FläktGroup GMPM, GMEB Installation And Maintenance Manual

CENTRIFLOW 3D PLUG FAN GMPM, GMEB

PUR (A, B, C, D)

INSTALLATION AND MAINTENANCE

SLIDE IN ROTOR CASSETTE

CENTRIFLOW 3D PLUG FAN WITH PERMANENT

MAGNET AND ASYNCHRONOUS MOTOR

CONTENT PAGE

1. Importent information ........................................................................ 2

2. Saferty notes ......................................................................................... 2

3. Technical description ........................................................................ 3

4. Transport .................................................................................................4

5. Mounting instructions ........................................................................ 5

6. Commissioning .................................................................................... 6

7. Maingenance ......................................................................................... 8

8. Faults ..................................................................................................... 10

9. Spare parts ...................................................................................... 10

10. Distances ............................................................................................. 10

11. Air flow measurement ..................................................................10

12. Disposal of the product ................................................................10

13. Declaration of conformity .............................................................11

FläktGroup DC_9853GB_20180425_R0

Specifications are subject to alteration without notice

2

Centriflow 3D GMPM, GMEB - Installation and Maintenance

IMPORTANT INFORMATION, SAFETY NOTES

1. IMPORTANT INFORMATION

FläktGroup fans comply with the requirements for health and

safety of the EC Machinery Directive.

All fans leave the factory after being subjected to testing.

These instructions are intended for use by professional service

staff. The installation, commissioning and operation of the fans

must be carried out by professional staff who are familiar with

the safety regulations.

Tools and protective equipment necessary for preventing acci

dents from occurring while installing and operating the fan must

be used/worn in accordance with the local safety regulations.

All personnel involved with the product must carefully study this

operating manual and diligently comply with all orders and in

structions.

FläktGroup does not accept responsibility for any damage

that can be attributed to non-observance of these instructions.

The warranty issued by the manufacturer will be forfeited if any

changes to the product are made without the manufacturer’s

consent.

-

-

2. SAFETY NOTES

This symbol is designed to point out all safety and

danger related information regarding danger on the

operating personnel’s lives and health.

FläktGroup DC_9853GB_20180425_R0

Specifications are subject to alteration without notice

Centriflow 3D GMPM, GMEB - Installation and Maintenance

TECHNICAL DESCRIPTION

3

3. TECHNICAL DESCRIPTION

The fan is used to generate a desired air volume at a given

pressure rise that corresponds to the pressure losses in the duct

system to which the fan is connected, and internal losses inside

of the Air Handling Unit.

The plug fan is intended to be used inside of the Air Handling Unit.

3.1 DESIGN

1

3

2

4

10

6

8

Sizes ≤ 071.

3

4

6

9

7

5

1

2

7

9

3.2 OPERATING CONDITIONS

The standard operating temperature range of the fan is –20° C +40° C. The maximum permissible ambient temperature of the

motors is +40° C.

If they are operated in conditions where the ambient temperature

is higher, the rated output will as a rule have to be reduced. See

the instructions of the motor manufacturer.

The fans are designed to be used as parts of equip

ment. They are not ready for use as a stand-alone

product and the standard version does not have

protection against body contact, the appropriate

protective measures are to be taken according to

EN 292/294.

Only operate the fan up to the maximum permissible speed given

in the information on the fan rating plate.

-

3.3 MOTORS

Both AC- and PM-motors can be used with GMPM and GMEB plug

fans.

AC-motors are IEC-standard IE2 or IE3 motors. The motors are

equipped with a thermistor and they are designed for a frequen

cy converter use. Admissible environmental temperature: from

–15°C up to +40° C.

PM-motors are high efficiency IE4 permanent magnet motors.

They shall be used together with a frequency converter and can

not be connected directly to the mains. Admissible environmental

temperature: from –15° C up to + 40° C.

-

-

3.4. FREQUENCY CONVERTERS

All fans used in an Air Handling Unit in the European Union area

shall be equipped with a speed controller in accordance with the

Regulation 1253/2014.

8

Sizes ≥ 080.

1. Front plate

2. Inlet cone

3. Impeller and hub

4. Motor

5. Base frame

6. Motor bracket

7. Front plate support (fan size 056 and bigger)

8. Vibration dampers (optional)

9. Built-on frequency converter (optional)

10. Frequency converter mounting plate (optional)

FläktGroup DC_9853GB_20180425_R0

5

Specifications are subject to alteration without notice

4

TRANSPORT

Centriflow 3D GMPM, GMEB - Installation and Maintenance

4 TRANSPORT

4.1 TRANSPORT INSPECTION

Check the fan immediately after you receive it and make sure that

it has not been damaged during transport. If you discover any

damage, get in touch with the transportation company without

delay. Briefly rotate the fan impeller to see that it rotates easily.

Check the information on the fan rating plate.

Proper procedures must be followed when transporting the product!

Faulty conditions in transporting may result in serious damage on

the product

4.2 TRANSPORT SAFETY

The transport material is to be selected according to the packaging and the weight of the product. Loading must be carried out

as instructed.

