MDH-302 42.75 (108.6) 31.00 (78.7) 32.38 (82.2) H22S44-(F or B)

MDH-402 60.00 (152.4) 30.50 (77.5) 32.38 (82.2) H22S60-(F or B)

Width

in (cm)

1

Depth

in (cm)

2

3

Height

in (cm) Top kit

4, 5

4, 6

4

7

8

7

7

7

7,9

1

All approved dispensers can be filled with a RIDE model Horizon Elite ice machine without a top kit except for Coca-Cola Freestyle 7000 and Pepsi Spire 3.0, 5.0 and 4.1, see page 4 for details.

2

Requires minimum 0.50" (1.27 cm) clearance between back of dispenser and wall.

3

Net height after installation of top kit (excluding height of ice machine).

4

Consult with Coca-Cola and Follett to qualify application prior to ordering.

5

Top adapter 46412 and ice kit 46430 must also be ordered from Coca-Cola.

6

Adapter must also be ordered from Coca-Cola. KO IC Code: 46010 (Silver), 46011 (Red) or 46012 (Black).

7

Specify “F” for front facing, or ”B“ for backward facing units.

8

Contact factory regarding IDC Pro.

9

60- inch models: Please specify number of Horizon Elite ice machines and location. D = 2; R = 1 on right side; L = 1 on left side.

Remote 1010, 1410 series ice machine

Form# 7035

5

Page 6

2 – Undercounter/in-cabinet mounting

Cabinet details

Important specifier notes

1. Cabinet door opening must meet

minimum size requirements shown

and be free of obstructions to allow

ice machine to slide out (no lip or

utilities to block removal).

2. Cabinet base must be capable

of supporting ice machine and

allow ice machine to rest flat on

cabinetbottom.

3. No counter supports, electric or

plumbing can run in front of the

icemachine.

Cabinet door opening

24.00"W x 23.5"H

(60.9 cm x 59.7 cm) minimum

Ice transport tube

slides

out

minimum 1/4" per foot

(2 cm per meter)

pitch toward ice machine

secure to prevent dips

and traps from forming

12.00" (30.5 cm) minimum

between ice machine

and dispenser

Cabinet base

must be flat and free of obstructions

(no lip or utilities to block removal)

3 – Horizon Elite ice machine mounting accessories

Optional wall mount bracket Optional machine stand Important specifier notes

1. For secure wall mounting, specify optional

wall mount bracket.

2. Wall and fasteners must support the weight

of the ice machine, bracket, supply water and

ice. Use of a backing board may be required

with hollow wall construction.

3. Machine stand mounting adds 6.88"

(17.5cm) to height of ice machine.

4. No dips in tube routing allowed.

5. Ice transport tube needs minimum 1/4"

per foot (2 cm per meter) pitch toward ice

machine and should be secured to prevent

dips and traps from forming.

23.00"

(58.4 cm)

25.50"

(64.8 cm)

22.00"

(55.9 cm)

A

B

A - 15.875" (40.3 cm)

B - 19.375" (49.2 cm)

6.88"

(17.5 cm)

C

D

C - 13.00" (33.0 cm)

D - 21.00" (53.3 cm)

6

Form# 7035

Remote 1010, 1410 series ice machine

Page 7

4 – Horizon Elite drain - specifier guidelines

Flush drain plumbing – For regular machine drainage

➊

Minimum 8"

radius

2 ft x 1" OD

silicone tubing

3/4" barb x 3/4" FPT

➋

3/4" MPT x 1" slip

1" Stand pipe/drain

➌

Chassis drain plumbing – To assist with condensate in high humidity areas

Important specifier notes: Where code allows,

follow recommendation below.

1. Connect the silicone tubing to the ice machine 3/4"

drainbarb

➊.

2. Assemble the 3/4" barb x 3/4" FPT to the 3/4" MPT x 1"

slip. Connect the other end of the silicone tubing to the

3/4" barb

3. Connect the 1" slip fitting to the 1" stand pipe/drain

➋.

➌.

Note: Minimum 8" radius on silicone drain line. Drain line

from the ice machine must have at least 1/4" per foot

pitch (6.4 mm/0.3 m).

Note: Stand pipe/drain provided by others. All other

components provided with ice machine.

Important specifier notes: Where code allows,

follow recommendation below.

1. Plug must be removed from John Guest fitting.

2. Route 3/8" drain tubing through knockout in back of

docking station and insert fully into John Guest fitting

connection at the rear of the machine chassis. Route

other end of 3/8" drain tubing to drain.

