Page 1

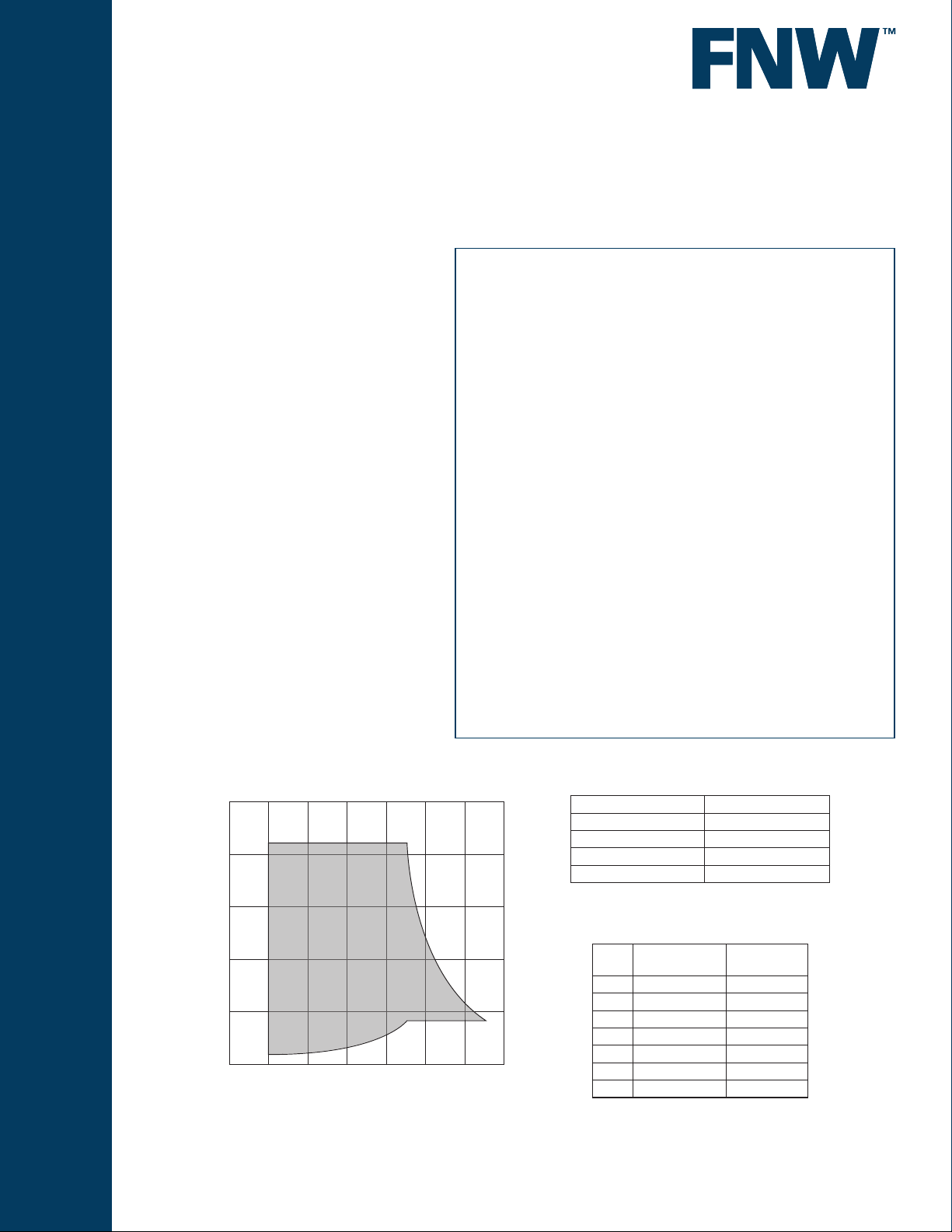

Figure 40

FLEXIBLE CONNECTORS

SINGLE SPHERE

FLEXIBLE CONNECTOR

Flexible connectors are used to absorb thermal and seismic

movement, absorb hydraulic shock, provide vibration and

noise dampening, ease installation and correct minor

misalignment of piping and components. They come

in a variety of sizes, materials, and connection ends for

numerous applications.

Similar to the metal exible connectors in application

advantages, single sphere exible connectors are suitable

for pressure and vacuum services. The spherical shape

is stronger than cylindrical elastomer connectors and

disperses pressure evenly over a larger surface area. The

streamline shape also reduces turbulence and sediment

build-up and lessens deformation while under pressure. The

elastomer allows greater movements in the axial, elongation,

lateral, and angular directions and provides a wide service

range due to its chemical resistance characteristics.

Pressure / Temperature*

290

232

145

Pressure (PSI)

72

0

25.59”Hg

-4 32 68 104 140 176 194

-40

Temperature (°F)

* Figure 40 should not be used at the maximum working pressure

and working temperature at the same time.

www.fnw.com

Ratings

Max. Working Pressure 232 PSI

Test Pressure 348 PSI

Burst Pressure @ 80°F 850 PSI

Vacuum Rating 25.59”Hg (650 Torr)

Operating Temperature -4°F to 194°F

Part Numbers & Weight

Size Part Number

2-1/2 FNW40L 14.74

3 FNW40M 16.50

4 FNW40P 18.26

5 FNW40S 23.98

6 FNW40U 31.68

8 FNW40x 42.24

10 FNW4010 55.00

Approx. Wt

(Lbs)

