FläktGroup MINIMASTER RDKS Installation, Operation, Maintenance And Spare Parts

HEAT RECOVERY UNIT

MINIMASTER RDKS

INSTALLATION, OPERATION, MAINTENANCE AND SPARE PARTS

2

CONTENTS

OPERATION AND MAINTENANCE (FOR USER)

Functions, system design, electrical data, energy class ............................................... 3

ISYteq Basic control panel

Operation .................................................................................................................................... 4

Overview of symbols and functions ................................................................................ 5

ISYteq Touch 3.5 control panel .....................................................................................................

General information ................................................................................................................6

Cleaning of the display .........................................................................................................6

General buttons and symbols ............................................................................................6

Home screen ............................................................................................................................ 7

Operation ....................................................................................................................................8

Maintenance and cleaning of heat exchanger and fans ..............................................10

Filter alarm and filter replacement .........................................................................................11

Overheating protection, impeller alarm, temperature alarm, other alarms .......... 12

INSTALLATION (FOR INSTALLER AND SERVICE PERSONNEL)

Dimensions, installation measurements 13

Wiring and connection diagram.............................................................................................. 14

Duct connection, duct insulation .............................................................................................15

Installation options and duct definitions .............................................................................. 16

Installation of unit with accessories .......................................................................................17

Heat recovery unit RDKS - Technical manual

ADJUSTMENT, COMMISSIONING (FOR INSTALLER AND SERVICE PERSONNEL)

Settings, date/time, language ................................................................................................. 22

Login, settings ................................................................................................................................ 23

Adjustment .......................................................................................................................................24

Control panel operation, commissioning ............................................................................ 25

Parameter list ................................................................................................................................. 28

MISCELLANEOUS

Spare parts ..................................................................................................................................... 33

EC Declaration of Conformity ....................................................................................................34

Disposal of products and packaging materials ............................................................... 35

Declaration of Conformity .......................................................................................................... 36

WARNING! THE APPLIANCE MAY BE USED BY CHILDREN OVER THE AGE OF 8, PERSONS (INCLUDING CHILDREN) WITH PHYSICAL,

SENSORY OR MENTAL DISABILITIES OR LACK OF KNOWLEDGE OR EXPERIENCE, PROVIDED THEY HAVE RECEIVED INSTRUCTION

OR INFORMATION ON SAFE USE OF THE APPLIANCE AND UNDERSTAND THE POTENTIAL RISKS. CHILDREN MAY NOT PLAY WITH

THE APPLIANCE. CHILDREN MAY NOT CLEAN OR PERFORM MAINTENANCE ON THE APPLIANCE WITHOUT SUPERVISION.

IN THESE INSTRUCTIONS MUST BE CARRIED OUT BY AN INSTALLER OR SERVICE PERSONNEL.

FläktGroup DC_9295GB_20190326_R5

NOTE! INSTALLATION, ADJUSTMENT AND COMMISSIONING AS DESCRIBED

We reserve the right to make changes without prior notice

Heat recovery unit RDKS - Technical manual

6, 10541

121311

7

OPERATION AND MAINTENANCE – FUNCTIONS, SYSTEM DESIGN, ELECTRICAL DATA, ENERGY CLASS

3

FANS

The fans are powered by energy-efficient EC motors. They are easy to

remove for service and maintenance. The speed of the fans can be ad

-

justed independently of each other.

HEAT RECOVERY AND SUPPLEMENTARY HEATING

In climates where the temperature seldom drops below -10 °C, there is

usually no need for supplementary heating. This is because the rotary

heat exchanger recovers enough thermal energy from the extract air (≤

temp

).

85% h

When the outdoor temperature is below -10 °C and the desired supply

air temperature cannot be achieved, a postheater is required, which is

controlled to maintain the set supply air temperature. In very cold are

as, the unit can also be supplemented with a heater that preheats the

outdoor air. This heater starts preheating the air when the outdoor

temperature falls below -12 °C.

The electric heaters have an integrated overheating protection function.

NOTE! THE ELECTRIC POSTHEATER IS ONLY ACTIVATED IF THE

IMPELLER IS IN OPERATION.

FILTER

As standard the unit is fitted with a class (M5) ISO Coarse 85% bag filter. For filter replacement, see page 11.

ETHERNET CONNECTION (OPTIONAL)

This function can be used to connect the unit to an existing network.

In that case, the unit is equipped with an integrated web server, which

makes it possible to read and change certain parameters via a web

browser. The connection can also be used for connection to a superior

system via Modbus TCP/IP.

To optimize the performance of communication, please follow the rec

ommendations below.

- Minimize the number of general broadcasts.

- Only send dedicated traffic to the controller.

- Do not attempt to access the web server when using Modbus TCP-IP.

- Maximum of one Modbus message per second is recommended.

Avoid data bursts.

- Only write to Modbus registers when values have been changed.

