Page 1

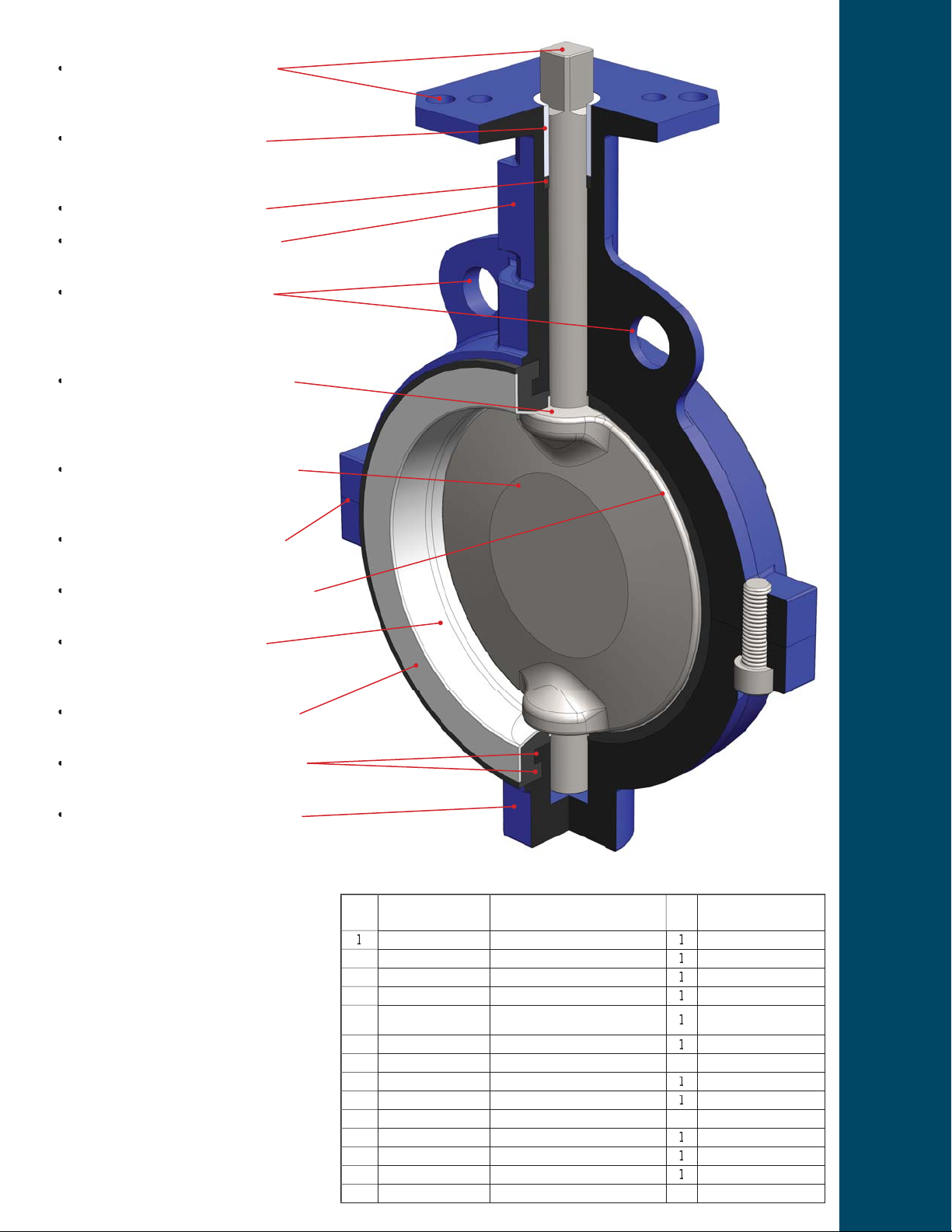

Figure 761 & 762

T

y

d

c

l

p

w

s

(Fig

)

*

g

)**

g

gn

1

BUTTERFLY VALVES

SPLIT BODY PTFE SEATED

BUTTERFLY VALVE

he fi gure 761/762 series valve is a

split bod

esigned for bubble tight service on

orrosive applications. The PTFE

ined seat and stainless steel disc/stem

rovide superior corrosion resistance, but

ith the economy of a cast iron body.

