Page 1

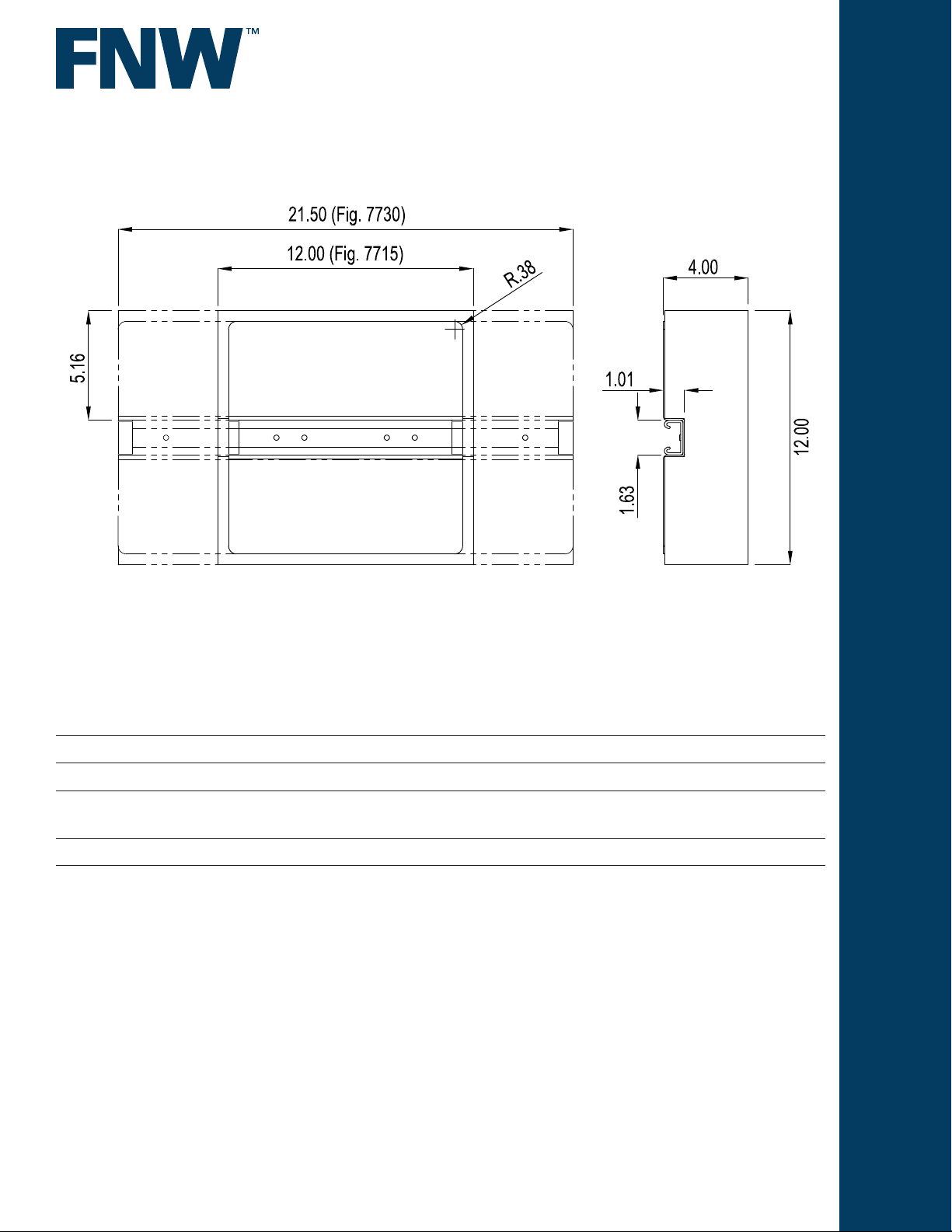

Figure 7715 & 7730

PIPING PRODUCTS

150# & 300# PIPE SUPPORTS

FNW gure 7715 and 7730 pipe

supports are designed and engineered

specically for rooftop and raised

oor applications. The patented*

pipe supports are made from closedcell polyethylene foam that is UV

and weather resistant, and include

a galvanized 13/16” strut channel

that is compatible with FNW strut

accessories. Sheet metal disperses

weight over the entire foam block for

increased capacity.

Features:

• Maximum Load

• 150 Lbs. (g. 7715)

• 300 Lbs. (g. 7730)

• Standard 4” Height

• Closed-Cell Medium Density

Black Polyethylene Foam

(Ethafoam® 400 plank **)

• 14 Gauge Galvaneal Sheet Metal

• 14 Gauge Strut Channel, ASTM

570 Gr 33 and ASTM A653 Carbon

Steel, Hot Dipped Mill Galvanized

• Hot Melt Adhesive-Bonding

Sheet Metal to Foam Block

(BONDMASTER INSTAWELD

34-3378)

* U.S. Patent No. 5,855,342

U.S. Patent No. 6,305,650

U.S. Patent No. 6,679,461

Other patents pending

** Ethafoam® is a registered trademark of

Sealed Air Corporation (US).

Part Number Height Width Depth Max. Load

FNW7715 4 12 12 150 lbs.

FNW7730 4 12 21-1/2 300 lbs.

Specications

www.fnw.com

Page 2

Figure 7715 & 7730

PIPING PRODUCTS

150# & 300# PIPE SUPPORTS

Components

Ethafoam® 400 plank - The polyethylene foam offers excellent strength, resistance to creep under loadings up to 5.0 psi,

vibration & shock absorbency and water resistance characteristics. Ethafoam HS 45 has successfully passed MVSS 302

ammability testing and meets or exceeds the requirements for U.S. Federal Standard PPP-C-1752C, T

Ethafoam® is a registered trademark of Sealed Air Corporation (US).

Physical Properties Test Method Direction Value

Density D3575, Sufx W, Method B N/A 3.9 pcf

Compression Set ASTM D 3575, Sufx B Vertical <15%

Compression Creep ASTM D 3575, Sufx BB Vertical <10%

@ 5.0 psi (1000 hr/72 F)

Thermal Stability ASTM D 3575, Sufx S N/A <1%

Water Absorption ASTM D 3575, Sufx L N/A <0.2 lb/sq ft

14 Gauge Strut Channel - The 14 gauge strut channel is cold roll-formed from high quality carbon steel. The channel nish

is hot dipped mill galvanized. The raw steel used conforms to ASTM 570 GR 33 and ASTM A653.

14 Gauge Galva Neal Sheet Metal - The 14 gauge sheet metal is hot-dipped zinc coated then brought up to and held at

temperature for a specic amount of time. This post-dip process causes the zinc to alloy with the surface iron in the steel to

produce a harder surface than galvanizing alone. The strut channel is welded to the formed sheet metal

BONDMASTER INSTAWELD 34-3378 - This adhesive is a sprayable heat & moisture-resistant hot melt adhesive. It has a

350°F melting point and is applied by a nozzle applicator during the manufacturing process. It conforms to MS-CC926.

ype III.

DOC: FNW7715-773010 Ver. 11/2010

© 2010 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while ef

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

fort has been made to ensure their accuracy, they are not to be construed as

Loading...

Loading...