Page 1

Figure 61B

KNIFE GATE VALVES

STAINLESS STEEL LINED

METAL SEATED KNIFE GATE VALVE

The gure 61B is a lined valve with the economy of a ductile

iron body and the corrosion resistance of all stainless steel

wetted parts. The 61B is designed for pulp and paper,

chemicals, mining and petroleum industries to handle dense

mixtures of stock and slurries. The shearing action of the

knife gate cuts through solids and cleans the seat as it closes.

Features:

• Unidirectional Shutoff

• Stainless Steel Lined Ductile Iron Body

• Thrust Ball Bearing Yoke Bushing (18” & Larger)

• Cast Iron Handwheel

• Bonnetless, Outside Screw & Yoke

• Rising Stem

• Corrosion Resistant Stainless Impregnated Coating

• Meets MSS SP-81 Specication for 150 PSI CWP

• Smooth Flow, Non-clogging Step Seat Design

• Available in sizes from 3” to 24”

Unidirectional

Metal Seated

Standards:

• Design: MSS SP-81

• Flange Drilling: ANSI B16.5

• Seat/Shell Test: MSS SP-81

Stainless Steel Lined

www.fnw.com

Page 2

Options

FNW Valve Company offers many options and

modications for valves. These include, but are

not limited to:

• Actuation including ratchets, chain wheels,

AWWA nuts, gear-operators, pneumatic &

hydraulic cylinders, and electric actuators

• Packing options for pH and temperature

requirements

• Back seat stops for low ΔP or reverse operation

applications, or to prevent knife blade deection.

• V-ports for reduced plugging in metering

applications

• Stem extensions in carbon and stainless steel

• Conversion to non-rising stem (NRS)

• Deection cones in Ni-Hard and HDPE for added

seat and gate protection in abrasive services

• Flush ports to clear suspended matter from the

valve chest or seat pocket area

• Quick opening levers

• Gate scraper

Contact FNW for knife gate valve options.