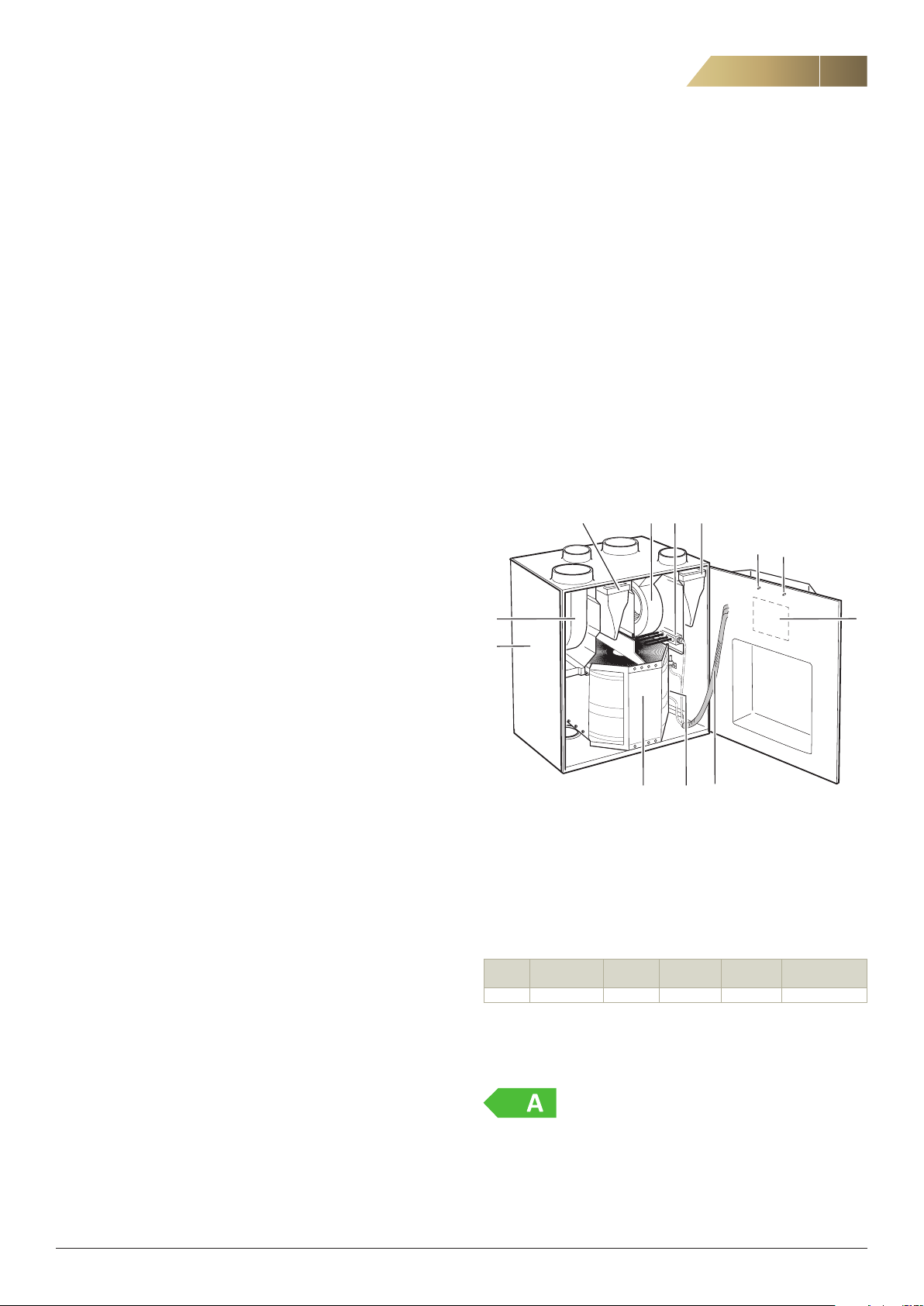

THE UNIT’S MAIN COMPONENTS

3

2

-

8

DEFROSTING

During cold periods, when frost may form in the impeller, the integrated control unit automatically activates a defrosting function. The unit

defrosts for 15 minutes every 6 hours if the outdoor temperature is

below -10 °C. The supply air fan stops and the impeller moves forward

in sections.

COOLING RECOVERY

In the summer, if the extract air is cooler than the outdoor air, the rotary heat exchanger starts to recover cooling from the cooler extract air.

This primarily applies if there is some type of cooling appliance in the

house.

ALARMS

The ISYteq Basic control panel (accessory) has a limited alarm

indicator function. The panel indicates, for instance, when there is a

temperature alarm or when the filter needs replacing.

If the ISYteq Touch 3.5 control panel (accessory) is used, the alarm will

be presented in plain text (see separate instructions).

MOISTURE CONTROL (OPTIONAL)

This function automatically limits the rotary heat exchanger’s moisture

recovery at high indoor humidity levels. This function can also be or

dered retrospectively to supplement the unit.

-

9

1. Outdoor air sensor

2. Extract air sensor

3. Supply air sensor

4. Preheater

5. Extract air fan

6. Heat exchanger

7. Supply air filter

8. Control unit

9. Casing

10. Heat exchanger motor

11. Extract air filter

12. Postheater

13. Supply air fan

ELECTRICAL DATA

Voltage: 230V, single phase, 50 Hz

Code Fan motors

Rated output, W

RDKS 2 x 83 500 500 1170 1210

1)

Rated output applies when both the preheating and the postheating devices are

installed.

Preheater

Electr., W

Postheater

Electr., W

Rated output

1)

Electr., W

Rated output

with cooker hood

ENERGY CLASS

CO2 CONTROL (OPTIONAL)

This function regulates towards a preset setpoint. The fan speed is

automatically adjusted to achieve the desired CO2 level.

NOTE! CO

tion can also be ordered retrospectively to supplement the unit.

FläktGroup DC_9295GB_20190326_R5

control requires a ISYteq Touch 3.5 control panel. This func-

2

Compliant with energy class A+ in cold climate conditions (Scandinavia).

If configured for on-demand control, the unit is compliant with energy

class A in average climate conditions (Central Europe). Ecodesign

Directive 1254/2014.

