FläktGroup ECO SIDE Installation And Maintenance Manual

INSTALLATION AND MAINTENANCE MANUAL

ECO SIDE

eCO Side - Installation and Maintenance Manual

2

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

Page

1. SAFETY INSTRUCTIONS ................................................................................3

VDI 6022 ............................................................................................................3

2. DESCRIPTION OG THE UNIT .......................................................................... 4

3. TRANSPORT AND PLACEMENT ..................................................................5

4. CONNECTIONS

4.1 Duct connections .....................................................................................6

4.2 Post heater, electrical (9 kW) .............................................................6

4.3 Post heater, hot water ...........................................................................6

4.4 Cooling coil, water ...................................................................................7

4.5 Valve and valve actuator ...................................................................... 7

4.6 Damper ........................................................................................................ 7

4.7 Silencer ........................................................................................................ 7

5. ELECTRICAL CONNECTIONS

5.1 Fuse protection ........................................................................................8

5.2 Electrical data...........................................................................................8

5.3 Main supply ...............................................................................................8

5.4 Connection of control panel ................................................................9

6. CONNECTION OF EXTERNAL COMPONENTS

6.1 Electrical post heater (Size 06, 9 kW) .........................................10

6.2 Post heater, hot water .........................................................................10

6.3 Cooling coil, water ................................................................................10

6.4 Cooling coil, DX ......................................................................................10

6.5 Damper .....................................................................................................10

6.6 Temperature sensors ...........................................................................11

6.7 Extended / Forced ventilation ..........................................................11

6.8 Fire protection function .......................................................................11

6.9 Summary alarm .....................................................................................11

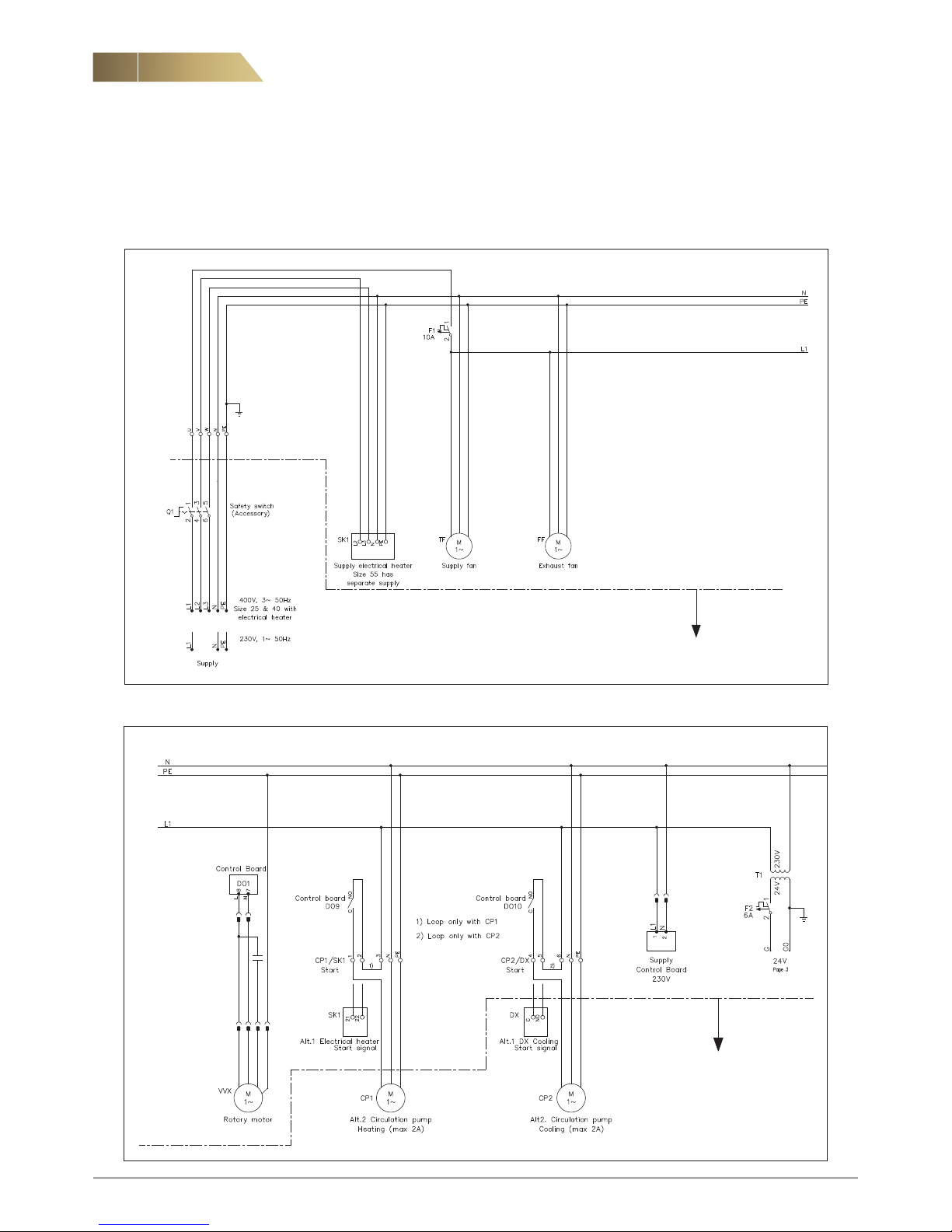

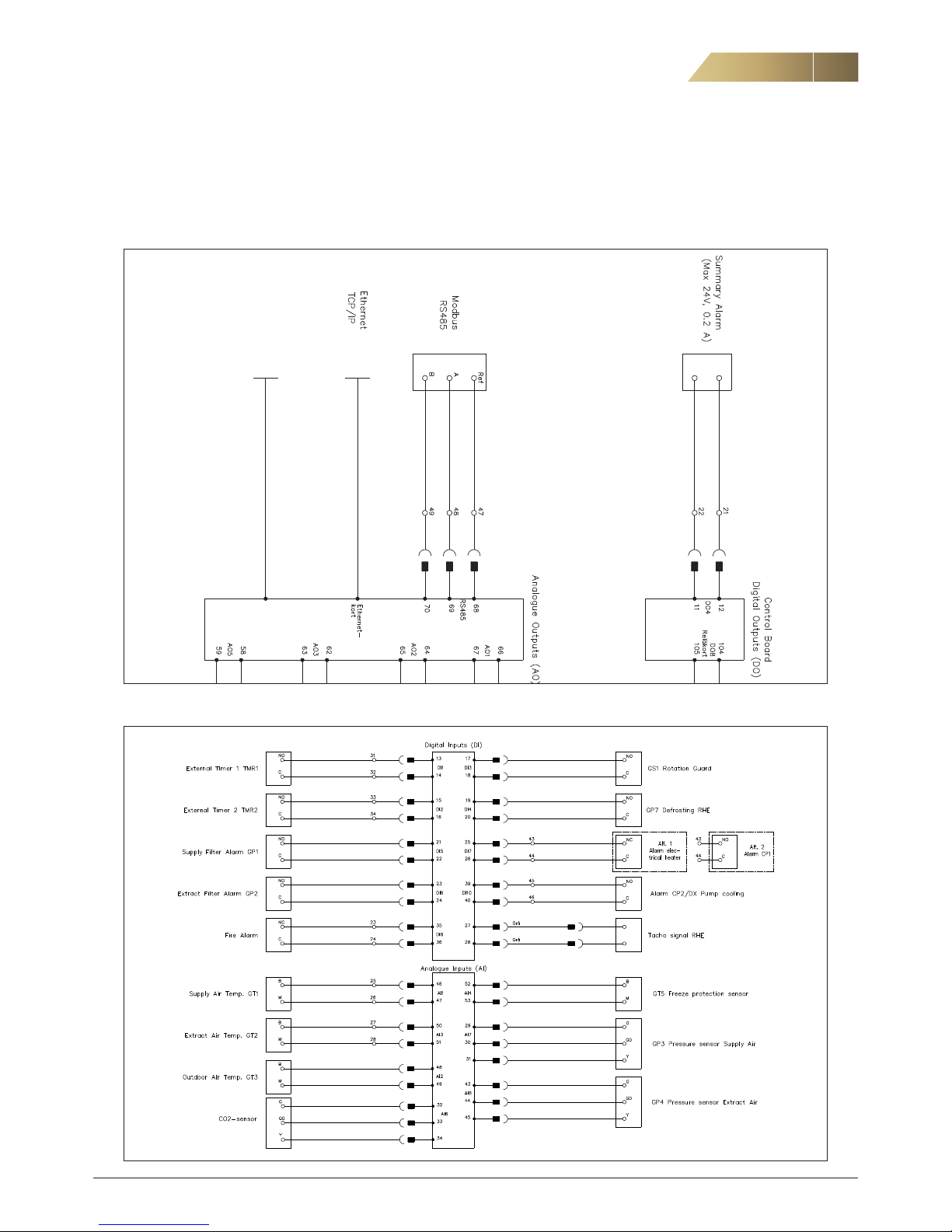

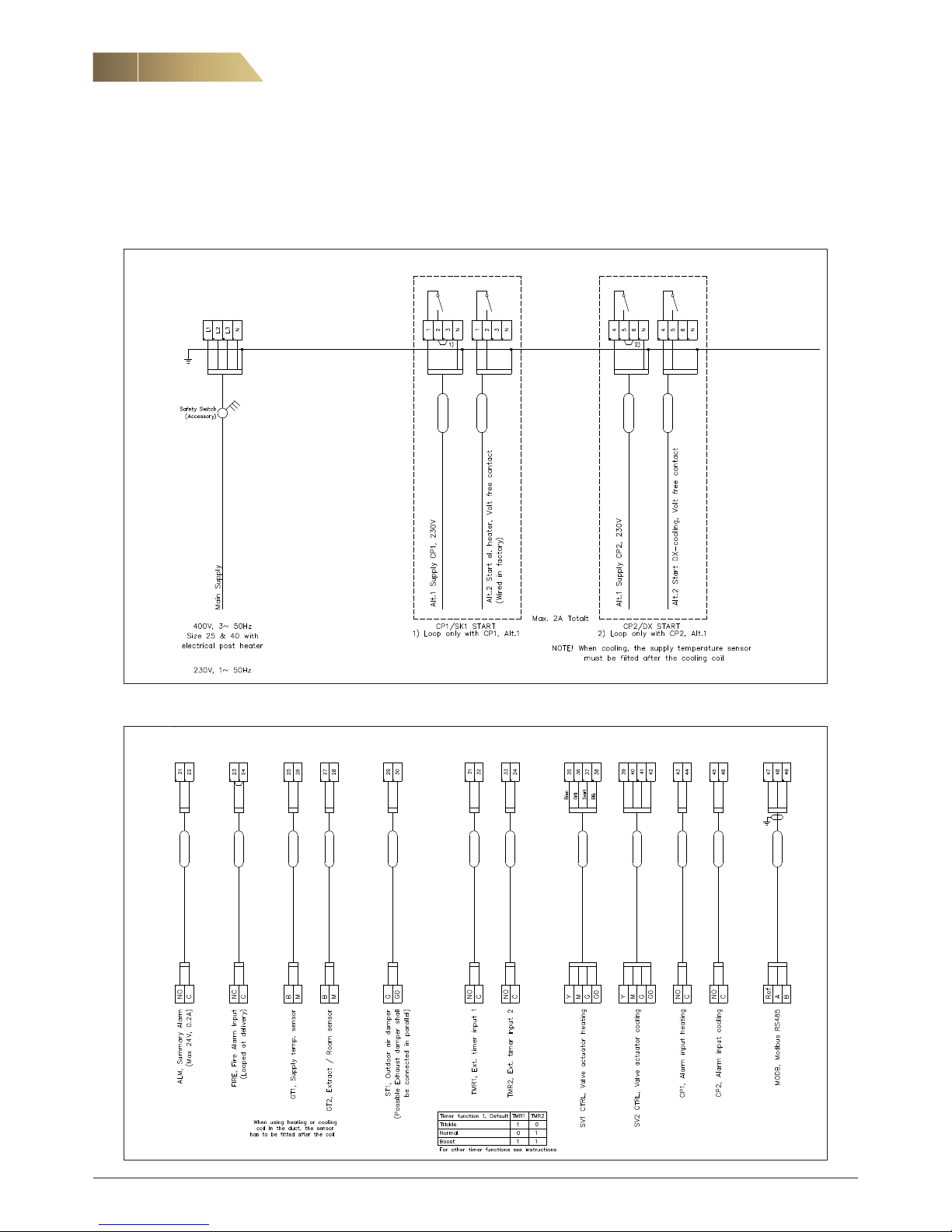

7. WIRING DIAGRAMS ...............................................................................12

8. TESTING OF FUNCTIONS.......................................................................15

9. CONTROL PANEL, OPEERATIONS, COMMISSIONING

9.1 General .......................................................................................................16

9.2 Home screen overview ......................................................................17

9.3 Sub menus ..............................................................................................19

9.4 Date/time, language ...........................................................................20

9.5 Advanced settings for installers and sevice personnel ..........21

9.6 Commissioning Wizard .....................................................................22

9.7 Schedules ................................................................................................ 26

Page

