UTOPIA BERYLLIUM LINE

User manual

Français page 11

BP 374 - 108, rue de l'Avenir - 42353 La Talaudière cedex - France - Tel.: 00 33 4 77 43 57 00 - Fax: 00 33 4 77 37 65 87 - www.focal-fr.com

JMlab®, Utopia®, W®, Focus Ti me®, OPC®,, Focus Rin g®, Power Flower® and Structure "γ"® are trademarks of Focal-JMlab® - ©Focal-JMlab- SCOS-030722/5

2

User precautions

User manual Utopia Be line

Thank you for choosing the Utopia Be loudspeakers. We are pleased to share with you our philosophy : “the Spirit of

Sound”. These high-performance speakers feature the latest technical developments from Focal-JMlab in terms of

speaker design, whether it is for high fidelity or home theater systems. In order to make the most of these speakers and

enjoy the maximum of their performance, we advise you to read this user manual.

Special precautions regarding the Beryllium dome tweeter

In its solid form, Beryllium is harmless. However, due to its nature, certain special precautions should be observed to avoid exposure to

unnecessary risk.

- Under no circumstances should the Beryllium dome be subjected to any form of abrasive action. To ensure no accidental damage to

the tweeter dome it is advised to carefully replace the protection covers while not in use.

- In the unlikely case of damage to the dome, of any form, the supplied piece of adhesive tape should be immediately used to seal the

whole front surface of the tweeter. The protective cover should then be replaced and also taped securely in place. You should then

inform the dealer from whom you purchased the product so that the tweeter can be removed by a professional and returned to the

product distributor for replacement.

- If the dome is broken in any way giving rise to loose particles of Beryllium, these should be carefully collected with the use of an

adhesive tape and sealed in a zip-top bag to be returned with the tweeter.

For further information, please contact Focal-JMlab directly: beryllium@focal-fr.com

Breaking-in period

The drivers used in the Utopia Be line are made up of complex mechanical elements and require an adaptation period before they deliver

their full potential. They must get adapted to the temperature and humidity conditions of their environment. This breaking-in period

depends upon the encountered conditions and can last several weeks. In order to shorten this period, we advise you to let your speaker

operate for about twenty hours at medium level, playing standard music programs, but with a large amount of bass. Once the components

of the loudspeaker are completely stabilized, it is possible to enjoy the real performance of your speakers.

Magnetic disturbance

The Utopia Be line speakers generate a magnetic leakage that may interfere with other sensitive household appliances. It is strongly advised

not to place the speakers closer than 50cm to your TV screen. Frame geometry as well as colours can be severely distorted by a magnetic

field if the loudspeaker is placed too close to the cathode ray tube.

Generally, every sensitive element (audio tapes, video tapes, magnetic data storages, projector and CRTS overhead-projector) should not be

placed too close to non-shielded loudspeakers.

User precautions

All the products in the Utopia Be range are lacquered in order to offer a resistant cabinet surface and to make the upkeep easy.

We recommend the use of a dry cloth to dust your pair of loudspeakers. If the loudspeaker is stained, then use a damp cloth.

Never use any solvents, detergents, alcohol or corrosive products, scrappers or scouring powder to clean the surface of the loudspeaker.

Avoid placing the loudspeakers near a heat source.

3

Utopia Beryllium line

User manual Utopia Be line

Early in 1993, 13 years after its creation, Focal-JMlab

realized the need to launch a one-off, no compromise,

reference loudspeaker. After two years the Grande Utopia

was born initiating major technological innovations such

as the ”W “ sandwich cone, the Tioxid inverted dome

tweeter and the Focus Time system and Gamma.

It represented to us a high precision laboratory, which

would serve as the absolute reference for each Focal-JMlab

loudspeaker thereafter.

The first public demonstration of the Grande Utopia took

place in the spring of ’95. But what started as a

laboratory project quickly became the object of interest for

audiophiles the world over. The impact was so big that the

Grande Utopia gave birth to a full range of products

comprising all these technologies.

Innovation is the base value of Focal-JMlab. The new

Utopia Be range proves it. Building on the principles of

the original research started in 1993, we have introduced

the first dome made of pure Beryllium and the Focus ring

and Power Flower new magnet structures.

This manual contains a detailed presentation of the

patented technologies applied in the Utopia Beryllium

range. We are proud to present you with these technologies that form the base value of our dedication to sound

perfection and our philosophy: “the Spirit of Sound”.

The extreme precision offered by Utopia Beryllium

loudspeakers requires installation by a specialist; your

dealer has been selected for his skills in this field. The

weight of these loudspeakers also requires specialist

unpacking.

Beryllium tweeter p. 4

•

“Focus Ring

•

The “W

•

Focus Time p . 7

•

The “ϒ” (gamma) front structure p . 8

•

OPC crossover p . 9

•

Technical specifications p. 10

•

™

” and “Power Flower™” p. 5

®

” cone p . 6

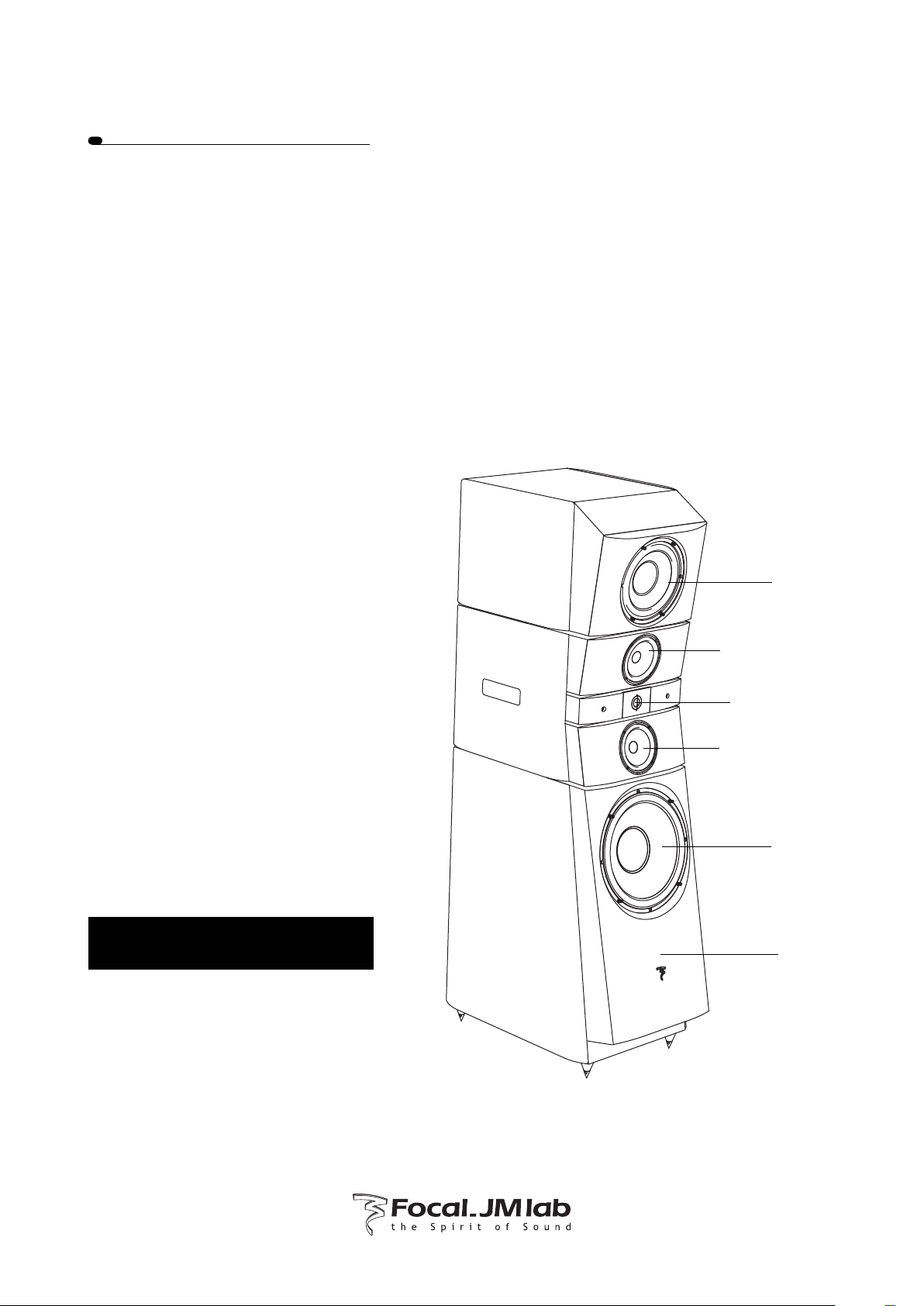

"W" Woofer

"Power Flower" magnet

"Power Flower" magnet

"W" Medium

Beryllium Tweeter

"Focus Ring" magnet

"W" Medium

"W" Woofer

THE FOCAL-JMLAB GUARANTEE ONLY APPLIES IF THE

ENCLOSED GUARANTEE CARD IS RETURNED TO US

10 DAYS OF PURCHASE.

WITHIN

"ϒ" structure cabinet

Focus Time

4

Beryllium tweeter™

User manual Utopia Be line

The reversed dome tweeter is a hallmak of Focal-JMlab. As a result of more than twenty

years of development into a tweeter that could produce a high output, but without requiring high energy input and without increasing directivity. And now the company is ready

to make a major leap forward with the introduction of the pure Beryllium version.

The main advantage of the inverted dome tweeter or the “full” range tweeter...

The experience acquired over the last twenty years has allowed Focal-JMlab to push back the limits

of reversed dome technology and the work on the suspension, driver shape, adhesives and materials

have at each stage produced an improvement in linearity and bandwidth.

The research began by testing fibre domes, as a simple and less sensitive way to validate the

advantages of the reversed dome with regards to energy response. Then the company introduced

more rigid metal domes to extend the response in high frequencies, and with Titanium producing

the most impressive results it has proved to be the most relevant choice. Today to exceed these

limits and particularly to extend the response to nearly 40kHz, we need to move towards a

material even lighter and more rigid. Already competitors have moved to introduce super tweeters

to satisfy the extreme requirements of the new high-bandwidth sources. However, Focal-JMlab does

not believe the adoption of the super tweeter is to be a satisfactory solution.

First of all, the distance between the tweeters, for frequencies where the wavelength is of the order

of cm, poses serious problems of coherence. A filtering is imposed which destroys, by the losses and

distortion of phase, the benefits introduced by extending the frequency response. So it is advisable

to point out that simply extending the high frequency response is not an end in itself, as the ear is

most sensitive to transients. The improvement with regards to the impulse response is only

perceptible at a tweeter output far beyond the 20kHz, limit and to far beyond the perception of

human hearing. We should not forget that Focal-JMlab’s first objective was to design tweeters offe-

ring an optimum coupling, being able to integrate with the mid-range at sufficiently low

frequencies and before the output of the mid- range begins to tighten or beam. Thus the only

successful solution is, therefore, to produce a tweeter with an extended response that covers more

than five octaves from 1 000Hz to 40 000Hz.

