Page 1

ASSEMBLY

INSTRUCTIONS

FOODSERVICE, LLC

Two people required for assembly. Read All Instructions & Tips before assembly.

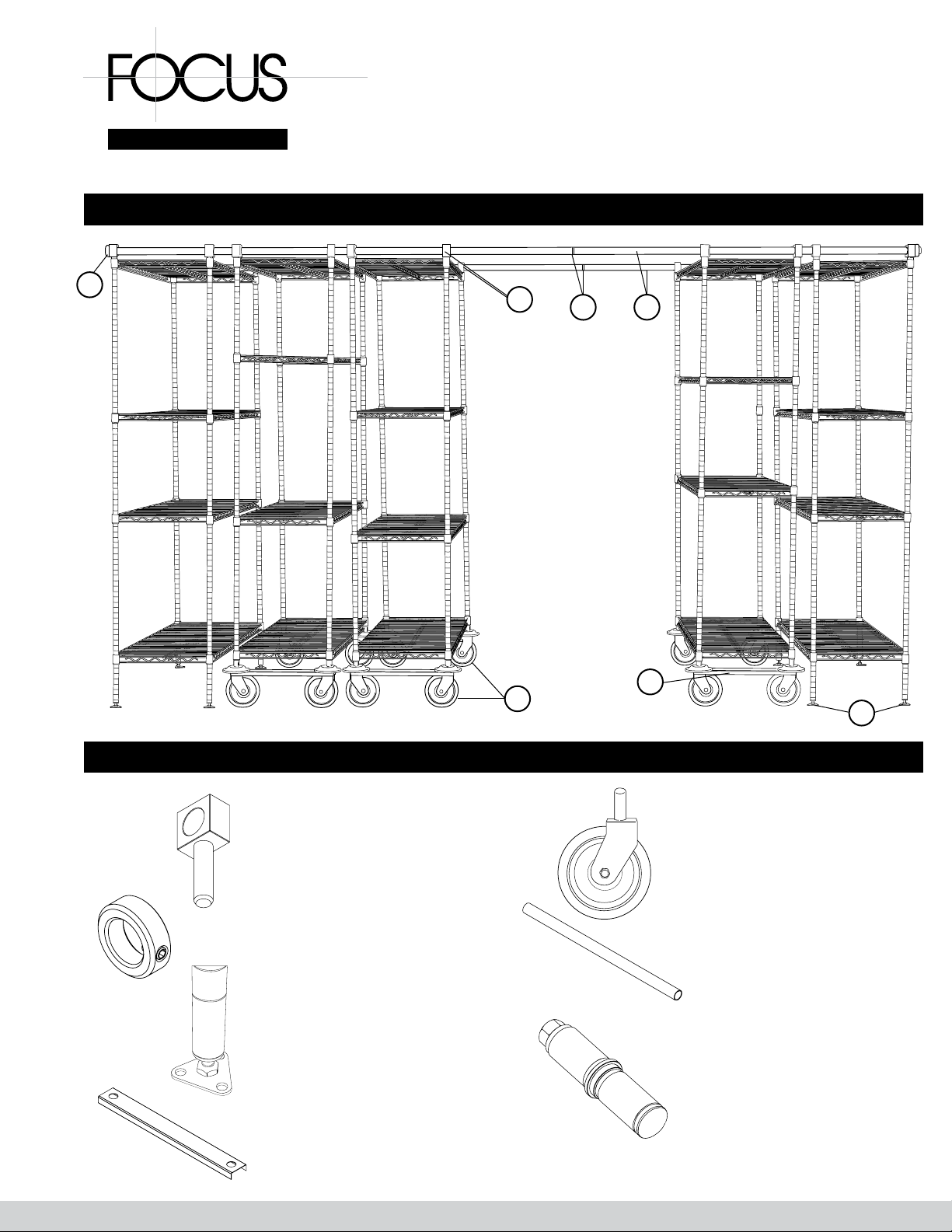

HDS-Plus™ High Density Storage System

2

1

5

7

6

4

3

Core HDS-Plus™ System Components (Full Component Checklist located at end of document)

1. FTSGB (Guide Blocks) Used at

tops of posts to guide mobile units

on track.

2. FTSLC (Locking Collars)

Used on stationary units to

lock in track position.

3. FTSFZ (Triangular Security Feet)

Used to anchor stationary units to

the floor.

4. FTSU18, FTSU21,

5. FTSC6 (6" Casters w/ Bumpers) -

Smooth rolling casters for

mobile units. Bumpers prevent

collision of units..

6. FTST2, FTST3, FTST5

(Stainless Steel Track Tubing)

Used at tops of units to allow

movement of mobile units on track.

7. FTSJ (Track Joiner Connectors)

that allow two sections of

stainless steel track tubing to

be joined together.

