Page 1

PFS

US

UNVENTED (VENT-FREE)

UNIVERSAL FIREBOX

OWNER’S OPERATION AND

INSTALLATION MANUAL

®

INDOOR VENT FREE (V)UM(36,42,50) SERIES

INDOOR/OUTDOOR VENT FREE (V)QM(36,42,50) SERIES

MASONRY FIREBOX WITH INSULATION

WARNING: If the information in this manual is not

followed exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other ammable

— WHAT TO DO IF YOU SMELL GAS

— Installation and service must be performed by a quali-

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

vapors and liquids in the vicinity of this or any other

appliance.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

ed installer, service agency or the gas supplier.

For more information, visit www.fmiproducts.com

Page 2

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual for correct installation and operational procedures. For assistance

or additional information consult a qualied installer,

service agency or the gas supplier.

WARNING: Carefully review the instructions supplied with the decorative type unvented room heater for

the minimum replace size requirement.

DO NOT INSTALL THE APPLIANCE IN THIS FIREBOX,

UNLESS THIS FIREBOX MEETS THE MINIMUM DIMEN-

SIONS REQUIRED FOR THE INSTALLATION.

WARNING: FOR USE ONLY WITH A LISTED, GASFIRED UNVENTED DECORATIVE ROOM HEATER NOT

TO EXCEED 40,000 BTU/H.

DO NOT BUILD A WOOD FIRE.

TABLE OF CONTENTS

Safety .................................................................. 2

Local Codes......................................................... 4

Product Features ................................................. 4

Locating Firebox .................................................. 4

Product Specications ......................................... 5

Air For Combustion and Ventilation ..................... 8

This appliance may be installed

in an aftermarket,* permanently

located, manufactured (mobile)

home, where not prohibited by

local codes.

* Aftermarket: Completion of sale, not for

purpose of resale, from the manufacturer

This rebox has been tested

under Z21.91b-2004 for use

with approved ANSI Z21.11.2

decorative type unvented room

heater.

Installation ......................................................... 10

Firebrick Wall Installation ................................... 14

Gas Line Installation .......................................... 16

Technical Service............................................... 17

Replacement Parts ............................................ 17

Parts .................................................................. 18

Warranty ..............................................Back Cover

SAFETY

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate or service this replace.

Improper use of this replace

can cause serious injury or

death from burns, re, explosion, electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

www.fmiproducts.com

122274-01G2

Page 3

SAFETY

Continued

WARNING: Any change to

this rebox or its controls can

be dangerous.

WARNING: Do not allow fans

to blow directly into the rebox.

Avoid any drafts that alter burner

ame patterns. Ceiling fans can

create drafts that alter burner

ame patterns. Altered burner

patterns can cause sooting.

WARNING: Do not use a blower insert, heat exchanger insert

or other accessory not approved

for use with this rebox.

Due to high temperatures, the

appliance should be located out

of trafc and away from furniture

and draperies.

Do not place clothing or other

ammable material on or near

the appliance. Never place any

objects in the rebox or on

logs.

Firebox front and screen becomes very hot when running

rebox. Keep children and adults

away from hot surfaces to avoid

burns or clothing ignition. Firebox will remain hot for a time

after shutdown. Allow surfaces

to cool before touching.

Carefully supervise young chil-

dren when they are in the room

with rebox.

Keep the replace area clear and

free from combustible materials,

gasoline, and other ammable

vapors and liquids.

122274-01G 3

www.fmiproducts.com

You must operate this replace

with the provided fireplace

screen and hood in place.

Make sure these parts are in

place and screens are closed

before running installed gas

log heater. Replace hood with

FMI PRODUCTS, LLC model

109511-01 50", 109511-02 42",

or 109511-03 36" only. This hood

has been designed to keep the

operation of your replace safe

and efcient.

1. Do not use this rebox as a wood burning

replace. Use only decorative unvented

room heaters (log sets).

2. Do not add extra logs or ornaments such as

pine cones, vermiculite or rock wool. Using

these added items can cause sooting.

3. Use only the provided hood. See Parts,

page 30.

4. Vent-free gas log heaters installed in these

reboxes require fresh air ventilation to

run properly. See Air for Combustion and

Ventilation, page 8.

5. Do not run vent-free heaters installed in

these reboxes

• where ammable liquids or vapors are

used or stored

• under dusty conditions

6. Do not use this rebox to cook food or

burn paper or other objects.

7. Turn unit off and let cool before servicing.

Only a qualied service person should

service and repair rebox.

8. Operating vent-free heaters installed in

these reboxes above elevations of 4,500

feet could cause pilot outage.

9. Do not use the rebox if it has been

under water.

10. Before using furniture polish, wax, carpet

cleaner or similar products, turn heater

off. If heated, the vapors from these prod-

ucts may create a white powder residue

within burner box or on adjacent walls

and furniture.

11. Provide adequate clearances around air

openings.

Page 4

LOCAL CODES

Install and use rebox with care. Follow all

local codes. In the absence of local codes,

use the latest edition of The National Fuel Gas

Code ANSI Z223.1/NFPA 54*. Firebox must

be electrically grounded in accordance with

the National Electrical Code, ANSI/NFPA70

(latest edition).

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

State of Massachusetts: The installation

must be made by a licensed plumber

or gas fitter in the Commonwealth of

Massachusetts.

Sellers of unvented propane or natural

gas-fired supplemental room heaters

shall provide to each purchaser a copy of

527 CMR 30 upon sale of the unit.

Vent-free gas products are prohibited for

bedroom and bathroom installation in

the Commonwealth of Massachusetts.

PRODUCT FEATURES

OPERATION

This rebox is designed for use with approved

ANSI Z21.11.2 decorative type unvented room

heaters. (Physical size limitations apply. Refer

to minimum rebox requirements supplied

with log heater.) It requires no outside vent-

ing or chimney making installation easy and

inexpensive.

LOCATING FIREBOX

PLANNING

Plan where you will install the rebox. This will

save time and money later when you install

the rebox. Before installation, consider the

following:

1. Where rebox will be located. Allow for

wall and ceiling clearances (see Installa-

tion Clearances, page 11).

2. Everything needed to complete installation.

3. These models CANNOT be installed in

a bedroom unless maximum Btu rating

of installed vent-free log set is less than

10,000 Btu/hr.