We reserve the right to make changes without prior notice

4

12315 30 60

15 30 60

BOOST

TRICKLE/NORMAL

14:35

21

14:35

21

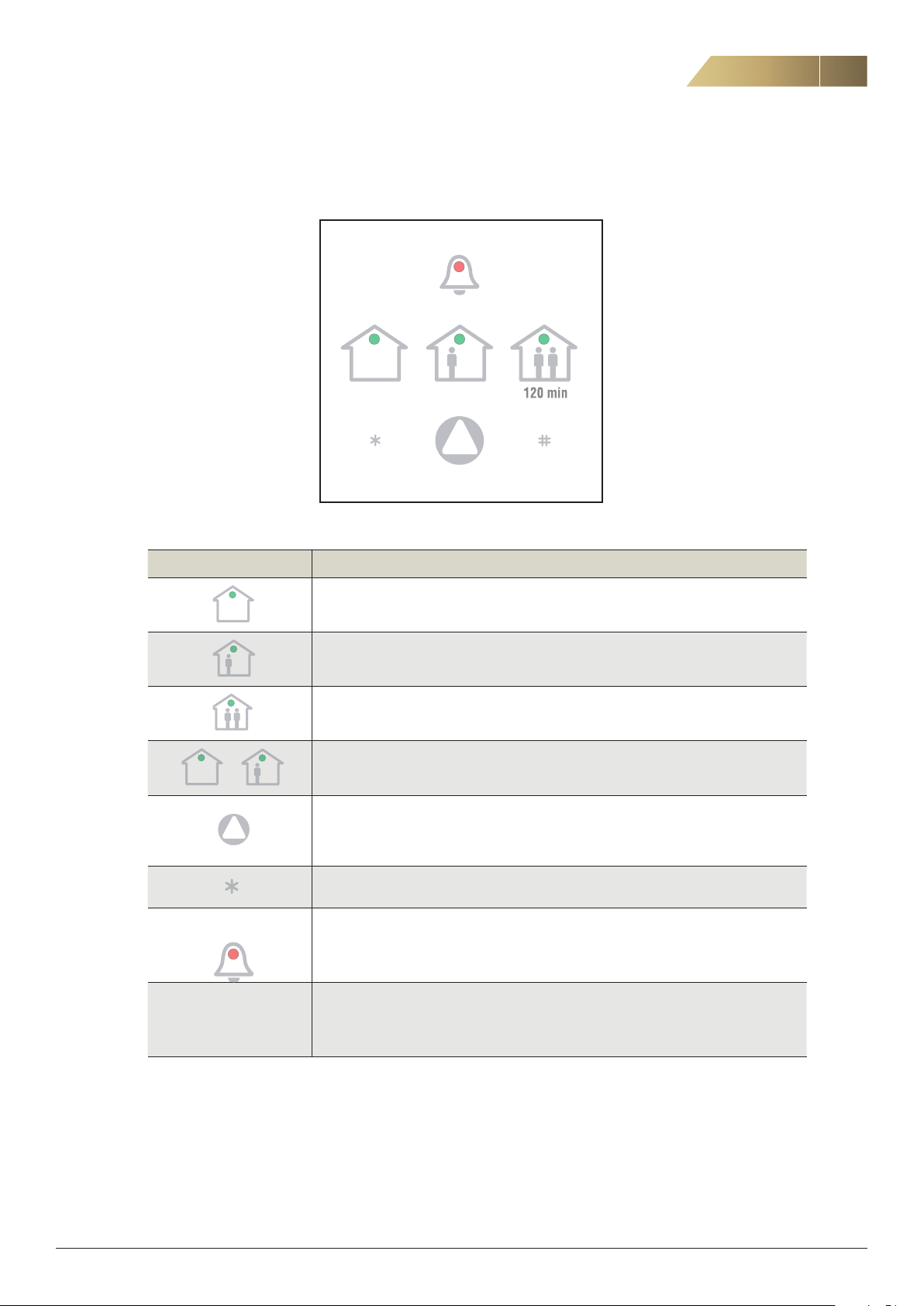

ISYteq BASIC CONTROL PANEL - OPERATION

Heat recovery unit RDKS - Technical manual

The unit has a built-in control unit that controls the operation of the

fans, the rotary heat exchanger and any electric heaters.

The unit is controlled via an external ISYteq Basic or ISYteq Touch 3.5

control panel (accessory), see page 6. The control unit should be in

-

stalled in a suitable place.

After being adjusted, the unit can also be operated without a control

panel, but only in one operating mode.

ISYteq Touch 3.5ISYteq Basic

Figure 1. Control panels.

The user can select between the following operating

modes:

“AWAY” is used when there is reduced need for ventilation, e.g.

when occupants are on holiday

“HOME” used for normal ventilation flow

“FORCED” is used when there is a greater need for ventilation (au

tomatically reverts to normal after 120 minutes)

Use the arrow button to switch operating modes (see figure 2). A LED

shows the current operating mode.

UNIT WITH COOKER HOOD

When the boost damper in the cooker hood is opened, the fan

speed increases. Forced mode continues while the boost damper

remains open. After that, the fans resume normal speed.

Forced via CPDJ cooker hood.

-

Boost damper

(one press per

time setting)

AWAY

Operating modes ISYteq Basic

FläktGroup DC_9295GB_20190326_R5

HOME

operating mode)

x1 = 15 min

x2 = 30 min

x3 = 60 min

Forced via CPTJ cooker hood.

FORCEDArrow button (for selecting

We reserve the right to make changes without prior notice

Heat recovery unit RDKS - Technical manual

ISYteq BASIC CONTROL PANEL - OVERVIEW OF SYMBOLS AND FUNCTIONS

SYMBOLS DURING NORMAL OPERATION

HOMEAWAY FORCED

5

Symbol Description

AWAY mode

HOME mode

FORCED mode for 120 minutes

+

Min. 10 sec. Press * for a minimum of 10 seconds to reset an alarm. Also see pages 11 and 12.

No symbols illuminated

indicates that unit has

stopped.

Defrosting mode. The unit resumes normal operation after 15 minutes

Switch operating modes between: AWAY, HOME and FORCED.

Disabled during defrosting

Continuously flashing alarm symbol indicates filter alarm. See page 11.

Three flashes at intervals indicates rotor alarm. See page 12.

Steady illumination indicates temperature alarm. See page 12.

See Other alarms on page 12.

Figure 5. Symbol description ISYteq Basic.