3. Drain must slope 1/4" inch per foot ( 6 mm per 30.4 cm).

5 – Horizon Elite ice tube runs - specifier guidelines

Long tube runs for RIDE remote ice delivery equipment

beverage

dispenser

support

straps

minimum of

6.00" (15.24 cm)

turn/corner

radius

ice transport tube –

1 3/16" OD,

2 1/8" OD with insulation

maximum

2' (60.9 cm)

transport tube slope

(toward ice machine)

1/4"

1'

(2 cm per meter)

wall-mounted

ice machine

Important specifier notes

1. 75' (22.8 m) maximum ice transport tuberun.

2. Tubing routing bends must have a

6.00"(15.24 cm) radius or larger.

3. Dips and traps are not allowed. If not

supported from underneath, secure insulated

ice transport tube at least every2' (60.9 cm)

to prevent drips andtraps.

4. Relative humidity levels above 80% in areas

where the ice machine or ice transport tube is

located may produce excessive condensation

that will cause water damage.

5.

Contact factory for recommendations

on

running tubing through a decorative soffit

orchase.

Remote 1010, 1410 series ice machine

Form# 7035

7

Page 8

Remote condensing unit

Condensing unit installation specifications

Important specifier notes

1. Provide front, back, top and side clearances

asshown.

2. The maximum refrigerant line run length is

100' (30.5 m). Installations require 12.5 lb for

1010/1410 single phase and 1010 three phase

and 8.5 lb for 1410 three phase.

3. The maximum line rise above the evaporator is

35' (10.7 m). Condensing unit above evaporator

unit – 35'(10.7m) (installations with rise over

20' (6.1 m) require additional suction line s-trap

at midpoint rise).

4. The evaporator can only be mounted a maximum

of 15' (4.6 m) above the condensing unit.

Note: The service loop is not included when

calculating length, rise or drop in the tubingrun.

exhaust

24.00"

(61.0 cm)

36.00" (91.4 cm)

height clearance

air in

=

48.00"

(121.9 cm)

24.00"

(61.0 cm)

48.00"

(121.9 cm)

Note: To connect evaporator/ice machine to rack systems, see page 3.

Ice production – Horizon Elite 1010 series,

air-cooled

Inlet water

temperature

F (C)

50 F (10 C)

60 F (16 C)

70 F (21 C)

80 F (27 C)

90 F (32 C)

60 (16) 70 (21) 80 (27) 90 (32) 100 (38)

1051 (477) 978 (444) 906 (411) 834 (379) 763 (346)

1037 (471) 925 (420) 855 (388) 796 (361) 737 (335)

937 (425) 871 (395) 805 (366) 758 (344) 711 (323)

904 (410) 839 (381) 774 (351) 727 (330) 680 (309)

872 (396) 807 (366) 743 (337) 696 (316) 648 (294)

Ambient air temperature F (C)

lb (kg) production in 24 hr

Ice production – Horizon Elite 1410 series,

air-cooled

Inlet water

temperature

F (C)

50 F (10 C)

60 F (16 C)

70 F (21 C)

80 F (27 C)

90 F (32 C)

60 (16) 70 (21) 80 (27) 90 (32) 100 (38)

1474 (669) 1372 (623) 1269 (576) 1212 (550) 1154 (524)

1385 (628) 1292 (586) 1198 (544) 1148 (521) 1097 (498)

1296 (588) 1212 (550) 1127 (511) 1083 (492) 1039 (472)

1239 (562) 1155 (524) 1072 (487) 1030 (468) 988 (449)

1181 (536) 1099 (499) 1017 (462) 976 (443) 936 (425)

Ambient air temperature F (C)

lb (kg) production in 24 hr

ENERGY STAR and the ENERGY STAR mark are registered trademarks owned by the U.S. Environmental Protection Agency.

Agion is a registered trademark of Sciessent LLC.

HORIZON ELITE, ICE•DEVICE, ICE MANAGER, MICRO CHEWBLET, SAFECLEAN PLUS, SANI SPONGE, SYMPHONY PLUS and VISION are trademarks of FollettLLC.

CHEWBLET, FOLLETT and RIDE are registered trademarks of Follett LLC, registered in the US.

Follett reserves the right to change specifications at any time without obligation. Certifications may vary depending on country of origin.

Remote 1010, 1410 series ice machine

801 Church Lane | Easton, PA 18040, USA

7035-202002 | © Follett LLC

1.800.523.9361 | 1.610.252.7301 | follettice.com

Loading...

Loading...