4. Proper air for combustion and ventilation

(page 8).

www.fmiproducts.com

122274-01G4

Page 5

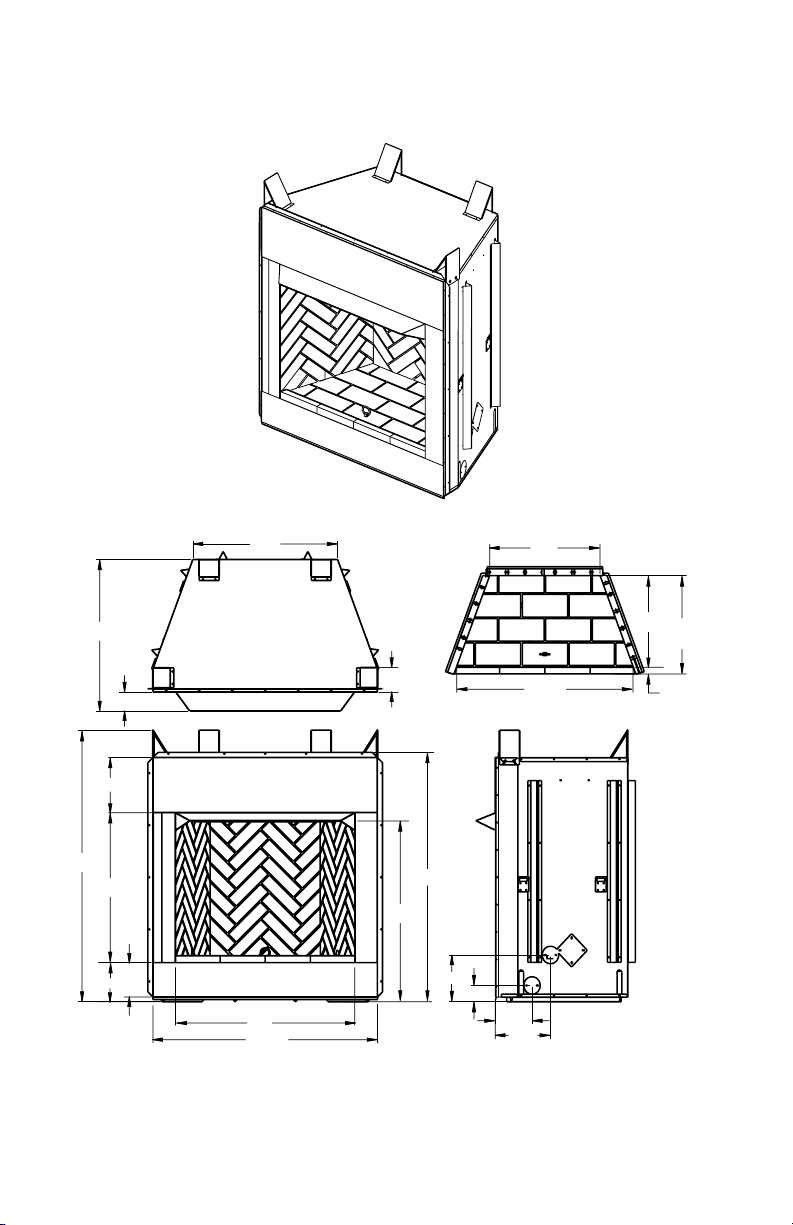

36" MODELS

PRODUCT SPECIFICATIONS

54

30 1/2"

11

1

/2"

30"

7

29"

22"

18

3

13

/8"

19

/16"

(Ref.)

7

4

/8"

3

3

/4"

1

/8"

3

34

/4"

36" HEARTH

5

/16"

1

50"

5

/16"

36

7"

7

/8"

36"

1

45

/8"

7

/16"

9

5

/16"

3

3

7

/8"

1

/8"

11

Figure 1 - 36" Models (V)UM36 and (V)QM36 Series

122274-01G 5

www.fmiproducts.com

Page 6

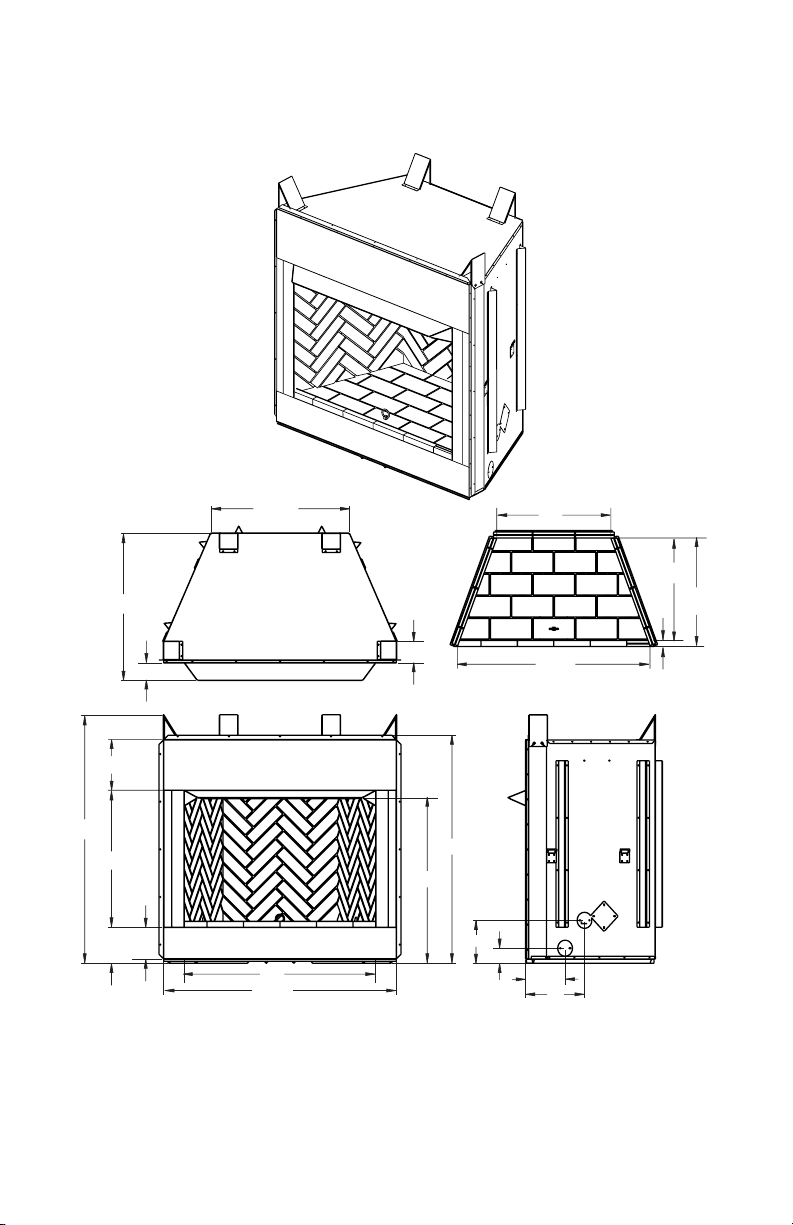

42" MODELS

3

/8"

32

PRODUCT SPECIFICATIONS

Continued

5

30

/16"

25"

22

1

/2"

23

(Ref.)