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

6

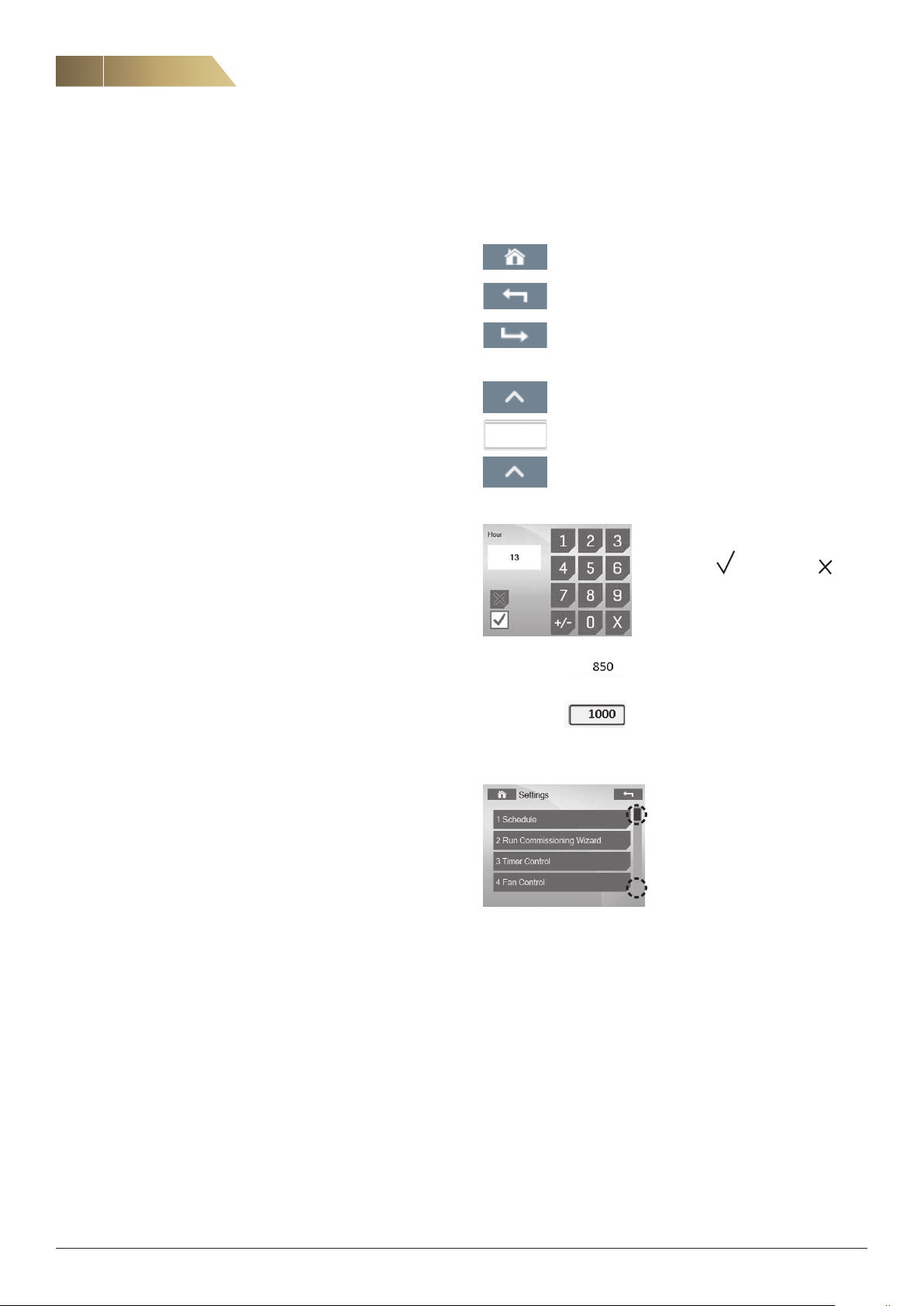

ISYteq TOUCH 3.5 CONTROL PANEL

Heat recovery unit RDKS - Technical manual

GENERAL

The control panel has a touch screen display. Use your finger or the

back of a pen to navigate in the menus.

When the power is switched on, all the menus will be imported into

the system. This will take about 20-30 seconds. After this, the home

screen will be displayed.

CLEANING OF THE DISPLAY

Disconnect the unit from the power supply by disconnecting the power

cord. Carefully wipe the display with a soft, dry, non-abrasive cloth.

If any marks remain, moisten the cloth slightly with a detergent spe

cially designed for LCD or mobile screens and wipe the screen gently

from top to bottom.

Never use other detergents, as they may contain ammonia or other

additives that could damage the display.

-

IMPORTANT:

• Never spray or pour liquids directly onto the display.

• Never clean the control panel when the system is switched on.

GENERAL BUTTONS AND SYMBOLS

The following buttons and symbols are universal and available on

many menu pages.

Home button, to return to the home screen.

Back button, to cancel and return to the previous page.

Confirm button, to confirm and proceed.

Use the number keys to enter a value.

Confirm with

or cancel with .

14

Changing a value.

Option 1: Press the arrow keys to increase or decrease

the value.

Option 2: Press the displayed number to enter the chosen value (see below).

Read-only values (without a surrounding

window), cannot be changed.

Editable values (surrounded by a win

dow), can be changed.

Some submenus have more than

one page. Click the upper

or lower part of the scroll list to

navigate between pages.

NOTE! The cursor cannot be

moved vertically.

