Page 1

Operating Manual BKS015

Steering Frame with Integrated Digital Controller

for Web Guiding

Version 1.81 11/2018 NS

Firmware Version 1.71

Diese Bedienungsanleitung ist auch in Deutsch erhältlich.

Bitte kontaktieren Sie Ihren nächstgelegenen FMS Vertreter.

© by FMS Force Measuring Systems AG, CH-8154 Oberglatt – All rights reserved.

Page 2

Operating Manual BKS015

Table of Contents

1 Safety Instructions ................................................................................... 2

1.1 Description Conditions 2

1.2 List of Safety Instructions 3

2 System Description .................................................................................. 4

2.1 Functional Description 4

2.2 Steering Frame 4

2.3 Web Guide Controller 4

2.4 Sensors 5

2.5 Cables 5

3 Quick Installation Guide ........................................................................... 6

3.1 Preparations for Set-up 6

3.2 Installation Procedure 6

4 Installation and Wiring ............................................................................. 7

4.1 Mounting the Steering Frame 7

4.2 Mounting the Sensors 7

4.3 Connecting the BKS015 8

4.4 Connector and Screw Terminal Arrangement 8

5 Configuring the System .......................................................................... 10

5.1 Powering up the BKS015 10

5.2 Adjustment of the Sensors 10

6 Operation ................................................................................................ 10

6.1 Operation Panel 10

6.2 Basic Instructions for Operation and Parameter Setting 11

6.3 Operating the Web Guiding System via the Front Panel 11

6.4 Operation in Automatic Mode 12

6.5 Operation in Manual Mode 13

6.6 Entering the Parameter Setting Mode 13

6.7 Description of the LED-row 14

6.8 Sensor Detection Range and Reference Position 15

7 Description Parameters ......................................................................... 15

7.1 Description Operation Parameters 15

7.2 Description of System Parameters 20

7.3 Reset to Default Parameter Set 21

8 Parameter Setting via a PC .................................................................... 22

8.1 Parameterization in a Network via Web Browser 24

8.2 Parameterization via a PC (peer-to-peer connection) 28

9 Mechanical Dimensions ......................................................................... 32

10 Trouble Shooting .................................................................................... 34

11 Technical Specification .......................................................................... 35

1 Safety Instructions

1.1 Description Conditions

a) Danger of health injury or loss of life

26.11.2018 2

Page 3

Operating Manual BKS015

Danger

This symbol refers to high risk for persons to get health injury or loss life. It has to

be followed strictly.

b) Risk of damage of machines

Caution

This symbol refers to information, that, if ignored, could cause heavy mechanical

damage. This warning has to be followed absolutely.

c) Note for proper function

Note

This symbol refers to an important information about proper use. If not followed,

malfunction can be the result.

1.2 List of Safety Instructions

Proper function of the FMS web guide is only guaranteed with the recommended

application of the components. In case of other arrangement, heavy malfunction

can be the result. Therefore, the installation instructions on the following pages

must be followed strictly.

Local installation regulations are to preserve safety of electric equipment. They are

not taken into consideration by this operating manual. However, they have to be

followed strictly.

Make sure that the sensor(s) are connected properly to the electronic unit by

means of the delivered cables. For left / right orientation please refer to Fig. 2. If

the connections are crossed over, malfunction can be the result.

System parameters are factory settings and should not be changed without

contacting the service department of FMS. An unauthorised change can cause

malfunctions in the system or damage in the machine

26.11.2018 3

Page 4

Operating Manual BKS015

2 System Description

2.1 Functional Description

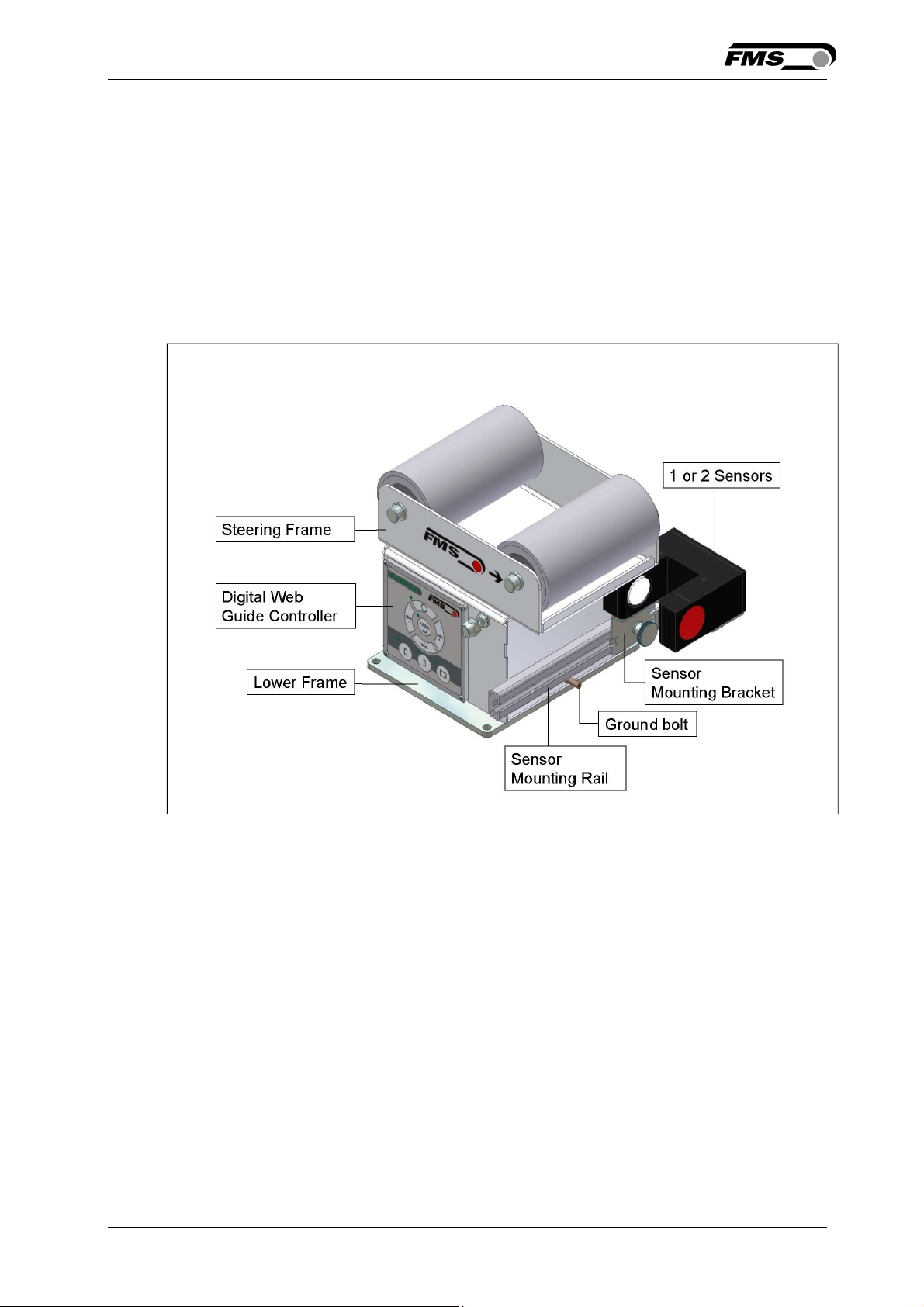

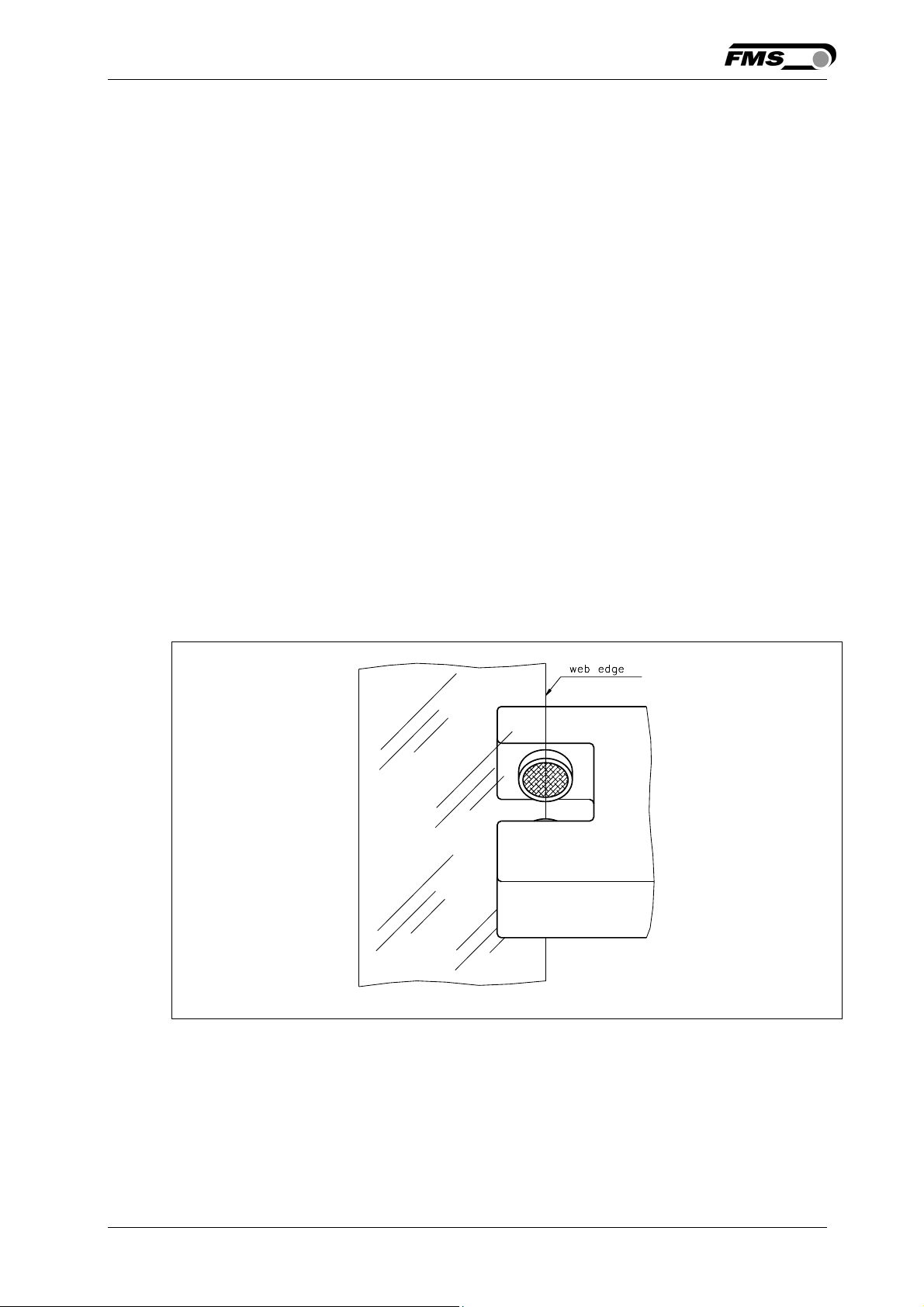

Figure 1 shows a typical web guiding system with its basic components.