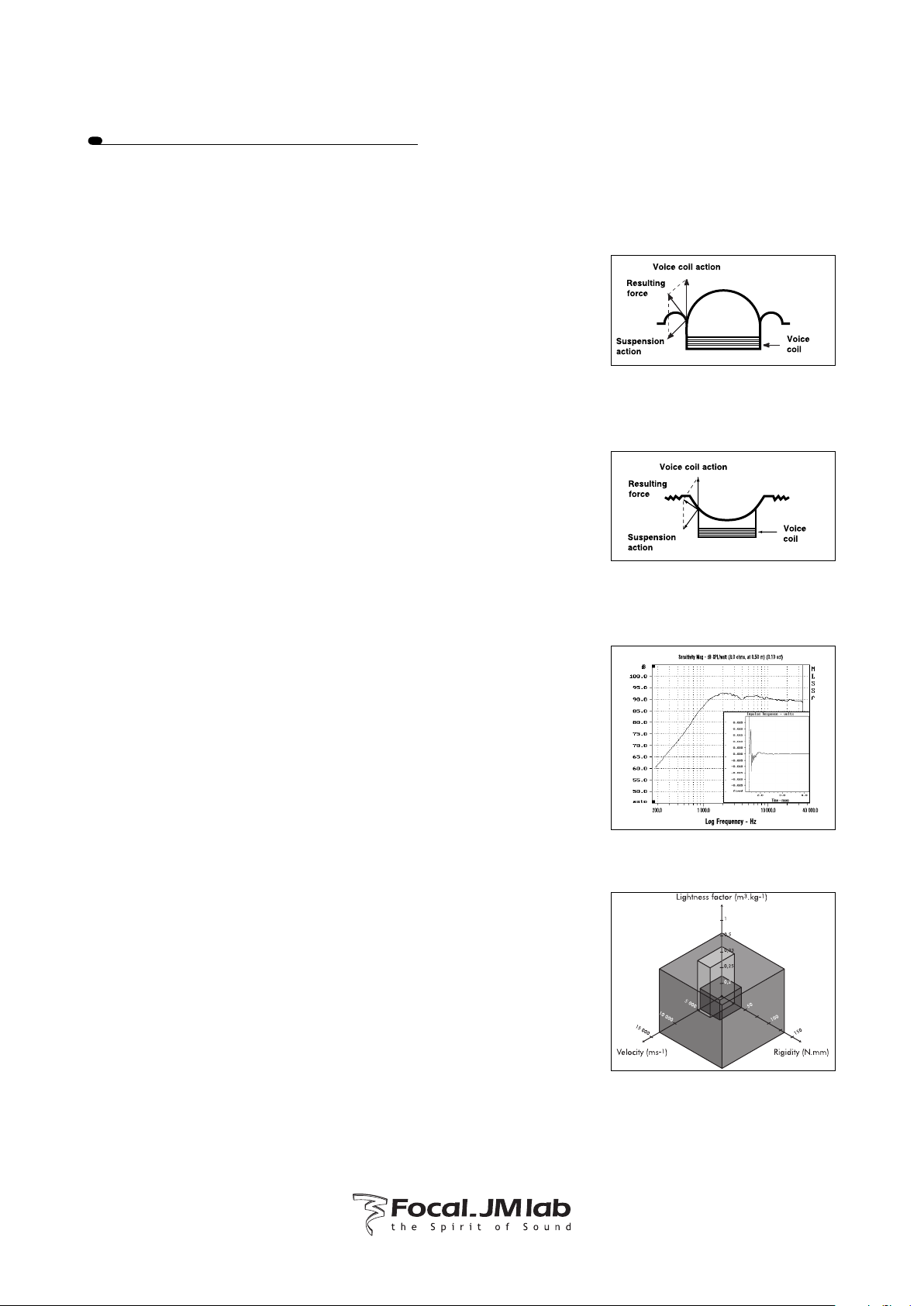

A standard dome tweeter has a poor mechanical coupling with the voice coil

attached to the outer diameter of the dome.

The result of the mechanical forces shows that considerable energy is lost into

the suspension where it is dissipated as heat.

Focal-JMlab inverted dome tweeter: The mechanical interface between the

voice coil and dome is optimal, the result of the forces tangential to the

dome. All of the energy is transmitted into the dome and radiated

as sound.

Beryllium - The ideal material for a dome.

An ideal dome must combine lightness, rigidity and damping. Currently, only one material offers

the possibility of a significant improvement. Beryllium’s density is 2.5 times lower than Titanium

and 1.5 times lower than Aluminium while its’ rigidity is 3 times higher than Titanium and 5 times

superior to Aluminium. Which means that for a dome of identical mass, a Beryllium version is 7

times more rigid than one made of Titanium or Aluminum - which have similar

rigidity for a given mass. Moreover, the velocity of sound in a Beryllium dome is 3 times faster

than a Titanium version and 2.5 times faster than Aluminum. However, the manufacturing of

Beryllium remains very difficult and its production has been limited to just three countries: the

United States, France and Russia. To date, Great Britain, Germany and Japan do not manufacture

pure Beryllium, rather using it in the form of an alloy. Beryllium is an excellent high-tech metal

- the only metal able to scratch glass - it is only used in strategic applications in the aeronautical and

military industries and consequently, its unique characteristics make it extraordinarily expensive,

much more than gold and nearly 100 times that of Titanium.

The only solution for Focal-JMlab - Control the manufactruing process.

The analysis of the mechanical characteristics inevitably leads to Beryllium’s choice as the ideal

material for a tweeter dome. However, a major problem exists because no company has been able

to manufacture such a dome. To arrive at a solution, required Focal-JMlab to conceive a process for

forming a pure Beryllium dome*. And after two years research and investment, the company now

posses a machine to carry out what was considered as utopia. Technological it is a world’s first and

certainly exceeds anything currently found in the audio field.

And the result is in line with the company’s hopes and expectations of an outstandingly detailed

loudspeaker which extends to nearly 40 kHz while maintaining a perfect impulse response.

* In the past certain manufacturers have attempted to use Beryllium for the construction of a direct radiating tweeter

dome. However, they have actually only used Beryllium as a surface coating on a dome structure leading to different

characteristics to anything achieved with pure Beryllium. .

The Beryllium tweeter offers a very extended response up to five octave

from 1,000Hz to 40,000Hz. The impulse response is ideal.

Comparaison beetween Beryllium, Titanium and Aluminum. Beryllium is

lighter and nearly five time more rigid.

5

Focus Ring™ and Power Flower

User manual Utopia Be line

™

Being hidden away magnetic circuits are seldom considered. However the energy

that they give is essential to the quality of reproduction. Focal-JMlab is always associated with investing in powerful arrays. And with the new Utopia line, the company wanted to apply its latest innovations.

“Focus Ring

An intense magnetic field is of the utmost importance for good tweeter performance and the TGU

conceived for large Utopia into 95 was a key point in the development of the Utopia line.

Selecting a magnet that combines high power with small dimensions narrows the choice of magnet

material to Neodymium. However the small dimensions required - and the need for a light coil

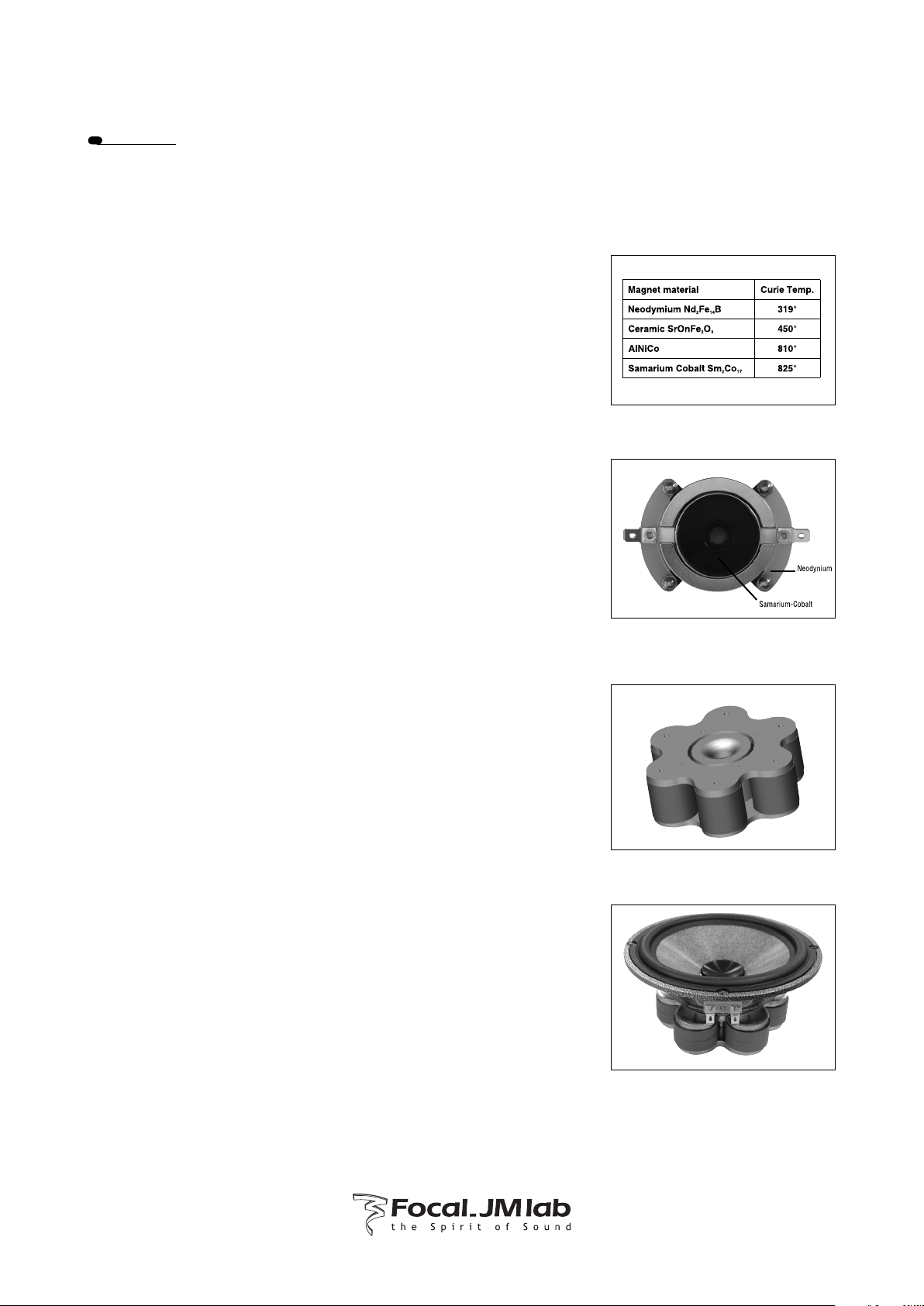

with a narrow air gap leads to intense heating of the magnet. A problem then occurs due to a

characteristic of Neodymium: its low “Curie Point”. The magnetisation saturation decreases as the

temperature rises and will cancel at a certain temperature, called the “Curie Point” (Tc). For a

ferrite, Tc is equal to 450 °C and, for a Neodymium Nd

Which means, should the magnet reach its Tc, the magnetic stru cture will loose its magnetism

bringing irreversible damage to its output and an audible loss of dynamics and definition. Since the

design of the TGU in 95, the evolution of the home cinema arena has imposed new constraints

with regards to power handling. In high fidelity musical performances very little energy is

demanded at high frequencies. However, with the special sound effects of home cinema new rules in

terms of power handling are created, with the subsequent effect on magnet temperatures.

