Page 1

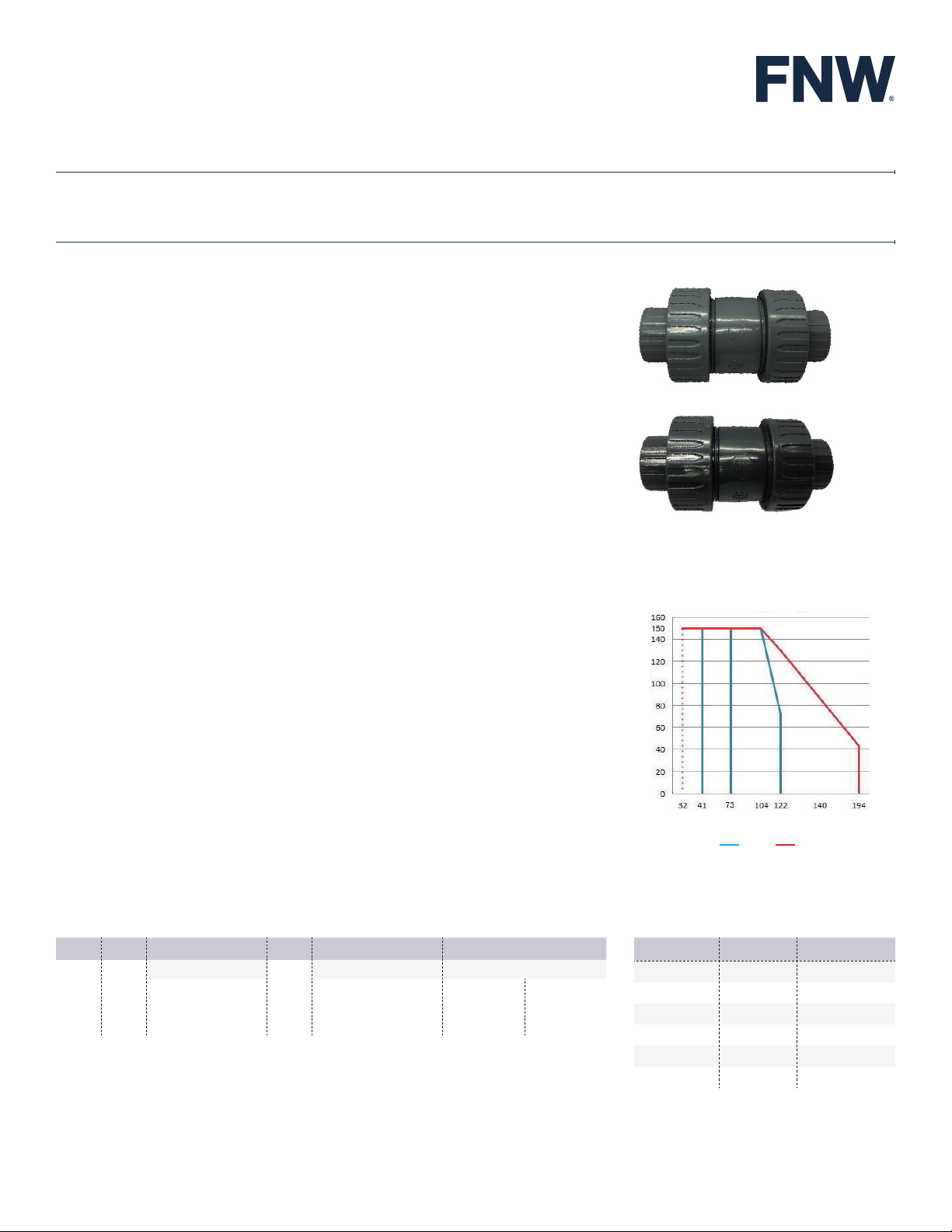

FIGURE 345A, 355A

PVC

160

CPVC

Pressure (psi)

THERMOPLASTIC VALVES

TRUEUNION BALL CHECK VALVE

FIGURE 345A PVC WITH NPT AND SW ENDS

FIGURE 355A CPVC WITH NPT AND SW ENDS

FEATURES

• Pressure Rating: 150 PSI @ 73°F

• 5 PSI minimum shuto

• Temperature Range:

• PVC: 41°F–122°F (5°C–50°C)

• CPVC: 32°F–194°F (0°C–90°C)

• EPDM or FPM (Viton®) seals

• Both NPT & socket ends included

• For vertical and horizontal installation*

• With flow direction arrow

• Machined and tumbled ball for hermetic seal

• Easy maintenance

• 5 PSI cracking pressure

*For vertical up flow only, not down flow. In horizontal installations, standard line drop typically will not allow the

ball to seat (a back pressure dierential of 5 PSI minimum is needed for shuto).