13

/16"

54 1/2"

11

3

3

/4"

1

/8"

30"

7

7"

7

/8"

42"

1

/8"

51

4 7/8"

36

50"

5

/16"

7

9

/16"

5

3

/16"

3

/4"

40

42" HEARTH

3

8

/4"

13"

5

/16"

1

Figure 2 - 42" Models (V)UM42 and (V)QM42 Series

www.fmiproducts.com

122274-01G6

Page 7

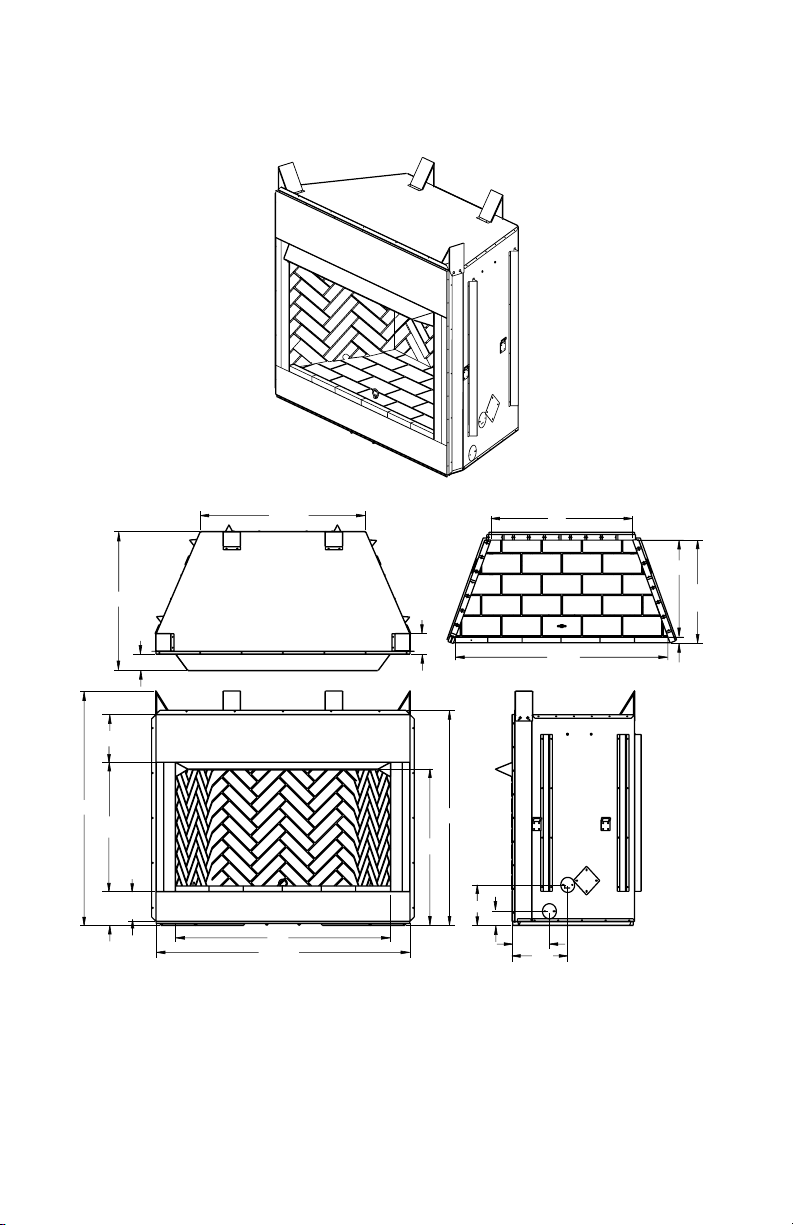

50" MODELS

3

32

/8"

3

/4"

3

PRODUCT SPECIFICATIONS

Continued

5

38

/16"

7

/8"

4

50" HEARTH

40

33"

1

/2"

22

13

/16"

23

(Ref.)

3

/4"

5

/16"

1

1

11

/8"

1

/2"

54

30"

50"

365/16"

7

7

7

/8"

7"

50"

1

59

/8"

/16"

9

5

3

/16"

3

8

/4"

13"

Figure 3 - 50" Models (V)UM50 AND (V)QM50 Series

122274-01G 7

www.fmiproducts.com

Page 8

AIR FOR COMBUSTION AND VENTILATION

WARNING: This heater shall

not be installed in a room or space

unless the required volume of indoor combustion air is provided

by the method described in the

National Fuel Gas Code, ANSI

Z223.1/NFPA 54, the International

Fuel Gas Code, or applicable lo-

cal codes. Read the following instructions to insure proper fresh

air for this and other fuel-burning

appliances in your home.

Today’s homes are built more energy efcient

than ever. New materials, increased insulation

and new construction methods help reduce

heat loss in homes. Home owners weather

strip and caulk around windows and doors to

keep the cold air out and the warm air in. During heating months, home owners want their

homes as airtight as possible.

While it is good to make your home energy

efcient, your home ne eds to breathe. Fresh

air must enter your home. All fuel-burning appliances need fresh air for proper combustion

and ventilation.

Exhaust fans, replaces, clothes dryers and

fuel burning appliances draw air from the house

to operate. You must provide adequate fresh

air for these appliances. This will insure proper

venting of vented fuel-burning appliances.

PROVIDING ADEQUATE

VENTILATION

The following are excerpts from National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Air for

Combustion and Ventilation.

All spaces in homes fall into one of the three

following ventilation classications:

1. Unusually Tight Construction

2. Unconned Space

3. Conned Space

The information on pages 8 through 10 will help

you classify your space and provide adequate

ventilation.