Handling these new demands was a key rational in the design process of the new tweeter Beryllium

Utopia (TBe), which adopted a key new concept called “Focus Ring

pending. The material used in the magnet is Samarium-Cobalt Sm2Co17, which is more expensive

and slightly less powerful than Neodymium. However it offers a major advantage in that it pushes

the “Curie Point” (Tc) back to 825 °C, avoiding any chance of temperature related magnetic losses.

However to obtain a magnetic field of 2 Tesla, as in the TGU, doping of the magnetic circuit is

required by using a Neodymium ring to surround the Samarium magnet, thereby concentrating the

magnetic flux and reaching the target field. In addition, with the ring being mounted away from

the coil it is not affected by temperature increases and gives the tweeter exceptional stability

™

” - a patent for the magnetic circuit of the tweeter.

B magnet Tc is equal to 319 °C.

2Fe14

™

” - Focal-JMlab patent

"Curie Point" of different magnets. Only Samarium-Cobalt and Alnico offer

a large safety area when temperature increases.

"Focus Ring™" : Neodynium ring concentrates the magnetic flux to 2T.

The central magnet uses Samarium-Cobalt to offer high stability with

temperature.

“Power Flower™” - a patent for a high precision mid-range

The new mid-range 165mm driver has also directly benefited from Focal-JMlab’s experience of

developing Cone “W” technology since 1995. A new membrane has been developed for use with a

new a 40mm coil and the optimisation of its rigidity has allowed a “single skin” cone to be formed,

which is perfectly controlled over a one octave range from 1 500-3 000Hz - essential to the setting

of the OPC filter. The phase plug is no longer effective and is replaced by a large aluminium focus

plug. Any risk of coloration is eliminated and directivity is optimal. The link with the tweeter can

be made seemless and the impusle response of the combined tweeter/mid-range is ideal.

This mechanical optimization of the drivers eliminates the source of various sonic problems and

in addition offers the guarantee of great manufacturing consistency. The magnetic circuit must

be of high precision with very low losses. But the utilisation of large pole parts generates a problem

of flatness. The bonding beetween pole piece and magnet is not consistent and generate magnetic

losses. The “multiferrites”, technology, first initiated by Focal-JMlab more than twenty years ago for

the company’s top woofer , also brings an unexpected solution to the mid range of the Beryllium

Utopia line. The new - patent pending - “Power Flower

ferrites laid out concentrically around the core. Bonding beetween pole piece and ferrites is very

accurate and cancel any variations due to small deviation in the flat surface. Moreover the polar

parts are machined in the shape of flower, whose petals match the shape of the ferrites, and to stop

magnetic escapes between the bottom and top of the field. Finally, this arrangement satisfies a

double requirement: high power output and perfect control of the magnetic discharge. Magnetic

loses in production are thus very small and in combination with the tight tolerances of the Cone

“W” manufacturing, the “Power Flower™”* design has given exceptional accuracy to the 165mm

mid range unit. The very small tolerances ensure a perfect reproduction of any performances,

particularly in the highly sensitive mid-range, guaranteeing the strict tonal balance of the speaker.

* The concept of “Power Flower

and offers two another advantages, an excellent cooling of the reel and a full back de compression.

™

” also offers two additional advantages of excellent coiling for the coil

™

”, uses seven powerful, but small diameter

The shape optimisation and the use of multiferrites reduce consistently the

magnetic field losses.

The new mid-range “Power Flower™”. A great manufacturing consistency

provides an exceptionnal accuracy to this 165mm, guaranteeing the strict

tonal balance of the speaker.

6

The "W"™ cone

User manual Utopia Be line

For more than 15 years the composite cone sandwich technology is a Focal-JMlab

exclusivity. The “W” process, fi rst initiated in 1995 with the Grande Utopia,

provides now a true optimisation of the frequency response.

Properties of a drive unit membrane

Three parameters are of prime importance: mass, internal damping and stiffness.

• Stiffness allows the cone to behave as a piston over a wide range of frequencies,

especially important at bass frequencies for low distortion.

• Low mass delivers maximum acceleration on transients for the best reproduction of fine detail.

• Internal Damping damps out any ringing or vibrations in the cone structure that

would otherwise color the sound.

Materials

• Paper a light material, though not very rigid, but with reasonable internal damping.

Sound often suffers from a “cardboard” coloration.

• Polypropylene/Plastics a material relatively heavy, but with good internal damping properties.

Not especially stiff and the sound tends to lack detail and precision.

• A simple woven aramid fibres cone (not a sandwich type construction) uses a resin to seal the cone

and bring about the rigidity required, but this tends to lead to a dull plastiky coloration.

Analysis using laser interferometry allows the optimization of the “W” cones

in terms of rigidity/damping/mass.

The sandwich structure Focal-JMlab

During the mid 1980s, a new type of cone was developed and patented by Focal-JMlab which combined low mass, stiffness and high internal damping; the “Poly-K sandwich”.

Using woven aramid fibres tissue skins and a core of hollow microspheres of glass mixed with

a resin, this structure exhibited extremely high rigidity and low mass.

The damping could be controlled by the properties of the core.

Since this original construction, the process has been refined and developed to produce a new

generation of aramid fibres sandwich. The major advance in the construction of this cone is the use

of a special structural foam in place of the resin + microballs. This foam is used primarily in the

Aerospace industry; no other foam offers the same high ratio of stiffness/mass.

The name “W” is derived from Verre-Verre (Verre = Glass). The “W” cone uses two very fine

tissues of woven glass that are lighter and thinner than aramid fibres.

In addition, the molecular bond between the foam and the glass tissue is far superior to that of the

aramid fibres. This results in a cone structure which is mechanically more stable and with superior

stiffness. This construction allows us to further optimize the transmission speed of the sound wave

in the cone. This new construction process allows the amount of internal damping in the structure

to be very accurately controlled by varying the thickness of the foam: the thicker the foam,

the higher the damping factor.

The relationship between the thickness of the glass tissues and the foam core allows us to finely

optimize the cone structure depending on the particular application and the frequency area

to reproduce.

The “W” cone produces an extremely transparent and neutral sound free from coloration and

distortions normally associated with loudspeakers.

Its only limitation, the price; more than ten times the price of a quality paper cone.

Comparison of the index of rigidity in flexure (expressed in N.mm).

The performance of the “W” cones significantly betters that of other materials

for the same mass. In addition, internal damping is also superior.

The hand-made manufacturing of the "W" cone. Our industrial process is

patented.

The ‘W’ structure, a central core of foam covered by skins of glass tissue.

7

User manual Utopia Be line

Creating a special virtual source capable of delivering a coherent sound

without any loss of audio quality over space.

The scale of the audio spectrum to be reproduced imposes unavoidable physical constraints.

To appreciate this, you only need to consider the wavelengths to be produced.

The wavelength is expressed by:

Focus Time

™

v is the speed of sound in air (340m/s)

λ = v/f

f is the frequency of the signal to be reproduced

Therefore at 100Hz the wavelength

At 1,000Hz the wavelength

And at 10,000Hz the wavelength λ = 3.4cm

The only solution to achieve a faithful reproduction of the original signal is to divide up this

reproduction through the use of optimized loudspeakers, the diameters of which are related to the

frequencies that they are designed to reproduce in order to obtain constant directivity for the

frequencies concerned.

For the bass, due to obvious size restrictions it would be impractical to use diameters running into

meters. Fortunately, directivity is not critical in view of the large wavelength of frequencies in the

bass register. In the midrange and treble, directivity has a major influence however, so here multiple

drive units are needed.

However, although this multiplication of sources is ideal for faithfully reproducing each of the

frequency zones, it does pose a problem of coherence. The sound from each of the drive units must

reach the ear of the listener at the same time (chronological synchronicity). If the midrange, the

treble or the bass is received ahead of any of the other registers, there will naturally be an impression

that the sound is distorted. Faithfully reproducing the original audio signal dictates that all

frequencies must reach the listener at the same time, perfectly in sync.

The Focus Time principle

The alignment of several loudspeakers on a flat front baffle inevitably leads to a small degree of

audio distortion. The treble will be heard first, followed by the medium and the bass - this time

smearing is heard as a blurring of transients. Naturally, it is possible to experiment with the

respective positioning of the transducers in order to compensate for this effect. Nevertheless, it is

obvious that the tweeter that emits the shortest (and therefore the most direct) frequencies must be

placed on the axis of the listener’s ear (at the same height). This means that in order that the mid

and bass frequencies arrive at the same time as the treble, the drivers designed to reproduce these

frequencies must ideally be positioned in a semicircle, the center of which is located at the same

height as the listener’s ear. This is the principle of Focus Time, in which all frequencies are focused

upon the listener and take the same time to cover the distance separating the loudspeaker from the

listener whatever the register, be it bass, mid or treble.

λ = 3.4m

λ = 34cm

The various loudspeakers are aligned vertically on a traditional front panel.

The distance from the emissive center of each of these loudspeakers to the ear of

the listener is not identical.

The Focus Time structure: each of these loudspeakers is positioned in a

semicircle, taking the listener’s ear as its center.

Towards the ideal of the single point source

As mentioned previously, the theoretical ideal for localized sources inevitably runs up against physical

constraints. This is even more evident when you add the notion of the directivity of the transducers

(see OPC filter) and the notion of energy reproduction, for the bass, arising from the movement of

the membrane which increases progressively as the diameter decreases.

The Focus Time solution offers an intelligent response to all of these problems by reconciling

temporal coherence and enhanced dynamic range. The final sound image is characterized by

excellent stability regardless of the amplitude concerned.

This is the best possible solution to simultaneously reconcile the criteria of tone, dynamic range and

the sound image.

Cutaway view of the Grande Utopia, clearly showing the Focus Time profile.

8

The "γ" front structure

User manual Utopia Be line

The structure of the front baffle needs to reconcile inertia and damping properties in order

to guarantee the dynamic range and the absence of coloration in the bass.

A loudspeaker is a transducer. Its role involves causing molecules of air to vibrate under the influence

of a voice coil coupled with a membrane. A variation in electrical current mirroring the musical

message stimulates the voice coil, which (submerged in the magnetic field) moves “in rhythm” with

the musical signal. The electrical energy is converted into acoustic energy. This is the principle. In

reality however, in order for this conversion to be as faithful as possible to the original audio signal,

it is vital that the membrane moves in relation to a perfectly fixed reference. When the membrane

moves, the chassis must not budge, and its acceleration must be zero. It should

comprise a totally inert mechanical reference.

Inertia: it’s a mass thing!

The chassis of the loudspeaker is solidly attached to the front baffle of the speaker system, the baffle.

The mass ratio between the mobile assembly (voice coil plus membrane) and the frame (the chassis

plus the front panel) must be as high as possible. This is an application of the fundamental principle

of dynamic range: F = m ϒ.

The “ϒ” (gamma) acceleration taken by the chassis subjected to the moving cone force “F” must

ideally be zero. Consequently, the mass “m” must be as high as possible: it must target infinity.

Thus, regardless of the material chosen to produce the front panel in terms of rigidity, it would be

a mistake to forget the mass. One could easily imagine that a highly dampened front panel would

be the solution to avoid spurious vibrations set up by the “kickback effect” but this would be at

the expense of dynamic output. Only a high mass can guarantee the transients. Damping can never

substitute for mass.

