Page 1

Figure 2000B

KNIFE GATE VALVES

STAINLESS STEEL HIGH PERFORMANCE

RESILIENT SEATED KNIFE GATE VALVE

The gure 2000B is an all cast stainless steel body

and yoke with investment cast packing follower.

Reminiscent of high performance buttery valves that

utilize a retaining ring to secure the valve seat, the dual

seat, bidirectional shut-off of the 2000B is a unique

design that performs in many applications not typical of

knife gate valves.

Features:

• Flex Teon Seats for Positive Shut Off at Minimal

Line Pressure

• Bidirectional Shutoff

• Cast Stainless Steel Body, Yoke and Packing Gland

• Thrust Ball Bearing Yoke Bushing (6” & Larger)

• Ductile Iron Handwheel

• Bonnetless, Outside Screw & Yoke

• Rising Stem

• Meets MSS SP-81 Specication for 150 PSI CWP

• Cast Lugs in Yoke for Lockout in Closed Position or

Optional Open Position (Lock Bar is Optional)

• Smooth Flow, Non-clogging Seat Design

• Available in sizes from 2” to 24”

Bidirectional

Resilient Seated

Standards:

• Design: MSS SP-81

• Flange Drilling: ANSI B16.5

• Shell Test: MSS SP-81

• Seat Test: Exceeds MSS SP-81

• Material: ASME B16.34

www.fnw.com

Page 2

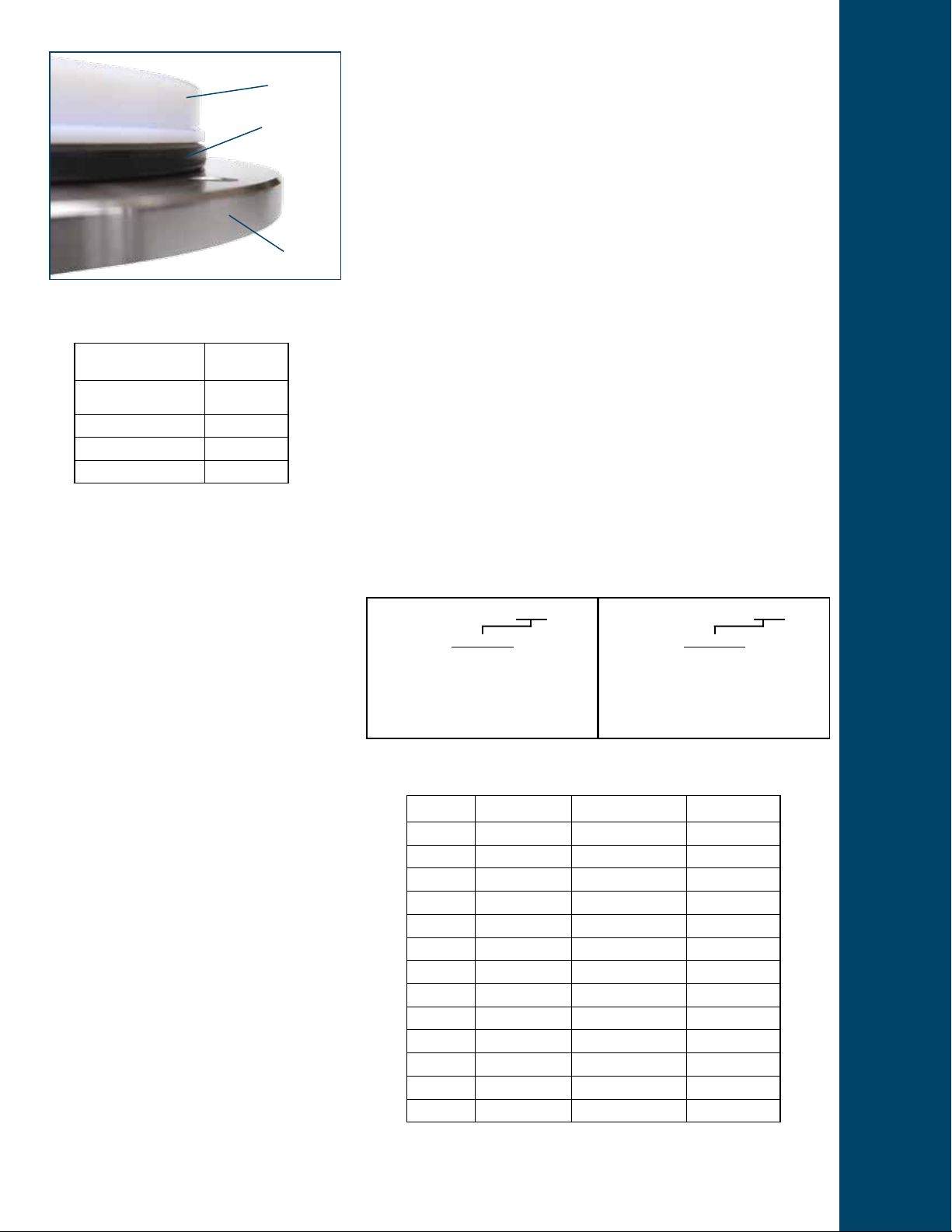

Flex Teon Seats

Seat Ring O-Ring

Retainer Ring

Packing Options

Type

PTFE Impregnated

Fiber (Standard)

Pure TFE 425ºF

TFE Fiber (Ultra) 500ºF

Graphite Filament Yarn 1000ºF

Temperature

Limit

425ºF

Seat Ring

The FNW gure 2000B utilizes a seating design that provides positive

shut-off in both directions, even at low pressure differentials. Similar

to high performance buttery valve designs, the gure 2000B uses

mechanically retained seat rings to hold the seats in place. The RTFE

seats are carried on the retainer rings and are pre-compressed with

o-rings to provide sealing pressure against the knife blade. These o-rings

also act as the seal between the body and seat rings. Seat material

can easily be replaced without disturbing the valve packing. This seat

conguration also improves the longevity of the seat as it is not directly in