The sensors measure the position of the web edge and send this information as an

analogue signal to the built-in web guide controller unit. The control compares the

position feedback signal with the reference. If the difference of these two values is

higher then the stored dead band value, the steering frame will be adjusted.

Fig. 1: Basic BKS015 system K015006e

2.2 Steering Frame

The steering frame consists of a fixed lower and a moveable upper frame that

supports the rollers. The upper frame is activated by a stepper motor. The rollers

are manufactured and balanced according to customer specification. End positions

are controlled by hall sensors. The material sensors are mounted on the lower

frame by means of a bracket array and are easily adjustable to the web width.

2.3 Web Guide Controller

The micro-processor based electronic control unit handles all calculations and

communications tasks. Three buttons and a five key wind-rose serve as the manmachine interface. Parameter setting can be performed via the front panel keys or

through a Web Browser (IE 7.0 or higher). The controller is then either connected to

a network (e.g. Ethernet) or via a peer-to-peer configuration to a laptop or local PC.

All parameters are stored in a none-volatile EEPROM memory.

26.11.2018 4

Page 5

Operating Manual BKS015

2.4 Sensors

Optical sensors (AZS04) and ultrasonic sensors (US01B) are available from FMS to

work in conjunction with the BKS015 system. These sensors provide a signal of

0...10V. With them edge and center applications can be covered. A wide range of

materials including opaque, transparent, open weave textiles and metallic webs can

be detected.

2.5 Cables

The power supply cable enters to the web guide via a PG-gland connection. For each

sensor a dedicated orange cable is delivered.

26.11.2018 5

Page 6

Operating Manual BKS015

3 Quick Installation Guide

The set-up of the BKS015 web guide including controller unit is limited to only

mounting the devices on the machine frame, wiring and powering up system.

3.1 Preparations for Set-up

• Prepare your machine frame to integrate the BKS015 web guide. The web guide

is mounted on the machine by means of the 4 holes on its base plate. Refer to

Fig. 21 for the mechanical dimensions and mounting holes of the BKS015.

• Check your system requirements such as:

– Desired guiding form (edge or centre guiding)

– Supply conditions

• Draw the wiring diagram for your configuration (ref. to 4.3 “Connecting the

BKS015“ and chapter 4.4 “Connector and Screw Terminal Arrangement”)

• If required, determine special parameters (ref. to 7.1 “Description Operation

Parameters”)

3.2 Installation Procedure

1. Mount and ajust your material sensor(s) to the steering frame (ref. to chapter 4.2)

2. Mount the web guide to the machine frame

3. Connect the sensor(s) to the electronic unit.

4. Make sure the power supply voltage is in the range 18 to 36V DC (Vnom= 24V)

5. Power your system on

6. If required, make additional settings (ref. also to chapters 6.4 to 6.8)

26.11.2018 6

Page 7

Operating Manual BKS015

4 Installation and Wiring

Caution

Proper function of the FMS web guides and actuators is only guaranteed with the

recommended application of the components. Other arrangements can cause

heavy malfunctions. Therefore, the installation instructions on the following pages

must strictly be followed.

Caution

Local installation regulations are to preserve safety of electric equipment. They are not

taken into consideration by this operating manual. However, they have to be followed

strictly.

4.1 Mounting the Steering Frame

The mounting orientation of the steering frame (indicated by an arrow), must

correspond with the web running direction. The lower frame is mounted with four

M5 screws to the machine frame. The machine must be prepared to accept the M5

mounting screws.

The steering frame must be connected to earth ground. Ensure that the base plate

of the steering frame has direct contact with the grounded machine frame. In

addition the ground bolt (see Fig. 1) must be connected to the machine earth.

Caution

Bad earth connection may cause electric shock to persons, malfunction of the total

system or damage of the control unit. It is vital to ensure that there is a proper and

secure earth connection.

4.2 Mounting the Sensors

The sensors will be mounted with brackets on a rail to the lower frame of the web

guide

They have to be installed after the outbound roller. Mount them as close as possible

to the steering frame (see Fig. 2). The sensors are connected to the web guide

controller by means of the delivered orange cables. Refer to the operation manual

AZS01, US01B for further information about the sensors.

26.11.2018 7

Page 8

Operating Manual BKS015

Definition of Left and Right:

Left and right are always seen in direction of the running web (see Fig. 2).

Fig. 2: Position of the sensors according to the web K400005e

Sensors of the type AZS must be mounted with its narrow side (thinner leg) on the

side of the steering frame

Caution

Make sure that the sensor(s) are connected properly to the electronic unit by

means of the delivered orange cables. For left / right orientation please refer to Fig.

2. If the connections are crossed over, malfunction can be the result.

4.3 Connecting the BKS015

The power supply unit musst deliver a voltage from 18 to 36V DC (Vnom= 24V).

Connect the cable coming out of the PG-gland to your power supply unit.

Wire colour Signal

brow 24 VDC

blue GND

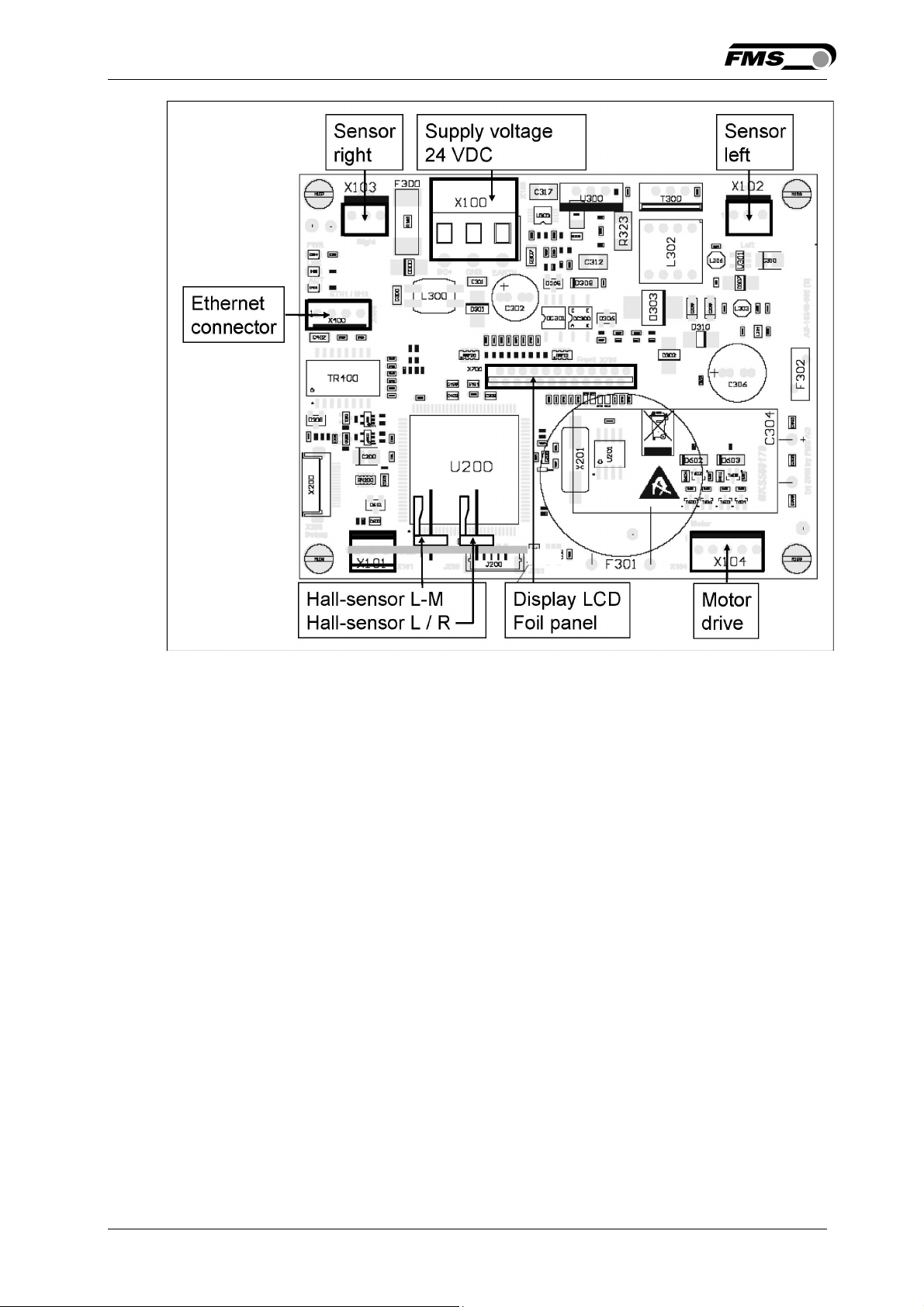

4.4 Connector and Screw Terminal Arrangement

26.11.2018 8

Page 9

Operating Manual BKS015

Fig. 3: Terminal arrangement on processor board K015008e

26.11.2018 9

Page 10

Operating Manual BKS015

5 Configuring the System

After having mounted and wired the web guide on the machine, the system can now

be configured to the specific requirements of the application.

5.1 Powering up the BKS015

1. Make sure the power supply delivers a voltage of 18…36 VDC (Vnom= 24V)

2. Check, if the web is in the detection range of the sensors.

3. Switch-on your power supply

4. The web guide starts-up in Manual Operating Mode.

5.2 Adjustment of the Sensors

Align sensor axis to the web edge:

Loosen the fixing nut on the bracket and adjust the sensor. Fix the sensor in the

new position. The sensor will be properly positioned, if the web edge goes through

the sensor axis (center of active window; ref. to Fig. 4).

Fig 4: Alignment of the sensor axis to the web edge K100004e

.