STANDARDS

Connections

• Threaded Dimension: ASTM F 1498, ref. ANSI B1.20.1

• Socket Dimension: PVC ASTM D 2467; CPVC ASTM F 439

Materials

• PVC: Cell classification 12454 per ASTM D1784 (formerly Type I, Grade 1)

• CPVC: Cell classification 23447 per ASTM D1784 (formerly Type IV, Grade 1)

CPVC

PVC

PRESSURE/TEMPERATURE

140

120

100

80

60

40

20

0

32 41 104 122 140 194

Temperature (Fº)

FIGURE NUMBER MATRIX

FNW.COM

©2020 Ferguson Enterprises, LLC 0420 1731963 We reserve the right to modify or improve the designs or specifications of our products at any time without notice.

FNW 3 4 5A E G

Body Type Seals Size Codes

4 = PVC E = EPDM 1/2 = D 1-1/4 = H

5 = CPVC V = FPM (Viton®) 3/4 = F 1-1/2 = J

1 = G 2 = K

CV & WEIGHTS

Size Cv Weight (lbs)

1/2" 10 0.44

3/4" 26 0.7 1

1" 37 0.99

1-1/4" 40 2.54

1-1/2" 80 2.25

2" 152 3.9

Page 2

FIGURE 345A, 355A

THERMOPLASTIC VALVES

TRUEUNION BALL CHECK VALVE

ABOUT PVC

• Unplasticised Polyvinyl Chloride, or PVC, is the most widely

used of all plastics and commonly used for pressure pipes,

fittings, and valves. It is rigid, suitable for above and below

ground applications. PVC has good chemical resistance and is

odorless and tasteless. It is for use with liquids and gases with

temperatures +32ºF to +140ºF* (for higher temperatures see

CPVC) at a wide range of operating pressures. Some poorer

quality PVC can leach chemicals into water which can build up

in recirculation systems, however most modern pipe is built to

specific standards (e.g. BS3505/6, ASTM D 1785, ASTM D2241,

DIN 8061/2, KIWA 49, BS4346 PART 1, DIN 8063) to control this.

ASTM D1784 controls the compounds for rigid PVC and CPVC.

Note: Other materials within valves besides PVC and CPVC can have an aect on the temperature limits of the valve. Temperatures noted above are for the thermoplastic

material alone.

ABOUT CPVC

• Chlorinated Polyvinyl Chloride, or CPVC, has been oering the

process industry superior corrosion resistance, mechanical

strength, and excellent life-cycle economics in a single package.

Conceptually, CPVC is a PVC homopolymer that has been

subjected to a chlorination reaction. It is generally inert to most

mineral acids, bases, salts, and paranic hydrocarbon solutions.

CPVC is not recommended for use with chlorinated or aromatic

hydrocarbons, esters, or ketones. The upper temperature limit

on CPVC is 200°F*. There is no lower temperature limit on CPVC

and the material will withstand pressure. However, at very cold

temperatures, the material will become brittle and the impact

strength will decline.

