Page 1

145

Visit us at www.fnw.com

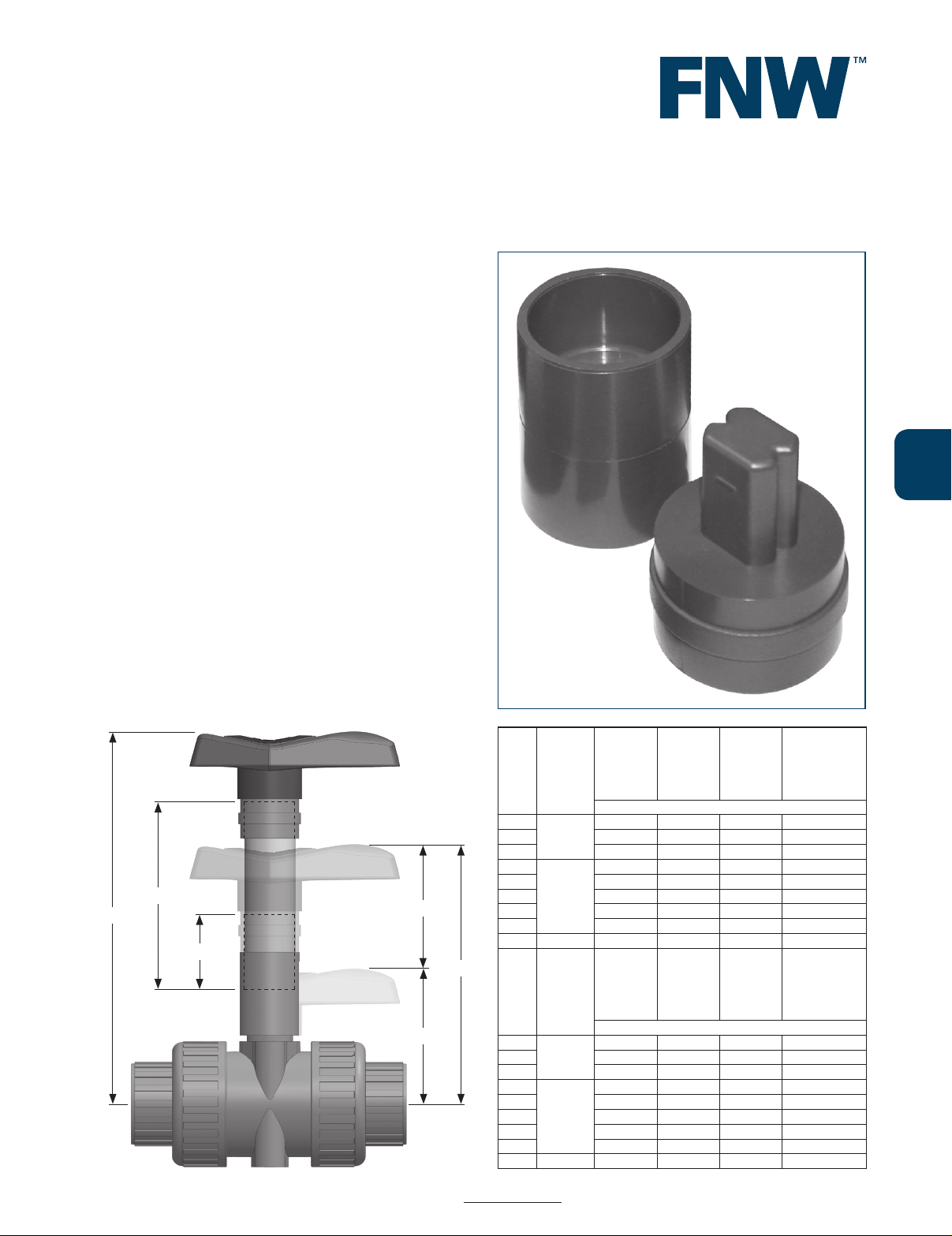

Figure340NSE

THERMOPLASTIC VALVES

STEM EXTENSION KIT FOR

FIGURE 340(N) & 350(N) BALL VALVE

Features:

• Simple Two-Piece Design

• Uses Valve’s Existing Handle (sold separately) & PVC

Schedule 80 Pipe (by others)

• Sizes Available for All FNW Thermoplastic Ball Valves

(Figure 340, 340N, 340F, 340NF, 350, & 350N)

• Corrosion Resistant PVC Material

• Kit Contains 1 Handle Adapter & 1 Stem Adapter

Extension Length Table:

Since the gure 340NSE uses PVC schedule 80 pipe between

the kits two adapter pieces, any Desired Handle Height (DHH)

between minimum and maximum can be achieved. Minimum

heights are indicated in the table. Maximum recommended

handle height is 48 inches. To determine the Pipe Length (PL)

needed to achieve the Desired Handle Height (DHH), deduct

the (SUBTRACT) value in the table from the Desired Handle

Height, or...