6 Operation

6.1 Operation Panel

26.11.2018 10

Page 11

Operating Manual BKS015

t

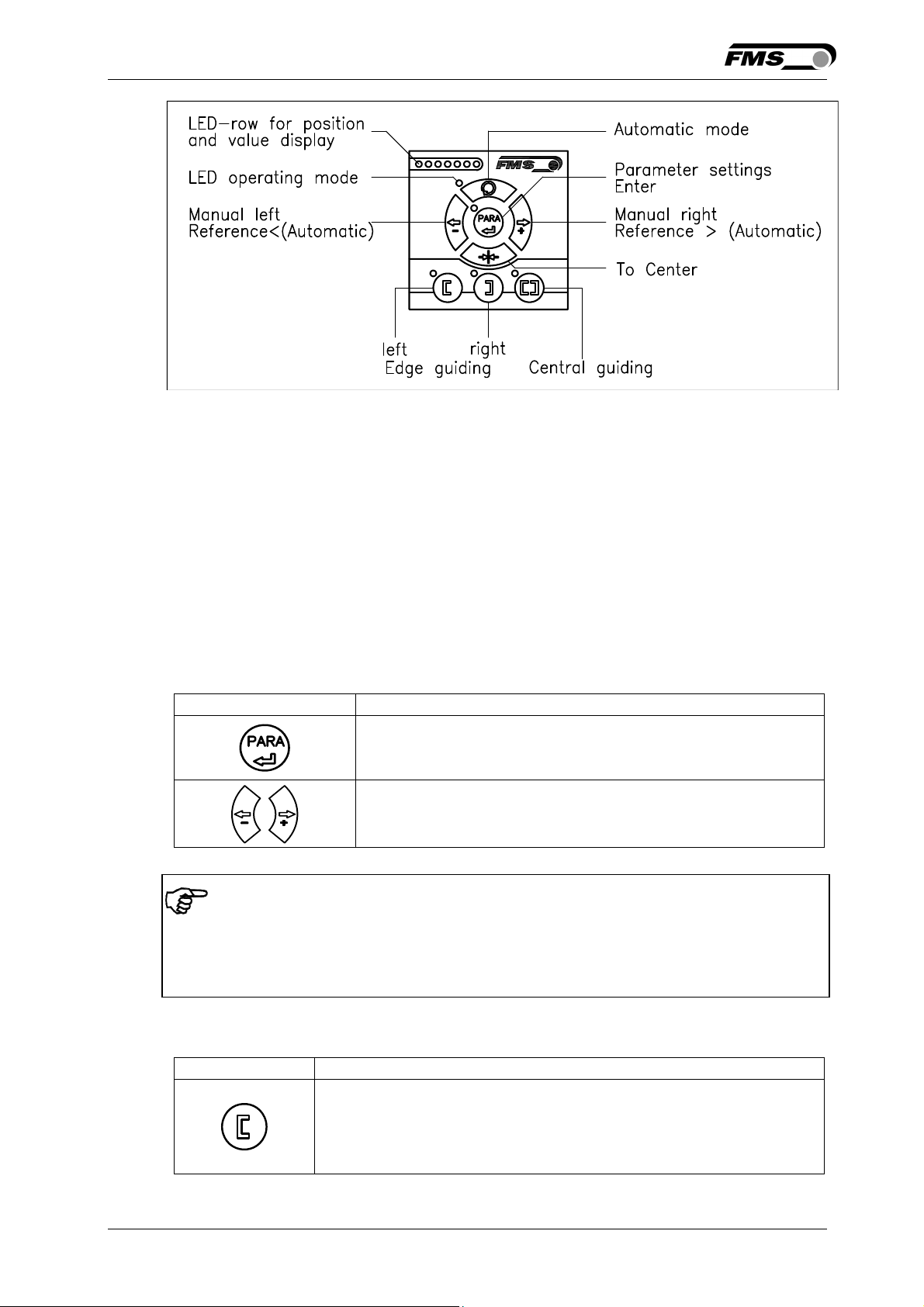

Fig. 5: View of the Operation Panel K015003e

6.2 Basic Instructions for Operation and Parameter Setting

The web guide controller has three operation mods:

• Operation Mode

• Parameter Setting Mode (e.g. Dead Band)

• Change Mode (change of Reference Position)

Parameter setting can be performed via the keys on the front panel or via a web

browser. When using the front panel, the user can toggle between these modi by

pressing the corresponding key or key combination. The Parameters are described

in chapter 7.1 “Description of Operation Parameters”). The keys have the following

functions:

Key Key function during parameter setting

Enter

Increase or decrease the values.

Permanent pressing of the keys expedites the changing speed.

Note

To make the settings easier for the operator, there is visual help in form of LED row.

The pattern on the LED row indicates the setting range (ref. to chapter 6.7

“Description of the LED row).

6.3 Operating the Web Guiding System via the Front Panel

Key Key function during operation

The sensor is mounted on the left side of the frame and

controls the material on the left edge or on the line, if a line

sensor is used. One sensor is necessary. The LED indicates

he left edge guiding mode.

26.11.2018 11

Page 12

Operating Manual BKS015

t

t

The sensor is mounted on the right side of the frame and

controls the material on right edge or on the line, if a line

sensor is used. One sensor is necessary. The LED indicates

he right edge guiding mode.

Two sensors are mounted on both sides of the frame. The

frame is controlled in a way that the material position is kept

centered with regard to both sensor positions. The LED

indicates the centre guiding mode.

Key to enter the Parameter Setting Mode. Hold the key for

longer then 3 sec. The LED above the PARA key lights. A

second press for longer then 3 sec. on the PARA key will store

he value (ref. to 6.6 “Entering the Parameter Setting”)

With this key you can select between automatic or manual

mode. The LED indicates the automatic mode.

Drive to center position. The frame moves to the center

Position. This function is only available in manual mode.

In manual mode the frame will move to the left in 0.1mm

steps by pressing the button once. By pressing the button

longer than 1 sec. it will continuously move the frame to the

left.

In automatic mode the Reference Position will be adjusted to

the left in 0.1 mm steps by pressing the button once. Pressing

the button longer than 1 sec. it will continuously move the

Reference Position to the left (see chapter 6.4)

In parameter setting mode: Pressing the button reduces

continuously the parameter value.

In manual mode the frame will move to the right in 0.1mm

steps by pressing the button once. By pressing the button

longer than 1 sec. it will continuously move the frame to the

right.

In automatic mode the Reference Position will be adjusted to

the right in 0.1 mm steps by pressing the button once.

Pressing the button longer than 1 sec. it will continuously

move the Reference Position to the right. (see chapter 6.4) “.

In parameter setting mode: Pressing the button increases

continuously the parameter value.

Fig. 6: Table of key functions

6.4 Operation in Automatic Mode

26.11.2018 12

Page 13

Operating Manual BKS015

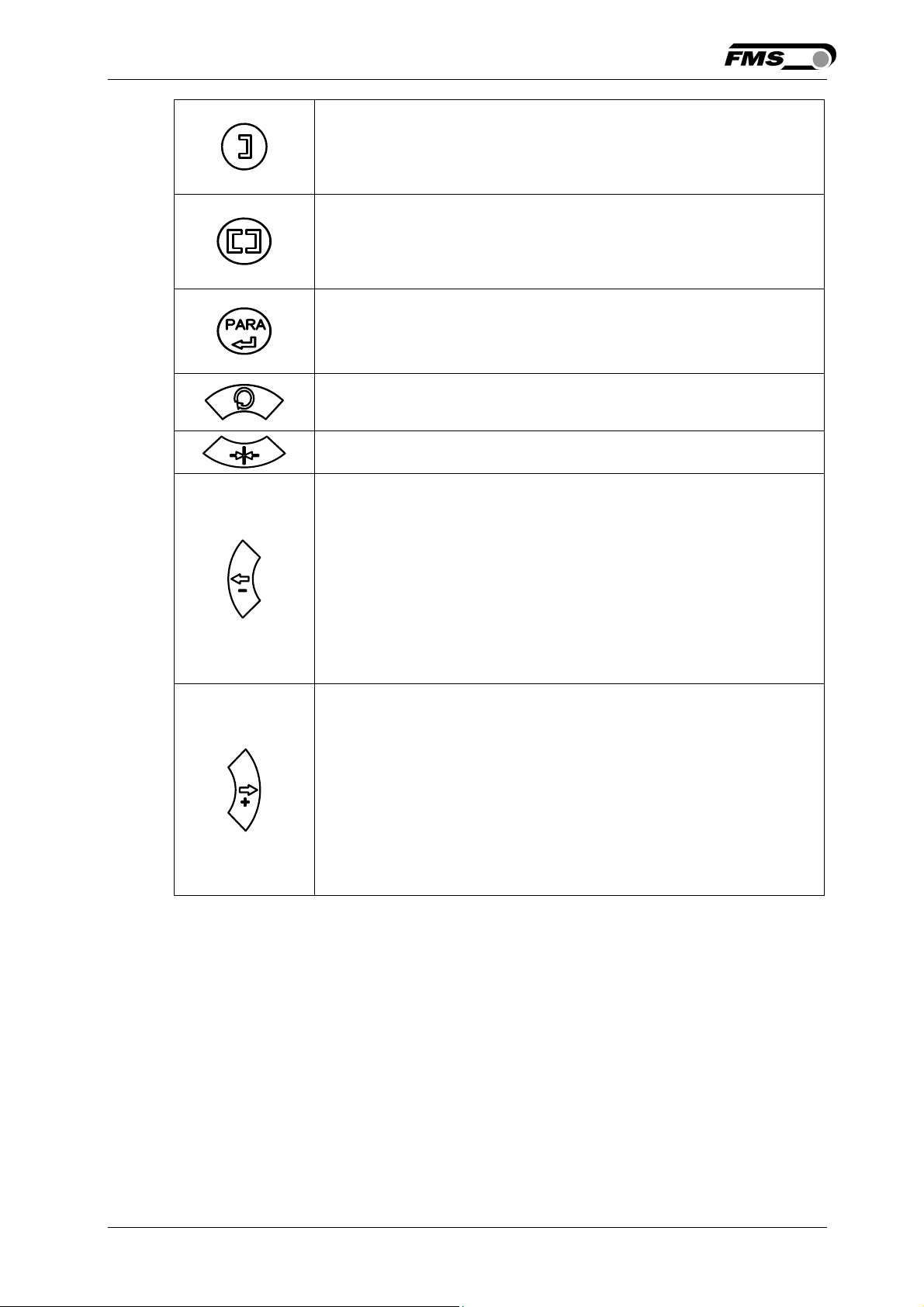

In Automatic Mode the web guide controller starts to guide the web to the Reference

Position and to hold this guiding point.

For edge guiding operations the Reference Position is in the middle of the sensor

detection range (Fig. 7). For centre guiding the Reference Position is in the middle

between the two sensor axis.

This Reference Position can be adjusted as

follows:

• Start automatic mode with the key.

• The Reference Position can be adjusted in

0.1mm steps by using the and keys.

• For left sensor operation the key causes

the web moving inside the sensor. The

key causes the web moving outside the

sensor. Using right sensor operation or

center guiding the setting behaves contrariwise (refer also to Fig. 10, 11 and 12)

• Terminate the automatic mode by using the key again.