the ow path.

Seat Rings

Made of RTFE, the seat rings are secured in place by an integral locator

lip around its circumference, tted into the valve body. Dual rings insure

shut-off in both directions.

Seat Ring O-Ring

Behind each seat ring is a hefty EPDM o-ring. This o-ring not only

provides sealing, but also maintains pressure behind the seat ring,

ensuring a tight shut-off.

Retainer Ring

Holding the seat rings and o-rings in place are the retainer rings. These

heavy stainless steel rings make replacing the seats and o-ring quick and

easy.

Options

FNW Valve Company offers many options

and modications for valves. These include,

but are not limited to:

• Actuation including ratchets, chain wheels,

AWWA nuts, gear-operators, pneumatic &

hydraulic cylinders, and electric actuators

• Packing options for pH and temperature

requirements

• Back seat stops for low ΔP or reverse

operation applications, or to prevent knife

blade deection

• V-ports for reduced plugging in metering

applications

• Stem extensions in carbon and stainless

steel

• Conversion to non-rising stem (NRS)

• Deection cones in Ni-Hard and HDPE for

added seat and gate protection in abrasive

services

• Flush ports to clear suspended matter from

the valve chest or seat pocket area

• Quick opening levers

Figure Number Matrix

FNW 2000BT Size

SIZE CODE

2 = K

2-1/2 = L

3 = M

4 = P

6 = U

8 = X

10 = 10

12 = 12

14 = 14

16 = 16

18 = 18

20 = 20

24 = 24

2 = K

2-1/2 = L

3 = M

4 = P

6 = U

Repair Kits

FNW 2000RKT Size

Flow Coefcients, Port Areas, & Weights

Size Cv Port Area (in²) Wt. (Lbs)

2 195 2.69 17.75

2-1/2 320 3.97 20.25

3 500 5.98 25.5

4 1,100 10.98 34.5

6 3,200 25.59 64

8 5,400 43.92 97

10 7,900 70.1 153

12 10,700 102.38 223

14 13,800 132.67 256

16 17,000 166.64 382

18 20,000 214.75 428

20 24,000 268.67 613

24 31,000 395.29 783

SIZE CODE

8 = X

10 = 10

12 = 12

14 = 14

16 = 16

18 = 18

20 = 20

24 = 24

• Gate scraper

Contact FNW for knife gate valve options.