Unusually Tight Construction

The air that leaks around doors and windows

may provide enough fresh air for combustion

and ventilation. However, in buildings of unusually tight construction, you must provide

additional fresh air.

www.fmiproducts.com

Unusually tight construction is dened as

construction where:

a. walls and ceilings exposed to the out-

side atmosphere have a continuous

water vapor retarder with a rating of

one perm (6 x 10

less with openings gasketed or sealed

and

b. weather stripping has been added on

openable windows and doors and

c. caulking or sealants are applied to

areas such as joints around window

and door frames, between sole plates

and oors, between wall-ceiling joints,

between wall panels, at penetrations

for plumbing, electrical and gas lines

and at other openings.

If your home meets all of the three criteria

above, you must provide additional fresh

air. See Ventilation Air From Outdoors,

page 10.

If your home does not meet all of the three

criteria above, proceed to Determining

Fresh-Air Flow For Firebox Location.

Conned and Unconned Space

The National Fuel Gas Code, ANSI Z223.1/

NFPA 54 denes a conned space as a space

whose volume is less than 50 cubic feet per

1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances installed

in that space and an unconned space as a

space whose volume is not less than 50 cubic

feet per 1,000 Btu per hour (4.8 m3 per kw)

of the aggregate input rating of all appliances

installed in that space. Rooms communicating

directly with the space in which the appliances

are installed*, through openings not furnished

with doors, are considered a part of the unconned space.

* Adjoining rooms are communicating only if

there are doorless passageways or ventilation

grills between them.

-11

kg per pa-sec-m2) or

DETERMINING FRESH-AIR FLOW

FOR FIREBOX LOCATION

Determining if You Have a Conned or

Unconned Space

Use this work sheet to determine if you have

a conned or unconned space.

Space: Includes the room in which you will

install heater plus any adjoining rooms with

doorless passageways or ventilation grills

between the rooms.

122274-01G8

Page 9

Or

Remove

Door into

Adjoining

Room,

Option

3

Ventilation Grills

Into Adjoining Room,

Option 2

Ventilation

Grills Into

Adjoining

Room,

Option 1

12"

12"

AIR FOR COMBUSTION AND VENTILATION

Continued

1. Determine the volume of the space (length

x width x height).

Length x Width x Height =__________cu. ft.

(volume of space)

Example: Space size 22 ft. (length) x 18 ft.

(width) x 8 ft. (ceiling height) = 3,168 cu. ft.

(volume of space)

If additional ventilation to adjoining room

is supplied with grills or openings, add the

volume of these rooms to the total volume

of the space.

2. Multiply the space volume by 20 to determine

the maximum Btu/Hr the space can support.

________ (volume of space) x 20 = (Maxi-

mum Btu/Hr the space can support)

Example: 3,168 cu. ft. (volume of space) x 20 =

63,360 (maximum Btu/Hr space can support)

3. Add the Btu/Hr of all fuel burning appliances

in the space.

Vent-free replace _________ Btu/Hr

Gas water heater* _________ Btu/Hr

Gas furnace _________ Btu/Hr

Vented gas heater _________ Btu/Hr

Gas replace logs _________ Btu/Hr

Other gas appliances* + _________ Btu/Hr

Total = _________ Btu/Hr

* Do not include direct-vent gas appliances.

Direct-vent draws combustion air from the

outdoors and vents to the outdoors.

Example:

Gas water heater _________ Btu/Hr

Vent-free replace + _________ Btu/Hr

Total = _________ Btu/Hr

40,000

39,000

79,000

4. Compare the maximum Btu/Hr the space

can support with the actual amount of Btu/Hr

used.

_______ Btu/Hr (maximum the space can

support)

_______ Btu/Hr (actual amount of Btu/Hr

used)

Example: 63,360 Btu/Hr (maximum the

space can support)

79,000 Btu/Hr (actual amount of

Btu/Hr used)

The space in the example is a conned space

because the actual Btu/Hr used is more than the

maximum Btu/Hr the space can support. You

must provide additional fresh air. Your options

are as follows:

A. Rework worksheet, adding the space of an

adjoining room. If the extra space provides an

unconned space, remove door to adjoining

room or add ventilation grills between rooms.

B. Vent room directly to the outdoors. See

C. Install a lower Btu/Hr replace, if lower Btu/

122274-01G 9

See Ventilation Air From Inside Building.

Ventilation Air From Outdoors, page 10.

Hr size makes room unconned.

www.fmiproducts.com

If the actual Btu/Hr used is less than the

maximum Btu/Hr the space can support, the

space is an unconned space. You will need

no additional fresh air ventilation.

WARNING: If the area in which

the heater may be operated does

not meet the required volume for

indoor combustion air, combustion and ventilation air shall be

provided by one of the methods

described in the National Fuel

Gas Code, ANSI Z223.1/NFPA 54,

the International Fuel Gas Code,

or applicable local codes.

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining

unconned space. When ventilating to an

adjoining unconned space, you must provide

two permanent openings: one within 12" of the

ceiling and one within 12" of the oor on the

wall connecting the two spaces (see options

1 and 2, Figure 4). You can also remove door

into adjoining room (see option 3, Figure 4 ).

Follow the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Air for Combustion and

Ventilation for required size of ventilation

grills or ducts.

Figure 4 - Ventilation Air from Inside

Building

Page 10

Outlet

Air

Ventilated

Attic

Outlet

Air

Inlet

Air

Inlet Air

Ventilated

Crawl Space

To

Crawl

Space

To Attic

AIR FOR COMBUSTION AND VENTILATION

Continued

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation

grills or ducts. You must provide two permanent openings: one within 12" of the ceiling

and one within 12" of the oor. Connect these

items directly to the outdoors or spaces open

to the outdoors. These spaces include attics

and crawl spaces. Follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Air for

Combustion and Ventilation for required size

of ventilation grills or ducts.

IMPORTANT: Do not provide openings for

inlet or outlet air into attic if attic has a thermo-

stat-controlled power vent. Heated air entering

the attic will activate the power vent.

INSTALLATION

Figure 5 - Ventilation Air from Outdoors

WARNING: A qualied service person must install rebox.

Follow all local codes.

WARNING: Never install

rebox

• in a bedroom or bathroom*

• in a recreational vehicle

• where curtains, furniture,

clothing, or other ammable

objects are less than 36" from

front or 42" from top of rebox;

for side clearances see Figure

4, page 11

• in high trafc areas

• in windy or drafty areas

* Unless installed log set is rated

at 10,000 Btu/Hr or less.