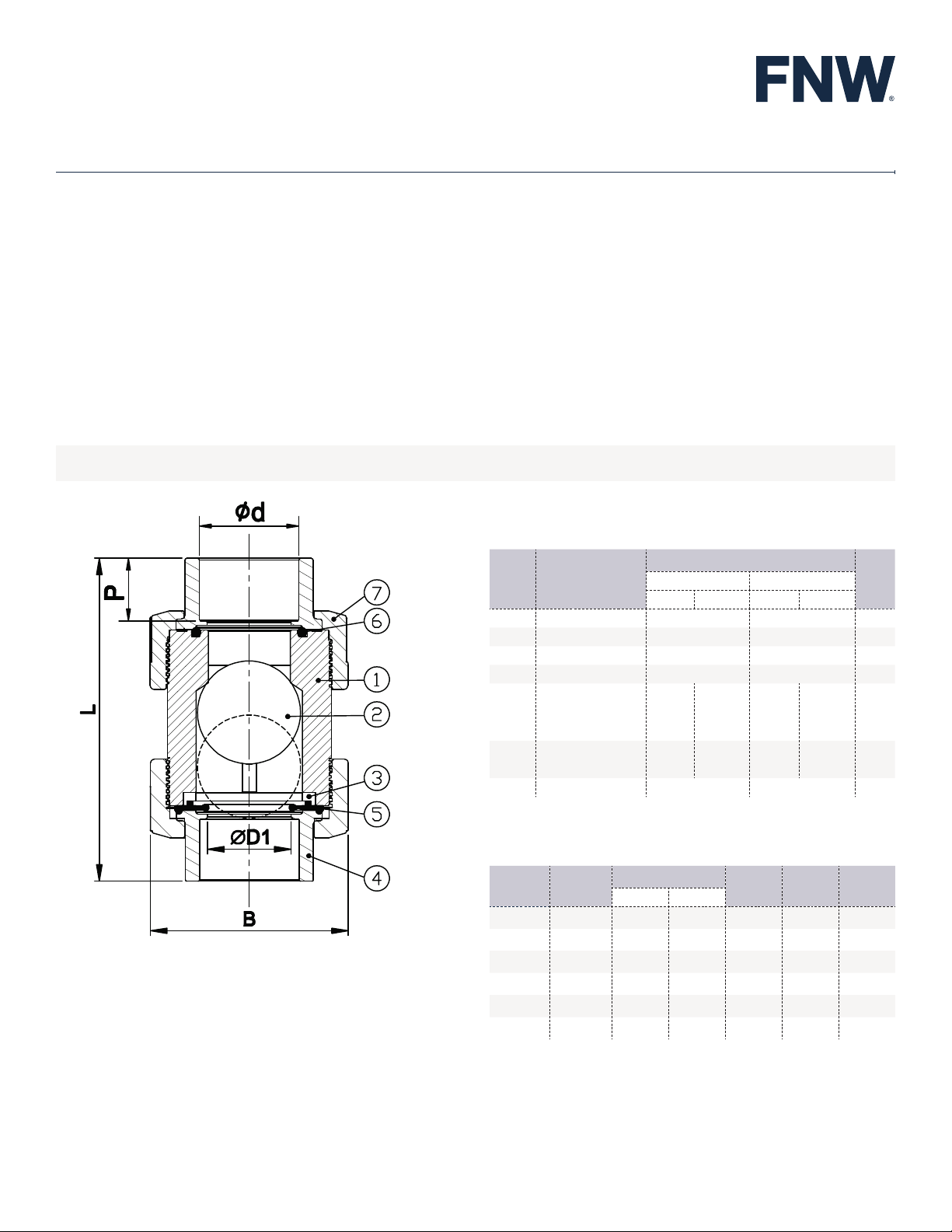

PART MATERIALS & QUANTITY

Materials

Ref # Parts

1 Body PVC CPVC 1

2 Ball PVC CPVC 1

3 Seat Carrier PVC CPVC 1

4 End Connector PVC CPVC 2

345A 355A

EPDM Viton® EPDM Viton®

Qty

* Threaded and socket weld unions.

5 Seat EPDM

6 Solid End O-Ring EPDM

7 Union Nut PVC CPVC 2

FPM

(Viton®)

FPM

(Viton®)

EPDM

EPDM

FPM

(Viton®)

FPM

(Viton®)

DIMENSIONS INCHES

Size D1

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

0.59 0.848 14 4.094 2.126 0.875

0.787 1.058 14 4.725 2.492 1

0.984 1.325 11.5 5.345 2.874 1.125

1.26 1.67 11.5 6.937 3.842 1.25

1.575 1.912 11.5 6.937 3.842 1.375

1.969 2.387 11.5 7.677 4.744 1.5

d

Socket Thread

L B P

1

1

FNW.COM

©2020 Ferguson Enterprises, LLC 0420 1731963 We reserve the right to modify or improve the designs or specifications of our products at any time without notice.

Loading...

Loading...