10. CONTROL FUNCTIONS

10.1 Rotor, heating and cooling .............................................................29

10.2 Temperature controls ......................................................................29

10.3 Freeze protection ...............................................................................31

10.4 Defrost function ...................................................................................31

10.5 Cooling recovery ................................................................................31

10.6 Night cooling ........................................................................................31

10.7

Pressure or Constant flow control .......................................32

11. COMMUNICATION

11.1 Modbus, RS485 ...................................................................................33

11.2 Modbus, TCP/IP .................................................................................33

11.3 Webserver ............................................................................................33

12. PARAMETER LIST ........................................................................................ 34

13. MAINTENANCE

13.1 General ...................................................................................................40

13.2 Filter........................................................................................................ 40

13.3 Rotary Heat Exchanger ................................................................... 41

13.4 Post heater, hot water ..................................................................... 42

13.5 Post heater, electrical .................................................................... 43

13.6 Cooling coil, water ............................................................................ 43

13.7 Fans ........................................................................................................ 44

13.8 Service schedule .............................................................................. 45

14. DECLARATION OF CONFORMITY ............................................................46

15. DISPOSAL ....................................................................................................... 47

CONTENTS

eCO Side - Installation and Maintenance Manual

3

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

OPERATION OF AIR HANDLING UNITS

AND ACCESSORIES

WARNING

Before taking the air handling unit into

operation fit any unused connections with

protective mesh.

In addition, all electrotechnical and me

chanical safety devices must be

installed before taking the air handling

unit into operation.

– Before opening the unit check that its power has been

disconnected.

– Take care when opening the isolating valves for the hot

water to the air heater. There is a risk of water hammer

or steam discharge.

– When servicing or inspecting the unit, turn off the

safety switch before opening the inspection doors.

Reset all safety devices before restarting.

– The clearance in front of electric heaters and electrical

cabinets shall conform to applicable electrical safety

regulations.

– Use the control panel to stop the unit.

– The unit’s hatches are fitted with locking handles.

Ensure that the unit is always left locked, and that the

keys cannot be accessed by unauthorized persons.

– Do not open inspection hatches when the unit is in

operation.

– Use protective gloves during installation and service.

1. SAFETY INSTRUCTIONS

Installation may only be

carried out by qualified personnel.

VDI 6022

eCO Side is designed in accordance to hygiene standard VDI 6022

and is easy to clean with no place where dirt can accumulate.

Nonmetallic part, have been chosen as proven free of micro bac

-

terial or mold growth.

Following the VDI 6022, AHU should ensure a physiologically

favourable indoor climate and a hygienically perfect indoor air

quality.