FTSU24 (Caster Channels)

Aligns casters on mobile units.

Page 2

ASSEMBLY INSTRUCTIONS

INSTALLATION TIPS

1 Two or more people are required for installation.

5 Locking collars must be used for each stationary unit.

2 Stationar y end unit should be used for heavier item storage.

3 If all shelving units are not the same width, the wider units

should always be used as the stationary units.

4 Guide blocks, when inserted into the tops of posts, must be

free to move up or down to adjust to uneven floors

(see illustration) - on page 3.

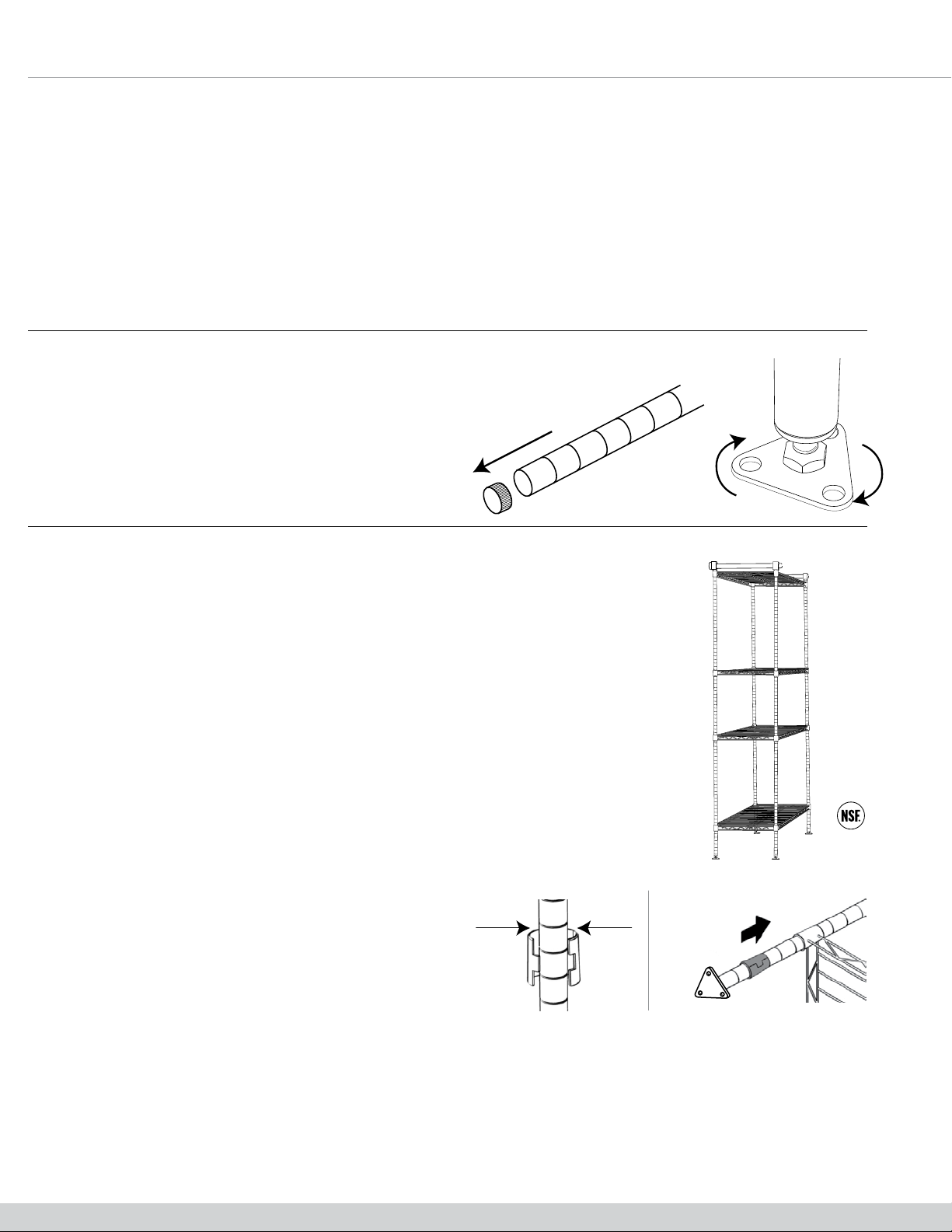

PART 1: TRIANGLE SECURITY FOOT ASSEMBLY Use 80" posts for stationary units.

Step 1 Remove black plastic post caps from top of all posts

(See illustration).

Step 2 First an unscrew the leveling bolt and then screw in

a Triangular Security Foot (FTSFZ) into a 80" post

(FG080CH or FG080GN). Turn clockwise until foot is

secure in post.

PART 2: ASSEMBLE SHELVING UNITS

Note: Please dispose of loose, round white plastic pieces in shelving boxes. These are used to separate

the shelves for shipping purposes only.

