Page 1

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

FIGURE 330A 3-PIECE SANITARY BALL VALVE

INTRODUCTION

This instruction manual includes installation, operation and maintenance information for the figure 330A 3-piece

400CWP, clamp end sanitary ball valve.

INSTALLATION

WARNING

To avoid personal injury to your self, fellow workers, or damage to property from release of process fluid, before

installation:

a. Shut off all operating lines to the valve site

b. Isolate the valve site completely from the process

c. Release process pressure

d. Drain the process fluid from the valve site

1. Remove the protective rubber caps from the clamp ends and clean or flush the valve.

2. Before installing the valve, inspect the valve body port and associated equipment for any damage that may

have occurred and for any foreign matter that may have collected in shipping or storage. Make certain the

body interior is clean.

3. Before installing the valve, inspect the pipe line and mating clamp end, making sure the pipe is free of foreign

material and the ends are clean and have no burrs or pits that could cause leakage.

4. Cycle the valve a couple of times before installation. The valves are tested to MSS SP-110 and while they

have cavity filled seats, there may still be water within the valve. This can be removed by partially opening

the valve, exposing the interior to the through port of the ball. Allow the water to drain out and dry as needed.

5. Ensure that piping is aligned properly so there is no tension applied to the valve when installed. Use pipe

hangers or other supports as necessary to properly align piping.

6. Before installing the valve, seal rings should be applied to the clamp ends per ISO 2852. Failure to apply

proper seal rings can result in leakage and damage.

7. Align the valve clamp end to the pipe clamp end and secure with a quick clamp.

8. Clean/flush the pipeline and leak test the system prior to using.

DOC: IOM_FNW330A_ ver_4-2011 Page 1 of 6

Page 2

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

FIGURE 330A 3-PIECE SANITARY BALL VALVE

Supplemental: The standard figure 330A is supplied with clamp ends so traditional 3-piece ball valve installation

by disassembly is not required. In the event that other end connections are supplied, the following steps are

supplied for reference.

A. For Threaded End Valve:

o Use applicable sealant (e.g. - PTFE tape, high temperature pipe seal, etc.) to seal threaded ends on the

pipeline.

o If required for installation (i.e. – The pipe can not be rotated), remove the body bolts and end caps.

Secure the seats and body seals with tape so they are not lost.

o To prevent distortion or damage to the valve, do not apply torque through the valve. When tightening

the valve, always use a wrench on the end nearest the pipe being tightened. It is preferred that the pipe

be screwed into the valve, holding the valve stationary at the end being connected. Do not use the

handle to tighten the assembly as damage to the valve may occur.

o If the valve was disassembled for installation, reinstall the body assembly and reinsert the body bolts.

SLIGHTLY tighten all bolts, making sure the body and end caps are parallel to prevent distortion of the

end caps during the final tightening phase. Using the torque values in Table 1, tighten the body bolts

evenly. Check the valve for proper operation. The valve should stroke smoothly and evenly with no

binding (Higher seating and unseating torque is normal).

B. For Socket Weld End Valve:

o With the valve in the open position and pipe fully inserted into the socket weld ends, tack-weld the valve

to the pipe in four equidistant points on both end caps.

o Remove all but one of the body bolts and loosen the remaining one so that the valve body assembly can

swing out of the way.

o Secure the seats and body seals with tape so they are not lost. It is recommended to temporarily cover

the body assembly during welding to protect the soft seats and seals from damage.

o Finish welding both end caps onto the pipe.

o After all components have cooled, clean all valve surfaces.

o Swing the body back to the original position and reinsert the body bolts.

o SLIGHTLY tighten all bolts, making sure the body and end caps are parallel to prevent distortion of the

end caps during the final tightening phase.

o Using the torque values in Table 1, tighten the body bolts evenly.

C. Check the valve for proper operation. The valve should stroke smoothly and evenly with no binding (Higher

seating and unseating torque is normal).

