Page 1

Figure 420

BRASS BODY BALL VALVES

2 PC FULL PORT 600 WOG

Features:

• Threaded Connection

• 600 WOG

• 150 WSP

• Full Port

• Threaded NPT Ends (ANSI B1.20.1)

• Forged Brass Body & EndCap

• 100% Electronically Tested in Open &

Closed Position at 80 PSI

• Meets MSS SP-110 Standards

• FM, UL & CSA Approved

(See Approval List Below)

• Blow-out Proof Stem

• Adjustable Packing

• Stocked Congurations:

○ Locking Handle (1/4”~2”)

○ Stainless Steel Ball & Stem

(Includes Locking Handle) (1/4”~2”)

• Optional Lock Lever Kit (1/4”~4”)

• Optional Stem Extension Kit (1/4”~4”)

• Optional Tee Handle Kit (1/4”~1”)

• Optional Oval Handle Kit (1/4”~2”)

• Optional Memory Stop Kit (1/4”~2”)

• Optional Stainless Handle (1/4”~2”)

Locking Handle Kits Stem

Accessories

Tee Handle Kits

Extension Kits

Additional Stocked Congurations

Oval Handle Kits

Memory

Stops

Stainless Steel

Handle

NOT FOR USE AT OR BELOW GROUND LEVEL

Figure Number Matrix

FNW 420 Conguration Size

CONFIGURATION CODE

Standard Handle = Blank

Locking Handle = LL

(1/4”~2”) =

SS Ball & Stem = SSLL

w/Locking Handle =

(1/4”~2”) =

SIZE CODE

1/4 = B

3/8 = C

1/2 = D

3/4 = F

1 = G

1-1/4 = H

1-1/2 = J

2 = K

2-1/2 = L

3 = M

4 = P

Kit Codes (Order Separately)

FNW 420 Kit Size

KIT TYPE

Locking Handle = LHK

Stem Extension = SE

Tee Handle = THK

Oval Handle = OHK

Memory Stop = MSK

Stainless Handle = SSHK

SIZE CODE

1/4”~1/2” = BD

3/4”~1” = FG

1-1/4”~1-1/2” = HJ

2” = K

2-1/2”~3” = LM

4” = P

With Locking Handle (1/4”~2”)

Up to 2” 1/4” ~ 4”

With Stainless Steel Ball & Stem (1/4”~2”)

(Includes Locking Lever)

See Below

Gas Approvals

• CSA Class 3371-10, CGA 3.16, 125 PSIG, -40°F~149°F (1/4”~4”)

• CSA Class 3371-88, ANSI Z21.15/CSA9.1, 1/2 PSIG, 32°F~188.6°F (1/2”~4”)

• CSA Class 3371-90, ASME B16.33/b16.38, 125 PSIG, -40°F~149°F (1/4”~4”)

• CSA Class 3371-92, ASME B16.44, 5 PSIG, -40°F~149°F (1/2”~2”)

• CSA Class 3371-94, ASME B16.33, 125 PSIG, -40°F~149°F (1/2”~4”)

• CSA Class 3371-97, UL-125, 250 PSIG, -40°F~130°F (1/4”~3/8”)

• UL Class YRPV, ANSI/UL-842, 250 PSIG, -20°F~125°F (1/4”~4”)

• UL Class YSDT, ANSI/UL-125, 250 PSIG, -40°F~130°F (1/4”~4”)

