Page 1

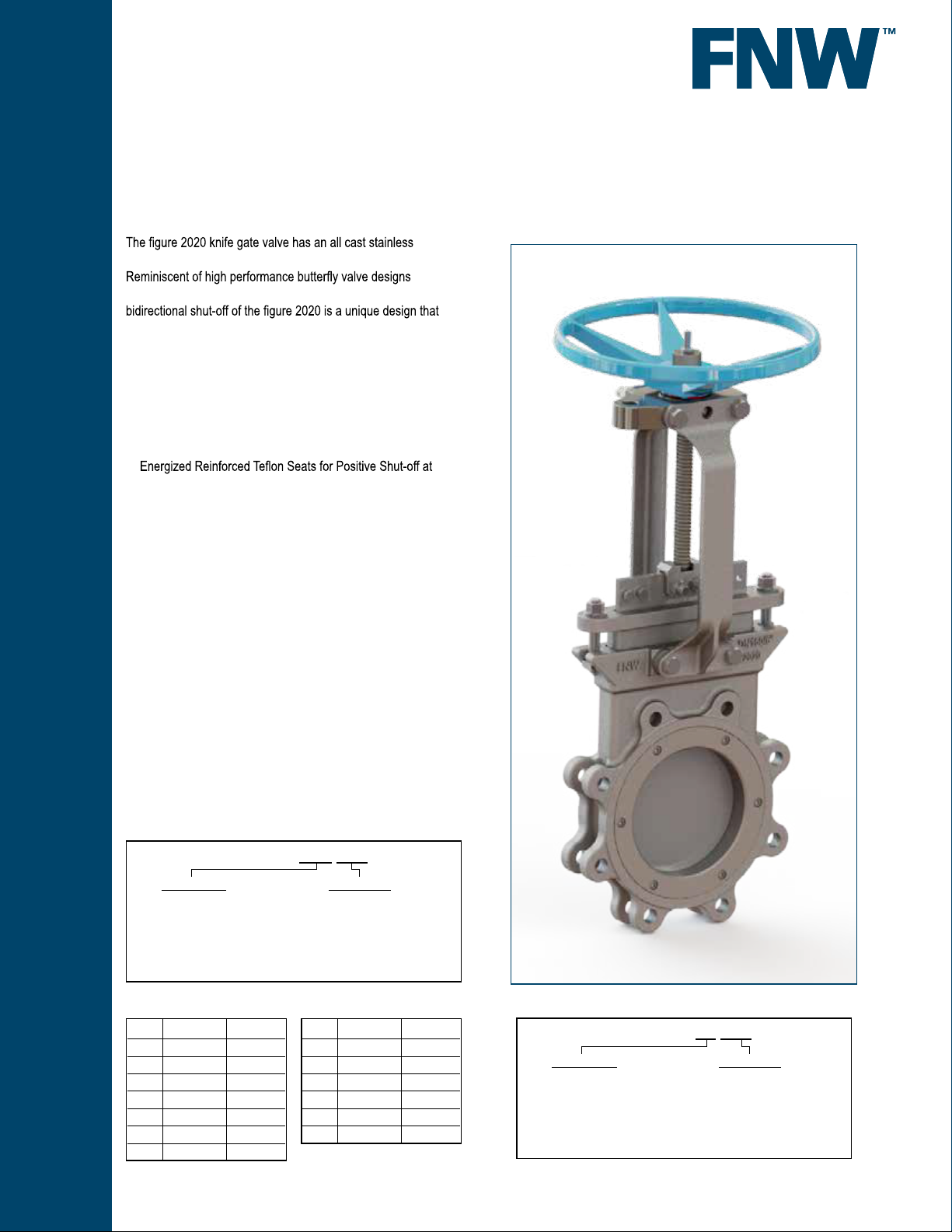

Figure 2020

KNIFE GATE VALVES

STAINLESS STEEL BIDIRECTIONAL

RESILIENT SEATED KNIFE GATE VALVE

steel body and yoke with investment cast packing follower.

that utilize a retaining ring to secure the seat, the dual seat,

performs in many applications not typical of knife gate valves.