Page 2

FLEXIBLE CONNECTORS

SINGLE SPHERE

FLEXIBLE CONNECTOR

Braid Limits

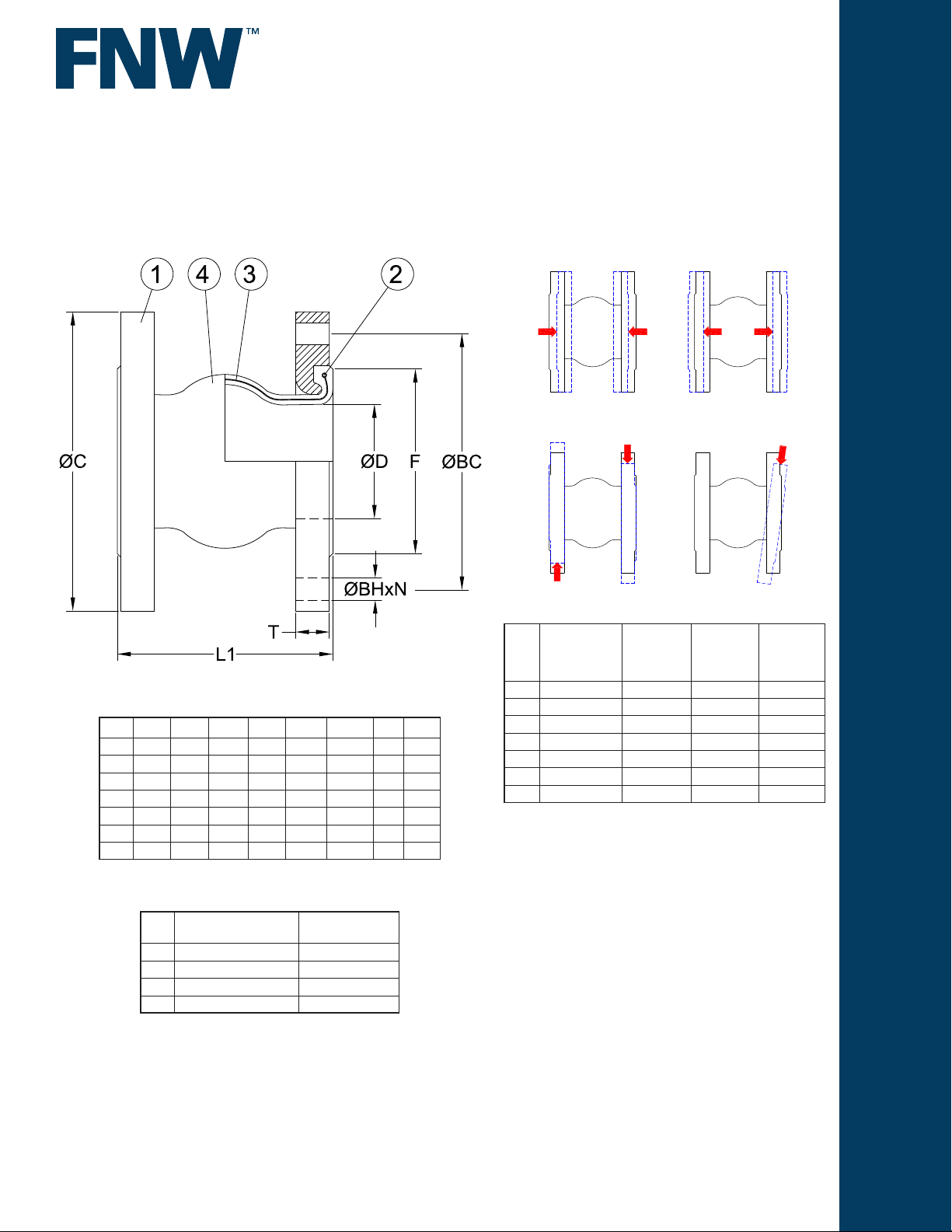

Figure 40

Dimensions (inches)

Size ØC ØD F L1 ØBC ØBH N T

2-1/2 7.0 2.68 4.17 6.0 5.50 0.75 4 0.71

3 7.5 2.99 4.57 6.0 6.00 0.75 4 0.71

4 9.0 4.06 5.91 6.0 7.50 0.75 8 0.71

5 10.0 5.04 7.09 6.0 8.50 0.87 8 0.79

6 11.0 5.98 8.23 6.0 9.50 0.87 8 .87

8 13.5 7.64 10.24 6.0 11.75 0.87 8 .87

10 16.0 9.84 12.60 8.0 14.25 1.00 12 .94

Axial Compression

Transverse Movement

Maximum

Size

2-1/2 0.500” 0.375” 0.50” 15°

3 0.500” 0.375” 0.50” 15°

4 0.625” 0.375” 0.50” 15°

5 0.625” 0.375” 0.50” 15°

6 0.625” 0.375” 0.50” 15°

8 0.625” 0.375” 0.50” 15°

10 0.625” 0.500” 0.75” 15°

Axial

Compression

Maximum

Axial

Elongation

Axial Elongation

Angular Deection

Maximum

Transverse

Movement

Maximum

Angular

Deection

Standard Materials

Ref.

No.

1 Flange Carbon Steel

2 Reinforcement Wire Carbon Steel

3 Reinforcement Fabric Synthetic Fiber

4 Elastomer Sleeve EPDM

DOC: FNW4005 Ver. 3/2012

© 2012 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while ef

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Description Material

fort has been made to ensure their accuracy, they are not to be construed as

Loading...

Loading...