The eCO Side is designed in order, not to endanger health, not to

disturb the condition and the thermal comfort, not to lead to odour

nuisance and to prevent exposure and impact of inorganic and

organic pollutants.

eCO Side - Installation and Maintenance Manual

4

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

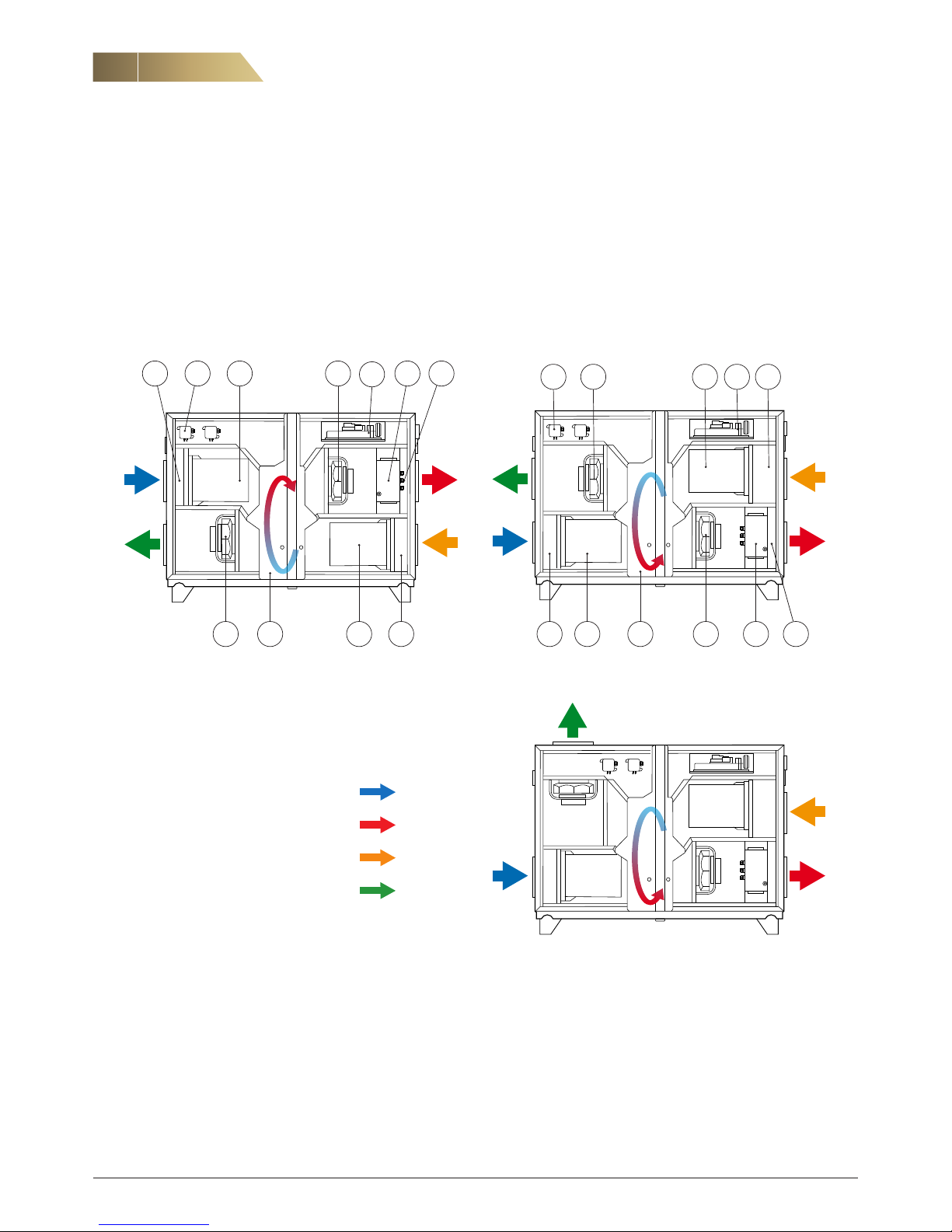

FANS

The unit has two plug fans with EC motors.

ROTARY HEAT EXCHANGER

The speed controlled rotor is fitted with a purge sector and a rotation sensor.