-

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

Heat recovery unit RDKS - Technical manual

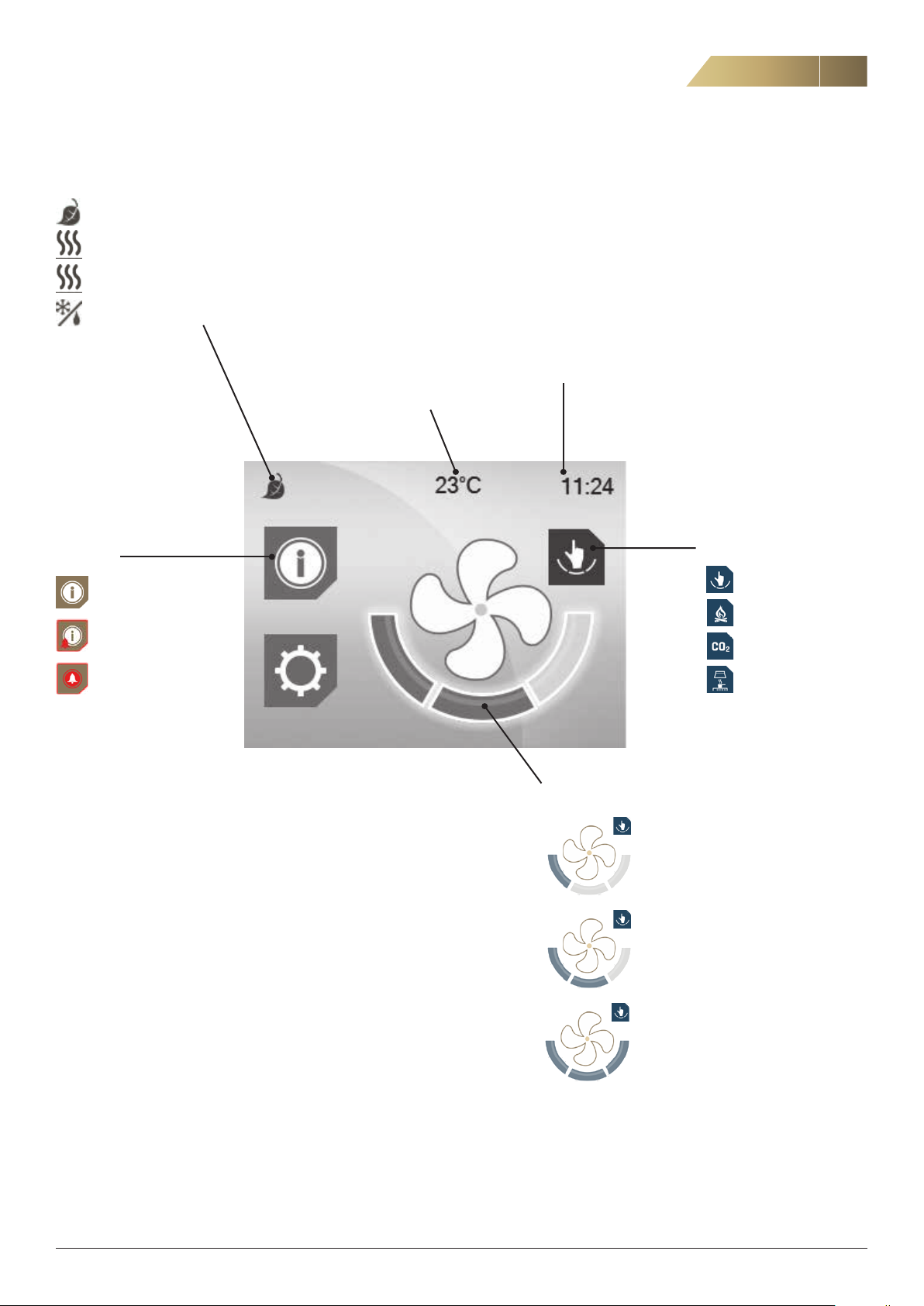

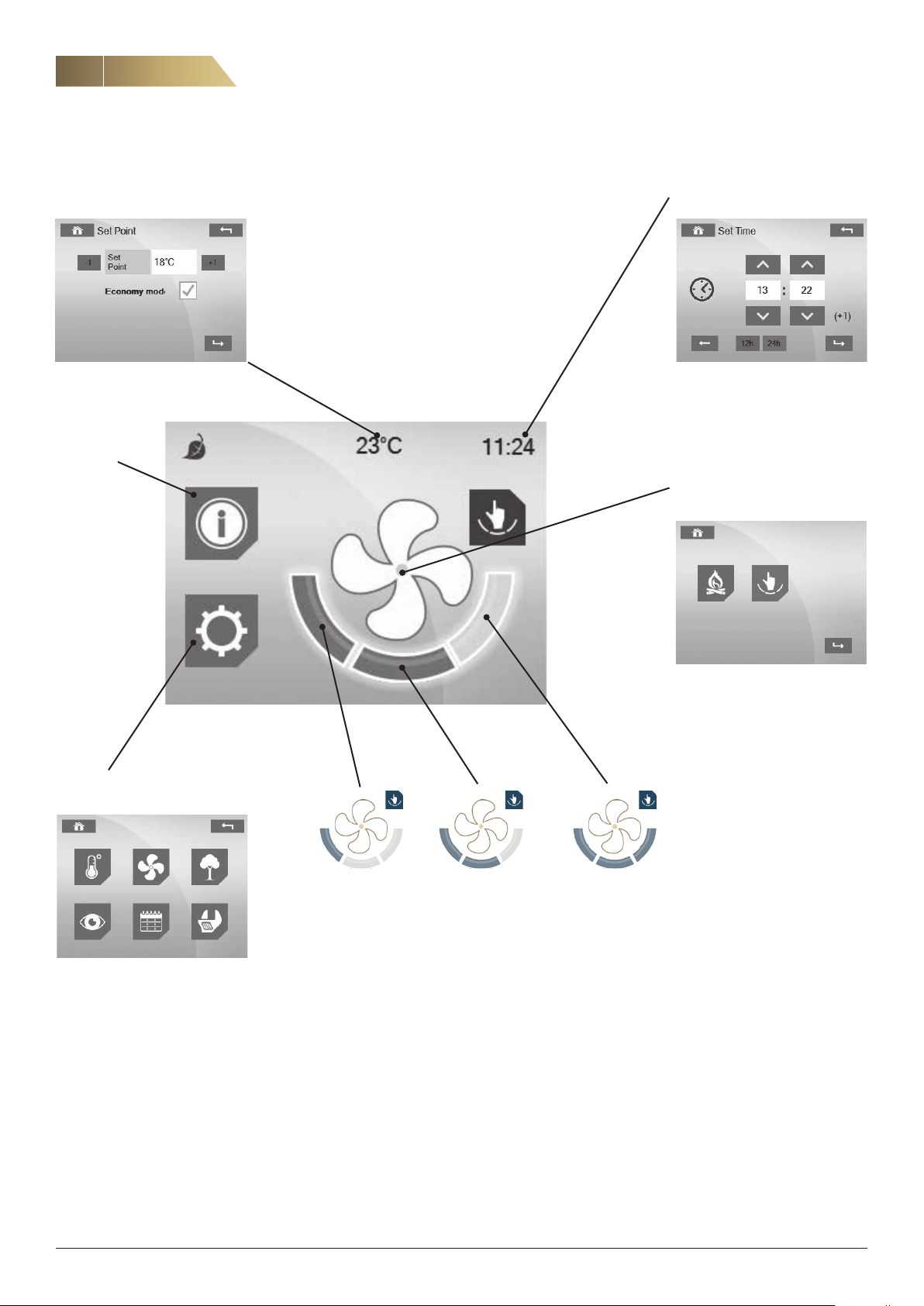

ISYteq TOUCH 3.5 CONTROL PANEL - HOME SCREEN

STATUS LINE

Heat recovery active

Postheater active

Preheater active

Defrosting in progress

7

ALARMS

No alarm

Alarm B

Alarm A

CURRENT SETPOINT,

SUPPLY AIR TEMPERATURE

CLOCK

OPERATING STATUS

Manual mode

Heating stove mode

CO2 control

Forced via cooker hood

OPERATING MODES

The user can select between the following operating modes:

“AWAY” used when there is reduced need for ventilation, e.g.

when occupants are on holiday

“HOME” used for normal ventilation flow

“FORCED” used when there is a greater need for ventilation

(automatically reverts to normal after 120 minutes)

FläktGroup DC_9295GB_20190326_R5

Away mode

Home mode

Forced mode

We reserve the right to make changes without prior notice

8

ISYteq TOUCH 3.5 CONTROL PANEL - OPERATION

Heat recovery unit RDKS - Technical manual

SHORTCUT TO SETTING OF TEMPERATURE SETPOINT

See page 9 for more information on temperatures.

ALARMS

See page 9.

SHORTCUT TO SETTING OF

DATE AND TIME

SELECT OPERATING STATUS

See page 9.

MENU

See page 9.

AWAY MODE HOME MODE FORCED MODE

Press the relevant field to select operating mode.

The operating mode cannot be changed during defrosting,

or during forced operation with a cooker hood.

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

Heat recovery unit RDKS - Technical manual

ISYteq TOUCH CONTROL 3.5 PANEL - OPERATION

9

SELECTING OPERATING STATUS

The symbol on the home screen shows the operating status. Press the

centre of the fan symbol to change the status.