™

In response to the force stimulating A the cone, the front panel applies a

reactive force R of equal amplitude

Coupling between loudspeakers

The highest energy is in the lower register. The woofers induce vibrations in the front baffle which

will interact with the medium and high end drivers and will thus cause intermodulation distortion,

mainly in the high-end where the scale of displacement of the driver membrane is particularly low.

The faithful reproduction of small details will be masked.

The adopted ultimate solution consists in giving each driver its own individual enclosure, set in a

complex curve that is expensive to engineer but is guaranteed to give a total mechanical decoupling

of the drivers.

The Structural solution

The front baffle solution in the Utopia Beryllium introduces a very high inertia to allow the bass

driver to reproduce the transitory information of the low register with all its impact.

The baffle is a massive structure of 50mm thick MDF which gives the front face a very high mass.

For an indication of the scale of that mass, the Grande Utopia -Beryllium weighs 210 kg whereas

the original 95 version weighed 186 kg. The new version is free from any distorting vibration and

the report/ratio of mass - the moving element compared to the frame + box – of the new Utopia is

more than ten times superior to the traditional solutions using curved enclosures.

The “piston” function of woofers

The rear clearance profile provided in the 50mm thickness offers another decisive advantage.

Carefully calculated, it offers a genuine wave-guide for the back emission of the woofers. As such,

the membrane operates like a true “piston”, and is not hindered by waves reflected from inside the

housing which impact against it creating distortions through torsion and/or rolling effects. When

operating ideally, reproduction from the woofers is not affected by distortions arising from

mechanical constraints.

Enhanced listening quality

Every effort is made to remove the source of spurious vibrations and to provide an outstanding

dynamic output from the bass. The sound image is enhanced and the tone offers greater

differentiation due to the absence of the coloration from the cabinet. The midrange and treble registers are consequently better defined and more transparent as the micro-information is

transmitted without any “masking effect”.

Front panel with gamma structure, produced in solid medium density

fiberboard with a thickness of 50mm provides a mechanical reference.

The ultimate solution consists in using individual cabinet for each drive-units to

avoid any intermodulation beetween the drivers.

➋

1

1

The motor systems of the drive units are mechanically coupled to the

internal braces.

2

The optimized profile offers perfect guidance for the cone, which

functions as a true piston. This is not affected by turbulence from the

back wave.

9

OPC crossover™ (Optimum Phase Crossover)

User manual Utopia Be line

The crossover is a key element in the design of a loudspeaker. Its role and

its development are very complicated, the personality of a loudspeaker depends on it.

The role of the Crossover

The crossover has the function of distributing the signal from the amplifier to the various drive units

in a loudspeaker: bass, midrange and treble. The most critical area of filtering this signal, with out

any doubt, is between the midrange and treble. A low-pass filter rolls off the higher frequencies of

the midrange. A high-pass filter rolls off the low frequencies from the tweeter. This crossover point

generally occurs in the region between 2-5kHz. This underlines a fundamental point in terms of

realistic sound reproduction: “directivity”.

Mastering Directivity

The diameter of a drive unit designed to reproduce midrange frequencies is generally between 130

and 170mm. These dimensions correspond to a frequency of between 2 and 2.6kHz. The directivity,

meaning the angle over which a drive unit will radiate its energy, reduces as frequency increases.

For frequencies where the wavelength is smaller than the diameter of the cone, the sound becomes

very directional. This means that the sound will be radiated in an increasingly narrow beam. As a

consequence, the acoustic power radiated from the loudspeaker is not evenly balanced, principle

criterion for the reproduction of a realistic image over a three dimensional space.

Here our inverted dome tweeter offers a unique advantage in that its design and conception allow it

work down to frequencies sufficiently low enough to avoid the effects of midrange beaming.

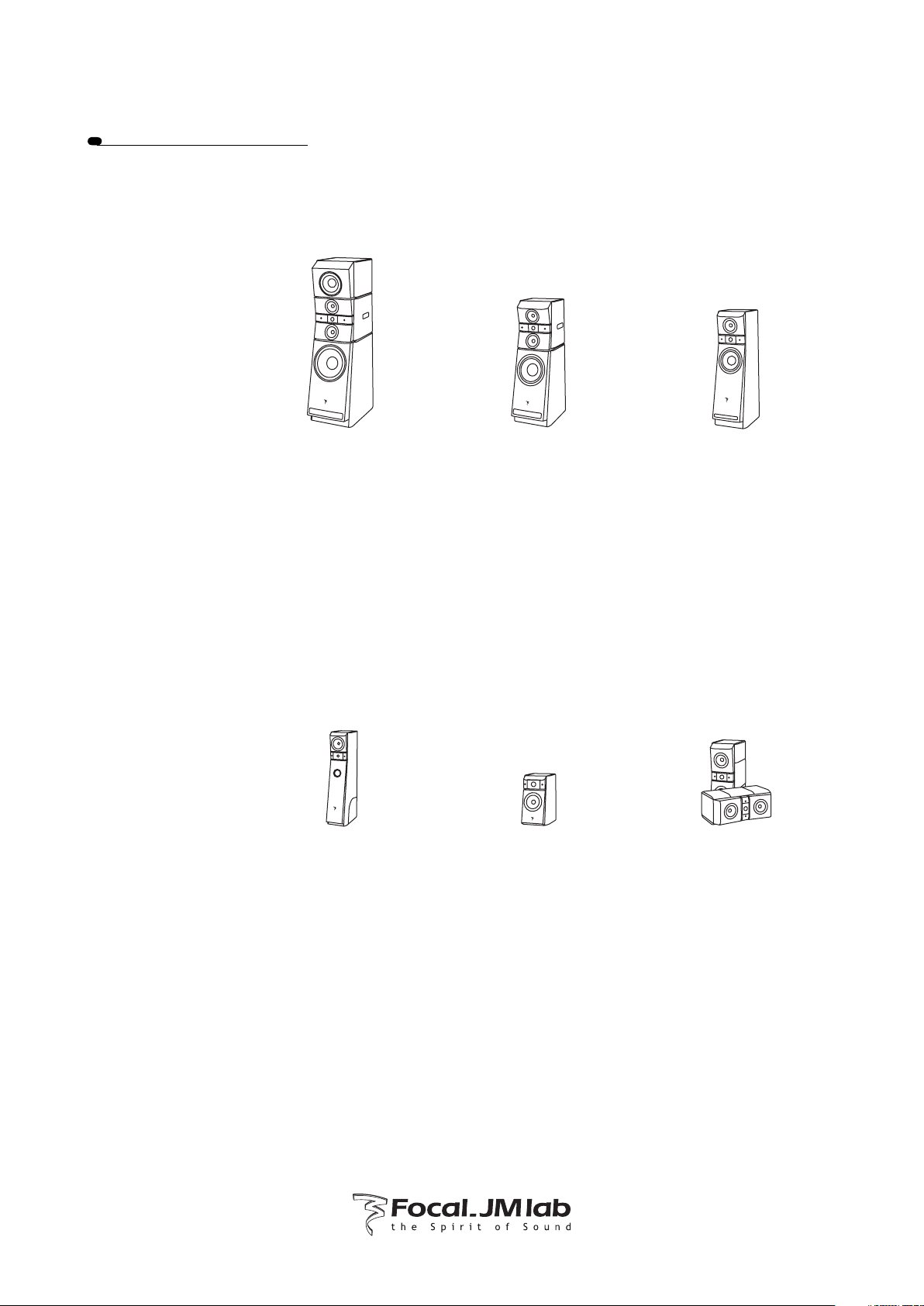

The high and low pass crossover sections “calibrate” the electrical signal

perfectly optimizing the range of frequencies passed to each drive unit.

5 000Hz

2 500Hz

Mastering Phase

In addition to the constraints imposed on the tweeter at low frequencies, there is also another very

critical aspect: the phase behavior of the loudspeaker and crossover combination in this critical

region. The ear and the auditive system are extremely sensitive in the zone 2-2.5kHz. The midrange

drive unit and its crossover must display an amplitude response that is “the exact mirror image” of

that of the tweeter and its crossover. For this criterion to be met, the phase between the midrange

and tweeter must be perfectly matched for the two to overlap and sum perfectly and

create a balanced tonality. The difference in phase between the tweeter and midrange at the crossover point must be zero. Thus, there is total summation between the two emission sources

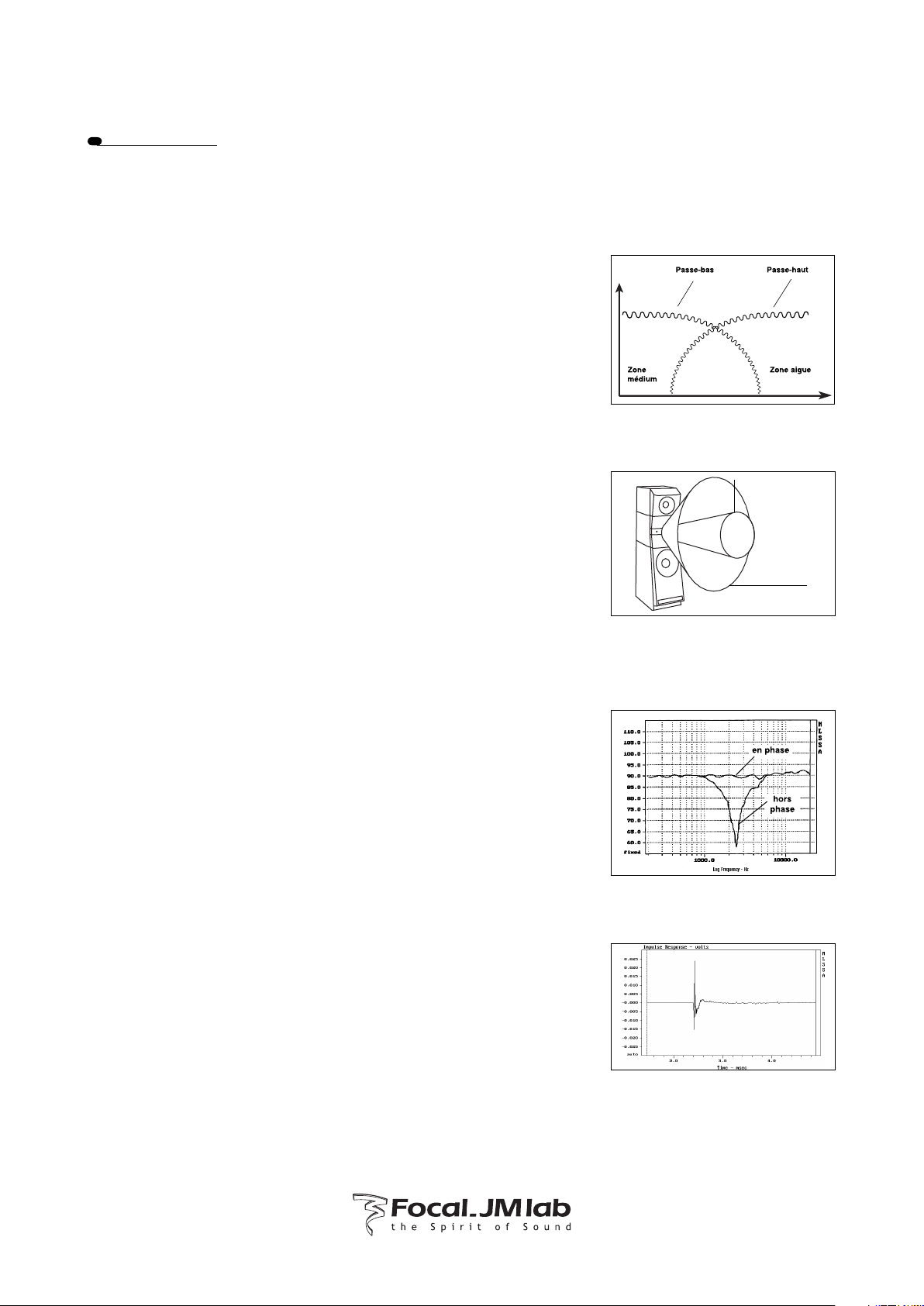

at the crossover frequency. Out of phase, the loudspeaker should show a very deep and symmetrical

hole in the response curve.