Fig. 7: Reference position at

automatic start K100005e

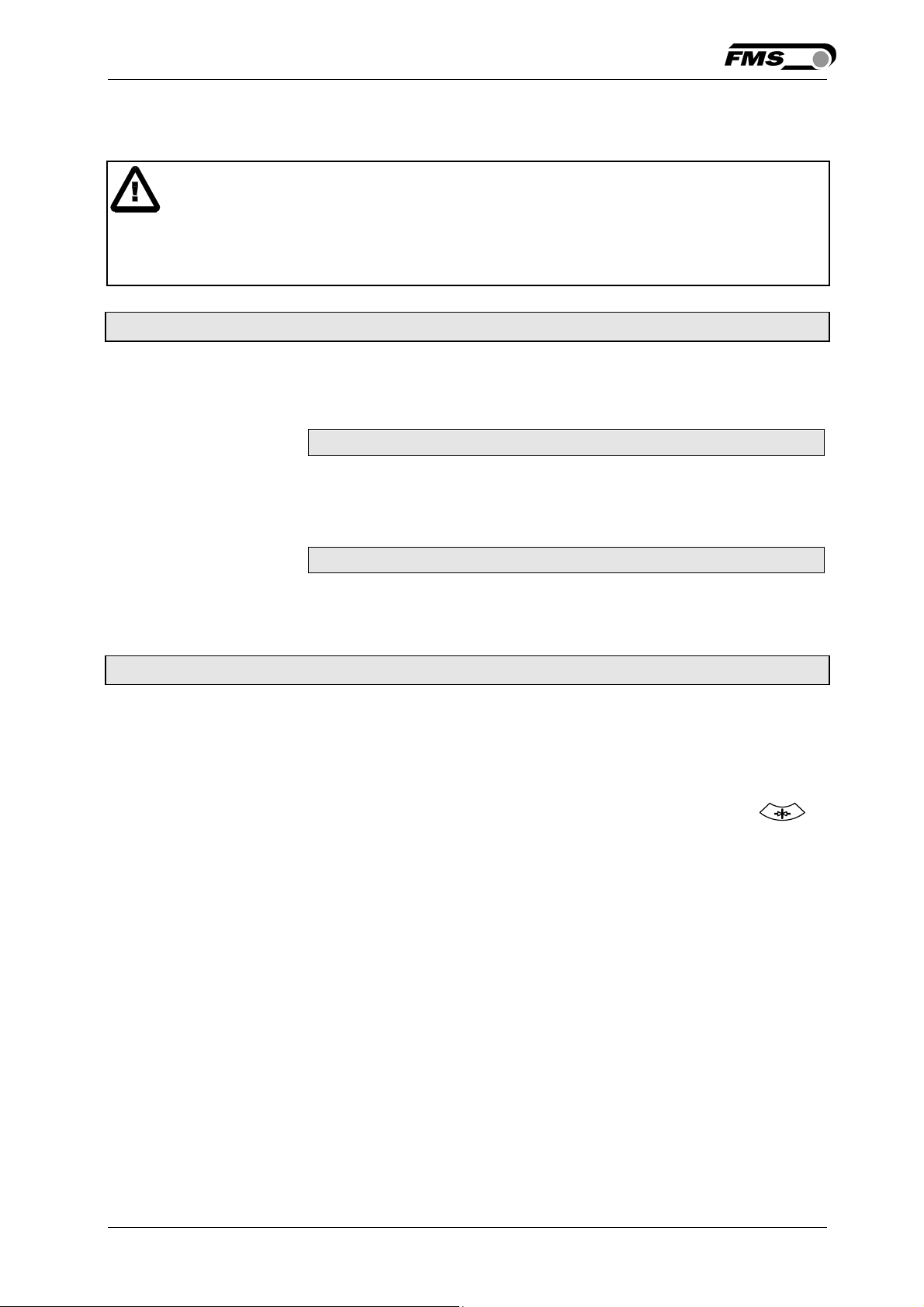

Caution

If web is not running, it can’t be guided properly to the Reference Position. The

steering frame moves in the limit-of-travel position and may damage the web. Start

automatic mode only when web is slowly running

Note

If the web leaves the sensor detection range, control is no longer effective. Hold the

web edge strictly inside the sensor detection band.

6.5 Operation in Manual Mode

In Manual Mode several operations and settings can be carried out (see Fig. 6):

• Center position : The steering frame will return to center position.

• Frame position and : The steering frame can be adjusted in 0.1mm steps. If

key is held, the steering frame will move continuously to chosen direction.

• Parameter Setting Mode: The Parameter Setting Mode can only be entered in

Manual Operation.

6.6 Entering the Parameter Setting Mode

To enter the Parameter Setting Mode the web guide controller must be in the

Manual Mode. In the Automatic Mode only the reference value can be changed.

26.11.2018 13

Page 14

Operating Manual BKS015

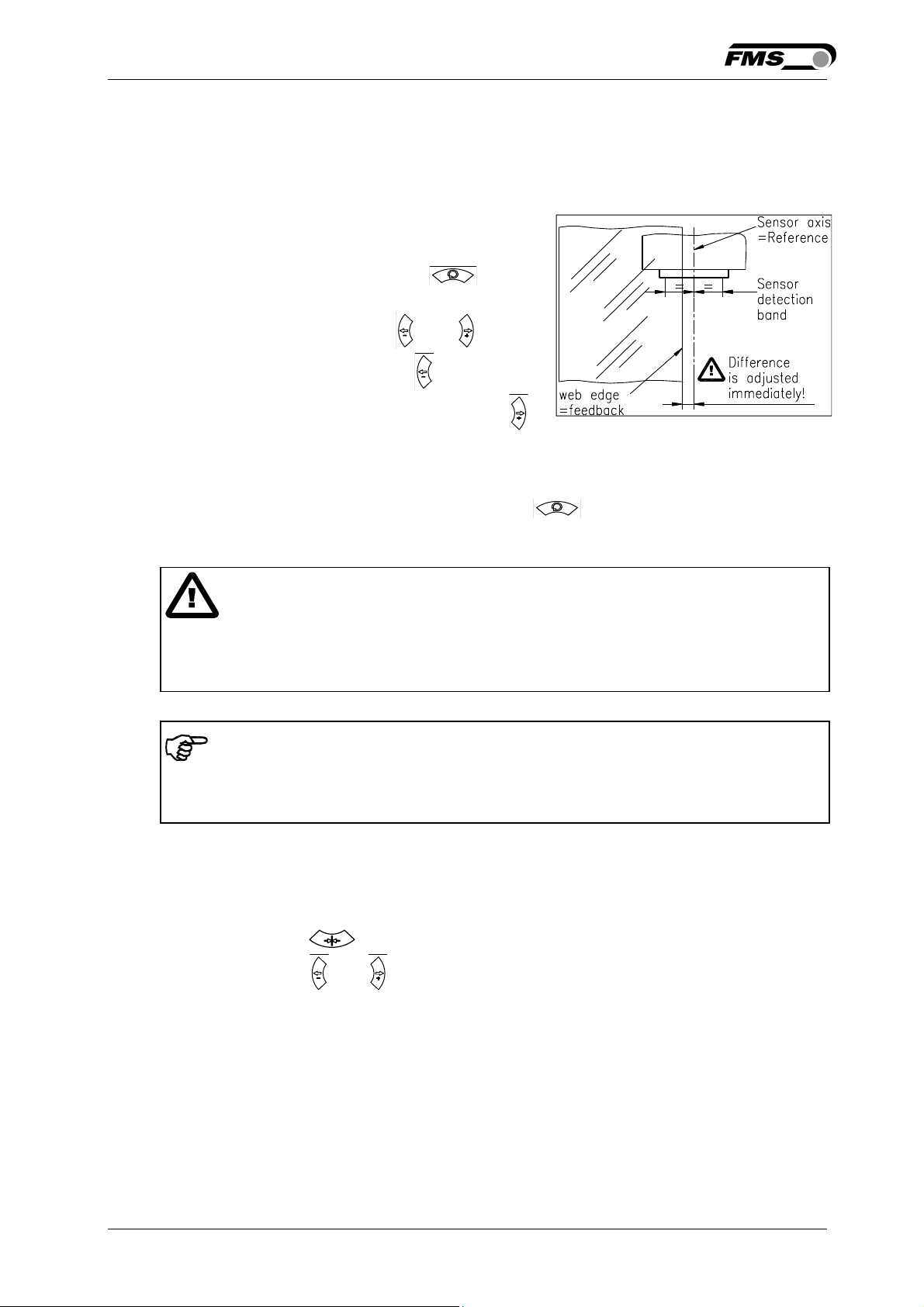

• Press the key for longer then 3 sec. The LED above the key will light

indicating that the controller entered the Parameter Setting Mode. In this mode

the Dead Band parameter can be adjusted (see chapter 7 “Description of

Operation Parameters”)

• With the keys and the desired band can be adjusted (see Fig. 9)

• Press the key again to confirm the setting and leave the Parameter Setting

Mode.