Packing Options

Type

PTFE Impregnated Fiber (Standard) 425ºF

Pure TFE 425ºF

TFE Fiber (Ultra) 500ºF

Graphite Filament Yarn 1000ºF

Temperature

Limit

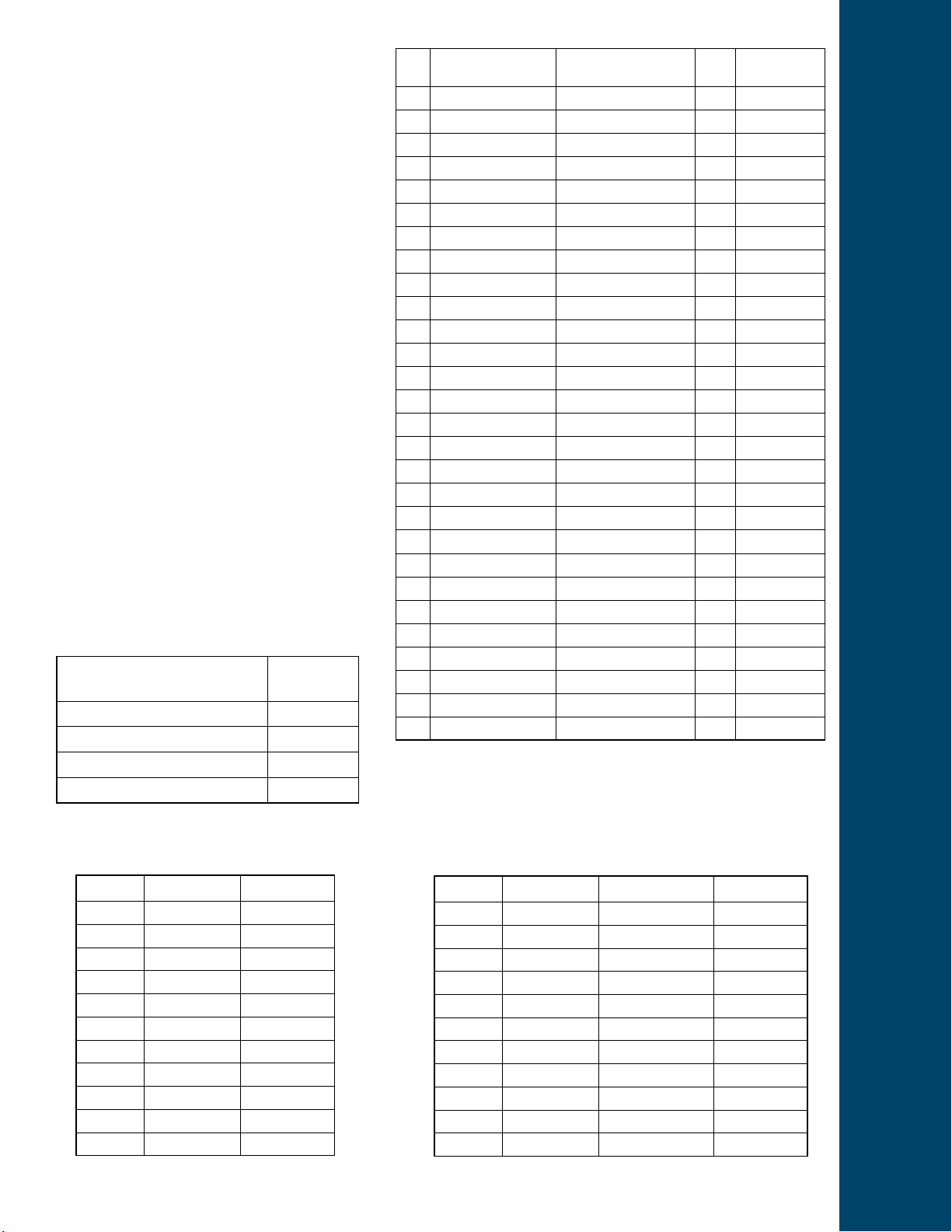

Standard Materials

Ref.

No.

1 Body Ductile Iron 1

2 Knife A240 316 1

3 Yoke A216 WCB 1

4 Stem A276 410 1

5 Body Seat Ring A240 316 1 Welding

6 Packing PTFE Impregnated Fiber 1 Set Non-Asbestos

7 Packing Gland A216 WCB 1

8-1 Gland Bolt STEEL 1 Set

8-2 Gland Nut STEEL 1 Set Nylon Lock Nut

9-1 Yoke Bolt STEEL 4

9-2 Yoke Nut STEEL 4

10-1 Clevis Bolt A193 B8 2

10-2 Clevis Nut A194 8 2 Nylon Lock Nut

11 Yoke Sleeve BRASS 1

12 Thrust Washer BRASS 1

13 Hand Wheel A338 1

14 Name Plate ALUMINUM 1

15 Lock Washer A240 304 1

16 Wheel Nut BRASS, STEEL 1

17 Bottom Stopper A240 316 2 Welding

18 Rivet ALUMINUM 2

19 Grease Nipple ASS’Y 1

20 Bearing Housing A216 WCB 1

21 Thrust Ball Bearing ASS’Y 2 18” And Larger

22 Bearing Gland A216 WCB 1 Tack Weld

23-1 Bearing Housing Bolt STEEL 4

23-2 Bearing Housing Nut STEEL 4

24 Body Liner A240 316 1 Set Welding

Description Material Qty Remarks

Torque

Size DN Torque

3 80 39

4 100 52

6 150 78

8 200 91

10 250 104

12 300 117

14 350 136

16 400 156

18 450 208

20 500 234

24 600 273

Flow Coefcients, Port Areas, & Weights

Size Cv Port Area (in²) Wt. (Lbs)

3 240 5.64 24

4 430 9.84 35

6 1,010 23.15 57

8 1,830 42.06 86

10 2,890 66.59 128

12 4,200 96.72 169

14 5,510 127.01 223

16 6,920 159.4 295

18 8,960 206.52 363

20 11,270 259.74 557

24 16,270 374.78 671

Page 3

Dimensions (inches)

Size L Ød ØG ØC N

3 2.00 2.68 5.00 6.00 4 5/8"-11 0.236 7.09 15.75

4 2.00 3.54 6.18 7.50 8 5/8"-11 0.276 7.87 18.90

6 2.25 5.43 8.50 9.50 8 3/4"-10 0.315 9.84 24.41

8 2.75 7.32 10.63 11.75 8 3/4"-10 0.315 11.81 31.50

10 2.75 9.21 12.76 14.25 12 7/8"-9 0.394 13.78 37.80

12 3.00 11.10 15.00 17.00 12 7/8"-9 0.394 15.75 43.31

14 3.00 12.72 16.26 18.75 12 1"-8 0.472 17.72 48.82

16 3.50 14.25 18.50 21.25 16 1"-8 0.472 19.69 53.94

18 3.50 16.22 20.98 22.75 16 1-1/8”-7 0.472 19.69 60.24

20 4.50 18.19 22.99 25.00 20 1-1/8”-7 0.591 21.65 67.72

24 4.50 21.85 27.24 29.50 20 1-1/4”-7 0.591 21.65 79.13

NC

P T ØW H

Figure Number Matrix

FNW 61 B Size

SIZE CODE

3 = M

4 = P

6 = U

8 = X

10 = 10

12 = 12

14 = 14

16 = 16

18 = 18

20 = 20

24 = 24

Page 4

Figure 61B

KNIFE GATE VALVES

STAINLESS STEEL LINED

METAL SEATED KNIFE GATE VALVE

DOC: FNW61B05 Ver. 1/2018

© 2018 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...