Normal mode (manual)

Heating stove mode, makes it easier to light a heating stove

or open fireplace. Temporarily creates overpressure in the

house.

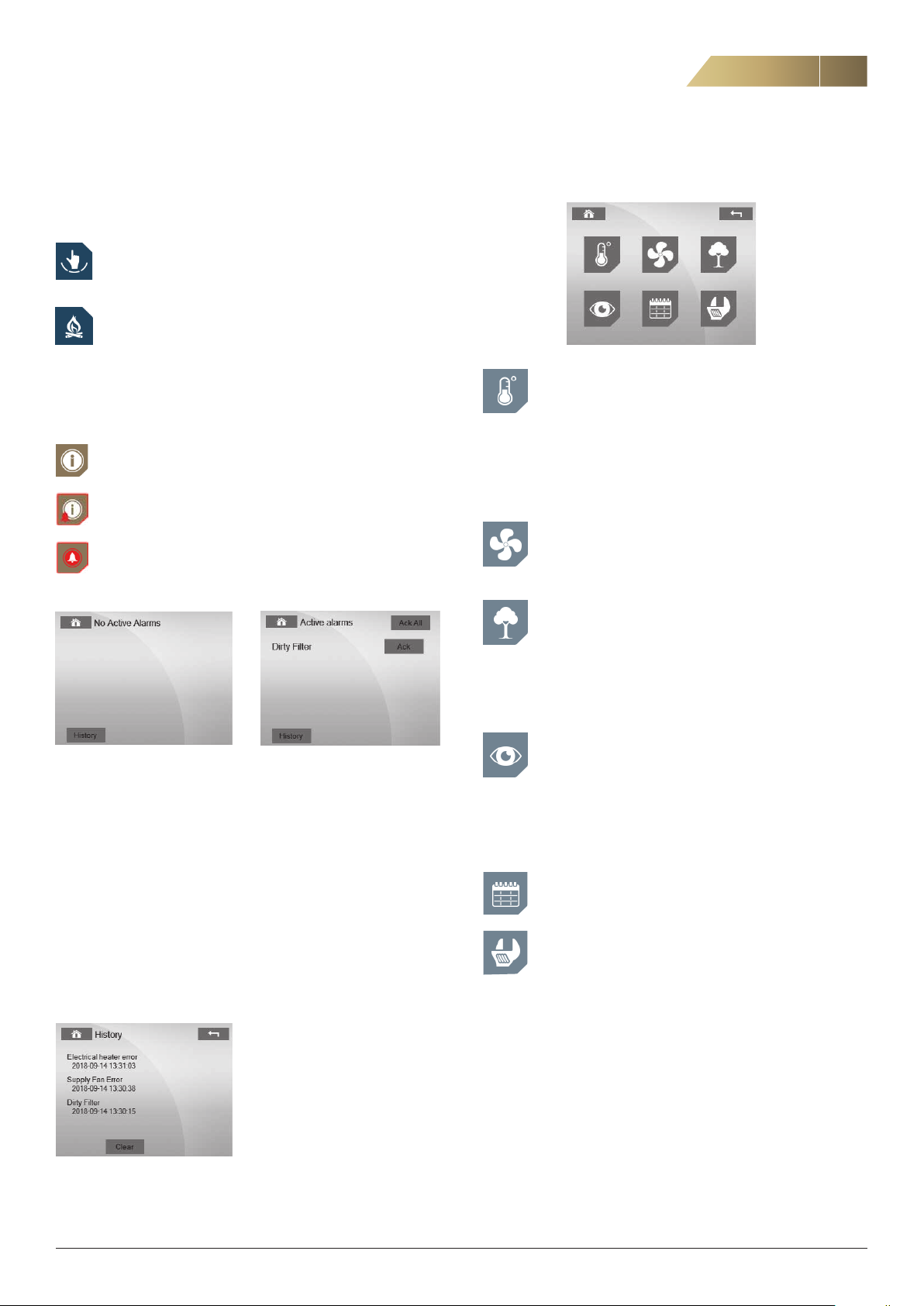

ALARMS

The symbol on the home screen shows the alarm status.

No alarm

Alarm B

Alarm A

Press the icon to enter the alarm screen.

MENU

TEMPERATURES

Here you set the desired supply air temperature (setpoint).

Note: This value is not to be confused with the desired in

door temperature, which is managed by the domestic heating system. The recommended setpoint is 16–19 °C. The

factory setting is 18 °C. Temperatures, output signals etc.

are read-only values.

-

FAN STATUS

Supply and extract air fan speeds can be read from

30 –100 % or as 0 (off).

AIR QUALITY

Air quality (only available if optional moisture control or CO

control is activated). Relative humidity of the supply and

extract air can be read from 0-100% RH.

The setpoint and current CO

be read.

value (up to 2,000 ppm) can

2

2

Example 1 No alarm Example 2. Active alarms

CLEARING ALARMS

To clear an individual alarm, press Acknowledge after the relevant

alarm. To clear all the alarms, press Acknowledge All button (top right).

If the alarm cannot be cleared, it will reappear on the display and the

underlying cause for this must be resolved before the alarm can be

cleared.

A built-in timer is normally set to provide a filter replacement reminder

(alarm) every six months. If a shorter replacement interval is required

(before the alarm is due) the filter alarm can be reset under the Set

tings menu. See page 22, fig. 3.

-

ALARM HISTORY

SYSTEM OVERVIEW

Version control panel -- -- -- -- -- -- -- -- -- -- -- --IP Octet 1

Bootloader control panel --------------------IP Octet 2

Version control card ------------------------IP Octet 3

Bootloader control card -- -- -- -- -- -- -- -- -- -- --IP Octet 4

Unit type

TIME SCHEDULES

(Not applicable to domestic ventilation).

SETTINGS

See pages 22–23.