6.7 Description of the LED-row

☼

= LED illuminated ● = LED off

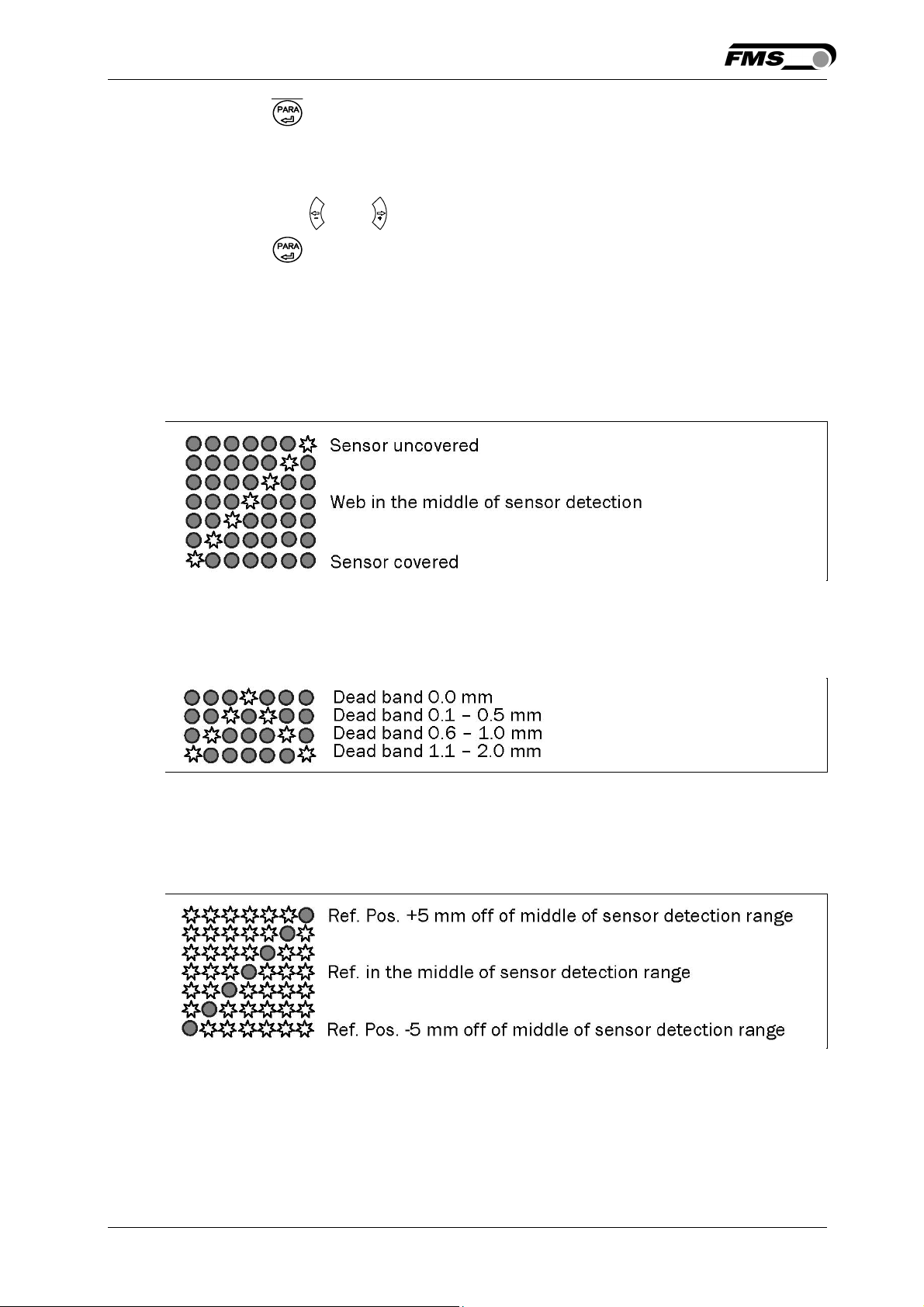

a) Automatic or manual mode. LED control of web position

Fig 8: LED row indicates material position K015004e

b) Setup mode for the adjustment of Dead Band

Fig 9: LED indication of Dead Band values K015005e

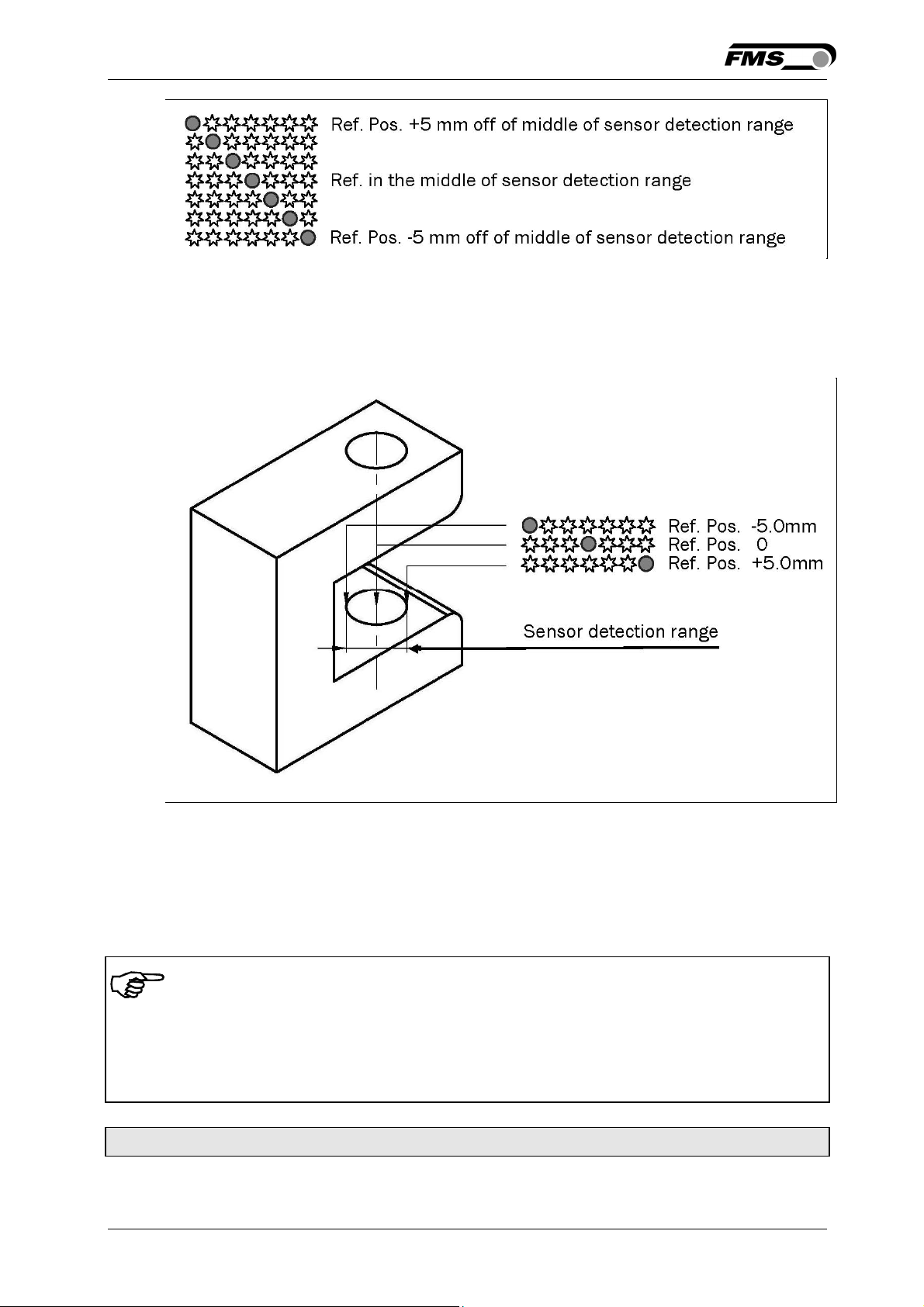

c) Setup mode for the adjustment of the Reference Position for left sensor

operation. Setup is only possible in automatic mode with the direction keys.

Fig 10: LED indication of Reference Position values (left sensor) K015013e

d) Setup mode for the adjustment of the Reference Position for right sensor

operation and center guiding. Setup is only possible in automatic mode with the

direction keys.

26.11.2018 14

Page 15

Operating Manual BKS015

Fig 11: LED indication Reference Position values (right sensor) K015014e

6.8 Sensor Detection Range and Reference Position

Fig. 12: View of the Sensor Detection Range K015007e

7 Description Parameters

7.1 Description Operation Parameters

Note

The first three parameters [RefPos], [RefMode] and [DeadBand] in the parameter list

below can be changed via the front panel (ref. to chapters 6.4 to 6.8). All other parameters

can only be accessed and changed vial the build-in web browser (ref. to chapter 8

“Parameter Setting via a PC”)

Adjusting Reference Position [Ref Pos]

Purpose: The [RefPos] parameter determines the reference position within

the sensor detection range. This reference point can also be

26.11.2018 15

Page 16

Operating Manual BKS015

adjusted over the front panel as described in chapter 6.2

“Automatic Operation”. The Reference Position is kept stored

until the next power-on.

Range: -5.0 to +5.0 Default: 0.0

Increment: 0.1 Unit: [mm]

Note

By pressing the keys and at the same time for longer then 1

sec., the Reference Position will reset to default

Setting Reference Mode [Ref Mode]

Purpose: This parameter determinates how the Reference Position is

defined. This can either be the position that is defined with

parameter [Ref Pos] or the actual material position within the

sensor when the controller is switched to automatic operation.

Two settings are possible:

Setting: [Manual]

Purpose: If [Manual] is chosen, the reference is taken from the parameter

[RefPos].

Setting: Automatic [Auto]

Purpose: If [Auto] behaviour is chosen then the reference is determent by

taking the actual material position within the sensor when the

controller is switched to automatic operation.

26.11.2018 16

Page 17

Operating Manual BKS015

Dead band [DeadBand]

Purpose: This parameter defines the dead band tolerance. Dead band is a

free programmable range, in which the web may move freely

without the controller re-adjusting the frame. If the deviation is

higher than the tolerance, the web will be re-adjusted into the

range of the dead band. Keep in mind that: A [DeadBand] of e.g.

0.3mm“ results in a tolerance band of ±0.3mm.

Range: 0.0 to 2.0 Default: 0.0

Increment: 0.1 Unit: [mm]

Note

By pressing the two keys and at the same time for longer

then 1 sec. will reset the Dead Band to default value.

Unit System [Unit Sys]

Purpose: This parameter determines the unit system that is used when the

parameters are set via the web browser.

The user can choose between two settings.

Setting: [Metric]

Purpose: Settings in the web browser are carried out in metric units.

Setting: [Imperial]

Purpose: Settings in the web browser are carried out in imperial units.

Gain Setting [Gain]

Purpose: This parameter defines the gain of the feed back value.

Range: 0.02 to 2.00 Default: 0.20

Increment: 0.01 Unit: [ - ]

26.11.2018 17

Page 18

Operating Manual BKS015

Adjusting Correction Speed [AdjSpeed]

Purpose: This parameter determines the maximum used correction speed.

Range: 1 bis 100 Default: 100

Increment: 1 Unit: [%]

Power Modes [Power ON]

Purpose: This parameter determines the operation mode after power on.

The user can choose between three behaviours.

Setting: [Manual]

Purpose: The controller goes to Manual Operation Mode after power on.

Setting: Automatic [Auto]

Purpose: The controller goes to Automatic Operation Mode after power on.

Setting: Last Setting Used [Last Set]

Purpose: The controller restores the operation mode that was previously

chosen before power off.

Behaviour when leaving Automatic Mode [Auto→Man]

Purpose: This parameter determines the behaviour of the controller leaving

the automatic mode.

The user can choose between two behaviours.

Setting: [Manual]

Purpose: The controller stops guiding. The web guide is locked at the

current position (Manual Mode).

Setting: [Centre]

Purpose: The controller stops guiding. Afterwards the web guide moves to

the centre.

26.11.2018 18

Page 19

Operating Manual BKS015

[IP Addr]

Purpose: The parameter assigns an IP address to the controller. This

enables the user to communicate via a web browser with the

controller that is imbedded in a network. The IP address must be

entered in 4 separate blocks (IP Bl. 1; IP Bl. 2; IP Bl. 3; and IP Bl.

4)

Range: 0 to 255 Default: 192.168.0.090

Increment: 1 Unit: [ - ]

[Subnet]

Purpose: The parameter assigns the Subnet Mask of the controller in the

Ethernet network. This enables the user to communicate via a

web browser with the controller. The Subnet Mask must be

entered in 4 separate blocks (Sub. Bl 1; Sub. Bl 2; Sub. Bl 3; and

Sub. Bl 4).

Range: 0 to 255 Default: 255.255.255.0

Increment: 1 Unit: [-]

[LANSpeed]

Purpose: [LANSpeed] determines the data speed of the web guide

controller to communicate the receiver (Switch, Hub or PC).

