Page 1

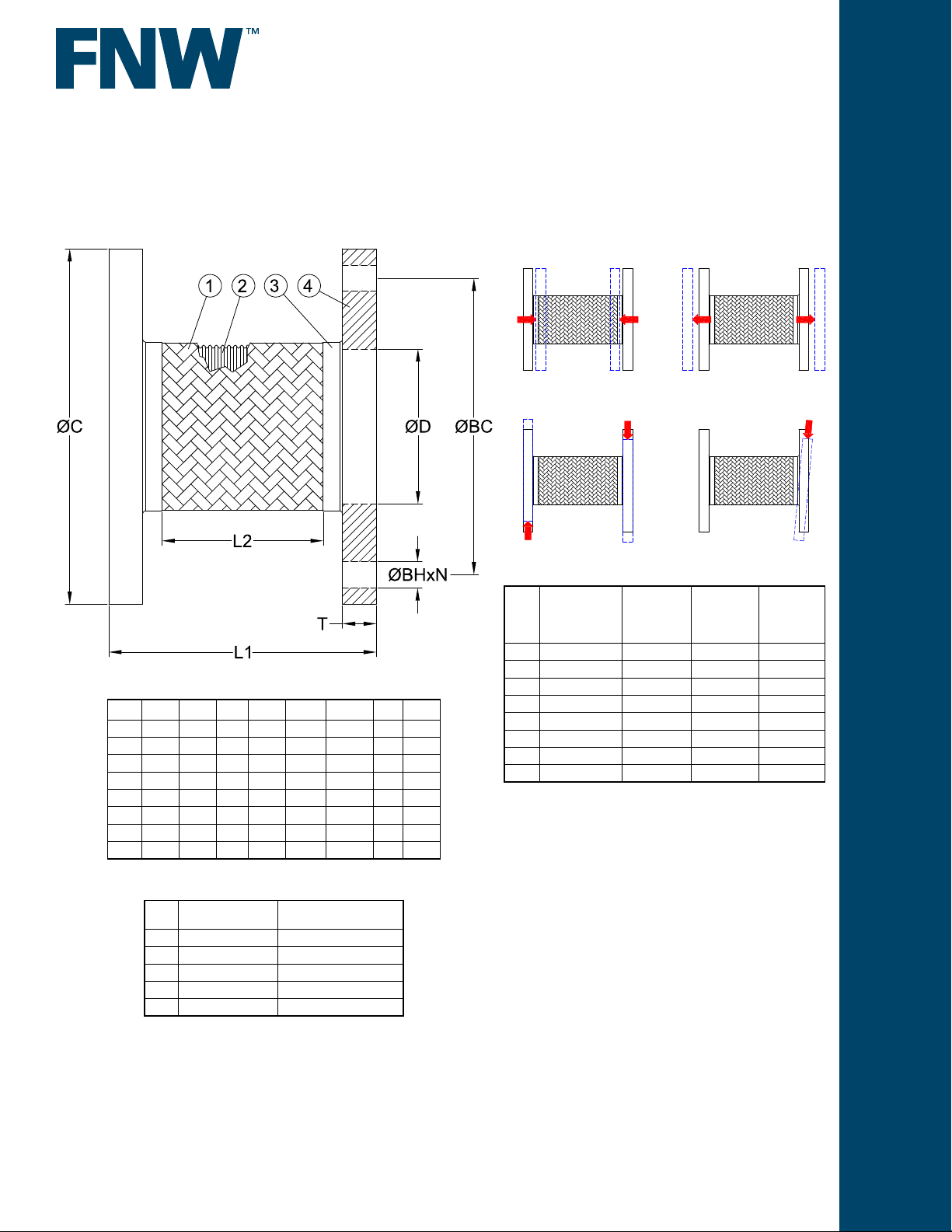

Figure 30F

* NOT RECOMMENDED FOR STEAM OR VACUUM SERVICE

FLEXIBLE CONNECTORS

FLANGED END METAL BRAIDED

FLEXIBLE CONNECTOR

Flexible connectors are used to absorb thermal and seismic movement,

absorb hydraulic shock, provide vibration and noise dampening, ease

installation and correct minor misalignment of piping and components.