Features

• Bidirectional Shut-off

• Maximum Pressure: 150 PSI CWP

• Maximum Temperature: 248°F (120°C)

• Cast Stainless Steel Body, Yoke, & Packing Gland

• Thrust Needle Bearings

•

Minimum Line Pressure

• Elastomer Quad Seal is Standard in Packing Arrangement

• Stainless Steel Position Indication Arrow

• Adjustable Close Stop

• Stainless Steel Hardware

• Machined Gland Pocket Area

• Bonnetless, Outside Screw & Yoke

• Rising Stem

• Cast Iron Hand Wheel

• Available in sizes 2” to 24”

• Standard design accommodates locking device

Standards

• Face-to-Face: MSS SP-81

• Flange Drilling: ANSI B16.5

• Testing:

○ Shell (Before Assembly): 1.5 Time Max. CWP (No Leak)

○ Seat: 1.1 Times Max. CWP (No Leak)

• Material: ASME B16.34

Figure Number Matrix

FNW 2020 Seat Size

SEAT CODE

RTFE = T

2 = K

2-1/2 = L

3 = M

4 = P

6 = U

SIZE CODE

8 = X

10 = 10

12 = 12

14 = 14

16 = 16

Cv & Weight

Size Cv Wt (Lbs)

2 240 37

2-1/2 565 40

3 565 44

4 1,040 53

6 2,440 88

8 4,460 139

10 6,250 181

Size Cv Wt (Lbs)

12 9,400 229

14 12,500 364

16 16,500 397

18 21,400 463

20 27,000 573

24 39,700 617

Weights are for general reference only.

18 = 18

20 = 20

24 = 24

Repair Kits (Order Separately)