Valve

Size

PVC

Schedule

80 Pipe

Diameter

(MPL)

Minimum

Pipe Length

(MHH)

Minimum

Handle Height

from (MPL)

(MHC)

Minimum

Height Change

from Standard

Height (SH)

(SUBTRACT)

Amount to Subtract

from Desired

Handle Height (DHH)

for needed Pipe

Length (PL)

FRACTION (Inches)

1/2

3/4

1-1/2 4-1/16 2-1/4 2-5/8

3/4 1-1/2 4-9/16 2-3/8 3-1/8

1 1-1/2 5-3/8 2-9/16 3-7/8

1-1/4

1

1-5/8 5-5/8 2-11/16 4

1-1/2 1-5/8 6-5/8 2-7/8 5

2 1-5/8 7-1/2 3 5-7/8

2-1/2 1-5/8 7-3/4 3-3/16 6-1/8

3 1-5/8 8-3/8 3-1/4 6-7/8

4 1-1/2 2-1/4 11-3/8 4-3/8 9-3/16

Valve

Size

PVC

Schedule

80 Pipe

Diameter

(MPL)

Minimum

Pipe Length

(MHH)

Minimum

Handle Height

from (MPL)

(MHC)

Minimum

Height Change

from Standard

Height (SH)

(SUBTRACT)

Amount to Subtract

from Desired

Handle Height (DHH)

for needed Pipe

Length (PL)

DECIMAL (Inches)