CAUTION: Log heaters

installed in this rebox create

warm air currents. These currents

move heat to wall surfaces next

to rebox. Installing rebox next

to vinyl or cloth wall coverings or

operating rebox where impurities (such as, but not limited to, tobacco smoke, aromatic candles,

cleaning uids, oil or kerosene

lamps, etc.) in the air exist, may

discolor walls or cause odors.

www.fmiproducts.com

NOTICE: The rebox identication label (including model number, serial number, clearances,

etc.) is located on a chain under

the bottom refractory.

IMPORTANT: Vent-free gas log heaters add

moisture to the air. Although this is benecial,

installing rebox in rooms without enough

ventilation air may cause mildew to form from

too much moisture. See, page 8.

IMPORTANT: Make sure the rebox is level.

If rebox is not level, log set will not work

properly.

Note: Your rebox is designed to be used in

zero clearance installations. Wall or framing

material can be placed against any exterior

surface on the rear, sides, top or bottom of

your rebox, except where standoff spacers

are integrally attached. If standoff spacers are

attached to your rebox, these spacers can

be placed directly against wall or framing materials. Use the dimensions shown for rough

opening to create the easiest installation.

Use dimensions shown for rough openings

to create the easiest installation (see Built-In

Firebox Installation, page 12).

122274-01G10

Page 11

INSTALLATION CLEARANCES

Supplied

Firebox Hood

Must Be Used

at All Times

Wire-mesh

Screen

Firebox

Noncombustible

Material May

Project Off this

Surface above

the Firebox Hood

Mantel Shelf

Note: Any portion of the

mantel shelf must NOT

extend beyond this profile.

12" 16" 20"

1

1

/

2"

6

3

/

4

"

12"

Note: All vertical

measurements are

from top of fireplace

hood opening to

bottom of mantel shelf.

These minimum

clearances replace any

other recommended

clearances supplied

with your ANSI Z21.11.2

approved gas logs.

Wall board or facing

material (above

firebox) may be of

combustible material,

including decorative

mantel ornaments or

other similar projections off of the facing

material.

Framing

Material

minimum clearances. If you

can, provide greater clearances

from oor, ceiling, and adjoining wall.

Carefully follow the instructions below. This

will ensure safe installation.

Minimum Wall and Ceiling Clearances

(see Figure 6)

A. Clearances from the side of the replace

Example: The face of a mantel, bookshelf,

B. Clearances from the top of the rebox

C. When the rebox is installed directly on

D. Clearances from the bottom of rebox to

These reboxes can be installed as freestanding units against a wall with approved

cabinet mantels that may be available from

your retailer or supplier, or as a built-in unit.

The clearances are the same for either installation method.

*Minimum 16" from Side Wall

122274-01G 11

INSTALLATION

Continued

WARNING: Maintain the

cabinet to any combustible material and

wall should follow diagram in Figure 6.

etc. is made of combustible material and

protrudes 3 1/2" from the wall. This com-

bustible material must be 4" from the side

of the replace cabinet (see Figure 4).

opening to the ceiling should not be less

than 42".

carpeting, tile or other combustible mate-

rial, other than wood ooring, the rebox

should be installed on a metal or wood

panel extending the full width and depth

of the enclosure.

the oor is 0".

Example

Figure 6 - Minimum Clearance for

Combustible to Wall

*

www.fmiproducts.com

Mantel Clearances for Built-In

Installation

If placing custom mantel above built-in rebox, you must meet the minimum allowable

clearance between mantel shelf and top of

rebox opening shown in Figure 7. These are

the minimum allowable mantel clearances

for a safe installation. Use larger clearances

wherever possible to minimize the heating of

objects and materials placed on the mantel.

CAUTION: Do not allow the

vent-free gas log heater to touch

or extend beyond the replace

screen.

NOTICE: Surface temperatures

of adjacent walls and mantels

become hot during operation.

Walls and mantels above the

firebox may become hot to

the touch. If installed properly,

these temperatures meet the

requirement of the national

product standard. Follow all

minimum clearances shown in

this manual.

Figure 7 - Minimum Mantel Clearances

for Built-In Installation

Page 12

INSTALLATION

Continued

NOTICE: If your installation does

not meet the minimum clearances shown, you must do one

of the following:

• raise the mantel to an accept-

able height

• remove the mantel

BUILT-IN FIREBOX INSTALLATION

Built-in installation of this rebox involves

installing rebox into a framed-in enclosure.

This makes the front of rebox ush with wall.

If installing a mantel above the rebox, you

must follow the clearances shown in Figure

7, page 11. Follow these instructions to install

the rebox in this manner.

1. Frame in rough opening. The rebox fram-

ing should be constructed of 2 x 4 lumber

or heavier. Use dimensions and rough

opening layout in Figure 8. Adjust framing

so that rebox ushes with nished wall

surface. If installing in a corner, use dimensions in Figure 9, for rough opening.

2. Install gas piping to rebox location. See

Installing Gas Line on page 14 and Connecting to Gas Supply in log set owner’s

manual.

3. Carefully set firebox in front of rough

opening with back of rebox inside wall

opening.

4. Carefully insert rebox into rough opening.

5. Attach rebox to wall studs using nails

or wood screws through holes in nailing

ange (see Figure 10).

6. Install and properly test gas log heater.

Follow installation instructions included

with the vent-free gas log heater that is

being installed.

IMPORTANT: When nishing your rebox,

combustible materials such as wall board,

gypsum board, sheet rock, drywall, plywood,

etc. may be butted up next to the sides and top

of the rebox. Combustible materials should

never overlap the rebox front facing.

WARNING: Do not allow any

combustible materials to overlap

the rebox front facing.

IMPORTANT: Noncombustible materials such

as brick, tile, etc. may overlap the front facing, but should never cover any necessary

openings.

WARNING: Do not allow non-

combustible materials to cover

any necessary openings.

54.625"

45.375" (36" Models)

51.375" (42" Models)

59.375" (50" Models)

Figure 8 - Framing Dimensions

Maintain 1

Clearance at Sides

61" (36" Models)

65" (42" Models)

71" (50" Models)

86.5" (36" Models)

92" (42" Models)

100" (50" Models)

and Back of Fireplace

Figure 9 - Corner Installation

Nails or

Wood

Screws

30.125"

28.250"

(36" Models)

1

/2"

1

1

/2" Clearance

Not Required at

Nailing Flanges

Figure 10 - Attaching Firebox to Wall

www.fmiproducts.com

Nailing

Flanges

Studs

122274-01G12

Page 13

INSTALLATION

Continued

WARNING: Use only non-

combustible mortar or adhesives when overlapping the front

facing with noncombustible

facing material.