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

10

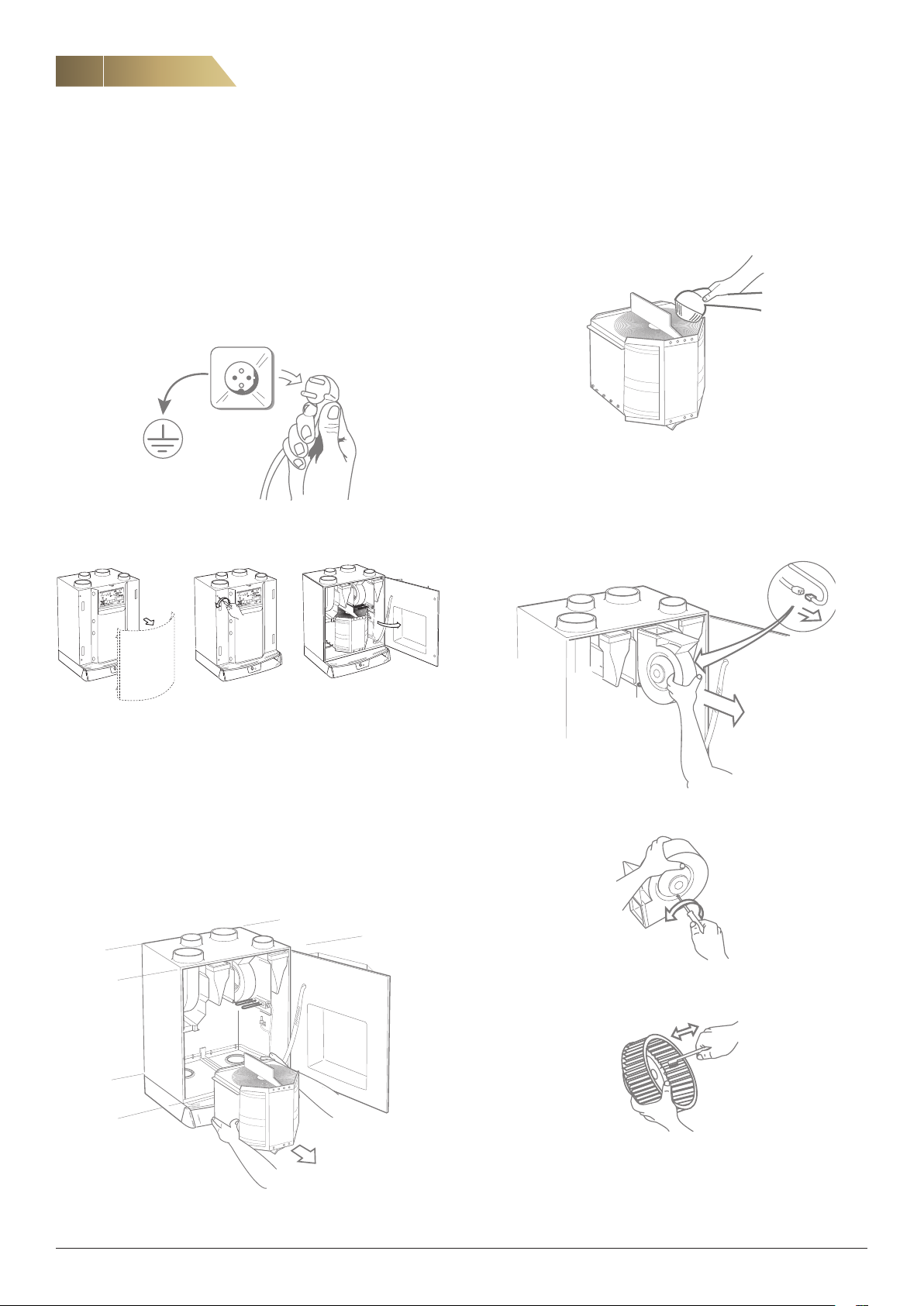

MAINTENANCE AND CLEANING OF HEAT EXCHANGER AND FANS

Heat recovery unit RDKS - Technical manual

GENERAL

The fans, filters and heat exchanger are very important for the operation and economy of the unit. For this reason, it is crucial for them to

be kept clean and in good condition.

We recommend a general check-up every 6 months. For safety rea

sons, general caution should be observed during maintenance of the

unit. Be careful to avoid trapping any cables. If necessary, use protec

tive gloves.

Before cleaning the heat exchanger, fans etc., the unit should always have the power

disconnected.

Mode

LED

Param.

Mode

LED

Param.

-

-

The drive belt and seals may need replacing due to wear and tear.

Check them for damage and replace if necessary. For designations,

see spare parts list on page 33.

Vacuum clean the heat exchanger or blow clean with compressed air.

CLEANING OF FANS

Note that the fans must not be cleaned with water or other fluids; they

may only be vacuum cleaned or brushed.

Remove the unit’s front cover (if there is one). Remove the screws on the door and

open the door. The picture shows a unit with right-hand configuration (RDKS-1).

CLEANING OF THE HEAT EXCHANGER

Check that the surface of the rotor is not coated with dust. Clean with

a vacuum cleaner or by blowing through with compressed air. If vac

uum cleaning is not sufficient, hand-spray with grease dissolving fluid

and then blow clean with compressed air. Use the compressed air to

blow away from the clean side towards the dusty side.

Note! Water, acetone or similar solvents must not be used.

Remove the heat exchanger package from the unit. Disconnect the electrical con

nection to the impeller motor.

-

-

Remove the fan from the unit. Disconnect the electrical connection.

Disconnect the impeller from the fan housing by unscrewing the screws on the side

of the fan housing.

Clean the impeller housing and the fan blades with a brush or a vacuum cleaner.

NOTE! Take care not to damage any impeller housing balancers, and ensure

that no cables are trapped during reassembly.

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

Heat recovery unit RDKS - Technical manual

B

A

Mode

LED

Param.