FNW 2020 Kit Size

SEAT CODE

Repair Kit = RK

Contains two seats / two o-rings

2 = K

2-1/2 = L

3 = M

4 = P

6 = U

SIZE CODE

8 = X

10 = 10

12 = 12

14 = 14

16 = 16

18 = 18

20 = 20

24 = 24

www.fnw.com

Page 2

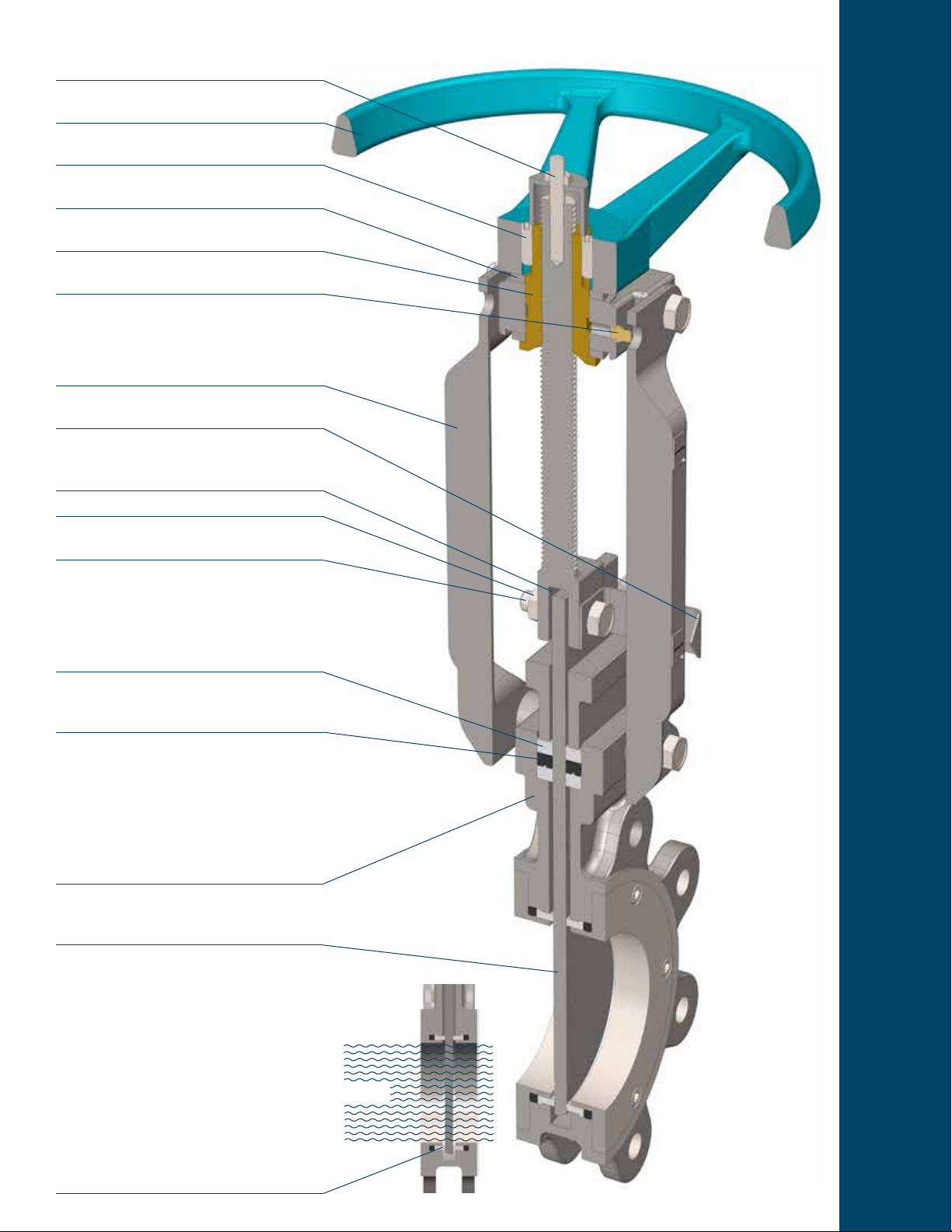

An adjustable stopper at the top of the stem sets

the close position of the gate.

Hand wheel is heavy cast iron, with a rounded grip

and epoxy coated hand wheel.

Double set screws prevent threaded-on hand

wheel from backing off or coming loose.

Stainless steel needle bearings reduce hand wheel

rim pull force.

Aluminum-Bronze thrust components for antigalling operation.

Grease tting for maintaining smooth drive sleeve

operation.

Cast stainless steel yoke arms provide optimum

exural rigidity.

Stainless steel position indication arrow is

standard

Stem-to-gate clevis is deliberately loose to allow

play in gate to minimize binding.

Stainless steel hardware is standard.

Horizontal clevis bolts provide exibility of the gate

during travel.

FEATURES

Multiple layers of PTFE impregnated square braid

packing provides excellent gland sealing at full

valve pressure differential.

Elastomer quad seal improves packing

performance by promoting live loading of the

packing.

The single piece cast all stainless steel body is

rugged and compact. It offers better leak tightness

than fabricated or two-piece designs.

The gate is high-quality, ground-nished stainless

steel. A generous gate thickness is well supported

by the packing.

The unique retainer, o-ring, seat assembly

provides positive shut-off at minimum pressure

differential. Securing the seats out of the ow path

improves the longevity of the resilient material;

however, this conguration also allows easy

replacement of the seat and o-ring.

FLOW

Page 3

Seat Seal Conguration

The gure 2020 utilizes a seating design that provides positive shut-off in both

directions, even at low pressure differentials. Similar to high performance buttery

valve designs, the 2020 uses mechanically held retainer rings to hold the seat in

place.

The RTFE seats are secured with an integral locator lip. Seats are energized with

hefty EPDM o-rings to provide sealing pressure against the gate. The o-rings also

act as the seal between the body and seat. Both are secured with stainless steel

retainer rings and screws.

Seats and o-rings can easily be replaced without disturbing the valve packing. This

conguration also impoves the longevity of the seats because they are not directly

in the ow path.

Standard Materials

Retainer Ring

Retainer Screws

Ref.

Description Material Qty

No.