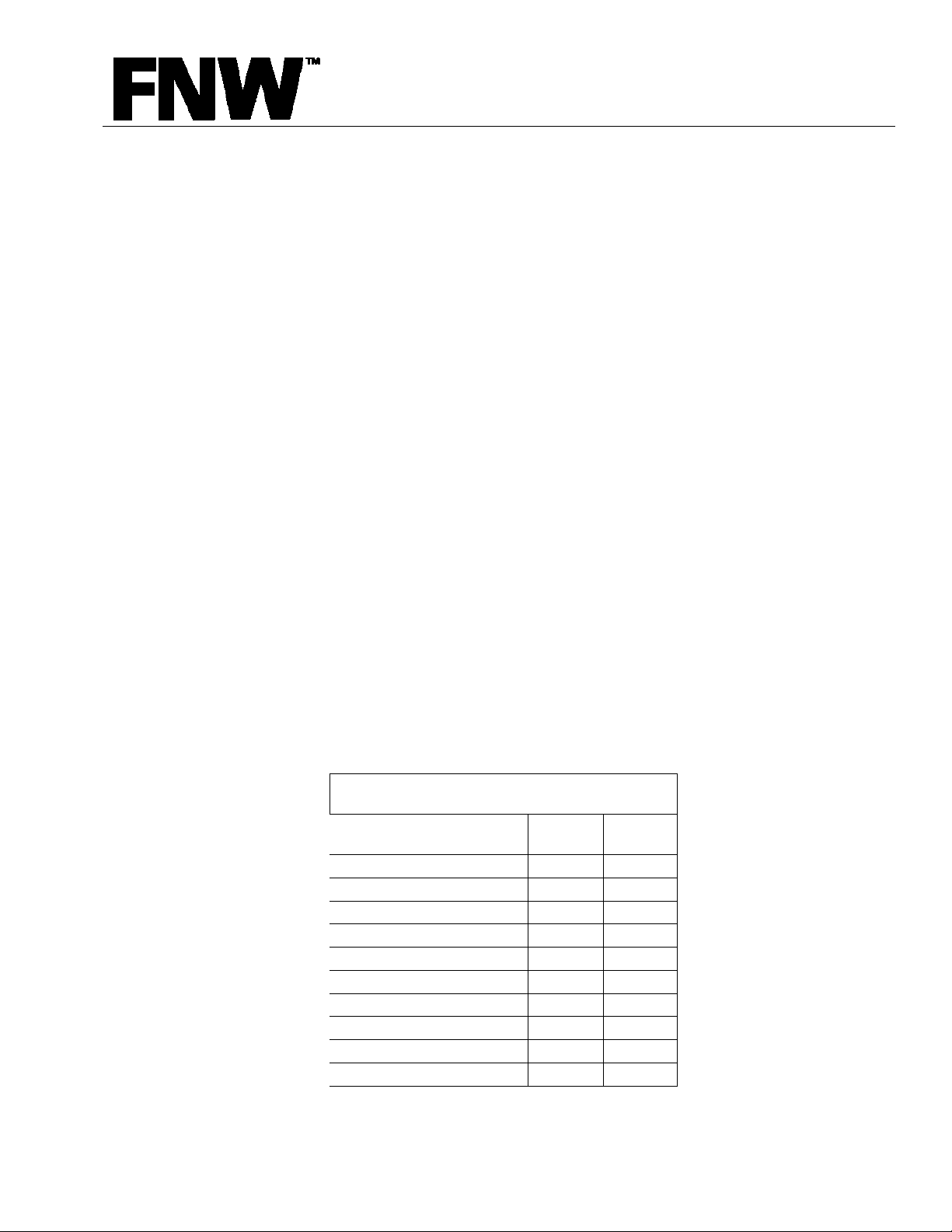

BODY BOLT TORQUES for ASTM A193-B8

Bolt Size

1/4-20 UNC / M6 70 7.9

5/16-18 UNC / M8 100 11.3

3/8-16 UNC / n/a 160 18.1

7/16-14 UNC / M10 280 31.7

1/2-13 UNC / M12 400 45.3

5/8-11 UNC / M16 800 90.5

3/4-10 UNC / M20 1400 158.4

7/8-9 UNC / M22 2250 254.6

1-8 UNC / M24 3250 367.7

1-1/8-8 UNC / M28 4000 452.6

Table 1

DOC: IOM_FNW330A_ ver_4-2011 Page 2 of 6

In-Lbs NM

Page 3

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

FIGURE 330A 3-PIECE SANITARY BALL VALVE

OPERATION

1. Ensure that the valve materials are compatible with the service and that the operating characteristics are

below the valve maximums.

2. Fluids containing particles or coagulating agents are not acceptable as they can reduce the life of the seats

and cause the torque to increase dramatically.