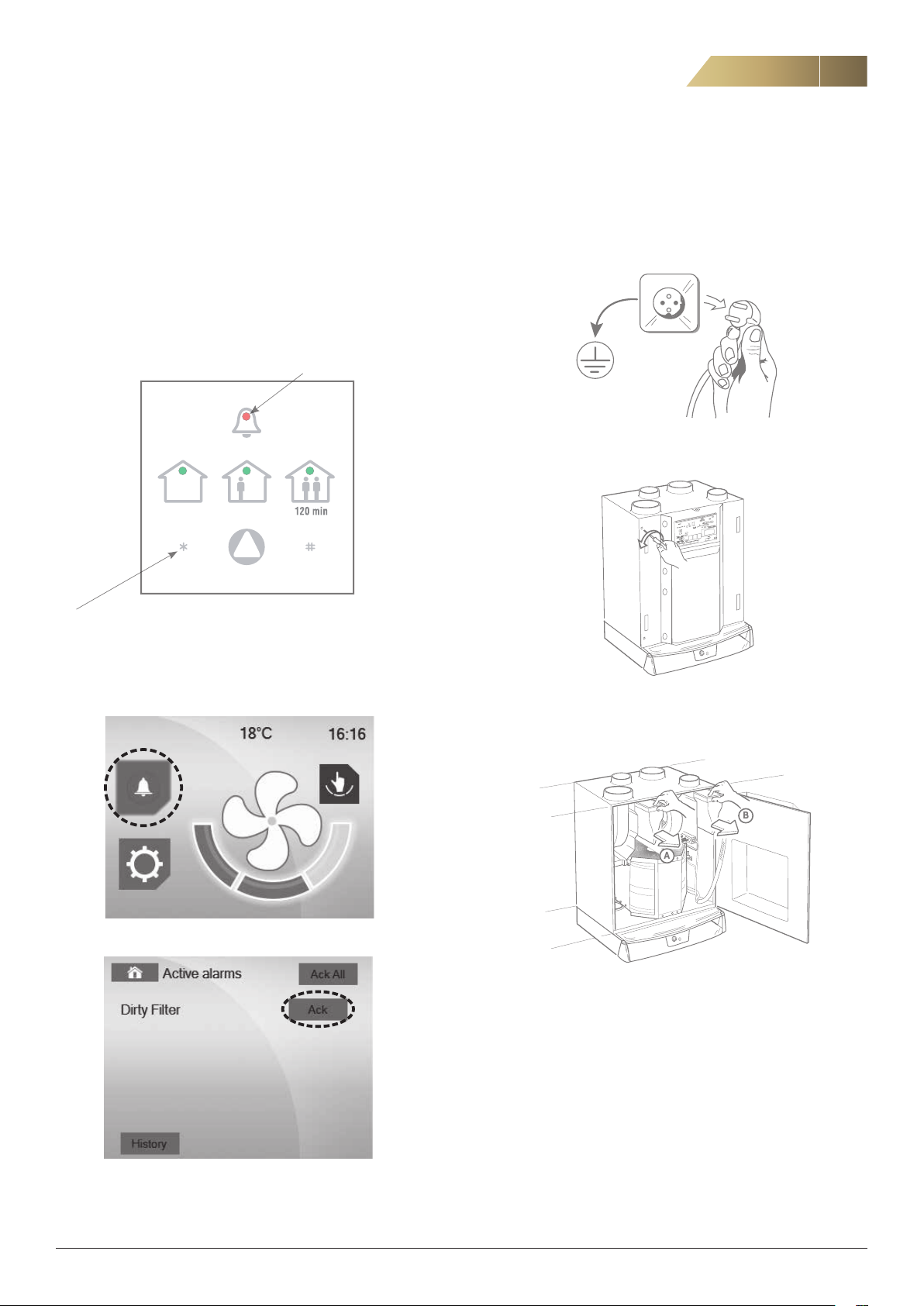

FILTER ALARM AND FILTER REPLACEMENT

11

The supply air and exhaust air filters should normally be replaced

every six months. In dirty areas, the filters may need to be replaced

more frequently.

A built-in timer is normally set to provide a filter replacement reminder

every six months.

FILTER ALARM ISYteq BASIC

When the filter needs replacing, a continuously flashing alarm light is

shown on the ISYteq Basic control panel.

A continuously flashing alarm

symbol indicates filter alarm.

After replacing the filter, reset the filter timer by pressing the * button on the

control panel for a minimum of 10 seconds.

TO REPLACE THE FILTER, FOLLOW THE STEPS BELOW.

When replacing dirty filters, use of a face mask is recommended (lowest class, FFP2).

1. Disconnect the unit from the power supply by pulling out the plug.

2. Open the door of the unit by unscrewing the two screws on the front

(see below).

FILTER ALARM ISYteq TOUCH 3.5

Press the Information/alarm button if the alarm is indicated.

The reason for the alarm is shown under active alarms.

After replacing the filter, acknowledge the alarm.

3. Pull out the supply air and exhaust air filters. Dispose of used filters

according to local waste regulations.

4. Insert new filters.

The picture shows a bag filter. A flat filter may also be used.

5. Close the door of the unit.

6. Connect the plug.

7. After replacing the filter, reset the filter alarm.

If a filter is replaced before the alarm is due, the filter replacement

timer cannot be reset via the ISYteq Basic control panel (accessory).

If there is no ISYteq Touch 3.5 control panel (accessory) on the unit

when the filter is replaced, the timer must be reset when the alarm is

due, i.e. when the set time is reached. For resetting, see page 22.

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

12

Heat recovery unit RDKS - Technical manual

OVERHEATING PROTECTION, ROTOR ALARM, TEMPERATURE ALARM, OTHER ALARMS

THERMAL OVERLOAD PROTECTION

The fan motors are equipped with thermal overload protection devices,

which are reset manually by briefly disconnecting the power.

The electric heaters have two thermal overload protection devices, one

automatic and one manual. The automatic overheating protection trips

before the manual one, which means it does not normally need to be

reset.

If the manual overheating protection for the electric heater has tripped

during operation, first the power to the unit should be switched off and

then the overheating protection should be reset by pressing the reset

button.

In order to access the button, the electric heater must be disconnect

ed.

If the manual overheating protection trips again, call qualified service

personnel.

-

ROTOR ALARM

If the rotor motor stops and the Tacho signal disappears, five attempts

will automatically be made to restart the rotor (start/stop). If this does

not solve the problem, the unit will stop and the rotor alarm will be in

dicated.

-

TEMPERATURE ALARM

Generates an alarm and stops operation if the supply air temperature

drops below +5 °C. The alarm is disabled during defrosting or dur

ing forced operation with a cooker hood. A 10-minute delay ensures

that the supply air temperature has time to rise if operation has been

stopped.

-

OTHER ALARMS

The unit has various alarms that are not supported by the simple

ISYteq Basic control panel (accessory).

If any of these alarms are triggered, the unit will stop running and all

the LEDs on the ISYteq Basic will be extinguished. This also happens

in the event of power failure. A LED on the control card indicates that

the power is not switched off.

To reset these alarms, the unit must be restarted by pulling out and

reconnecting the plug.

If the ISYteq Touch 3.5 control panel (accessory) is used, the alarm will

be presented in plain text.

If the alarm recurs, service personnel will be called for assistance.

SENSOR ERROR

If any of the temperature sensors starts malfunctioning, the unit will

stop running. To reset, follow the instructions under Other alarms.

EXTERNAL ALARM

An external alarm can be connected to the unit. If this alarm is triggered, the unit will stop running To reset, follow the instructions under

Other alarms.

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

Loading...

Loading...