Selection: 10 or 100 Default: 100

Unit: [MBPS]

26.11.2018 19

Page 20

Operating Manual BKS015

7.2 Description of System Parameters

Caution

System parameters are factory settings and should not be changed without contacting the

service department of FMS. An unauthorised change can cause malfunctions in the

system or damage in the machine.

Offset Centre [Offset><]

Purpose: This parameter adjusts the position of a steering frame exactly to

the centre.

Type: [One Hall]

Purpose: One hall sensor is used to detect the Home position, Middle

Position and Maximum Position.

Type: [Two Hall]

Purpose: Two hall sensors are used to detect the Home position, Middle

Position and Maximum Position.

Centre Position [CentrPos]

Purpose: The [CentrPos] parameter is only used with the position detection

system based on hall sensors. For all other position detection

system this parameter is not used and hence not displayed. The

parameter determines the centre position of the actuator spindle

in motor steps (measured from the left reference position). The

actuator stops at this position, if you press the centre key .

In Automatic Operation this parameter has no meaning.

Range: 0 to 10’000 Default: Factory setting

Increment: 1 Unit: [Step]

26.11.2018 20

Page 21

Operating Manual BKS015

Right Limit [RightLim]

Purpose: The [RightLim] parameter is only used with the position detection

system based on hall sensors. For all other position detection

system this parameter is not used and hence not displayed. The

parameter limits the maximum travel to the right side of the

actuator spindle in motor steps (measured from the left reference

position). In the operation or in manual mode this limit will never

be exceeded

Range: 0 to 10’000 Default: Factory setting

Increment: 1 Unit: [Step]

Drive Direction [DriveDir]

Purpose: This parameter determines the guiding orientation of the

controller. Usually stepper motors turn clockwise. This setting

changes the turning direction of the motor. There are two other

possibilities to change the guiding direction:

The user can choose between two settings

Setting: [Standard]

Purpose: [Standard] is chosen when standard motors and standard frames

are used.

Setting: [Invers]

Purpose: [Invers] is chosen when motors are used that turn anticlockwise.

7.3 Reset to Default Parameter Set

Factory settings of your BKS015 web guide controller can be re-established by

pressing a combination of two keys.

Hold the two keys + while powering -up the controller

26.11.2018 21

Page 22

Operating Manual BKS015

8 Parameter Setting via a PC

The BKS015 web guide controller can be embedded in an Ethernet network and the

parameter setting can be done over this network by means of a web browser

(Internet Explorer 7). The devices have a static IP-address that can be set over the

user interface. The IP-address is not automatically received over DHCP.

The parameter setting can also be carried out with a desktop- or laptop computer

via a peer-to-peer connection (see chapter 8.2)

Fig. 13: BKS015 configuration in a LAN (Local Area Network). K015009e

Note

Fig. 14 and 15 show the peer-to-peer connection between PC und BKS015. Use for

this configuration a cross-over-cable and not the standard patch Ethernet cable.

26.11.2018 22

Page 23

Operating Manual BKS015

Fig. 14: Correct connection with crossover-cable. K015010e

Fig 15: Connection with wrong cable

K05011e

26.11.2018 23

Page 24

Operating Manual BKS015

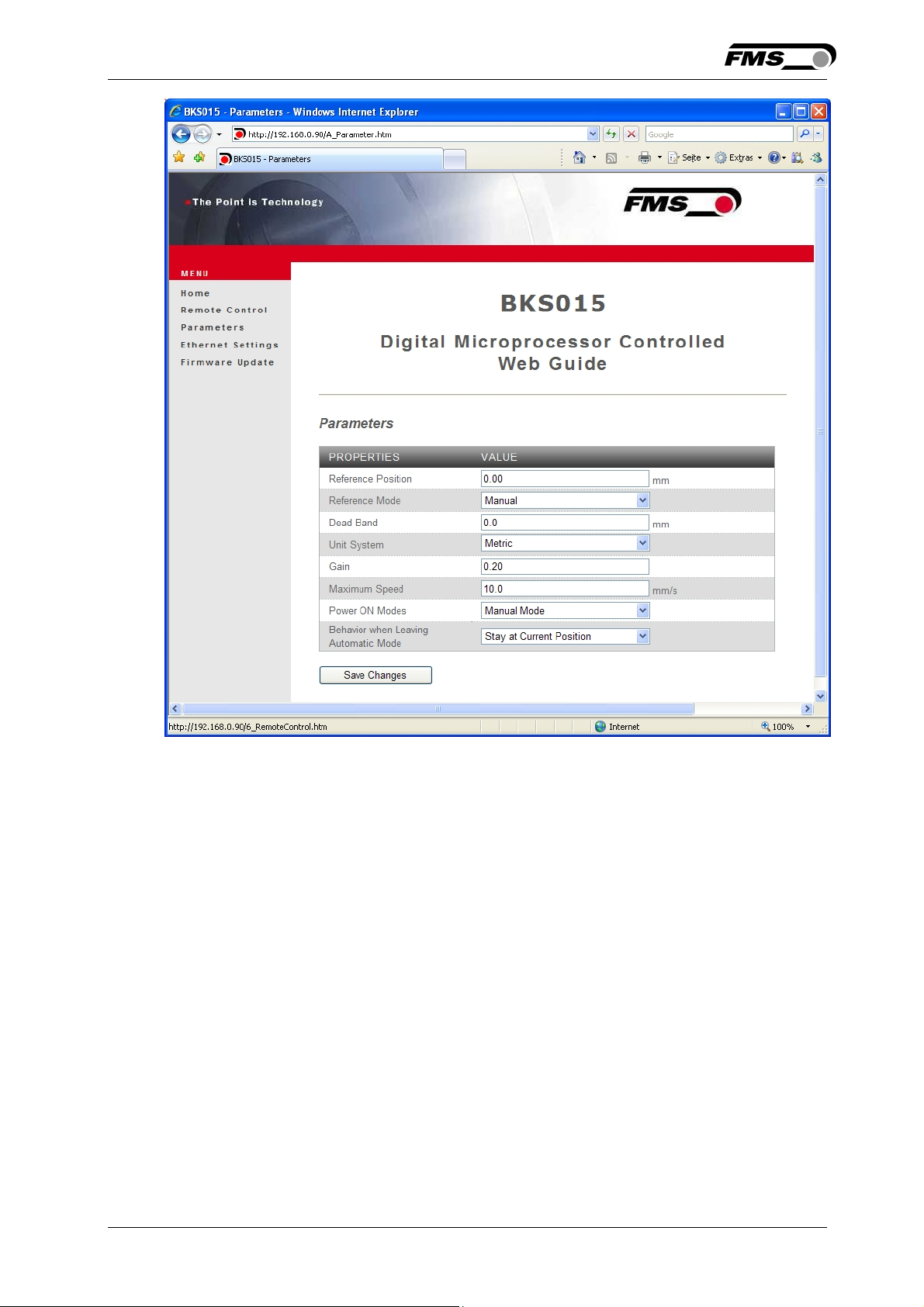

8.1 Parameterization in a Network via Web Browser

Before the parameterization of the BKS015 is done it must be certain that the

BKS015 uses an IP address in a static block. For the integration of a BKS15 web

guide controller in your Ethernet network please contact your IT system

administrator.

Once the BKS015 was integrated in the network you can address the device e.g.

with http://192.168.000.090 . After establishing the link, the screen Fig.16 will

open up.

Fig. 16: Serial number and device information

Home.jpg

With the menu on the left side of the screen you can navigate through the web

page.