1 Body

1A Seat RTFE 2

1B Seat O-ring EPDM 2

1C

1D

10 Yoke Bolt

11 Stem

12 Clevis Bolt

13 Clevis Nut

14 Collar

15 Collar Bolt

16 Collar Nut

17 Hand Wheel Cast Iron, ASTM A126 Gr. B 1

18 Yoke Sleeve

19

20 Set Screws Stainless Steel, 304SS 2

21

23 Stopper Stud

24 Stopper

25 Stopper Nut

Seat

Retainer

Ring

Retainer

Screws

2 Gate

3 Packing

4 Quad Seal EPDM 1

6 Gland

7 Gland Bolt

8 Gland Nut

9 Yoke Arm

Thrust

Needle

Bearing

Position

Indicator

Stainless Steel, ASTM A351

Stainless Steel, ASTM A351

Stainless Steel, ASTM A240

PTFE Impregnated Syntex

Stainless Steel, ASTM A351

Stainless Steel, ASTM A351

Stainless Steel, ASTM A276

Stainless Steel, ASTM A351

ASTM B148, UNS C95200

Stainless Steel, ASTM A276

RTFE Seat

EPDM O-ring

Gr. CF8M

Gr. CF8M

Stainless Steel 316,

ASTM A193 Gr. B8M

Type 316

2 (2”~18”)

Fiber

Gr.CF8M

Stainless Steel 304,

ASTM A193 Gr. B8

Stainless Steel 304,

ASTM A194 Gr. 8

Gr.CF8

Stainless Steel 304,

ASTM A193 Gr. B8

Type 304

Stainless Steel 304,

ASTM A193 Gr. B8

Stainless Steel 304,

ASTM A194 Gr. 8

Gr.CF8

Stainless Steel 304,

ASTM A193 Gr. B8

Stainless Steel 304,

ASTM A194 Gr. 8

Aluminum Bronze,

Stainless Steel, 2

Stainless Steel, 304SS 1

Stainless Steel 304,

ASTM A193 Gr. B8

Type 304

Stainless Steel 304,

ASTM A194 Gr. 8

3 (20”~24”)

2 (2”~8”)

4 (10”~24”)

2 (2”~8”)

1

2

2 Sets

1

1

2~10

2~10

2

4

1

2

2

1

1

1

1

1

Page 4

Figure 2020

KNIFE GATE VALVES

STAINLESS STEEL BIDIRECTIONAL

RESILIENT SEATED KNIFE GATE VALVE

Dimensions (inches)

Size A B C D E F G H J K N S

2 1.88 4.75 3.62 13.98 16.26 10.00 2 5/8”-11 0.35 2 1.83 0.50

2-1/2 2.00 5.50 5.00 15.83 19.53 10.00 2 5/8”-11 0.39 2 2.74 0.50

3 2.00 6.00 5.00 15.83 19.53 10.00 2 5/8”-11 0.39 2 2.74 0.50

4 2.00 7.50 6.19 17.95 22.36 10.00 2 5/8”-11 0.39 6 3.72 0.50

6 2.25 9.50 8.50 21.81 28.19 11.75 2 3/4”-10 0.43 6 5.69 0.63

8 2.75 11.75 10.62 26.38 34.57 16.00 2 3/4”-10 0.43 6 7.46 0.63

10 2.75 14.25 12.75 30.91 41.14 16.00 4 7/8”-9 0.49 8 9.43 0.75

12 3.00 17.00 15.00 35.12 47.17 20.00 4 7/8”-9 0.43 8 11.40 0.75

14 3.00 18.75 16.25 39.17 52.95 20.00 4 1”-8 0.51 8 12.97 0.81

16 3.50 21.25 18.50 41.73 58.27 20.00 6 1”-8 0.55 10 14.55 0.88

18 3.50 22.75 21.00 47.24 64.57 20.00 6 1-1/8”-7 0.59 10 16.52 0.94

20 4.50 25.00 23.00 52.44 71.65 20.00 8 1-1/8”-7 0.75 12 18.48 1.00

24 4.50 29.50 27.25 61.18 84.25 20.00 8 1-1/4”-7 0.91 12 22.42 1.00

DOC: FNW202017 Ver. 7/2017

© 2017 - FNW. All rights reserved. 22038

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...