Features:

boot seated butterfl y valve

ated to 150 PSI

esigned for 125/150 Lbs Flange

ocating Flange Holes on All Wafer

Models

plit Body for Easy Maintenance

eavy-duty Square Groove Boot Seat

ockable Lever Handle

ug Bodies for Dead-End Service

ated to 75 PSI Without Downstream

lange

acuum Rated to 29.92”H

0.00075 Torr

hell Tested to 150% & Seat Tested to

10% of Maximum Working Pressure

wo Layer Epoxy/Polyurethane Body

oatin

ow Maintenance Desi

izes 2” to 12”

. 761

Fig. 762

Fig. 761

Standards:

esign: API 609

lange Connection: ANSI B16.5

esting: API 598

Mounting Pad: ISO 521

Dead-end service with downstream fl ange is rated to the valve’s full 150 PSI capacity.

Leakage rate not exceeding 1x10 cc/sec. Vacuum measurements are often made in inches of mercury

elow atmospheric pressure. The values calculated here assume standard atmospheric pressure of 29.92

nches of mercury.

www.fnw.com

Page 2

.

n

y

s

y

ON

y

ON

g

m

SS316 S

M

s

8

n

d

d

ON

"

Design Features:

w

n

f

n

n

y

stem

g

s

y

y

A

n

y

fi

g

-

g

fi

ISO 5211 actuator mounting pad

ith square stem for direct mounted

actuatio

eavy-duty polyacetal bushing

absorbs side load

ressure on the stem/disc

idirectional “U” cup stem seal

xtended neck accommodates 2”

iping insulatio

Wafer valves include two fl ange

ocating holes meeting ANSI B16.5 for

25/150 lbs fl anged for easy alignment

uring installatio

Precision machined wide radius on

upper and lower disc hubs provide a

superior primar

and

ingle-piece stainless steel disc and

stem provides corrosion resistance,

stren

th, and a thin profi le to fl ow

orces created by

seal between disc

eavy-duty cast iron split body for

ea

ier maintenance

isc edge and hubs are hand polished

or improved seal abilit

PTFE seat with EPDM backing

rovides corrosion resistance and seat

esilienc

resilient fl ange face acts as fl ange

asket for installatio

eady-duty square groove locks boot

seat in place

wo layer coating starting with Epoxy

inc Phosphate Primer followed by a

Pol

urethane top coat

Options:

NW offers many options and

modi

cations for valves. These include,

ut are not limited to: Actuation includin

hain wheels, square drive nuts, worm

ear operators, pneumatic and electric

perators, control accessories, stem

extensions, and custom mountin

ardware. Contact FNW with your

speci

c application needs.

ef.

o

ody Locating Pin

4

Standard Materials

Descriptio

pper Bod

ower Bod

tem Seal NITRILE

tem Bushin

isc / Ste

eat PTFE LINED EPD

top Plate

ever

ody Screw

ever Bolt

ear Operator

andwheel

ear Mtg Bolt

ASTM A126 Gr. B CAST IR

ASTM A126 Gr. B CAST IR

ASTM A351 CF8M /

ARBON STEEL ZINC PLATED

Material

POLYACETAL

TAINLESS STEEL

ARBON STEEL En

ARBON STEEL

4SS STAINLESS STEEL

ARBON STEEL

AST IR

ARBON STEEL

ARBON STEEL

t

H

Remark

inc Plated, Not Show

inc Plate

"~6", Powder Coated

inc Plate

"~12

"~12", Fabricated

"~12", Zinc Plated

Page 3

14

e

1H2

V

y

g

C)