26.11.2018 24

Page 25

Operating Manual BKS015

Fig. 17: Front panel for remote control purposes Remote Control

26.11.2018 25

Page 26

Operating Manual BKS015

Fig. 18: Parameter list. Parameters can be changed Parameters

26.11.2018 26

Page 27

Operating Manual BKS015

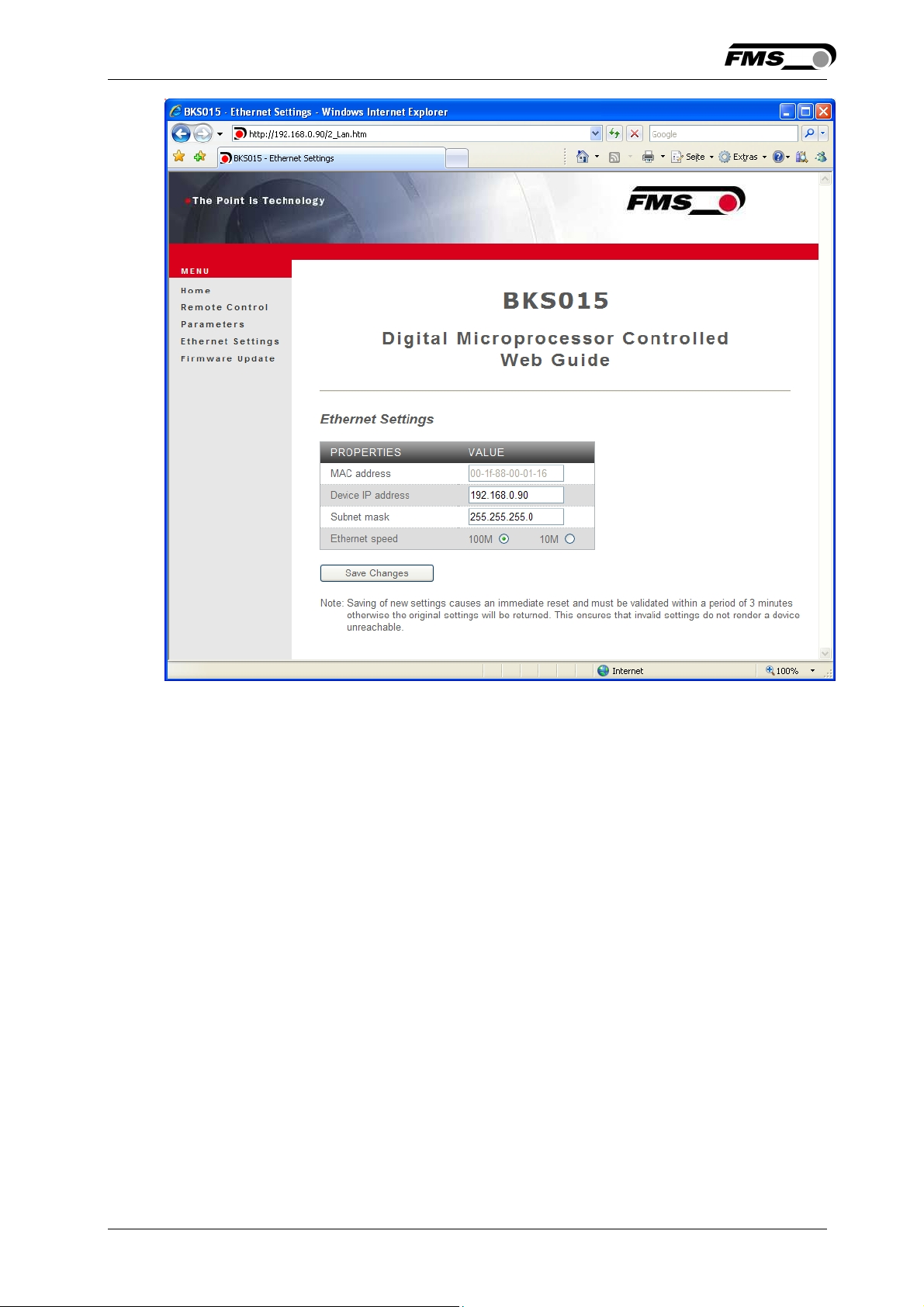

Fig. 19: Ethernet settings and device addresses

Ethernet Settings

26.11.2018 27

Page 28

Operating Manual BKS015

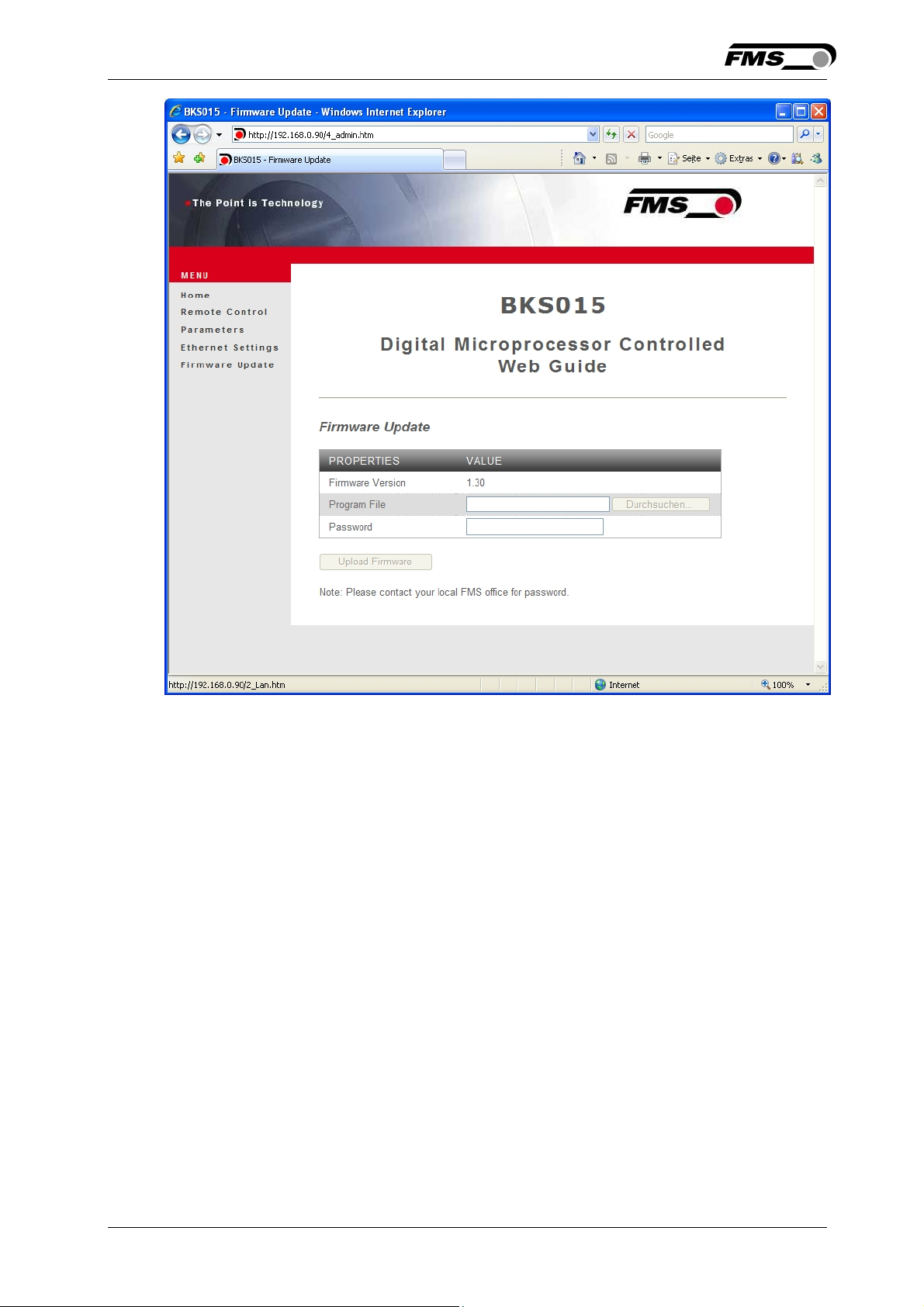

Fig. 20: Firmware update Firware Updates

8.2 Parameterization via a PC (peer-to-peer connection)

This chapter describes the procedure for setting up a desktop or laptop computer to

communicate with FMS BKS015 web guide controller.

Before connecting the FMS BKS015 controller with a “cross-over-cable” directly to a

PC, the computer must be configured with a “static” IP address that lets it recognize

the BKS015. If the BKS015 controller is connected to a network by using e.g. a

switch, the following procedure is not necessary. To establish the connection

between your PC and the BKS015 follow the steps below.

26.11.2018 28

Page 29

Operating Manual BKS015

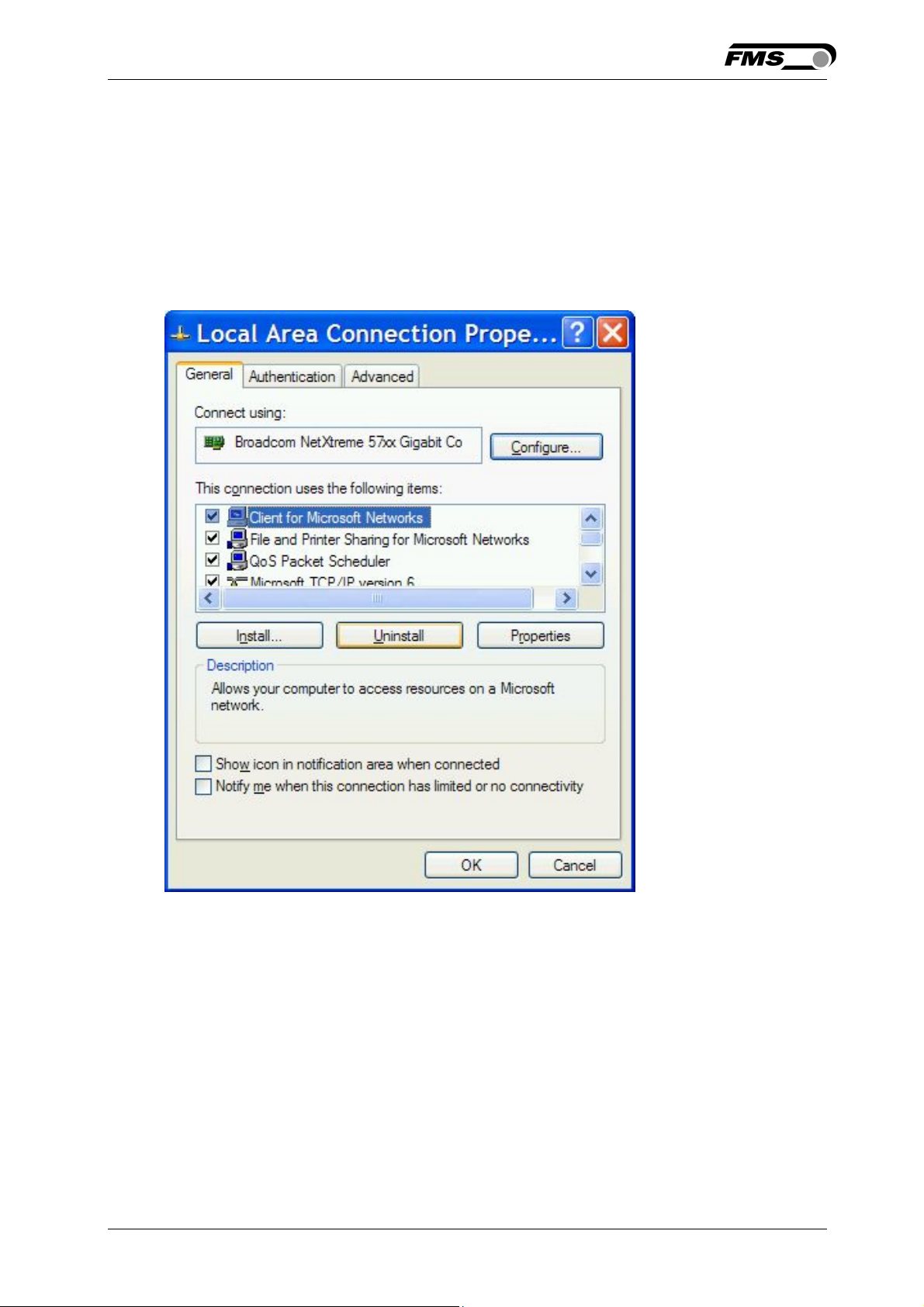

Setup in Microsoft Windows XP:

1. Click on the Start button (lower left-hand corner of the screen)

2. Click on Control Panel

3. Double click on Local Area Network

4. Right click on the network adapter that is used for the connection.

5. Click on Properties on the pop up menu, the following dialog box “Local Area

Connection Properties” will appear.