Cabinet

Mantel

INSTALLING FIREBOX USING

OPTIONAL MANTELS AVAILABLE

FROM RETAILER OR CUSTOM BUILT

WARNING: A qualied service person must install rebox.

Follow all local codes.

This rebox may be installed using a cabinet

mantel against a wall in your home. The

rebox and cabinet mantel can be installed

directly on the oor. Mantels may be avail-

able from your retailer or custom built for

your home.

1. Assemble cabinet mantel as instructed.

2. Install gas piping to rebox location. See

Installing Gas Line, page 14. You may have

to cut an access hole in the oor or wall to

run gas line to rebox. Make sure to locate

access hole so cabinet mantel will cover it

when installed (see Figure 11).

3. Place rebox on oor in desired location.

Make sure mantel will be ush against

wall when installed.

4. Carefully slide cabinet mantel over rebox.

Be careful not to scratch rebox, cabinet

mantel, ooring, etc., when installing (see

Figure 12).

5. Install and properly test gas log heater.

Follow installation instructions included

with the vent-free gas log heater that is

being installed.

Gas Line

Access Hole

(Either Side

of Firebox)

Figure 11 - Installing Cabinet Mantel

(Mantel May Vary From Illustration)

Figure 12 - Inserting Firebox Into Cabinet

Mantel (Mantel May Vary From Illustration)

Gas

Piping

122274-01G 13

www.fmiproducts.com

Page 14

FIREBRICK WALL INSTALLATION

IMPORTANT: Installation of brick

should be done after the replace is placed in a permanent

location.

1. The replace is shipped with the hearth

preinstalled. It is held in place for ship-

ping with 3 shipping brackets (Figure 13).

Remove these brackets before installing

any of the other rebrick walls.

Shipping

Brackets

Figure 13 - Removing Shipping Brackets

2. Install the left and right rebrick walls.

There is a bracket with 2 tabs on the

bottom of each rebrick wall. Angle the

wall into the replace opening and into

the slots on the side of the hearth (Figure

14), then tilt the top of the panel toward

the rebox surround.

Slot

Right Face

3. Secure the rebrick wall using 2 of the

retainers provided. The bracket will slip

underneath the metal lip on the top of the

wall and screw into the inner dome of the

replace (Figure 15).

Retaining

Right Wall

Figure 15 - Installing Side Walls

4. Install the rear rebrick wall last. Place the

wall face side down on the hearth with the

bottom of the wall toward the rear of the

rebox and the top toward the front of the

replace. Tilt the wall up toward the back

of the rebox. Secure with 2 rear retaining

bracks provided (Figure 16).

Bracket

Leading

Bricks

Retaining

Bracket

Hearth

Figure 14 - Slots for Firebrick Walls

www.fmiproducts.com

Figure 16 - Installing Rear Wall

5. It is recommended that the joints between

all rebrick walls be grouted for a more

nished look. See page 15. For grouting

instructions.

For more information and to watch a how to

video go to www.fmiproducts.com and select

Technical Support.

122274-01G14

Page 15

FIREBRICK WALL INSTALLATION

Continued

GROUTING INSTRUCTIONS

Material provided:

Bag of cement

Bag of sand

Material required:

Piping bag

Joints striker

Heavy duty mixing bucket

Sponge or Wet Cloth

1. Moisten brick surface with damp sponge

or spray bottle just prior to application.

When bricks are wet, any excess grout

mixture on bricks will easily wipe off.

2. In a heavy duty mixing bucket, add equal

parts cement and sand. Add enough water

and mix together well using a power drill

with mixing wand attachment to a yogurt

like consistency. Not adding enough water

can lead to grout falling out after burning.

3. The overall length of piping bag should be

about 16". If the bag is longer than 16",

cut it down to size by removing end with

larger opening. This will make the bag

easier to handle.

4. Put grout mixture into piping bag making

sure the smaller opening is downward and

over a moist towel to avoid spilling. Place

a wet towel over the bucket making sure it

is directly on the surface of grout mixture.

This will keep the mixture moist and it will

not dry out before use.

5. Grout all joints where two rebrick walls

come together.

6. Using a trowel, remove excess grout mixture by moving trowel in the direction of

the joint. Grout mixture in the joint should

now be ush with brick surface. If not

enough grout is applied into each space,

grout may fall out after burning.

7. Using a joint striker, smooth out grout line.

Allow 72 hours before

operating replace.

INSTALLING FIREPLACE HOOD

AND SCREENS

1. Attach hood to rebox using screws provided (see Figure 17).

1. Slide round end of screen rod into rings at

top of screen. Attach one push-on nut to end

of rod before attaching last ring of screen.

2. Insert the round end screen rod into hole

on the left and right side of smoke shelf

(Figure 18).

3. Mount at end of screen rod with #10 x 5/8"

to center of smoke shelf.

4. Install other screen rod in same manner.

Screws

Figure 17 - Screw and Hood Placement

Rating

Plate

Figure 18 - Installing Fireplace Screen

Hole for Screen

Rod

Leading Bricks

122274-01G 15

www.fmiproducts.com

Page 16

GAS LINE INSTALLATION

WARNING: A qualied service person must connect heater

to gas supply. Follow all local

codes.

IMPORTANT: See Connecting to Gas Supply

in your log set owner’s manual for details on

gas hookup.

Note: Before you proceed, make sure your

gas supply is turned off.

Use only a 1/2" black iron pipe and appropriate ttings.

1. Remove knockout indentation on refrac-

tory or rebrick wall located above refractory hearth oor. Knockout indentation

must be rmly tapped with any solid object

such as a 1/2" dowel until it is released.

Remove fragmented portions of refractory

(see Figure 19).

2. Remove gas line cover plate located on

either side of replace and pull out insulation from gas line conduit sleeve. Save

insulation for reuse. Replace screws.

3. Run a 1/2" black iron gas line into replace

through the rear at gas line conduit sleeve (if

using a raised platform, add height). Provide

sufcient gas line into replace chamber for

tting connection (see Figure 20).

Note: Secure incoming gas line to wood

framing to provide rigidity for threaded end.