OPC Technology

These aforementioned steps form the basis of OPC technology. However, it would be naive to

think that this ideal could be reached simply through an extensive development of crossover

technology. It is necessary to have total control over the response and performance of the transducers

themselves, as is only possible for a few manufacturers who develop their own drive units as

Focal-JMlab: a specific drive unit is developed for each individual type of product. It's unrealistic to

think that a mechanical deffect can be corrected electricaly.

With the OPC technology, we use an acoustic roll-off of 36dB/Octave for the slopes between

midrange and tweeter along with a perfectly aligned phase. This translates into a sound that is

extremely coherent and with a natural timbre. Imaging is extremely precise and at the same time

dispersion wide so that the result can be enjoyed over a wide listening area.

A bass-mid drive unit will radiate sound in an increasingly directional manner

as frequency increases. It becomes more directive. Therefore the crossover

should introduce the tweeter before this phenomena starts to take effect.

Frequency response in and out of phase. The Grande Utopia shows a

perfectly symmetrical cancellation out of phase indicating a perfect

optimization of phase.

The OPC crossover offers a remarkable impulse response, even on a 4-way

loudspeaker like the Grande Utopia Be.

10

Technical specifications

User manual Utopia Be line

GRANDE UTOPIA Be NOVA UTOPIA Be ALTO UTOPIA Be

Description 4-way bass refl ex fl oor standing 3-way bass refl ex fl oor standing 3-way bass refl ex fl oor standing

• Speakers • 15" “ W ” cone, multiferrite subwoofer

• Frequency response (+/- 3dB) 20Hz - 40kHz 25Hz - 40kHz 30Hz - 40kHz

• Sensitivity ( 2,83V / 1m) 92dB 91.5dB 90dB

• Nominal / mini impedance 8 Ohms / 3 Ohms 8 Ohms / 3.6 Ohms 8 Ohms / 3.2 Ohms

• Crossover frequencies 50Hz / 250Hz / 2500Hz at 24dB/octave 250Hz / 2500Hz at 24dB/octave 250Hz / 2500Hz at 24dB/octave

• Max. power handling

with musical program

• Dimensions (HxWxD) 1740x500x780mm

• Weight (unit) 210kg (462.5lbs) 124.5kg (274.2lbs) 75.5kg (166.2lbs)

• 11" “ W ” cone, multiferrite woofer

• Two 6-1/2" “ W ” cone midrange

Power Flower magnet system

• 1" pure Beryllium inverted dome tweeter.

Focus Ring magnet system

500W 350W 250W

68.5x19.7x33.7in

DIVA UTOPIA Be MICRO UTOPIA Be CENTER UTOPIA Be

Description 3-way bass refl ex fl oor standing 2-way bass refl ex compact loudspeaker 3-way bass refl ex LCR channel

• Speakers • Two 8" “ W ” cone woofer

• Frequency response (+/- 3dB) 35Hz - 40kHz 50Hz - 40kHz 45Hz - 40kHz

• Sensitivity ( 2,83V / 1m) 89dB 89dB 90dB

• Nominal / mini impedance 8 Ohms / 3 Ohms 8 Ohms / 5 Ohms 8 Ohms / 3.4 Ohms

• Crossover frequencies 100Hz / 2500Hz at 24dB/octave 2500Hz at 24 dB/octave 250Hz / 2500Hz at 24dB/octave

• Max. power handling

with musical program

• Dimensions (HxWxD) 1100x250x532mm

• Weight (unit) 48kg (105.8lbs) 17.5kg (38.5lbs) 39kg (85.9bs)

• 6-1/2" “ W ” cone midrange

Power Flower magnet system

• 1" pure Beryllium inverted dome tweeter.

Focus Ring magnet system

200W 100W 250W

43.3x9.8x20.9in

• 13" “ W ” cone, multiferrite woofer

• Two 6-1/2" “ W ” cone midrange

Power Flower magnet system

• 1" pure Berylllium inverted dome tweeter.

Focus Ring magnet system

1337x440x621mm

52.6x17.3x24.4in

• 6-1/2" “ W ” cone midrange

Power Flower magnet system

• 1" pure Beryllium inverted dome tweeter.

Focus Ring magnet system

425x250x380mm

16.7x9.8x15in

• 11" “ W ” cone woofer

• 6-1/2" “ W ” cone midrange

Power Flower magnet system

• 1" pure Beryllium inverted dome tweeter.

Focus Ring magnet system

1208x370x530mm

47.6x14.6x20.9in

L&R UTOPIA Be

• 10" “ W ” cone woofer

• Two 6-1/2" “ W ” cone midrange

Power Flower magnet system

• 1" pure Beryllium inverted dome tweeter.

Focus Ring magnet system

Center Utopia Be: 300x700x443 mm

L&R Utopia Be: 700x300x443 mm

11.8x27.6x17.4in

27.6x11.8x17.4in

11

Caractéristiques techniques

Manuel d'utilisation ligne Utopia Be

GRANDE UTOPIA Be NOVA UTOPIA Be ALTO UTOPIA Be

Description Système colonne bass-refl ex, 4 voies Système colonne bass-refl ex, 3 voies Système colonne bass-refl ex, 3 voies

• Haut-parleurs • Grave cône “W” 38 cm, multiferrites

• Réponse en fréquences (+/- 3 dB) 20 Hz - 40 kHz 25 Hz - 40 kHz 30 Hz - 40 kHz

• Sensibilité (2,83 V / 1 m) 92 dB 91,5 dB 90 dB

• Impédance nominale / mini 8 Ohms / 3 Ohms 8 Ohms / 3,6 Ohms 8 Ohms / 3,2 Ohms

• Fréquence de fi ltrage 50 Hz / 250 Hz / 2500 Hz à 24 dB/octave 250 Hz / 2500 Hz à 24 dB/octave 250 Hz / 2500 Hz à 24 dB/octave

• Puissance admissible

sur programme musical

• Dimensions (H x L x P) 1740 x 500 x 780 mm 1337 x 440 x 621 mm 1208 x 370 x 530 mm

• Poids 210 kg 124,5 kg 75,5 kg

• Bas médium cône “ W ” 27 cm, multiferrites

• Deux médium 16,5 cm cône “ W ”

Power Flower

• Tweeter TBU 25 mm à dôme inversé en Béryllium

pur, aimant Focus Ring

500 W 350 W 250 W

DIVA UTOPIA Be MICRO UTOPIA Be CENTER UTOPIA Be

Description Système colonne bass-refl ex, 3 voies Compacte bass-refl ex, 2 voies Centrale bass-refl ex, 3 voies et multicanal

• Haut-parleurs • Deux grave cône “ W ” 21 cm,

• Réponse en fréquences (+/- 3 dB) 35 Hz - 40 kHz 50 Hz - 40 kHz 45 Hz - 40 kHz

• Sensibilité (2,83 V / 1 m) 89 dB 89 dB 90 dB

• Impédance nominale / mini 8 Ohms / 3 Ohms 8 Ohms / 5 Ohms 8 Ohms / 3,4 Ohms

• Fréquence de fi ltrage 100 Hz / 2500 Hz à 24 dB/octave 2500 Hz à 24 dB/octave 250 Hz / 2500 Hz à 24 dB/octave

• Puissance admissible

sur programme musical

• Dimensions (H x L x P) 1100 x 250 x 532 mm 425 x 250 x 380 mm Center Utopia Be : 300 x 700 x 443 mm

• Poids 48 kg 17,5 kg 39 kg

• Médium 16,5 cm cône “ W ”

Power Flower

• Tweeter TBU 25 mm à dôme inversé

en Béryllium pur, aimant Focus Ring

200 W 100 W 250 W

• Grave cône “ W ” 33 cm, multiferrites

• Deux médium 16,5 cm cône “ W ”

Power Flower

• Tweeter TBU 25 mm à dôme inversé en Béryllium

pur, aimant Focus Ring

• Médium 16,5 cm cône “ W ”

Power Flower

• Tweeter TBU 25 mm à dôme inversé en Béryllium

pur, aimant Focus Ring

• Grave cône “ W ” 28 cm

• Médium 16,5 cm cône “ W ”

Power Flower

• Tweeter TBU 25 mm à dôme inversé en Béryllium

pur, aimant Focus Ring

L&R UTOPIA Be

• Grave 25 cm cône “ W ”

• Deux médium 16,5 cm cône “ W ”

Power Flower

• Tweeter TBU 25 mm à dôme inversé en Béryllium

pur, aimant Focus Ring

L&R Utopia Be : 700 x 300 x 443

12

Précautions d'utilisation

Manuel d'utilisation ligne Utopia Be

Nous vous remercions d’avoir choisi les enceintes de la ligne Utopia Be et de partager avec nous notre philosophie

« the Spirit of Sound ». Ces enceintes de haute technicité intègrent les ultimes perfectionnements Focal-JMlab en

matière de conception de haut-parleurs pour la haute fidélité et le home cinéma. Afin d’exploiter toutes leurs

performances, nous vous conseillons de lire les instructions de ce livret, en particulier celles liées au tweeter en

Béryllium, puis de le conserver avec précaution pour vous y référer ultérieurement.

Mise en garde

Les enceintes de la ligne Utopia Be utilisent un tweeter à dôme inversé en Béryllium pur, capable d’étendre la bande passante à plus de

40 kHz. Sous sa forme solide, ce matériaux est innofensif. Toutefois, de par sa nature, certaines précautions doivent être appliquées pour

ne pas s’exposer à des risques inutiles :

- Le dôme Béryllium ne doit jamais être au contact d’une matière abrasive. Pour éviter tout dommage accidentel, nous vous conseillons

de mettre en place la cache de protection lorsque l'enceinte n'est pas utilisée.

- Si le cône Béryllium est endommagé sous quelque forme que ce soit, le recouvrir dès que possible sur toute sa surface avec la bande

adhésive de protection fournie. Prendre contact avec le revendeur afin de démonter et de remplacer le tweeter auprès d’un service

compétent chez le distributeur.

- Si le dôme est brisé, les particules éventuelles de Béryllium doivent être récupérées avec soin au moyen d’un ruban adhésif, puis doivent être

placées dans un sac plastique hermétiquement clos. Il sera renvoyé en même temps que l’enceinte chez le revendeur.