1/2

3/4

1.500 4.063 2.250 2.625

3/4 1.500 4.563 2.325 3.125

1 1.500 5.375 2.563 3.875

1-1/4

1

1.625 5.625 2.688 4.000

1-1/2 1.625 6.625 2.875 5.000

2 1.625 7.500 3.000 5.875

2-1/2 1.625 7.750 3.188 6.125

3 1.625 8.375 3.250 6.875

4 1-1/2 2.250 11.375 4.375 9.188

SH

MPL

MHC

PL

DHH

MHH

PL = DHH - SUBTRACT

Page 2

146

Visit us at www.fnw.com

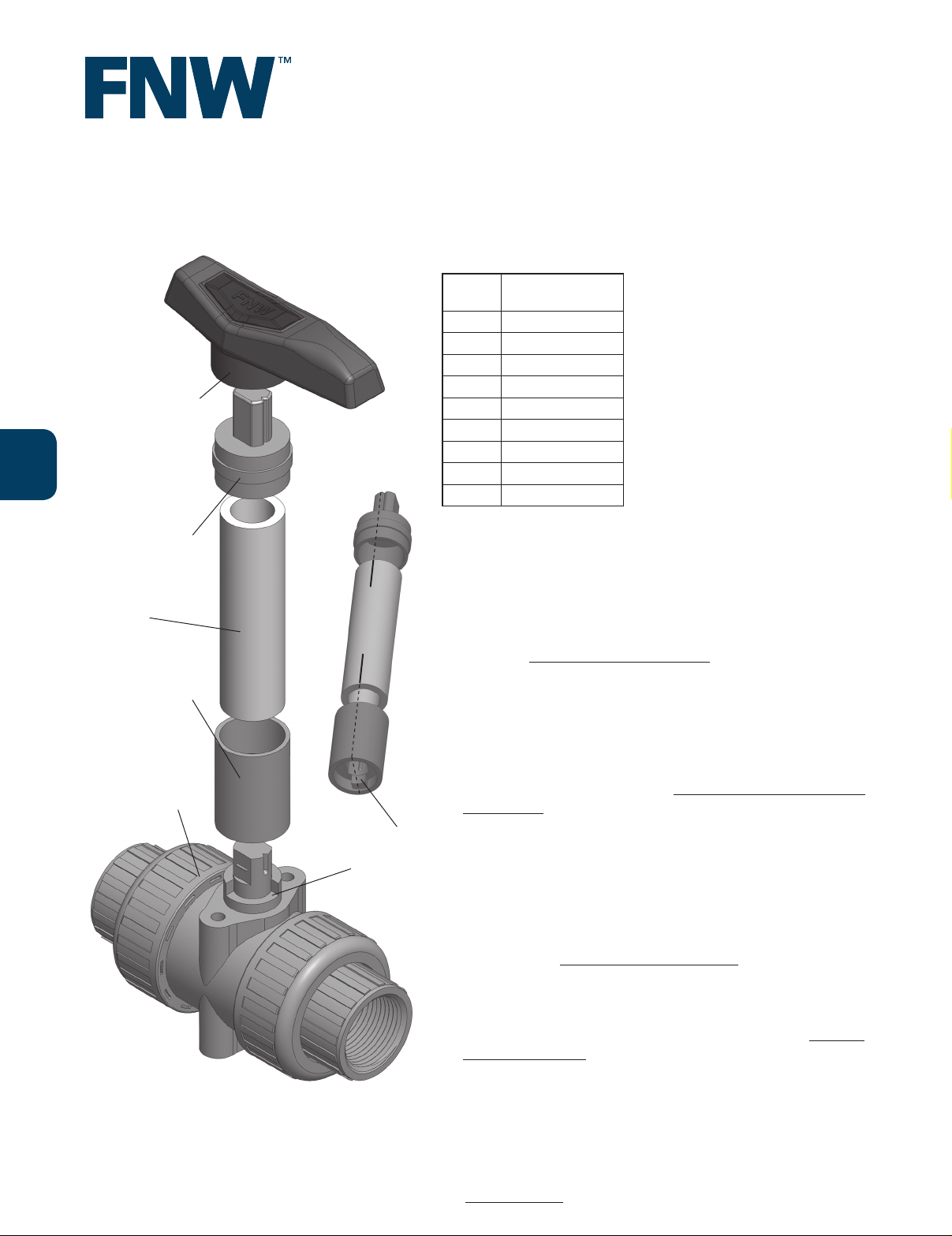

Figure340NSE

THERMOPLASTIC VALVES

STEM EXTENSION KIT FOR

FIGURE 340(N) & 350(N) BALL VALVE

Part Numbers

Valve

Size

Part Number

1/2" FNW340NSED

3/4" FNW340NSEF

1" FNW340NSEG

1-1/4" FNW340NSEH

1-1/2" FNW340NSEJ

2" FNW340NSEK

2-1/2" FNW340NSEL

3" FNW340NSEM

4" FNW340NSEP

Installation Requirements

• Correct Size Figure 340NSE

Stem Extension Kit

• Tools for Cutting PVC Schedule

80 Pipe (Recommend Saw &

Miter Box or Wheel-Type Cutter)

• PVC Primer & Solvent Cement

• Length of PVC Schedule 80

Pipe (See Chart for Determining

Needed Length for Desired

Handle Height)

• Marker

• Ruler

Valve

(sold separately)

Stem Adapter

(part of 340NSE kit)

Handle Adapter

(part of 340NSE kit)

PVC Sch’d 80 Pipe

(by others)

Valve Handle

(included with valve)

Installation Procedure

1. Select the proper diameter of PVC schedule 80 pipe.

2. From the Extension Length Table, determine the needed length

of pipe for the desired handle height and then mark the length

of pipe needed.

3. Using a saw and miter box, or a wheel-type cutter, cut the pipe

to length. The pipe must be cut square.

4. To ensure a clean t, bevel and de-burr the pipe ends.

5. Using a ruler and marker, draw an alignment line straight down

the extension pipe piece (end-to-end) to ensure that the handle

and adapters are aligned properly. The printing on the pipe can

be used for this purpose if it is straight.

6. Dry t the adapter pieces and pipe together to determine that

they t and are aligned properly. Do not attach the assembly to

the valve yet.

7. Follow the manufacturer’s recommendations for using the PVC

primer and Solvent Cement to join the adapter pieces to the

pipe, making sure that the pieces are straight according to the

alignment marks or pipe printing.

8. Allow the solvent to cure per manufacturer’s recommendations.

9. With the valve closed, remove the handle by pulling it up while

gently rocking it back and forth. Push the handle onto the top of

the extension. Do NOT use solvent cement.

10. Locate the position of the stop block on the extension piece.

Make sure it is located over the stop gap on the valve and

lower the assembly onto the valve stem. Push the assembly

down while slightly twisting the handle back and forth. Do NOT

use solvent cement. For larger valves (over 2"), it may be

necessary to use a rubber mallet to tap the extension onto the

stem.

PVC SCH 80 PIPE

Alignment

Marks

Stop Block

Stop Gap

Loading...

Loading...