4. Repack insulation around gas line and into

sleeve opening. Seal any gaps between

gas line and refractory knockout hole with

refractory cement or commercial furnace

cement, Install the gas appliance or cap-off

gas line if desired.

CAUTION: All gas piping

and connections must be tested

for leaks after the installation

is completed. After ensuring

that the gas valve is on, apply

soap and water solution to all

connections and joints. Bubbles

forming show a leak. Correct

all leaks at once. DO NOT USE

AN OPEN FLAME FOR LEAK

TESTING AND DO NOT OPER-

ATE ANY APPLIANCE IF A LEAK

IS DETECTED. LEAK TESTING

SHOULD BE DONE BY A QUALI-

FIED SERVICE PERSON.

Outside of

Fireplace

Gas Line

Conduit

Insulation

Gas

Conduit

Cover

Figure 19 - Gas Line Access

Outside of

Fireplace

Gas Line

Conduit

Remove

Knockout

Incoming

1/2" Black

Iron Pipe

1/2" Dowel

Brick with

Access

Hole

Side

Firebrick

Finished

Side

Side

Firebrick

Finished

Side

Repack

Insulation

Figure 20 - Gas Line Installation

www.fmiproducts.com

Seal

Opening

with

Refractory

Cement

Provide Enough

Threaded

End for Fitting

Connection

122274-01G16

Page 17

TECHNICAL SERVICE

You may have further questions about installation, operation, or troubleshooting.

If so, contact FMI PRODUCTS, LLC at

1-866-328-4537.

REPLACEMENT PARTS

If this product is missing a part or has a broken

component, please do not return it to the store.

Call FMI PRODUCTS, LLC at 1-866-328-4537

to answer questions and replace parts under

warranty.

Note: Use only original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

ACCESSORIES

OPTIONAL OUTSIDE AIR KIT FOR

FLOOR INSTALLATION - AK4F

When calling please have your model and se-

rial numbers of your replace ready.

You can also visit our web site at

www.fmiproducts.com.

When calling or writing, please have your

model and serial numbers of your replace

ready.

Model and serial number information are in the

replace's rating plate located on the replace

smoke shelf.

OPTIONAL OUTSIDE AIR KIT FOR

SIDEWALL INSTALLATION - AK4

122274-01G 17

www.fmiproducts.com

Page 18

PARTS

9

MODELS (V)UM SERIES AND (V)QM SERIES

8

11

7

12

6

15/16

10

5

19

22

1

20

21

20

14

13

11

4

3

11

2

17

14

18

12

13

14

15/16

www.fmiproducts.com

122274-01G18

Page 19

This list contains replaceable parts used in your rebox. When ordering parts, follow the

PARTS

instructions listed under Replacement Parts on page 17 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

(V)UM36

1 ** Face Assembly • • • • • • 1

2 ** Firebox Bottom Assembly • • • • • • 1

3 ** Firebox Bottom • • • • • • 1

4 ** Firebox Surround • • • • • • 1

5 ** Insulation Pan Support • • • • • • 1

6 ** Insulation Pan • • • • • • 1

7 ** Top Insulation • • • • • • 1

8 110454-03 Fireplace Top 36" • • 1

110454-02 Fireplace Top 42" • • 1

110454-01 Fireplace Top 50" • • 1

9 23490SA Standoff • • • • • • 4

10 ** Fireplace Surround Assembly • • • • • • 1

11 109720-02 Clearance Spacer • • • • • • 6

12 117891-01 Fireplace Handle Bracket • • • • • • 4

13 20042 Outside Air Cover Plate • • • • • • 2

14 21171 Gas Conduit Cover • • • • • • 4

15 109752-01 Conduit One • • • • • • 2

16 109752-02 Conduit Two • • • • • • 2

17 ** Heat Shield Support • • • • • • 1

18 123298-02 Ash Box Assembly • • • • • • 1

19 ** Firebox Top • • • • • • 1

20 109457-03 Screen 36" • 2

109457-02 Screen 42" • 2

109457-01 Screen 50" • 2

117556-03 Screen 36" Stainless • 2

117556-02 Screen 42" Stainless • 2

117556-01 Screen 50" Stainless • 2

21 20806 Screen Rod 36" • 2

110146-03 Screen Rod 42" • 2

110146-02 Screen Rod 50" • 2

117568-03 Screen Rod 36" Stainless • 2

117568-02 Screen Rod 42" Stainless • 2

117568-01 Screen Rod 50" Stainless • 2

22 109511-01 Hood 50" • 1

109511-02 Hood 42" • 1

109511-03 Hood 36" • 1

109511-04 Hood Stainless 36" • 1

109511-05 Hood Stainless 42" • 1

109511-06 Hood Stainless 50" • 1

PARTS AVAILABLE NOT SHOWN

see page 20 Firebrick Walls • • • • • •

** Not a eld replaceable part.

(V)UM42

(V)UM50

(V)QM36

(V)QM42

(V)QM50

122274-01G 19

www.fmiproducts.com

Page 20

PARTS

7

MODELS MODELS (V)UM SERIES AND (V)QM SERIES

Picture may vary from actual

7

6

8

8

1

4

7

7

5

9

3

2

www.fmiproducts.com

122274-01G20

Page 21

This list contains replaceable parts used in your rebox. When ordering parts, follow the

PARTS

instructions listed under Replacement Parts on page 17 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