Page 3

Dimensions (inches)

Size L Ød Open H1 H2 H3 O

2 1.88 1.85 14.75 4.21 5.49 - 7.09 6.00 4.75 3.62 0.50 0.06 4 5/8 - 11

2-1/2 2.00 2.25 16.17 4.72 5.94

3 2.00 2.76 18.18 5.00 6.67

4 2.00 3.74 21.65 6.10 7.81

6 2.25 5.71 29.88 7.42 12.26

8 2.75 7.48 36.95 9.76 14.54

10 2.75 9.45 44.06 11.93 17.00

12 3.00 11.42 50.75 14.09 16.93 3.24 17.72 19.00 17.00 15.00 0.75 0.06 12 7/8 - 9

14 3.00 13.00 57.11 15.47 19.94 3.48 19.68 21.00 18.75 16.25 0.81 0.06 12 1 - 8

16 3.50 14.57 64.95 18.11 22.28 3.67 21.65 23.50 21.25 18.50 0.88 0.06 16 1 - 8

18 3.50 16.54 70.65 19.92 24.19 3.67 21.65 25.00 22.75 21.00 0.94 0.06 16 1-1/8 - 7

20 4.50 18.50 77.17 22.36 27.18 3.67 21.65 27.50 25.00 23.00 1.00 0.06 20 1-1/8 - 7

24 4.50 22.40 90.18 26.30 31.31 3.67 21.65 32.00 29.50 27.25 1.00 0.06 20 1-1/4 - 7

7.09 7.00 5.50 4.19 0.50 0.06 4 5/8 - 11

-

7.87 7.50 6.00 5.00 0.50 0.06 4 5/8 - 11

-

9.84 9.00 7.50 6.19 0.50 0.06 8 5/8 - 11

-

11.81 11.00 9.50 8.50 0.63 0.06 8 3/4 - 10

-

13.78 13.50 11.75 10.62 0.63 0.06 8 3/4 - 10

-

15.75 16.00 14.25 12.75 0.75 0.06 12 7/8 - 9

-

O.D. B.C. ØR C t N H

Flange

Page 4

Figure 2000B

KNIFE GATE VALVES

STAINLESS STEEL HIGH PERFORMANCE

RESILIENT SEATED KNIFE GATE VALVE

Standard Materials

Ref.

No.

01 Body A351 CF8M 1

04 Retainer A351 CF8M 2

05 Yoke A351 CF8 1

06 Knife A240 316 1

08 Gland Flange A351 CF8M 1

12 Sleeve Gland A351 CF8 1

14 Wheel Nut A351 CF8 1

15 Handwheel A536 65-45-12 1

16 Yoke Sleeve A439 D2C 1

18 Stem A182 F304 1

19 Seat Ring RTFE 2

38 Sleeve Box A351 CF8 1 12 - 24” Sizes Only

56 Yoke Bolt A193 B8 1 Set

57 Yoke Nut A194 8 1 Set

58 Gland Bolt A193 B8 1 Set

59 Gland Nut A194 8 1 Set

62 Seat Ring Bolt A193 B8M 1 Set

64 Washer A276 304 1 Set

66 Stopper A182 F304 1

69 Grease Nipple A307 Gr. B 1 Cr. Plating

70 Set Screw A193 B8 1

71 Name Plate A240 304 1

73 Bearing Ass’y 2 6 - 24” Sizes Only

74 Key A108 1045 2

75 O-Ring EPDM 2

76 Stopper Bolt A193 B8 1

77 Stopper Nut A194 8 1

84 Pin Bolt A193 B8 1

85 Pin Nut A194 8 1

86 Sleeve Box Bolt A193 B8 1 Set 12 - 24” Sizes Only

87 Sleeve Box Nut A194 8 1 Set 12 - 24” Sizes Only

97 Packing PTFE 1 Set PTFE Impregnated Fiber

97-1 Packing / Wiper Seal EPDM 1

Description Material Qty Remarks

DOC: FNW2000B05 Ver. 10/2017

© 2017 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...