6 HDS-Plus system should only be used on hard surface.

7 For added stability, it is recommended that the bottom shelf is

installed no more than 6" from the floor and the top shelf no

more than 6"(2 – 3 lines) from the top – for all shelving units in

the system.

Helpful Hint: When placing the plastic tapered sleeves onto the posts (Step 1), slide the plastic

tapered sleeves up or down on the post until you feel it “snap” into the lines or grooves of the post. It is

normal to have a slight gap in-between the two pieces of the plastic tapered sleeves when it is placed

on the post.

Step 1 Choose the desired height of the bottom shelf for added stability, it is recommended

that the bottom shelf is installed no more than 6" from the floor and the top shelf no

more than 6" from the top.

Snap two (2) plastic tapered sleeves, with the arrows facing up, at the desired height on

each post. (See Diagram #1) Shelves can be adjusted every 1". (Note: double grooves in

the posts are placed every 8th groove for simple shelf height reference. Posts are numbered in even number increments).

Step 2 Place shelf on its side, making sure the wider

portion of the four (4) round shelf collars are

facing the bottom of the unit. Slide the top of the

posts through the round shelf collars on each

corner of the shelves. Push the shelves firmly onto

the plastic tapered sleeves. (See Diagram #2) After

installing the bottom shelf, set the unit upright.

Step 3 For remaining shelves, snap the plastic tapered sleeves into place on posts at the next desired shelf height. Slide the shelf down

from the top of the posts onto the plastic tapered sleeves and repeat this step for the remaining shelves.

NOTE: HEAVY OBJECTS MUST BE PLACED--NOT DROPPED--ONTO THE SHELVES!!

DIAGRAM 1

Top

DIAGRAM 2

Top

Note: When all shelf heights are established, a rubber mallet may be used to tap each corner of the shelves so they firmly install onto the

plastic tapered sleeves.

Note: The triangle leveling feet may need to be adjusted in order to make the unit level.

Page 3

PART 3: CASTER ASSEMBLY OR MOBILE POST ASSEMBLY. Use 74" mobile posts.

Step 1 Lay completed shelving unit(s) with 74" posts on their side.

Step 2 With the opening of the bumper facing towards the bottom, slide bumper

over bottom of posts.

Step 3 Install 6" Casters (FTSC6 - CASTER MUST POINT INWARD AS SHOWN) through

openings in caster channels (FTSU18, FTSU21 or FTSU24).

Step 4 Install caster/caster channel assembly into 74" posts (FGN074C or FGN074G) until

caster fit is tight. If needed, use a rubber mallet and tap bottom of caster to drive

casters into posts. Repeat process for all mobile shelving units.

PART 4: OVERHEAD TRACK ASSEMBLY

Step 1 Connect track tube lengths using track joiners. To connect tubes with track joiners,

insert cap end of track joiner into tube section until it stops. Use wrench to tighten nut

on exposed end of track joiner until track joiner is snug in tubing. Take another section

of tube and twist onto exposed section of track joiner until two sections of tube meet.

Repeat process until both sections of track are assembled.

SHELVING

Step 2 Place locking collar on one end of fully assembled track length and tighten with Allen

wrench. Slide on ½ of the guide blocks, if your system requires a stationary

middle unit, place 1 locking collar on the track, then slide on 2 guide blocks then slide

on another locking collar. Do not tighten inner locking collars at this point. Then place

another locking collar on open end of tube and tighten with Allen wrench. Repeat

process with second section of track.

PART 5: INSTALL TRACK ASSEMBLY ONTO SHELVING UNITS

Step 1 Line up Shelving Units in a straight line in the area where the unit will be installed. Allow a minimum of 30" of open aisle

space for each system. Bumpers add a minimum of 3" to the width of the mobile units. Place stationary units on the outside

and middle (as needed**) and mobile units on the inside. To ensure smooth movement of mobile sections take great care

that all shelving units are aligned in a straight line.

Note: Track lengths over 20 ft in length require a stationary unit in the middle of the system.

Step 2 Using two or more people, raise one section of track assembly over tops of posts and starting on one end of shelving

run. Insert guide blocks into tops of posts. Continue to opposite end. Repeat process with second section of track. Recheck

shelving sections to ensure they are in straight alignment. To adjust for uneven floor surfaces, turn triangle security feet on

stationary posts (clockwise or counter-clockwise). For systems with stationary units in the middle of the track, tighten down

the locking collars surrounding these units..

Page 4

ASSEMBLY INSTRUCTIONS

FULL HDS-PLUS SYSTEM COMPONENT CHECKLIST

Please use this reference checklist to ensure that have all the components necessary to assemble your

HDS-Plus shelving system.