3. Throttling the valve (operation in the partially open position) is not recommended as critical pressure drops

and high flow rates can decrease the life of, or damage, the seats. For optimum operation, open/close

applications are recommended.

4. The valve comes standard with a locking device (except the 4” size). Slide the locking plate up the lever

before operating. Open and close the valve by turning the handle one-quarter turn (90°).

5. The valve is in the open position when the handle is parallel to the pipe, and in the closed position when

perpendicular to the pipe.

DOC: IOM_FNW330A_ ver_4-2011 Page 3 of 6

Page 4

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

FIGURE 330A 3-PIECE SANITARY BALL VALVE

MAINTENANCE

Valve parts are subject to normal wear and must be inspected and replaced as necessary. Inspection and

maintenance frequency depends on the severity of the service conditions. This section includes instructions for

packing adjustments, repacking, seat replacement and seating adjustment.

WARNING

To avoid personal injury, fellow workers, or damage to property from release of process fluids, before installation:

a. Shut off all operating lines to the valve.

b. Isolate the valve completely from the process.

c. Release process pressure.

d. Drain the process fluid from the valve.

1. Ball valves, if properly used, do not require internal lubrication or maintenance. However, a visual inspection

should be part of a regular maintenance program. A higher frequency of inspection is recommended for

valves operating under extreme conditions. Also, for proper operation it is recommended that the valve be

opened and closed at least twice a year.

2. CAUTION: Care should be taken to not scratch any of the machined and/or polished surfaces during

maintenance. Scratches can compromise sealing integrity and create areas for media build-up that defeat the

sanitary aspects of the valve.

3. Before any maintenance, open and close the valve at least once to release the pressure completely from the

valve body.

4. The valve includes live loaded packing that reacts to pressure changes and packing fatigue to reduce the

intervals needed for packing adjustments. If the stem packing leaks, remove the operator to access the stem

nut. Use a long reaching socket over the stem to turn the stem nut clockwise at 30° to 60° intervals until the

leak stops. If the stem nut can not be turned clockwise any further, or if the stem packing continues to leak, it

will have to be replaced or repaired. NEVER REPLACE VALVE PACKING WHILE THE VALVE IS IN

SERVICE.

5. The valve can be rebuilt by using a “Soft Goods” repair kit from FNW.

Disassembly

A. In the closed position, secure the valve by the body in a vise. Do not over-tighten the vise or the

B. Remove the handle nut (12), handle (18), square washer (17), stop-lock-cap (15), stem nut (14),

C. If the end caps are present, remove them by removing the body bolts (5), nuts (23), and washers

D. Remove the seats (4), and the body gaskets (21).

E. Remove the ball (3).

F. Push the stem (5) down through the body (1), and then remove the o-ring (9) and thrust washer (8)

G. Remove the bushing (11) and pa cking (10) from the body.

Assembly

A. Rebuild the valve by using all the replacement parts of the rebuild kit.

B. Ensure that all parts are clean and undamaged.

C. Assemble the valve in reverse order of the disassembly instructions, except install the packing after

D. Use the body bolt tightening steps listed in the installation instructions and tighten according to the

It is recommended to cycle and test the valve prior to resuming service. After reinstallation into the piping system,

it may be necessary to adjust the stem nut/packing gland as described in step 4.

valve may be deformed.

Belleville washers (13) and gland (12). For 4” valves, remove the set screw (26) and lift the handle

assembly and stopper (29) off the stem before proceeding to the square washer.

(22).

from the stem.

the stem is inserted.

torques listed in Table 1.

DOC: IOM_FNW330A_ ver_4-2011 Page 4 of 6

Page 5

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

FIGURE 330A 3-PIECE SANITARY BALL VALVE

W

201918

1311 12

10

9

8

7

6

5

4

3

2

1715 1614

21

22

M

23

H

20°

Ød

ØA

ØB

H1

1

T

L2

L

26

27

4-ØU2

K

?P

4-ØU1

28

ØE2

ØE1

29

4" Handle

Ref.

Description Material Qty

No.