They come in a variety of sizes, materials, and connection ends for

numerous applications.

The inner hose is an annular (bellows) design. An annular hose is better

suited for pump connections because it can better sustain torsion stress

due to longitudinal expansion from rises in pressure. Metal wire braid on a

hose assembly restrains against hose elongation under higher pressures

and acts to dampen vibration. A heavy braid also increases abrasion

resistance. Optimal braid coverage will contain the core under pressure

and reduce the possibility of twisting and squirming.

The use of braided metal connectors for applications such as pumps,

compressors and other mechanical equipment can enhance the overall

operation of a system.

Braided connectors have the advantages of:

• Longer service life

• Increased pressure capacity

• Greater fatigue resistance due to ex

• Increased temperature capacity of media

• Greater protection of annular hose

• Acceptance of thermal expansion

Pressure / Temperature

Pressure @ 70°F

Size

Working PSI Test PSI

2 455 683

2-1/2 345 518

3 290 435

4 250 375

5 200 300

6 210 315

8 190 285

10 150 225

* Multiply working pressure by pressure factor for temperature adjusted pressure rating.

Pressure Factors for Above 70°F*

°F Factor °F Factor

100 0.99 450 0.81

150 0.96 500 0.79

200 0.94 550 0.76

250 0.92 600 0.74

300 0.89 650 0.72

350 0.86 800 0.66

400 0.84 1000 0.60

www.fnw.com

Part Numbers & Weight

Size Part Number

2 FNW30FK 12

2-1/2 FNW30FL 13

3 FNW30FM 14

4 FNW30FP 19

5 FNW30FS 27

6 FNW30FU 32

8 FNW30Fx 50

10 FNW30F10 76

Approx. Wt

(Lbs)

Page 2

Figure 30F

FLEXIBLE CONNECTORS

FLANGED END METAL BRAIDED

FLEXIBLE CONNECTOR

Braid Limits

Dimensions (inches)

Size ØC ØD L1 L2 ØBC ØBH N T

2 6.0 2.44 9 5.78 4.75 0.75 4 0.62

2-1/2 7.0 2.94 9 5.78 5.50 0.75 4 0.62

3 7.5 3.57 9 5.78 6.00 0.75 4 0.62

4 9.0 4.57 9 5.39 7.50 0.75 8 0.62

5 10.0 5.66 11 7.14 8.50 0.87 8 0.75

6 11.0 6.72 11 6.74 9.50 0.87 8 0.75

8 13.5 8.72 12 7.24 11.75 0.87 8 1.00

10 16.0 10.88 13 7.85 14.25 1.00 12 1.00

Axial Compression

Transverse Movement

Maximum

Size

2 0.16” 0.16” ±0.12” 1.5°

2-1/2 0.16” 0.16” ±0.12” 1.5°

3 0.16” 0.16” ±0.12” 1.5°

4 0.16” 0.16” ±0.12” 1.5°

5 0.20” 0.20” ±0.16” 1°

6 0.20” 0.20” ±0.16” 1°

8 0.20” 0.20” ±0.16” 1°

10 0.20” 0.20” ±0.16” 1°

Axial

Compression

Maximum

Axial

Elongation

Axial Elongation

Angular Deection

Maximum

Transverse

Movement

Maximum

Angular

Deection

Standard Materials

Ref.

Description Material

No.

1 Hose Braid 304 Stainless Steel

2 Corrugated Hose 321 Stainless Steel

3 Braid Band 304 Stainless Steel

4 Flange Carbon Steel

5 Welding Grade er308 Stainless

DOC: FNW30F05 Ver. 6/2018

© 2018 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...