26.11.2018 29

Page 30

Operating Manual BKS015

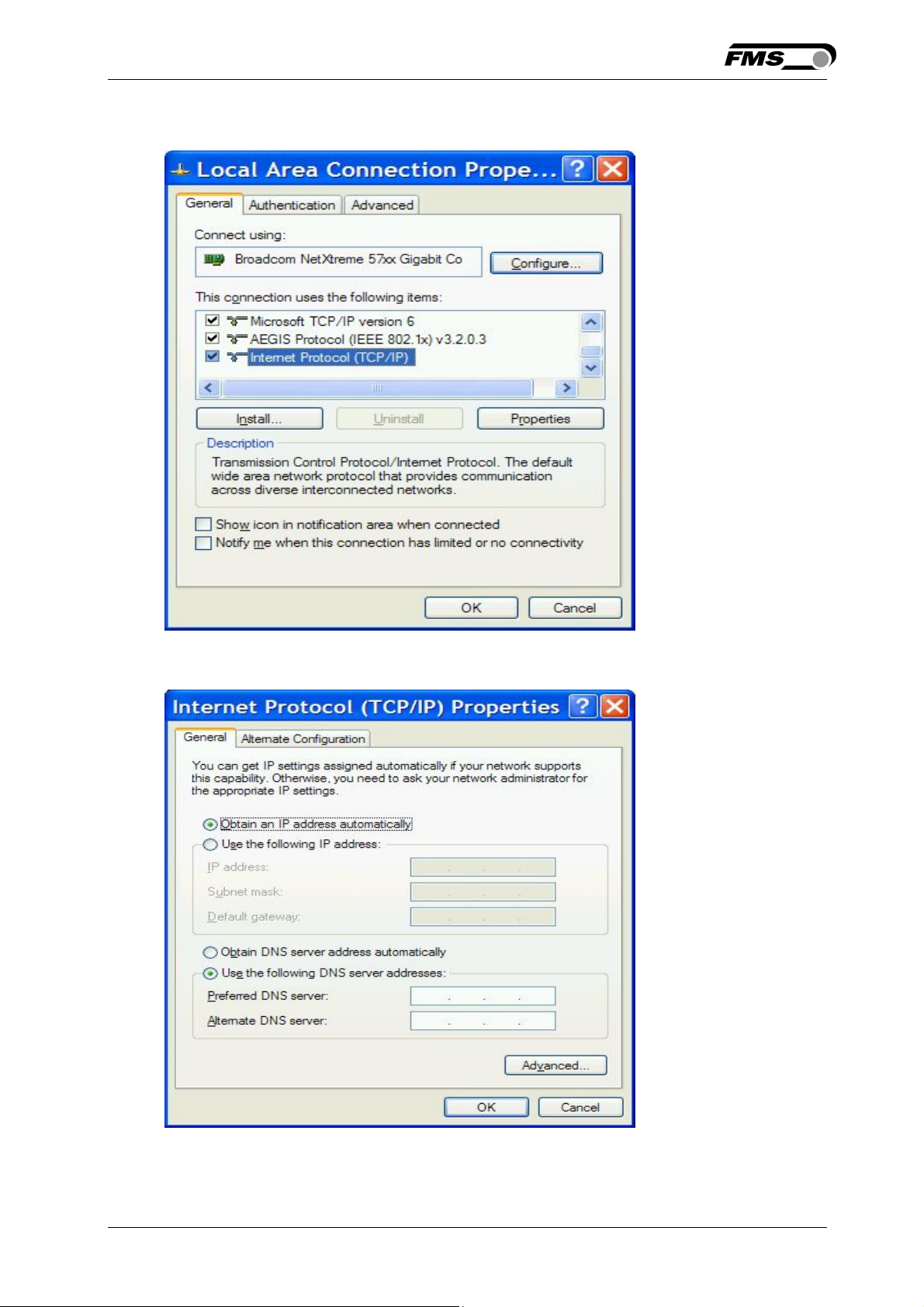

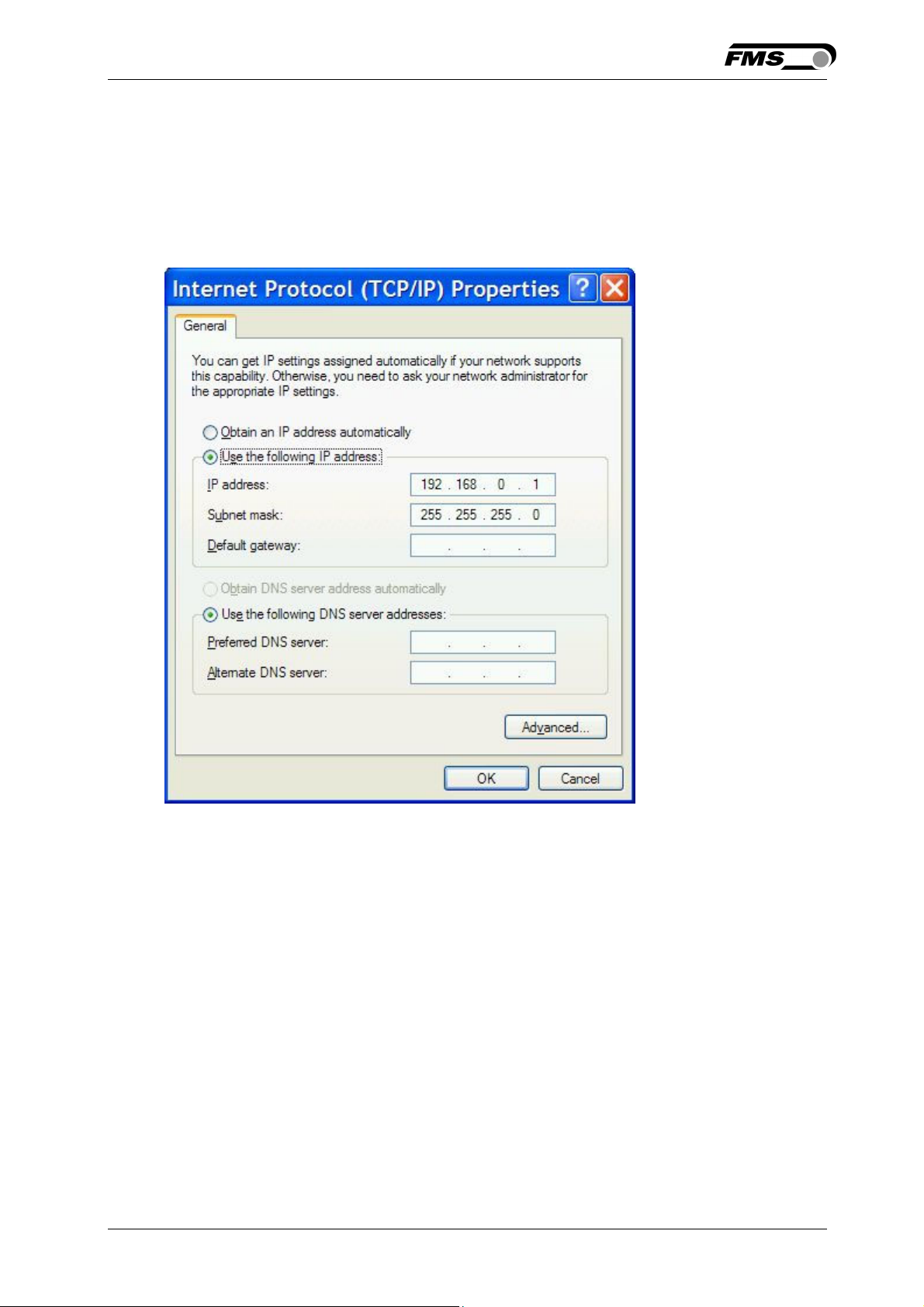

In the box “This connection uses the following items:”, scroll down to “Internet

Protocol (TCP/IP). Select the “Internet Protocol (TCP/IP) and click “Properties” button.

The following dialog box will appear. Make sure the “General” tab is selected.

Select the radio button “Use the following IP address:”

26.11.2018 30

Page 31

Operating Manual BKS015

In the IP address box enter the IP address for the computer that could be

192.168.0.1.

In the Subnet mask, enter 255 255 255 000, as shown below.

Notice that the “000” in both boxes will change automatically to “0”.

The dialog box will change to look like the following:

Click the “OK” button. The following dialog box will appear again:

26.11.2018 31

Page 32

Operating Manual BKS015

Click on the “Close” button.

Close the “Network Connection” window

Close “Control Panel”

The computer is now ready to communicate with the BKS015 controller:

1. Connect the “cross over cable” to both the BKS015 and to the appropriate

port on the desktop or laptop computer (see Fig. 13 and 14).

2. Open Microsoft Internet Explorer or Mizilla Firefox.

3. The default IP address for the BKS015 is 192.168.000.090 as long as it

was not changed over the operating penal. Enter the IP address in the

address bar and hit the Enter key. If a different IP address and subnet mask

is configured at the BKS015 make sure that the computer is setup

appropriate.

4. The screen (Fig.16) will open up. Continue then with the procedure described

in 8.1 “Parametrization in a Network via a Web Browser”.

9 Dimensions

The BKS015 series is available in three different roller length sizes:

• 100mm

• 200mm

26.11.2018 32

Page 33

Operating Manual BKS015

• 250mm

The mechanical dimensions can be seen in the following drawing.

Fig. 21: Outline Drawing BKS015 K015002

26.11.2018 33

Page 34

Operating Manual BKS015

10 Trouble Shooting

Error Cause Corrective action

Edge outside

detection band

Edge has moved

outside the sensor

detection band

BKS guides web

edge immediately

Sensor is mounted on

the wrong side

out of the sensor

Sensor is connected

to the wrong socket

Steering frame

does not move

No signal; sensor not

correctly connected

No signal; cable

interruption

No signal; sensor

defect

No response of

Wiring not correct Check wiring

the interface

LED-row shows

Fuse blown Replace Fuse on power supply board

nothing, frame

doesn’t react

Adjust sensor more accurately to the

web edge;

Adjust reference position less during

automatic operation

Mount sensor to the correct side (right

sensor for „Edge right“, etc.)

Connect sensor plug to the correct

socket (left plug to left socket, etc.)

Connect sensor correctly according to

screw terminal arrangement and

installation guide

Replace cable or send sensor to FMS

Send sensor to FMS; use other sensor

Power supply defect Check or correct power supply

installation

Electronic control unit

Contact FMS customer service

defect

Frame moves

abrupt to one of

the end positions

Stepper motor driver

defective

Exchange actuator of the frame.

Contact FMS service department for

spare parts and installation guide.

26.11.2018 34

Page 35

Operating Manual BKS015

11 Technical Specification

Cycle time 1ms

Drive of steering

frame

Dead band 0…2mm, adjustable in 0.1mm steps

Position reference ±5mm, adjustable in 0.1mm steps

Control modes edge left / edge right / center guiding

Interface Web browser Ethernet Explorer 7 or higher

Operation 3 keys and 5–key wind rose pad

Analogue inputs 2 inputs 0...10V (for sensors)

Supply voltage 24 (18 to 36) VDC

Temperature range -10 ... 60°C (14 to 140°F)

Protection class IP 30

Stepper motor. Power amplifier 24V integrated in housing

26.11.2018 35

Page 36

Operating Manual BKS015

FMS Force Measuring

Systems AG

Aspstrasse 6

8154 Oberglatt (Switzerland)

Tel. 0041 1 852 80 80

Fax 0041 1 850 60 06

info@fms-technology.com

www.fms-technology.com

FMS USA, Inc.

2155 Stonington Avenue

Suite 119

Hoffman Estates,, IL 60169

(USA)

Tel. +1 847 519 4400

Fax +1 847 519 4401

fmsusa@fmstechnology.com

FMS (UK)

Aspstrasse 6

8154 Oberglatt (Switzerland)

Tel. +44 (0)1767 221 303

fmsuk@fms-technology.com

FMS (Italy)

Aspstrasse 6

8154 Oberglatt (Switzerland)

Tel. +39 02 39487035

fmsit@fms-technology.com

26.11.2018 36

Loading...

Loading...