Pour plus d’informations complémentaires, veuillez nous contacter directement à l’adresse suivante : beryllium@focal-fr.com

Période de rodage

Les haut-parleurs utilisés sur la ligne Utopia Be sont des éléments mécaniques complexes qui exigent une période d’adaptation pour

fonctionner au mieux de leurs possibilités et s’adapter aux conditions de température et d’humidité de votre environnement. Cette période

de rodage varie selon les conditions rencontrées et peut se prolonger sur quelques semaines. Pour accélérer cette opération, nous vous

conseillons de faire fonctionner vos enceintes une vingtaine d’heures à niveau moyen, sur des programmes musicaux standards mais

riches en grave. Une fois les caractéristiques de l’enceinte totalement stabilisées, vous pourrez profiter intégralement des performances de vos

enceintes Utopia Be.

Perturbations magnétiques

Les enceintes de la ligne Utopia Be génèrent un champ magnétique de fuite pouvant perturber le fonctionnement des appareils qui y sont

sensibles. Il est strictement déconseillé d’utiliser des enceintes frontales à moins de 50 cm d'un téléviseur, qui se révèle particulièrement

sensible à ce phénomène. La géométrie de l’image mais aussi les couleurs peuvent se trouver gravement déformées par le champ d’une

enceinte trop proche d’un tube cathodique. D’une manière générale, tous les éléments sensibles (cassettes audio et vidéo, stockage de

données magnétique, projecteur et rétroprojecteurs CRT…) ne doivent pas être placés à proximité immédiate des enceintes non blindées.

Précaution importantes

Les enceintes de la ligne Utopia Be sont vernies afin de présenter un état de surface très résistant et faciliter leur entretien. Celui-ci se limite

généralement à un simple dépoussiérage à l’aide d’un chiffon sec. Si l’enceinte est tâchée, nous vous recommandons simplement l’utilisation

d’un chiffon humide.

Ne jamais utiliser de solvants, détergents, alcools ou produits corrosifs, grattoirs abrasifs récurant pour nettoyer la surface de l’enceinte. Ne

jamais mettre en contact les haut-parleurs avec un liquide ou même un chiffon humide ou peluchant.

Eviter la proximité d’une source de chaleur.

En cas de rayure des flancs en bois, il existe un kit de réparation sous la forme d’un stylo de masquage spécial pour les trois finitions

Avant-Garde, Classic et Signature. La procédure de réparation exige un savoir-faire pour être efficace. Contactez votre revendeur pour

demander conseil.

13

En 1993, 13 ans après sa création, Focal-JMlab a voulu

donner corps à un rêve : créer une enceinte de référence

absolue, sans limitations ni contraintes ou compromis.

Deux ans plus tard, la Grande Utopia était née et avec elle

des innovations technologiques majeures comme les

membranes composites W, le tweeter à dôme inversé

Tioxid ou le profil d’enceinte Focus Time et Gamma.

l s’agissait pour nous d’un outil de laboratoire de haute

précision, d’un repère cumulant les plus hauts standards de

qualité et les meilleures technologies du moment qui

servirait de point de référence absolu pour toutes les

productions Focal-JMlab.

La Grande Utopia fut présentée au public en tant que

telle au printemps 95. L’impact fut si considérable que la

Grande Utopia donna naissance par la suite à une véritable

ligne Utopia qui déclinait toutes ses technologies.

L’essence même de Focal-JMlab est de progresser.

La nouvelle ligne Utopia Béryllium en est la plus pure

expression. Reprenant les grands principes immuables

élaborés dès 1993, nous nous sommes imposés de

nouveaux défis : maîtrise de la technologie Béryllium

pour la première fois, appliqué à l’état pur sur un tweeter

à dôme, nouvelles structures de moteurs Focus Ring et

Power Flower.

Ce document contient une description détaillée de toutes

ces technologies brevetées ou en cours de brevet appliquées

sur la ligne Utopia Béryllium. Nous sommes fiers de vous

les présenter car elles sont l'essence même de notre

conception de la perfection sonore et de notre

philosophie : « the Spirit of Sound »

Ligne Utopia Béryllium

Manuel d'utilisation ligne Utopia Be

Tweeter Béryllium p. 14

•

“Focus Ring

•

Cône “W

•

Focus Time p. 17

•

Face avant structure “ϒ” p. 18

•

Filtre OPC p. 19

•

Caractéristiques techniques p. 11

•

™

” et “Power Flower™” p. 15

®

” p. 16

Woofer "W"

Moteur "Power Flower"

Moteur "Power Flower"

Médium "W"

Tweeter Béryllium

Moteur "Focus Ring"

Médium "W"

L’extrême précision dont sont capables toutes les enceintes

Utopia Béryllium suppose une mise en œuvre faite par un

spécialiste, votre revendeur qui a été soigneusement

sélectionné pour ses compétences. Le poids imposant de

ces enceintes implique également que le

déconditionnement soit une affaire de spécialiste.

POUR VALIDATION DE LA GARANTIE FOCAL-JMLAB,

MERCI DE NOUS RETOURNER LA GARANTIE JOINTE DANS

LES 10 JOURS.

Woofer "W"

Ébénisterie structure "ϒ"

Focus Time

14

Tweeter Béryllium

Manuel d'utilisation ligne Utopia Be

Le tweeter à dôme inversé est une signature Focal-JMlab. Initiée il y a plus de vingt

ans pour concevoir un tweeter à haut rendement très peu directif et à haute énergie.

Aujourd’hui, l’introduction du tweeter à dôme inversé en Béryllium pur constitue une

avancée

déterminante.

™

L’avantage décisif du dôme inversé ou le tweeter “large bande”...

L’expérience acquise au cours des vingt dernières années sur la technologie des tweeters à dôme

inversé nous a permis d’en repousser les limites. Travail sur la suspension, sur la forme, sur les

colles et sur les matériaux utilisés pour la réalisation du dôme, à chaque étape nous avons

progressé pour concilier linéarité et étendue de la réponse. Nous avons d’abord utilisé des dômes en

fibres, moins critiques à mettre en œuvre, pour valider les avantages du dôme inversé en matière de

réponse en énergie. Ensuite, nous avons introduit des dômes plus rigides en métal pour étendre la

réponse en hautes fréquences : le Titane constituant en cela un choix pertinent. Aujourd’hui, pour

dépasser ces limites et particulièrement pour étendre la réponse à près de 40 kHz, il fallait

s’orienter vers un matériau encore plus léger et plus rigide. Nos concurrents ont recours à l’utilisation

d’un super tweeter pour satisfaire aux exigences extrêmes des nouvelles sources numériques.

Pour nous, le recours à un super tweeter n’est pas satisfaisant. Tout d’abord, l’écartement des

sources, à des fréquences dont la longueur d’onde est de l’ordre du centimètre, pose de graves problèmes de cohérence. Ensuite, ce tweeter impose un filtrage qui anéantit, par les pertes et distorsions

de phase qu’il introduit, le gain en étendue de la réponse en fréquence.

Il convient de préciser que l’étendue de la réponse en hautes fréquences n’est pas une fin en soi,

l’oreille étant un capteur de transitoires. Seul est perceptible le gain apporté en matière de réponse

impulsionnelle par une réponse du tweeter s’étendant bien au-delà de 20 kHz, limite haute, rappelonsle, de la perception de l’oreille. Il ne faut pas oublier notre objectif premier qui a toujours été de

concevoir des tweeters offrant un couplage optimum, pouvant se raccorder au médium à des

fréquences suffisamment basses. Ceci avant que l’émission du médium ne se resserre et se manifeste

à l’écoute par un phénomène de projection ou de “pincement” (détaillé dans la rubrique OPC).

En final, la seule solution réellement satisfaisante consiste a élaborer un tweeter dont la réponse

s’étend sur plus de cinq octaves de 1 000 Hz à 40 000 Hz.

Le matériau idéal pour un dôme, le Béryllium

Un dôme idéal doit concilier légèreté, rigidité et amortissement. À ce jour, un seul et unique

matériau permet de franchir un pas décisif, il s’agit du Béryllium. Sa densité est de 2,5 fois

inférieure au Titane et 1,5 fois inférieure à l’Aluminium. Sa rigidité est 3 fois supérieure au Titane

et 5 fois supérieure à l’Aluminium. Ce qui signifie que pour des dômes de masse identique celui qui

est en Béryllium est 7 fois plus rigide que celui qui est en Titane ou en Aluminium, matériaux qui

offrent à masse équivalente la même rigidité.

Tweeter à dôme classique convexe : le couplage mécanique entre dôme

et bobine se fait sur le pourtour. La résultante des forces montre qu’une

part importante de l’énergie est transmise à la suspension où elle se

dissipe en chaleur.

Le tweeter à dôme inversé Focal-JMlab. Le couplage bobine/dôme est

optimal, la résultante des forces est tangente au dôme. L’énergie électrique

est transformée en onde acoustique avec un minimum de pertes.

De plus, le son se propage 3 fois plus vite que dans le Titane et 2,5 plus vite que dans l’Aluminium.

Par contre, la métallurgie du Béryllium reste très délicate, sa production est limitée dans le monde

à trois pays, les Etats-unis, la France et l’ex-URSS. À ce jour, la Grande-Bretagne, l’Allemagne et le

Japon ne fabriquent pas le Béryllium pur, ils l’utilisent sous forme d’alliage. Hi-Tech par excellence,

seul à rayer le verre, il ne concerne que des domaines d’applications stratégiques comme l’aéronautique,

le militaire (les missiles) et le nucléaire. En conséquence, ses particularités uniques rendent son prix

extraordinairement élevé, supérieur à l’or et près de 100 fois à celui du Titane.

La seule solution pour Focal-JMlab, la maîtrise du process de fabrication

Si l’analyse des caractéristiques mécaniques conduit inévitablement au choix du Béryllium pour

réaliser le dôme du tweeter idéal, l’écueil majeur réside dans le fait qu’aucune société externe n’est

capable de fournir un tel dôme. Pour parvenir à nos fins la seule et unique solution consistait à

concevoir un process de formage de dôme en Béryllium pur*. Nous avons investi dans cette voie il

y a deux ans et aujourd'hui nous possédons en nos murs une machine capable de réaliser cette utopie.

C’est une première technologique mondiale qui dépasse très largement le domaine de l’audio....

Le résultat est à la hauteur de nos espérances avec un haut-parleur d’aigus dont la réponse s’étend

à près de 40 kHz et avec une réponse impulsionnelle parfaite.

* Par le passé, certains constructeurs ont tenté d'utiliser le Béryllium pour la réalisation de dôme à émission directe.

En réalité, il ne s’agissait que de métallisation de surface en Béryllium sur une structure de dôme dont les caractéristiques

n’avaient rien à voir avec celles du Béryllium pur.

La réponse en fréquence du tweeter Béryllium s'étend sur plus de cinq

octaves de 1 000 Hz à 40 000 Hz. La réponse impulsionnelle qui en

découle est remarquable.

Tableau comparatif entre le Béryllium, le Titane et l'Aluminium. Le Béryllium

plus léger surclasse en rigidité les deux autres métaux.