1 125116-01 Left Leading Brick 36" Red • • 1

125118-01 Left Leading Brick 42"/50" Red • • • • 1

2 125116-02 Right Leading Brick 36" Red • • 1

125118-02 Right Leading Brick 42"/50" Red • • • • 1

3 125036-01 Hearth 36" Red • • 1

125037-01 Hearth 42" Red • • 1

125038-01 Hearth 50" Red • • 1

4 124210-01 Rear Stacked 36" Red • 1

124222-01 Rear Herringbone 36" Red • 1

125413-01 Rear Stacked 42" Red • 1

125425-01 Rear Herringbone 42" Red • 1

125437-01 Rear Stacked 50" Red • 1

125449-01 Rear Herringbone 50" Red • 1

5 124212-01 Right Stacked 36" Red • 1

124224-01 Right Herringbone 36" Red • 1

125415-01 Right Stacked 42" Red • 1

125427-01 Right Herringbone 42" Red • 1

125439-01 Right Stacked 50" Red • 1

125451-01 Right Herringbone 50" Red • 1

6 124214-01 Left Stacked 36" Red • 1

124226-01 Left Herringbone 36" Red • 1

125417-01 Left Stacked 42" Red • 1

125429-01 Left Herringbone 42" Red • 1

124441-01 Left Stacked 50" Red • 1

125453-01 Left Herringbone 50" Red • 1

7 124134-01 Side Retainer 36" (UM Series) • • 4

124134-02 Side Retainer 42"/50" (UM Series) • • • • 4

124134-04 Side Retainer 36" Stainless (QM Series) • • 4

124134-05 Side Retainer 42"/50" Stainless (QM Series) • • • • 4

8 124134-03 Rear Retainer (UM Series) • • • • • • 2

124134-06 Rear Retainer Stainless (QM Series) • • • • • • 2

9 120848-01 Ash Brick Red • • • • • • 1

(V)UM,QM36SRA

(V)UM,QM36HRA

(V)UM,QM42SRA

(V)UM,QM42HRA

(V)UM,QM50SRA

(V)UM,QM50HRA

122274-01G 21

www.fmiproducts.com

Page 22

This list contains replaceable parts used in your rebox. When ordering parts, follow the

PARTS

instructions listed under Replacement Parts on page 17 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

1 125116-03 Left Leading Brick 36" Ivory • • 1

125118-03 Left Leading Brick 42"/50" Ivory • • • • 1

2 125116-04 Right Leading Brick 36" Ivory • • 1

125118-04 Right Leading Brick 42"/50" Ivory • • • • 1

3 125036-02 Hearth 36" Ivory • • 1

125037-02 Hearth 42" Ivory • • 1

125038-02 Hearth 50" Ivory • • 1

4 124210-02 Rear Stacked 36" Ivory • 1

124222-02 Rear Herringbone 36" Ivory • 1

125413-02 Rear Stacked 42" Ivory • 1

125425-02 Rear Herringbone 42" Ivory • 1

125437-02 Rear Stacked 50" Ivory • 1

125449-02 Rear Herringbone 50" Ivory • 1

5 124212-02 Right Stacked 36" Ivory • 1

124224-02 Right Herringbone 36" Ivory • 1

125415-02 Right Stacked 42" Ivory • 1

125427-02 Right Herringbone 42" Ivory • 1

125439-02 Right Stacked 50" Ivory • 1

125451-02 Right Herringbone 50" Ivory • 1

6 124214-02 Left Stacked 36" Ivory • 1

124226-02 Left Herringbone 36" Ivory • 1

125417-02 Left Stacked 42" Ivory • 1

125429-02 Left Herringbone 42" Ivory • 1

124441-02 Left Stacked 50" Ivory • 1

125453-02 Left Herringbone 50" Ivory • 1

7 124134-01 Side Retainer 36" (GM Series) • • 4

124134-02 Side Retainer 42"/50" (GM Series) • • • • 4

124134-04 Side Retainer 36" Stainless (JM Series) • • 4

124134-05 Side Retainer 42"/50" Stainless (JM Series) • • • • 4

8 124134-03 Rear Retainer • • • • • • 2

124134-06 Rear Retainer Stainless (JM Series) • • • • • • 2

9 120848-03 Ash Brick Ivory • • • • • • 1

(V)UM,QM36SIA

(V)UM,QM36HIA

(V)UM,QM42SIA

(V)UM,QM42HIA

(V)UM,QM50SIA

(V)UM,QM50HIA

www.fmiproducts.com

122274-01G22

Page 23

NOTES

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

122274-01G 23

www.fmiproducts.com

Page 24

WARRANTY

KEEP THIS WARRANTY

Model (

located on product or identication tag

Serial No. (

located on product or identication tag

Date Purchased __________________________

Keep receipt for warranty verication.

FMI PRODUCTS, LLC LIMITED WARRANTIES

Standard Warranty: FMI PRODUCTS, LLC warrants this new product and any parts thereof to be free from defects

in material and workmanship for a period of four (4) years from the date of rst purchase from an authorized dealer

provided the product has been installed, maintained and operated in accordance with FMI PRODUCTS, LLC’s

warnings and instructions.

For products purchased for commercial, industrial or rental usage, this warranty is limited to 90 days from the date

of rst purchase.

Limited Warranty: FMI PRODUCTS, LLC warrants factory reconditioned products and any parts thereof to be

free from defects in material and workmanship for 30 days from the date of rst purchase from an authorized dealer

provided the product has been installed, maintained and operated in accordance with FMI PRODUCTS, LLC’s

warnings and instructions.

The following terms apply to all of the above warranties:

Always specify model number and serial number when contacting the manufacturer. To make a claim under this

warranty the bill of sale or other proof of purchase must be presented.

This warranty is extended only to the original retail purchaser when purchased from an authorized dealer, and only

when installed by a qualied installer in accordance with all local codes and instructions furnished with this product.

This warranty covers the cost of part(s) required to restore this product to proper operating condition and an allowance for labor when provided by a FMI PRODUCTS, LLC Authorized Service Center or a provider approved by

FMI PRODUCTS, LLC. Warranty parts must be obtained through authorized dealers of this product and/or FMI

PRODUCTS, LLC who will provide original factory replacement parts. Failure to use original factory replacement

parts voids this warranty.

Travel, handling, transportation, diagnostic, material, labor and incidental costs associated with warranty repairs,

unless expressly covered by this warranty, are not reimbursable under this warranty and are the responsibility of

the owner.

Excluded from this warranty are products or parts that fail or become damaged due to misuse, accidents, improper

installation, lack of proper maintenance, tampering, or alteration(s).

This is FMI PRODUCTS, LLC’s exclusive warranty, and to the full extent allowed by law; this express warranty

excludes any and all other warranties, express or implied, written or verbal and limits the duration of any and all

implied warranties, including warranties of merchantability and tness for a particular purpose to four (4) years on

new products and 30 days on factory reconditioned products from the date of rst purchase. FMI PRODUCTS, LLC

makes no other warranties regarding this product.

FMI PRODUCTS, LLC’s liability is limited to the purchase price of the product, and FMI PRODUCTS, LLC shall not

be liable for any other damages whatsoever under any circumstances including indirect, incidental, or consequential

damages.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

For information about this warranty contact:

New Products

Factory Reconditioned Products

Terms Common to All Warranties

) _____________________________

) __________________________

2701 S. Harbor Blvd.

Santa Ana, CA 92704

1-866-328-4537

www.fmiproducts.com

124382-01

Rev.A

09/10

Loading...

Loading...