C

51.63

63.23.39.15.76.39.56.43

1.75

95.95.98.63

3.39.15.76.39.56.43

1.50.35.35.30.63

3.39.15.76.39.56.43

1.00

09.75.20

01.23.39.15.76.39.71.55

1.50

80

56.81.5

85.45.9

67

0.50.31.31.07.81.5

85.45.9

67

0.50.69.69.49.9

9.8

01.9

5

0

5.07.87.75.9

87.78.55

81.87.49

01.9

87"-9

5

99

06"-9

00

E

*

)

Wt (Lbs)

(

)

g

3

9

9.0

9.0

07.516.1.8

57.6

3

8

3.0

0

116.5

X

E

OR

S

R

)

)

)

y.

L2

16

4

13

HxN

H2

3

on

1

C b.c.

6

15

H1

7

2

L1

WAFER

LUG

L

V

17 18

T

G1

H4

H3

G2

19

GEAR-OP (8"~12")

Dimensions (inches)

iz

-1/2

Dimension “L” represents the approximate uncompressed, pre-installation seat width. Actual dimension can var

H

Wafer Lu

.76.76.

.

.13.09.

.

2

.26.062.24

.72

H3H4L*L1L2øG1

.22

.81.

.22

.93.75.2

.22

.93.75.2

.24

.

.

4

4

.14

4

.36.15.

4

.36.15.

.52

.78.4

.

.11.25.

4

.84

.49.72

11.

7.71.19.49.72

øQ1øQ2øS1øS2ø

4

.76.01.39.47.87.

4

.76.01.39.47.87.

.

.72

.

P

TOPWORKS

2

.47.55.99.7

2

.47.55.11.

.92

2"~4" & 12"

.55.43.

5" & 6"

8" & 10"

øH (UN

Lug Onl

"-1

"-1

"-1

"-1

4"-1

4"-1

4"-1

H4

Q2

S2

Q2

Q1

S1

S2

Q2

Q1

S1

S2

ø

1.7

2

4.2

2

7.

Figure Number Matrix

F N W 7 6

DY TYP

WAFE

EAT

PTFE (EPDM

ACKER

PERAT

LANK0 POSITION LEVER (2”-6”

EAP OPERATOR (8”-12”

Note: Torques listed are for maximum pressure

ifferential on wet, lubricating services. An application

specifi c safety factor adder is recommended for

actuation.

IZE CODE

-1/2

2

2

Torque & Weight

orque

IZ

in-lbs

-1/2

3,385

2

Wafer

4

12.

,084 18.

,11

,10

.2

.

.

2.2

.

.

.

2.

Page 4

Figure 761 & 762

E

G

0°

0

7

7

7

5

8

346

7

0

6

8

3

8

7

1

8

1

9

1

BUTTERFLY VALVES

SPLIT BODY PTFE SEATED

BUTTERFLY VALVE

Cv (Flow Coeffi cient)

IZ

”

-1/2”

”

”

”

”

”

”

2”

v is the volume of water in U.S. gallons per minute that passes through the valve at a pressure drop of 1 PSI at 68°F.

utterfl y valves used for throttling service is limited to a maximum pressure drop of 20% of the inlet pressure at maximum open position.

Recommended control angles are between 25° and 70°. Preferred angle for control valve sizing is 60° to 65° open.

2

2

4

1

DEGREES of DISC OPENIN

4

4

2

42

2

4

,32

1

7

22

,552

,425

,136 3,66

,45

2

7

4

,19

,36

3,77

,60

2

2

24

,14

,454

,76

,525

6,73

150

125

100

75

Pressure (PSIG)

50

25

0 13 100 150 200 266

PTFE Lined EPDM Seat

Temperature (°F)

30050

DOC: FNWBFV761-76212 Ver. 3/2013

© 2013 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specifi cations of our products at any time without notice. Always

verify that you have the most recent product specifi cations or other documentation prior to the installation of these products.

Loading...

Loading...