www.fnw.com

Page 2

BRASS BODY BALL VALVES

2 PC FULL PORT 600 WOG

Figure 420

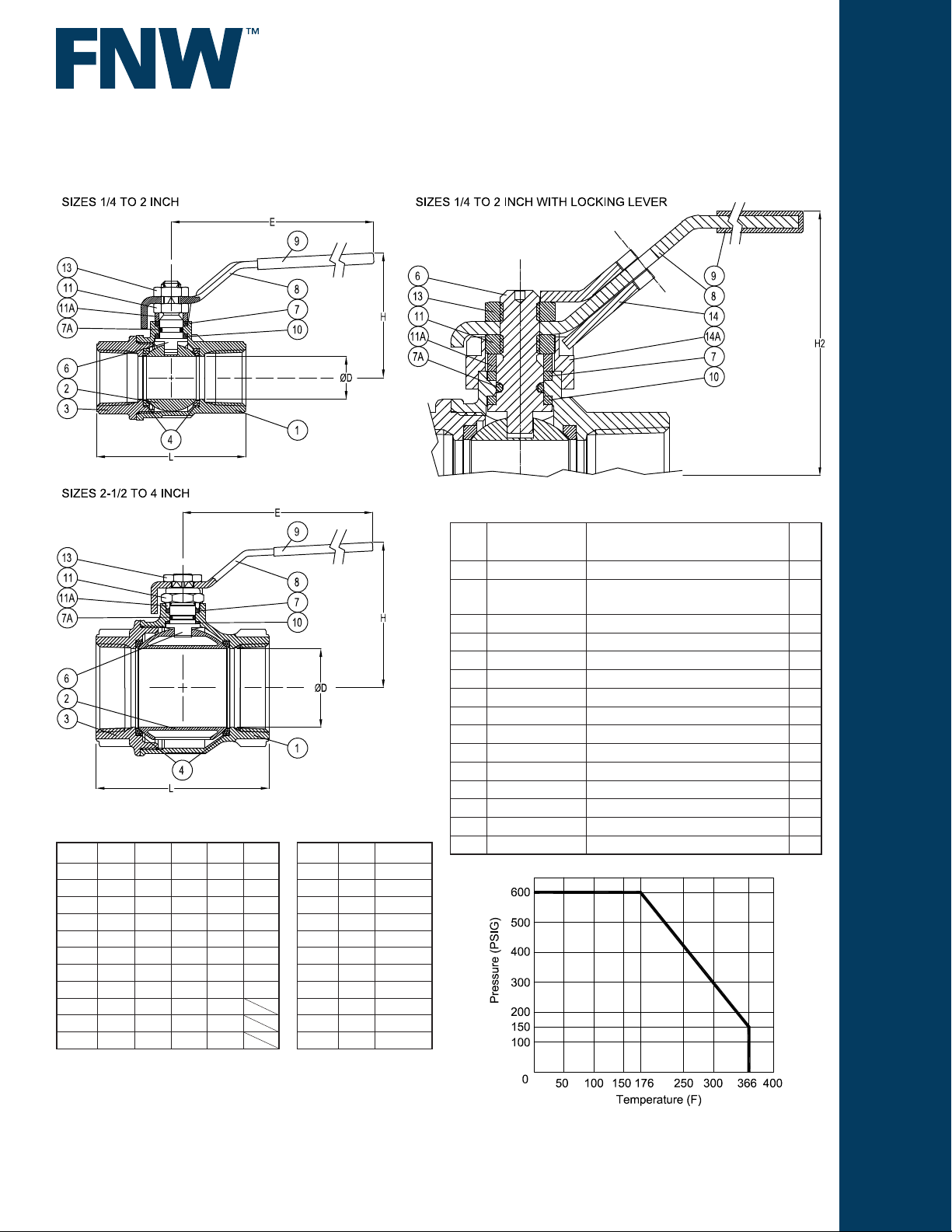

Dimensions (inches)

Size ØD E L H H2

1/4 0.39 3.78 2.02 1.65 1.83

3/8 0.39 3.78 2.02 1.65 1.83

1/2 0.59 3.78 2.44 1.81 1.99

3/4 0.78 4.76 2.71 2.28 2.48

1 0.98 4.76 3.07 2.44 2.64

1-1/4 1.25 5.94 3.42 3.00 3.15

1-1/2 1.57 5.94 3.89 3.23 3.38

2 1.94 6.30 4.33 3.74

2-1/2 2.56 8.11 5.59 4.84

3 3.15 8.11 6.45 5.23

4 3.94 10.27 7.60 6.49

3.74

Cv & Weights

Size Cv Wt. (Lbs)

1/4 6 0.3

3/8 7 0.3

1/2 19 0.5

3/4 34 0.7

1 50 1.1

1-1/4 104 2.0

1-1/2 268 3.1

2 309 4.2

2-1/2 629 8.0

3 1018 12.9

4 1622 22.0

Standard Materials

Ref.

14A Bushing ZAMA G Zn A14 UNI EN1774 1

Description Material Qty

No.

1 Body Brass CW 617N UNI EN 12165 1

2 Ball

3 End Cap Brass CW 617N UNI EN 12165 1

4 Seat PTFE 2

6 Stem Brass CW 614N UNI EN 12164 1

7 Stem Packing PTFE 1

7A Stem O-ring NBR 75 Shore A 1

8 Handle Fe P 11 UNI 5867 1

9 Handle Cover Vinyl 1

10 Thrust Washer PTFE 1

11 Gland Nut Zinc Plated Steel 6S 1

11A Packing Gland Brass CW 614N UNI EN 12164 1

13 Handle Nut Zinc Plated Steel 6S 1

14 Locking Pad Fe P 11 UNI EN 10111 1

Brass CW 617N UNI EN 12165

(Nickel-Chrome Plated)

1

DOC: FNWBV420SSLL07 Ver. 11/2013

© 2013 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...