1 Body ASTM A351 Gr. CF8M Stainless 1

2 End Cap ASTM A351 Gr. CF8M Stainless 2

3 Ball 316SS Stainless 1 18 Handle 304SS Stainless 1

4 Seat TFM1600 2 19 Lock Device 304SS Stainless 1

5 Body Bolt ASTM A193-B8 Stainless 4

6 Stem 316SS Stainless 1 21 Body Gasket PTFE 2

7 Anti-Static Device 316SS Stainless 2 22 Bolt Washer 304SS Stainless 4

8 Thrust Washer PTFE 1 23 Bolt Nut 304SS Stainless 4

9 O-Ring FKM 1 24 Stop Bolt 304SS Stainless 1

10 V-Ring Packing PTFE 1 Set

11 Bushing 50% Stainless + 50% PTFE 1

12 Gland 316SS Stainless 1 27 Handle (4” only) ASTM A53 Steel + Zinc Plating 1

13 Bellev ille Washer 301SS Stainless 2

14 Stem Nut 304SS Stainless 1 29 Stopper (4” only) 420SS Stainless 1

15 Stop-Lock-Cap 304SS Stainless 1

Ref.

No.

16 Handle Nut 304SS Stainless 1

17 Square Washer 304SS Stainless 1

20 Handle Sleeve Vinyl Plastic 1

25 Nut 304SS Stainless 1

26 Set Screw (4” only) 304SS Stainless 1

28 Adapter (4” only) 304SS Stainless 1

Description Material Qty

DOC: IOM_FNW330A_ ver_4-2011 Page 5 of 6

Page 6

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

FIGURE 330A 3-PIECE SANITARY BALL VALVE

WARRANTY

1. LIMITED WARRANTY: Subject to the limitations expressed herein, Seller warrants that products

manufactured by Seller shall be free from defects in design, material and workmanship under normal use for

a period of one (1) year from installation but in no case shall the warranty period extend longer than eighteen

months from the date of sale. This warranty is void for any damage caused by misuse, abuse, neglect, acts of

God, or improper installation. For the purpose of this section, “Normal Use” means in strict accordance with

the installation, operation and maintenance manual. The warranty for all other products is provided by the

original equipment manufacturer.

2. REMEDIES: Seller shall repair or replace, at its option, any non-conforming or otherwise defective product,

upon receipt of notice from Buyer during the Manufacturer’s warranty period at no additional charge. SELLER

HEREBY DISCLAIMS ALL OTHER EXPRESSED OR IMPLIED WARRANTIES, INCLUDING, WITHOUT

LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS OR FITNESS FOR A

PARTICULAR PURPOSE.

3. LIMITATION OF LIABILITY: UNDER NO CIRCUMSTANCES SHALL EITHER PARTY BE LIABLE TO THE

OTHER FOR INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

BUYER HEREBY ACKNOWLEDGES AND AGREES THAT UNDER NO CIRCUMSTANCES, AND IN NO

EVENT, SHALL SELLER'S LIABILITY, IF ANY, EXCEED THE NET SALES PRICE OF THE DEFECTIVE

PRODUCT(S) PURCHASED DURING THE PREVIOUS CONTRACT YEAR.

4. LABOR ALLOWANCE: Seller makes NO ADDITIONAL ALLOWANCE FOR THE LABOR OR EXPENSE OF

REPAIRING OR REPLACING DEFECTIVE PRODUCTS OR WORKMANSHIP OR DAMAGE RESULTING

FROM THE SAME.

5. RECOMMENDATIONS BY SELLER: Seller may assist Buyer in selection decisions by providing information

regarding products that it manufacturers and those manufactured by others. However, Buyer acknowledges

that Buyer ultimately chooses the product’s suitability for its particular use, as normally signified by the

signature of Buyer’s technical representative. Any recommendations made by Seller concerning the use,

design, application or operation of the products shall not be construed as representations or warranties,

expressed or implied. Failure by Seller to make recommendations or give advice to Buyer shall not impose

any liability upon Seller.

6. EXCUSED PERFORMANCE: Seller will make a good faith effort to complete delivery of the products as

indicated by Seller in writing, but Seller assumes no responsibility or liability and will accept no back-charge

for loss or damage due to delay or inability to deliver, caused by acts of God, war, labor difficulties, accidents,

inability to obtain materials, delays of carriers, contractors or suppliers or any other causes of any kind

whatever beyond the control of Seller. Under no circumstances shall Seller be liable for any special,

consequential, incidental, or indirect damages, losses, or expense (whether or not based on negligence)

arising directly or indirectly from delays or failure to give notice of delay.

DOC: IOM_FNW330A_ ver_4-2011 Page 6 of 6

Loading...

Loading...