15

Focus Ring™ et Power Flower

Manuel d'utilisation ligne Utopia Be

Cachés, les circuits magnétiques sont rarement évoqués. Pourtant l’énergie qu’ils

procurent est essentielle dans la qualité de reproduction. Focal s’est toujours

démarqué en “investissant” dans de puissants moteurs. Avec la nouvelle ligne

Utopia, nous nous devions d’appliquer les dernières innovations.

“Focus Ring™” un brevet pour le circuit magnétique du tweeter.

L’importance d’un champ magnétique intense est fondamental pour un tweeter : le TGU conçu

pour la Grande Utopia en 95 a été un point clef du développement de la ligne Utopia. L’utilisation

d’aimant surpuissant et de faible dimension conduit au choix d’aimants Néodyme. Pourtant, les

faibles dimensions de la bobine, qui doit être très légère, associée à un entrefer étroit, sans brassage

d’air comme dans le grave, conduisent à un échauffement intense. Or, le Néodyme souffre d’une

particularité : son faible “Point de Curie”. L’aimantation à saturation décroît régulièrement à mesure

que la température s’élève et s’annule à une certaine température, appelée “Point de Curie” (Tc).

Pour une ferrite, Tc est égal à 450 °C et pour le Néodyme Nd

structure magnétique va se désaimanter et apporter un préjudice irréversible en terme de

rendement, de dynamique et de définition.

Depuis la conception en 1995 du TGU, l’évolution du home cinéma impose désormais des

contraintes nouvelles en matière de tenue en puissance. En haute fidélité musicale il y a très peu

d’énergie dans l’aigu. Par contre en home cinéma, les effets, bruitages …imposent de nouvelles

règles en terme de tenue en puissance et donc de tenue en température.

Cette nouvelle donne a été intégrée dans le TBU, nouveau tweeter Beryllium Utopia, il s’agit

d’un nouveau concept dénommé

Le matériau retenu pour l’aimant est le Samarium-Cobalt Sm2Co17 : onéreux et légèrement moins

puissant que le Néodyme, il offre l’avantage majeur de repousser le

ce qui le rend totalement inaltérable. Cependant, pour obtenir un champ de 2 Tesla, comme dans

le TGU, il convenait de doper ce circuit magnétique. Pour cela un imposant anneau de Néodyme

entoure l’aimant Samarium et concentre le flux magnétique. Au final, cet anneau concentrateur

pousse le champ à 2 Tesla. Cet anneau étant éloigné de la bobine, il ne sera pas affecté par l’échauf-

fement et procure au tweeter une stabilité inconditionnelle dans le temps.

“Focus Ring™”, pour lequel Focal-JMlab a déposé un brevet.

B, à 319 °C. Cela signifie que la

2Fe14

“Point de Curie” Tc à 825 °C,

™

"Points de Curie" des divers type d'aimants. Seuls le Samarium-Cobalt

et l'Alnico offrent une marge de sécurité satisfaisante vis à vis de la

température.

™

"Focus Ring

" : l'anneau de Néodyme concentre le champ magnétique à 2T,

l'aimant central en Samarium-Cobalt assure la stabilité dans le temps.

“Power Flower™” : un brevet pour un médium de haute précision.

Le nouveau médium de 165 mm bénéficie de l’expérience acquise depuis 1995 dans la réalisation

des cônes

de sa rigidité nous a conduit à utiliser un cône

de sa réponse sur l’octave 1 500-3 000 Hz, préalable essentiel à la mise en œuvre du filtrage “OPC”.

L’ogive de correction n’ayant plus d’utilité, une parabole en aluminium massif la remplace. Tout

risque de coloration est éliminé et le diagramme de directivité est optimal. La liaison avec le tweeter

se fait sans rupture et la réponse impulsionnelle de l’ensemble est idéale.

Cette optimisation mécanique de l’équipage mobile, offre de surcroît la garantie d’une grande

constance de fabrication. Cela impose le recours à un circuit magnétique de précision à très faibles

pertes. L'utilisation de pièces polaires de dimensions conséquentes engendre des problèmes de planéité.

La liaison pièces polaires-aimant n’est pas parfaite et s’accompagne de pertes magnétiques.

La technique

une solution inattendue aux médiums de la ligne Utopia Béryllium.

Le moteur

concentriquement autour du noyau. Les liaisons ferrites-pièces polaires sont intimes éliminant les

variations inhérentes aux écarts de planéité. Usinées en forme de fleur, dont les pétales épousent

la forme des ferrites, pour s'affranchir des fuites magnétiques entre plaque de fond et plaque de

champ. Au final, ce moteur satisfait une double exigence : puissance élevée et réduction des fuites

magnétiques. Les dispersions en production sont ainsi très faibles. Associé à la maîtrise acquise sur

le process

Les très faibles tolérances assurent une reproductibilité parfaite des performances dans la zone très

sensible du registre médium, garantie du respect strict de l’équilibre tonal de l’enceinte.

* Le concept “Power Flower™” offre, par ailleurs, deux autre avantages, un excellent refroidissement de la bobine

“W. Une nouvelle membrane pour bobine de 40 mm a été développée. L’optimisation

“simple peau” pour contrôler parfaitement la forme

“multiferrites”, initiée il y plus de vingt ans par Focal-JMlab pour les woofers apporte

“Power Flower™”, objet d’un brevet, utilise sept ferrites puissantes de petit diamètre disposées

“W”, le moteur “Power Flower™”* fait de ce 165 mm un médium de très haute précision.

et une décompression arrière totale.

L'optimisation de la forme et l'utilisation de multiferrites réduit

considérablement les pertes de champ magnétique.

Le nouveau moteur “Power Flower™” procure une extrème précision à ce

165 mm garantissant l'équilibre tonal de l'enceinte.

Index de rigidité

16

Le cône "W"

Manuel d'utilisation ligne Utopia Be

La technologie des membranes composite sandwich est depuis plus de 15 ans une spé-

cificité Focal-JMlab. Le procédé “W” initié avec la Grande Utopia en 95,

autorise une véritable optimisation de la réponse à la conception.

Propriétés de la membrane d’un haut-parleur

Elle doit concilier trois paramètres contradictoires : le poids, l’amortissement et la rigidité.

• La rigidité permet un fonctionnement en piston parfait sur une large bande de

fréquences, et donc une élimination de la distorsion dans le grave (pas de fractionnement).

• La légèreté autorise une accélération maximale, importante pour la reproduction

des transitoires dans le médium et pour l’absence de traînage dans le grave.

• L’amortissement caractérise la neutralité de la membrane. Elle ne doit pas avoir de

sonorité caractéristique.

Les matériaux habituellement utilisés

• Le papier ou pulpe de cellulose, matériau léger, assez rigide, apporte un bon amortissement

et a souvent une coloration dite “son de carton”.

• Le polypropylène et les membranes synthétiques, à l’inverse, sont des matériaux assez

lourds et amortis, mais qui manquent de rigidité et ont tendance à éliminer les détails.

• La membrane composite (fibres aramides) monocouche (pas de structure sandwich), tire sa

rigidité de la résine qui l’imprègne avec pour défaut une coloration de “plastique froissé ”.

™

L’analyse par interférométrie laser permet d’optimiser la mise au point des

cônes “W” en fonction des exigences de rigidité/amortissement/poids.

La structure sandwich Focal-JMlab

Au milieu des années 80, la réponse apportée par Focal-JMlab pour allier légèreté, rigidité et

amortissement, a été “le sandwich Poly-K”. Il fait l’objet d’un brevet.

La rigidité est apportée par la structure sandwich de deux tissus de fibres aramides, placés de part et

d’autre d’une âme, constituée d’un mélange de résine et de microsphères creuses.

Par polymérisation, l’ensemble particulièrement léger est rigidifié, l’amortissement étant procuré par

les microsphères.

Depuis, une deuxième génération de structure sandwich a vu le jour.

Les principales évolutions que nous avons apportées concernent les microbilles de verre et la résine

que l’on a remplacées par des feuilles de mousse structurale. Cette mousse est utilisée principalement

en construction aéronautique ; aucune autre mousse n’atteint un rapport rigidité/masse aussi élevé.

Le sigle “W” signifie Verre-Verre, car il s’agit de deux feuilles de verre apposées de part et d’autre

du corps central en mousse. Le verre utilisé se présente sous forme d’un fin tissage de fibres

longues, qui offrent l’avantage sur les tissus en fibres aramides, d’une masse et d’une épaisseur

bien moindre.

De plus, la liaison moléculaire entre la résine et le verre est très supérieure à celle obtenue avec

les fibres aramides. La structure du cône est plus homogène et son comportement en flexion

très supérieur.

Ces caractéristiques uniques de légèreté alliées à la rigidité, permettent la maîtrise de la vitesse de

transmission du signal au sein du matériau.

L’intérêt du procédé est que l’on peut moduler l’épaisseur de la mousse pour contrôler très précisément

l’amortissement de la structure, plus l’épaisseur est élevée et plus grand est le facteur d’amortissement.

En jouant sur les épaisseurs des “peaux” de verre et de la couche de mousse structurale, une

multitude de solutions est offerte pour une optimisation du comportement de la membrane selon la

zone de fréquences à reproduire.

La membrane “W” procure une extrême transparence sonore due à une coloration inexistante,

un très faible taux de distorsion et une excellente réponse en phase.

Seule limitation, son coût, près de dix fois supérieur à celui d’une membrane papier.

Comparaison de l’indice de rigidité en flexion (exprimée en N.mm)

Performances du “W” : il surclasse de très loin les autres matériaux en

rigidité à la flexion à poids équivalent. De plus, son amortissement est

très supérieur.

Fabrication manuelle d'un cône "W". Le process industriel a été développé

par nos soins et fait l’objet d’un brevet.

La structure “W”: le corps central en mousse structurale est recouvert sur

ses deux faces par une feuille de verre.

17

Manuel d'utilisation ligne Utopia Be

Créer une source ponctuelle virtuelle capable de délivrer un son cohérent

sans altération spatiale de la scène sonore.

L'étendue du spectre sonore à restituer impose des contraintes physiques incontournables.

Pour s'en convaincre, il suffit de considérer les longueurs d'ondes à reproduire.

La longueur d'onde s'exprime par :

v est la vitesse du son dans l'air soit 340 m/s

f est la fréquence du signal à reproduire

Ainsi à 100 Hz la longueur d'onde

à 1 000 Hz la longueur d'onde λ = 34 cm

et à 10 000 Hz la longueur d'onde

La seule et unique solution pour reproduire fidèlement le message original est de fractionner la

reproduction en spécialisant des haut-parleurs dont le diamètre est en rapport avec les fréquences

qu'ils sont en charge de reproduire, afin d'obtenir une directivité constante en fonction de la fréquence.

Pour le grave, il serait illusoire, pour des raisons évidentes de dimensions, d'utiliser des diamètres de

l'ordre du mètre. La solution consiste à doubler la surface émissive en utilisant deux haut-parleurs de

grave. De plus, la directivité dans ce registre n'est pas critique compte-tenu des grandes longueurs

d'ondes des fréquences du registre de grave.

Cependant, cette multiplication des sources, si elle est légitime pour une reproduction fidèle de chacune

des zones de fréquence, pose un problème de cohérence : l’émission de chacun des haut-parleurs doit

parvenir à l'oreille de l'auditeur en même temps (simultanéité temporelle). Si le médium,

l'aigu ou le grave est capté en avance sur les autres registres, il y aura inévitablement une perception

déformée. Le respect du message original impose que chacune des fréquences parvienne à l'auditeur

dans le même temps, c'est-à-dire parfaitement en phase.