4.3 INTERMEDIATE STORAGE

If the fan is to be stored before or in between uses, the following

needs to be taken in account:

– Original packaging is to be used. If the storage conditions re

quire it, additional protection may be added

– The storage environment must be dry, dust-free and not have

a high level of humidity (<70%)

– Storage temperature must be in between –25° C and +40° C

Before commissioning, the respective instructions must be

studied thoroughly.

-

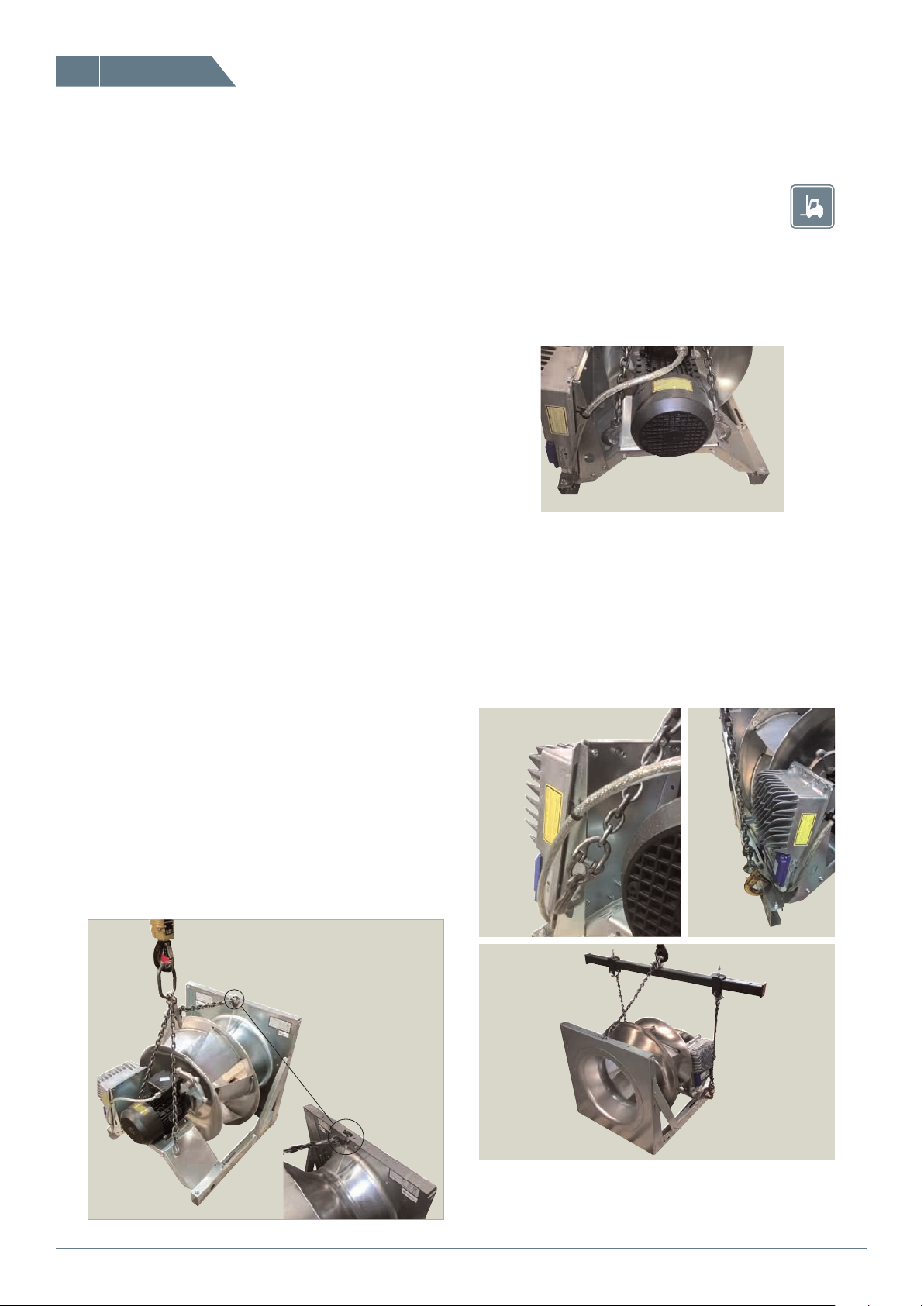

There are three alternative places to attach the rear lifting hooks,

which are to be used depending on the fan combination.

Wherever possible, use holes on the motor bracket as shown in

the picture below.

In case of a built-on frequency converter, if there is no access to

the hole on the motor bracket behind the frequency converter

assembly bracket, one of the rear chains/beams could be

attached to the hole on the frequency converter assembly bracket

(up to fan size 045).

With bigger fans (or if there are no holes on the motor bracket)

holes on the base frame are to be used. In this case it must be

taken into account not to damage the frequency converter.

Transverse beam must be used if needed.

4.4 LIFTING OF THE FAN

4.4.1 SIZES ≤071

The fan is to be lifted with three lifting chains/beams (one

attached to the front plate and two to the rear end of the fan).

FläktGroup DC_9853GB_20180425_R0

Beware of damaging the fan while lifting. Always adjust chains/

beams long enough not to get in touch with motor, frequency

converter or impeller.

Specifications are subject to alteration without notice

Loading...

Loading...