Page 1

Figure 6701

KNIFE GATE VALVES

STAINLESS WETTED PARTS UNIDIRECTIONAL

METAL SEATED KNIFE GATE VALVE

The gure 6701 is a stainless steel wetted parts by carbon

steel and iron topworks. This con guration provides a more

economical knife gate solution without sacri cing the ruggedness

and corrosion resistance needed for harsh applications. It

is designed for the pulp and paper, chemical, mining, power,

petroleum, and food process industries, as well as municipal

water and waste treatment plants. It is ideal for handling dense

mixtures of stock and slurries with unidirectional shut-off. The

shearing action of the knife gate cuts through solids and cleans

the seat as it closes.

Features

• Unidirectional Shutoff

• Maximum Pressure: 150 PSI CWP (30” to 100 PSI CWP)

• Maximum Temperature: 446°F (230°C)

• Cast Stainless Steel Body and Packing Gland

• Zinc Plated Carbon Steel Hardware

• Machined Gland Pocket Area

• Bonnetless, Outside Screw & Yoke

• Rising Stem

• Smooth Flow, Non-Clogging Step Seat Design

• Cast Iron Hand Wheel

• Gear-Operator Standard on 30” Valve

• Available in sizes 3” to 30”

• Standard design accommodates locking device

Standards

• Design: MSS SP-81

• Flange Drilling: ANSI B16.5

(30” to MSS SP-44 Flanges)

• Seat/Shell Test: MSS SP-81

• Material: ASME B16.34

CALIFORNIA PROP 65 WARNING:

• This product contains lead or lead compounds known to

the State of California to cause cancer and birth defects

and other reproductive harm. Do not use in connection

with drinking water. Wash hands after handling.

Figure Number Matrix

FNW 6701 Seat Size

SEAT CODE

Stainless Steel = S

(Integral)

3 = M

4 = P

6 = U

8 = X

SIZE CODE

10 = 10

12 = 12

14 = 14

16 = 16

18 = 18

20 = 20

24 = 24

30 = 30

Cv & Weight

Size Cv Wt (Lbs)

3 565 20

4 1,040 31

6 2,440 51

8 4,460 75

10 6,250 128

12 9,400 163

Weights are for general reference only.

Size Cv Wt (Lbs)

14 12,500 243

16 16,500 309

18 21,400 386

20 27,000 463

24 39,700 540

30 60,000 992

www.fnw.com

Page 2

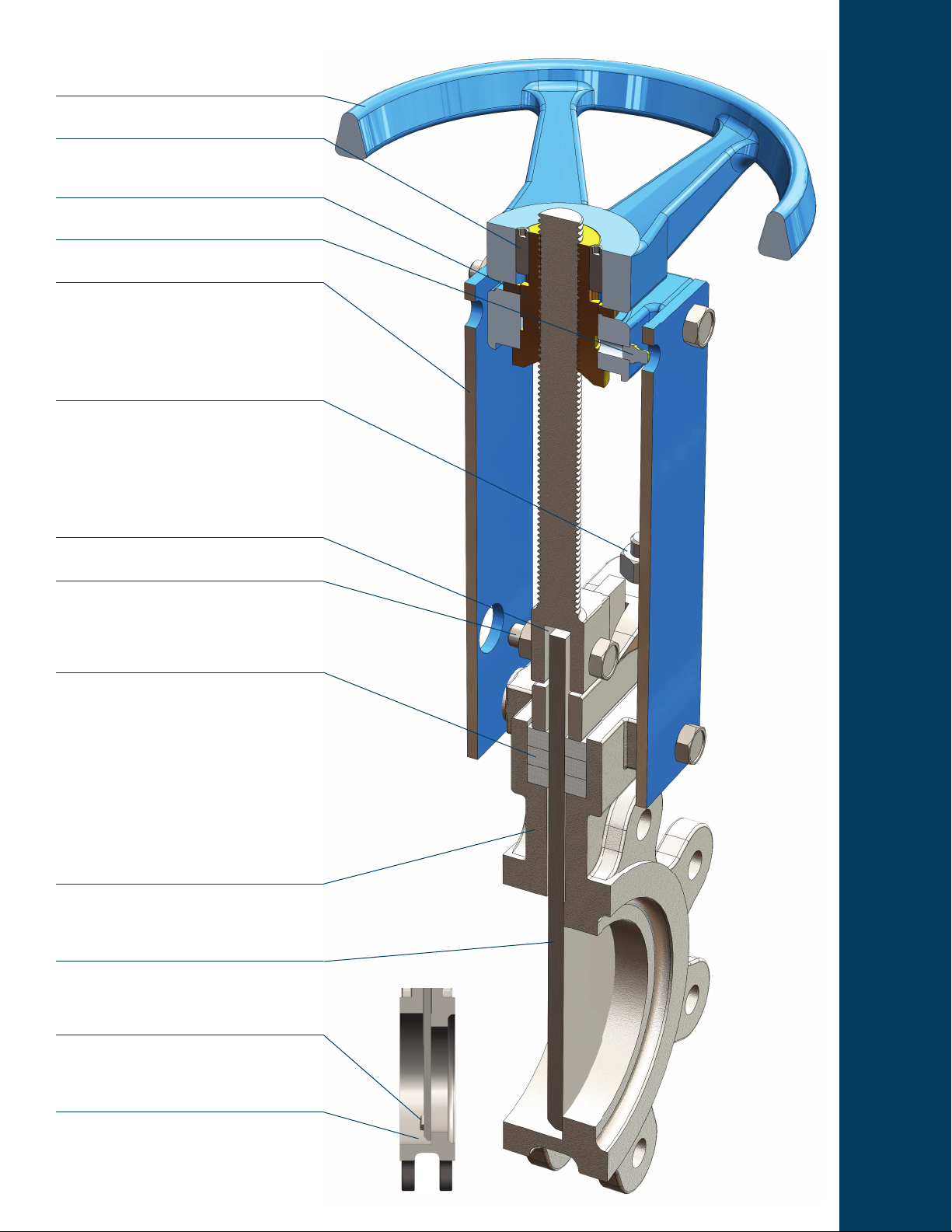

Hand wheel is heavy cast iron, with a rounded grip

and epoxy coated hand wheel.