BASE HDS-PLUS

COMPONENTS

Kit Item # Desc Qty.

Kit Component #

FTSSU Stationary Unit Kit

FTSFZ Triangular Security Feet, Zinc 4/Pkg 1

FTSGB Guide Blocks, Set Of 4 1

FTSLC

FTSMU18 Mobile Unit Kit 18 In.

FTSC6 6 In. Casters W/ Bumpers, Set Of 4 1

FTSGB Guide Blocks, Set Of 4 1

FTSU18 18 In. Caster Channels, Set Of 2 1

FTSMU21 Mobile Unit Kit 21 In.

FTSC6 6 In. Casters W/ Bumpers, Set Of 4 1

FTSGB Guide Blocks, Set Of 4 1

FTSU21 21 In. Caster Channels, Set Of 2 1

FTSMU24 Mobile Unit Kit 24 In.

FTSC6 6 In. Casters W/ Bumpers, Set Of 4 1

FTSGB Guide Blocks, Set Of 4 1

FTSU24 24 In. Caster Channels, Set Of 2 1

FTSTK6 Track Set 6 Ft.

FTST3 3 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 1

FTSTK7 Track Set 7 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 1

FTST2 2 Ft. Track Tube, Set Of 2 1

FTSJ Track Joiner, Set Of 2 1

FTSTK8 Track Set 8 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 1

FTST3 3 Ft. Track Tube, Set Of 2 1

FTSJ Track Joiner, Set Of 2 1

FTSTK9 Track Set 9 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 1

FTST2 2 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 2

FTSTK10 Track Set 10 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 1

FTSTK11 Track Set 11 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 1

FTST3 3 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 2

Locking Collars, Set Of 4 W/ Allen Wrench

Kit Item # Desc Qty.

Kit Component #

FTSTK12 Track Set 12 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 2

FTST2 2 Ft. Track Tube, Set Of 2 1

1

FTSJ Track Joiner, Set Of 2 2

FTSTK13 Track Set 13 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 2

FTST3 3 Ft. Track Tube, Set Of 2 1

FTSJ Track Joiner, Set Of 2 2

FTSTK14 Track Set 14 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 2

FTST2 2 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 3

FTSTK15 Track Set 15 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 3

FTSJ Track Joiner, Set Of 2 2

FTSTK16 Track Set 16 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 2

FTST3 3 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 3

FTSTK17 Track Set 17 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 3

FTST2 2 Ft. Track Tube, Set Of 2 1

FTSJ Track Joiner, Set Of 2 3

FTSTK18 Track Set 18 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 3

FTST3 3 Ft. Track Tube, Set Of 2 1

FTSJ Track Joiner, Set Of 2 3

FTSTK19 Track Set 19 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 3

FTST2 2 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 4

FTSTK20 Track Set 20 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 4

FTSJ Track Joiner, Set Of 2 3

FTSTK21 Track Set 21 Ft.

FTST5 5 Ft. Track Tube, Set Of 2 3

FTST3 3 Ft. Track Tube, Set Of 2 2

FTSJ Track Joiner, Set Of 2 4

SHELVING

Item No. Qty. Item No. Qty. Width Length

Chromate Green Epoxy (in) (mm) (in) (mm)

FF1824C

FF1830C FF1830G 18 455 30 760

FF1836C FF1836G 18 455 36 910

FF1842C FF1842G 18 455 42 1060

FF1848C FF1848G 18 455 48 1220

FF1854C FF1854G 18 455 54 1370

FF1860C FF1860G 18 455 60 1525

FF1872C FF1872G 18 455 72 1825

FF2124C FF2124G 21 530 24 610

FF2130C FF2130G 21 530 30 760

FF2136C FF2136G 21 530 36 910

FF2142C FF2142G 21 530 42 1060

FF2148C FF2148G 21 530 48 1220

FF2154C FF2154G 21 530 54 1370

FF2160C FF2160G 21 530 60 1525

FF2172C FF2172G 21 530 72 1825

FF2424C FF2424G 24 610 24 610

FF2430C FF2430G 24 610 30 760

FF2436C FF2436G 24 610 36 910

FF2442C FF2442G 24 610 42 1060

FF2448C FF2448G 24 610 48 1220

FF2454C FF2454G 24 610 54 1370

FF2460C FF2460G 24 610 60 1525

FF2472C FF2472G 24 610 72 1825

FF1824G

18 455 24 610

Call Customer Service at 1.800.968.3918 | Fax 1.800.968.4129

FOODSERVICE, LLC

POSTS

Item No. Qty. Item No. Qty. Length

Chromate Green Epoxy (in) (mm)

FG080CH FG080GN

FGN074C FGN074G Mobile Posts 74 1880

Stationary

Posts

80 2032

www.focusfoodservice.com

LTS0510 rev. 0311

Loading...

Loading...