λ = v/f

λ = 3,4 m

λ = 3,4 cm

Focus Time

™

Sur une face avant classique, les divers haut-parleurs sont alignés verticalement.

La distance du centre émissif de chacun de ces haut-parleurs à l’oreille de

l’auditeur n’est pas identique.

Structure Focus Time : chacun des haut-parleurs est positionné sur un arc de

cercle ayant pour centre l’oreille de l’auditeur.

Le principe Focus Time

L'alignement sur une face avant plane de divers haut-parleurs va créer inévitablement une petite distorsion temporelle. L'aigu sera perçu en premier, suivi du médium et du grave. Certes, il est

possible de jouer sur le positionnement respectif des transducteurs pour pallier à ce défaut.

Néanmoins, il est évident que le tweeter qui émet les fréquences les plus courtes et donc les plus

directives, doit être placé dans l'axe de l'oreille de l'auditeur (à la même hauteur). Ainsi, pour que

les fréquences médium et grave arrivent en simultanéité temporelle avec l'aigu, les haut-parleurs

chargés de reproduire ces fréquences devront être idéalement positionnés sur un arc de cercle dont

le centre est situé au niveau de l'oreille de l'auditeur. C'est le principe du Focus Time, l'ensemble

des fréquences est focalisé sur l'auditeur et met le même temps pour parcourir la distance séparant le

haut-parleur et l'auditeur, cela pour les registres grave, médium et aigu.

Vers l'idéal de la source ponctuelle unique

Comme évoquée précédemment, l'idéal théorique de la source ponctuelle se heurte à des contraintes

physiques. Cela est d'autant plus vrai lorsque l'on intègre la notion de directivité des transducteurs

(voir filtre OPC) et la notion de reproduction de l'énergie dans le grave qui impose un déplacement

de la membrane d'autant plus important que le diamètre est faible.

La solution Focus Time apporte une solution pertinente à l'ensemble de ces contraintes en conciliant

cohérence temporelle et dynamique élevée. L'image sonore en final reste d'une stabilité exemplaire

quelle que soit l'amplitude du signal.

Il s'agit là de la solution la plus appropriée pour concilier simultanément les critères de timbre, de

dynamique et d’image sonore.

Vue en coupe de la Grande Utopia mettant clairement en évidence le

profil Focus Time.

18

Face avant structure "γ"

Manuel d'utilisation ligne Utopia Be

La structure de la face avant, le “baffle”, doit concilier inertie et amortissement

pour garantir respect de la dynamique et absence de coloration dans le grave.

Un haut-parleur est un transducteur. Son rôle consiste à mettre en vibrations les molécules d'air sous

l'impulsion d'une bobine couplée à une membrane. Les variations de courant électrique, réplique du

message musical, excitent la bobine qui, plongée dans le champ magnétique se déplace “en rythme” .

Il y a transformation de l'énergie électrique en énergie acoustique. Ceci est le principe. Dans la réalité,

pour que cette transformation soit la plus fidèle possible, il est fondamental que la membrane se déplace

par rapport à un châssis parfaitement immobile. Lorsque la membrane avance, le châssis ne doit pas

reculer, son accélération doit être nulle. Il doit constituer un référentiel mécanique totalement inerte.

L'inertie : une affaire de masse

Le châssis du haut-parleur est solidarisé solidement à la face avant de l'enceinte acoustique, le baffle.

Le rapport de masse entre l'équipage mobile (bobine plus membrane) et le bâti, (le châssis plus la face

avant) doit être le plus élevé possible.

C'est une application du principe fondamental de la dynamique : F = m ϒ.

L'accélération “ϒ” (gamma) prise par le châssis soumis à la force de recul “F” doit être nulle dans

l'idéal. En conséquence, la masse “m” doit être la plus élevée possible : elle doit tendre vers l'infini.

Il en ressort que, quelque soit le matériau choisi pour la réalisation de la face avant en terme de

rigidité, il serait illusoire de s'affranchir d'une masse élevée. En effet, on pourrait imaginer qu'une

face avant très amortie est la solution pour éliminer les vibrations parasites engendrées par “l'effet

de recul”. Ce serait négliger le rendu dynamique. Seule une masse élevée de support peut garantir le

respect des transitoires. L'amortissement ne peut se substituer à la masse.

™

À la force d’action A animant le cône, la face avant vient opposer une force

de réaction R d’égale amplitude.

Le couplage entre haut-parleurs

L'énergie la plus élevée se situe dans le registre grave. Les woofers induisent des vibrations dans la

face avant de l’enceinte qui vont interagir avec les haut-parleurs de médium et d’aigu et créer ainsi

des distorsions d’intermodulation, principalement dans l’aigu où l’amplitude de déplacement de

la membrane est particulièrement faible. Les micro-informations, gages d’une reproduction fidèle,

seront masquées.

La solution ultime retenue consiste à individualiser les coffrets de chacune des voies. La mise en

œuvre est complexe et coûteuse mais elle garantit un total découplage mécanique entre les voies.

La solution structure “ϒ”

La face avant “ϒ” mise en œuvre dans les Utopia Béryllium apporte une inertie très élevée pour

reproduire le rendu transitoire du grave avec tout son impact.

Réalisée dans une structure massive en MDF de 50 mm, la face avant participe à une masse très

élevée. Pour indication la masse de la Grande Utopia Béryllium atteint 210 kg alors que la version

95 pesait 186 kg. Celle-ci est donc intacte de toute vibration parasite. Le rapport de masse,

équipage mobile par rapport au châssis + coffret, dans une Utopia est plus de dix fois supérieur aux

solutions classiques habituellement mises en œuvre.

Un fonctionnement des woofers “en piston”

Le profil du dégagement arrière réalisé dans l'épaisseur de 50 mm apporte un autre avantage décisif.

Soigneusement calculé, il offre un véritable “guide d'onde” pour l’émission arrière des woofers.

Ainsi la membrane fonctionne en “piston” parfait, elle n'est pas contrainte par des ondes réfléchies

à l'intérieur du coffret qui viendraient l'impacter transversalement en créant des distorsions par effet

de torsion et/ou de roulis. Fonctionnant idéalement, la reproduction des woofers n'est pas affectée

par des distorsions issues de ces contraintes mécaniques.

Le gain à l'écoute

Tout l'intérêt de supprimer à la source l'émission des vibrations parasites est d’apporter un rendu

dynamique du grave exceptionnel. De plus, le coffret est moins sollicité et ainsi il est beaucoup

moins émissif. L'image sonore gagne en précision et les timbres sont plus différenciés du fait de

l'absence de coloration de coffret. Les registres médium et aigu sont, par conséquent, beaucoup plus

définis et transparents car les micro-informations sont restituées sans “effet de masque”.

La face avant à structure gamma, réalisée en MDF massif de 50 mm

d’épaisseur, constitue un référentiel mécanique idéal.

L'individualisation des coffrets est la solution ultime pour éviter le couplage

entre haut-parleurs.

➋

1

1

Les circuits magnétiques sont couplés mécaniquement avec les

tasseaux internes.

2

Le profil optimisé de la face avant offre un guidage parfait du cône,

il fonctionne en piston idéal. Il n’est pas affecté par les turbulences

de l’onde arrière.

19

Filtre OPC™ (filtre à phase optimisée)

Manuel d'utilisation ligne Utopia Be

Le filtrage est un élément clef dans la conception d'une enceinte acoustique.

Son rôle et sa mise au point sont complexes, la personnalité de l’enceinte en dépend.

Le rôle du filtre

Le filtre a pour fonction de répartir le signal en provenance de l'amplificateur entre les différentes

voies constituant l'enceinte acoustique : grave, médium et aigu.

La coupure la plus critique est sans aucun doute celle qui concerne le raccordement du médium

et de l’aigu. Un filtre passe-bas coupe la réponse dans les fréquences élevées du médium. Un filtre

passe-haut coupe la réponse dans les fréquences basses du tweeter. Dans la réalité le filtre est utilisé

également pour corriger les défauts de linéarité des haut-parleurs. Le raccordement (la coupure)

intervient généralement entre 2 000 Hz et 5 000 Hz. Un point fondamental est ici à prendre en

compte dans une reproduction de qualité : “la directivité”.

Le filtre passe haut et le filtre passe bas “calibrent” le signal électrique pour

alimenter les haut-parleurs de manière optimale.

La maîtrise de la directivité

Le diamètre d'un haut-parleur de médium est généralement compris entre 130 et 170 mm. De telles

dimensions correspondent à des longueurs d'ondes de fréquences comprises entre 2000 Hz et

2600 Hz. La directivité, c'est-à-dire l'angle d’émission dans lequel le haut-parleur va rayonner son

énergie, va se resserrer avec l’augmentation de la fréquence. Pour des fréquences dont la longueur

d'onde devient inférieure au diamètre, le haut-parleur va devenir directif, c’est-à-dire que l’énergie

dans cette zone de fréquence sera distribuée dans un cône, un angle solide, de plus en plus serré.

La puissance acoustique rayonnée n'est alors plus homogène. Il y aura subjectivement mise en avant

d’une partie du spectre. Pour éviter cette distorsion spatiale, il convient de couper le tweeter

suffisamment bas, ce qui est rendu possible par notre technique unique du tweeter à dôme inversé.

La maîtrise de la phase

Autre aspect très critique : le comportement en phase de l'ensemble haut-parleur et filtre dans la

zone de raccordement médium-aigu particulièrement critique au plan auditif. L'oreille est d'une

sensibilité extrême dans la zone 2 000 - 2 500 Hz. Le haut-parleur en charge du médium avec son

filtre associé doit avoir une réponse en amplitude et en phase qui est la “réplique miroir”,

“l'exacte symétrie” de la réponse du tweeter associé à son filtre. À ce niveau intervient donc le

critère de phase pour garantir la simultanéité temporelle de l'émission sonore à la fréquence de

raccordement : le médium et le tweeter doivent être en coïncidence parfaite. Pour cela, la différence

de phase entre le médium et son filtre associé, et le tweeter et son filtre associé, doit être nulle.

Ainsi, il y a fusion totale entre les deux sources d’émission à la fréquence de raccordement.

L’inversion de la phase de l’une des voies se traduira par un accident très marqué et parfaitement

symétrique à la coupure, preuve d’un raccord parfaitement maîtrisé.

La technologie OPC

Ces démarches constituent le fondement de la technologie OPC. Il serait illusoire de parvenir à

cet idéal en ne travaillant que sur le filtrage. La maîtrise totale de la réponse des transducteurs n’est

possible que pour les fabricants développant eux-mêmes leurs haut-parleurs comme c’est le cas pour

Focal-JMlab. Des transducteurs spécifiques sont conçus pour chaque nouveau développement.

On ne corrige pas électriquement un défaut mécanique.

Avec la technologie OPC, nous conjuguons ainsi des réponses offrant une atténuation effective de

36 dB/oct. pour les pentes des sections passe-bas et passe-haut, ceci avec une différence de phase

nulle entre ces deux sections. À l’écoute, cela se traduit par une grande cohérence de timbre due au

fait que la zone d’émission simultanée des deux transducteurs est très étroite en fréquence.