Double set screws prevent threaded-on hand

wheel from backing off or coming loose.

Aluminum-Bronze thrust components for antigalling operation.

Grease tting for maintaining smooth drive sleeve

operation.

Carbon steel plate yoke arms provide economy

without sacri cing strength and are epoxy coated.

All nuts and bolts are carbon steel grade B7 or 2H.

FEATURES

Stem-to-gate clevis is deliberately loose to allow

play in gate to minimize binding.

Horizontal clevis bolts provide fl exibility of the gate

during travel.

Multiple layers of PTFE impregnated square braid

packing provides excellent gland sealing at full

valve pressure differential.

The single piece cast all stainless steel body is

rugged and compact. It offers better leak tightness

than fabricated or two-piece designs.

The gate is high-quality, ground- nished stainless

steel. A generous gate thickness, well supported

by the packing, resists distortion or defl ection and

is less likely to bend in severe conditions.

Gate wedges located in the body aid the nal gate/

seat sealing with a non-sliding motion.

A stepped seating design keeps the upstream

area clear. There is no dead pocket space in the

bottom of the body where suspeded solids/media

can collect.

Page 3

Standard Materials

Ref.

Description Material Qty

No.

1 Body

1A

10 Yoke Bolt

11 Stem

12 Clevis Bolt

Seat

(Integral)

2 Gate

3 Packing PTFE Impregnated Syntex Fiber

6 Gland

7 Gland Bolt

8 Gland Nut

9 Yoke Arm

Stainless Steel, ASTM A351 Gr.

CF8M

Stainless Steel, ASTM A351 Gr.

CF8M

Stainless Steel, ASTM A240 Type

316

Stainless Steel, ASTM A351

Gr.CF8

Zinc Plated Carbon Steel,

ASTM A193 Gr. B7

Zinc Plated Carbon Steel,

ASTM A194 Gr. 2H

Carbon Steel,

ASTM A36

Zinc Plated Carbon Steel,

ASTM A193 Gr. B7

Stainless Steel, ASTM A276 Type

304

Zinc Plated Carbon Steel,

ASTM A193 Gr. B7

1

1

1

3 (3”~18”)

3 (20” & 30”)

1

2~10

2~10

2

4

1

2

13 Clevis Nut

14 Collar

15 Collar Bolt

16 Collar Nut

17 Hand Wheel Cast Iron, ASTM A126 Gr. B 1

18 Yoke Sleeve

Thrust

19

Washer

20 Set Screws Stainless Steel, 304SS 2

30

Gear

Operator

Zinc Plated Carbon Steel,

ASTM A194 Gr. 2H

Ductile Iron,

ASTM A536 Gr. 65-45-12

Zinc Plated Carbon Steel,

ASTM A193 Gr. B7

Zinc Plated Carbon Steel,

ASTM A194 Gr. 2H

Aluminum Bronze,

ASTM B148, UNS C95200

Aluminum Bronze,

ASTM B150, UNS C62300

Enclosed Type,

Model BG02 (Not shown)

2 (2”~8”)

4 (10”~24”)

2 (2”~8” only)

1 (30” only)

2

1

1

1

Page 4

Figure 6701

KNIFE GATE VALVES

STAINLESS WETTED PARTS UNIDIRECTIONAL

METAL SEATED KNIFE GATE VALVE

Dimensions (inches)

Size A B C D E F G H J K N S

3 2.00 6.00 5.00 15.55 17.72 7.99 2 5/8” 0.37 2 2.95 0.47

4 2.00 7.50 6.18 17.52 20.67 7.99 2 5/8” 0.37 6 4.00 0.47

6 2.25 9.50 8.50 20.87 25.98 10.00 2 3/4” 0.43 6 6.00 0.57

8 2.75 11.75 10.63 25.00 31.89 12.01 2 3/4” 0.43 6 8.00 0.57

10 2.75 14.25 12.76 27.56 37.40 15.98 4 7/8” 0.43 8 9.37 0.69

12 3.00 17.00 14.76 30.51 42.72 15.98 4 7/8” 0.43 8 11.42 0.69

14 3.00 18.75 16.26 32.68 47.05 20.00 4 1” 0.51 8 12.76 0.75

16 3.50 21.25 18.50 36.81 52.17 20.00 6 1” 0.67 10 14.57 0.87

18 3.50 22.75 21.00 41.34 59.25 20.00 6 1-1/8” 0.67 10 16.93 0.94

20 4.50 25.00 22.99 46.06 65.35 20.00 8 1-1/8” 0.91 12 18.50 0.98

24 4.50 29.50 27.24 53.54 77.17 20.00 8 1-1/4” 0.91 12 22.64 0.98

30 4.62 36.00 33.75 73.20* 100.40 19.68 10 1-1/4” 0.82 18 27.08 1.12

* Dimension “D” for 30” valve is centerline of valve to centerline of gear-operator hand wheel shaft.

DOC: FNW670113 Ver. 8/2014

© 2014 - FNW. All rights reserved. 22038

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...