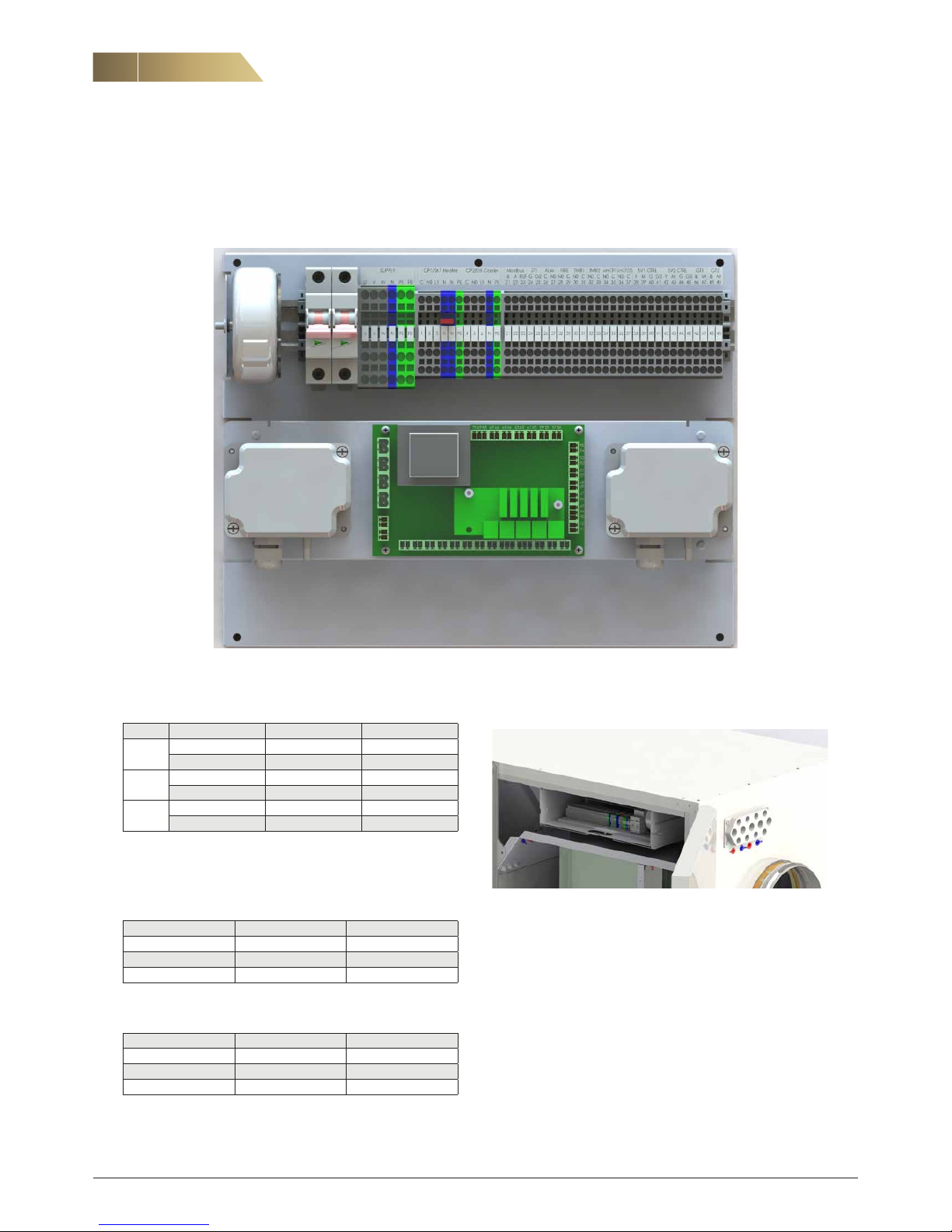

CONTROL SYSTEM

The ISYteq Mini control system is integrated with the unit and is

ready for use with a large number of functions.

COMPONENTS

The unit can be supplied in left-hand or right-hand configurations.

Left-hand configurations is mirror-reversed to right-hand. Refer to

the order code in Technical Instruction.

2. DESCRIPTION OF THE UNIT

FILTER

Bag filter class (F7) ePM1 50% on both supply and extract air.

POST HEATER, HOT WATER

Hot water coil containing copper tubes and aluminum fins. Pipe

connection ø15 mm. Freeze protection temperature sensor is

included. Max operating pressure 3.0 MPa.

POST HEATER, ELECTRICAL

The heater for size 03 and 04 is built-in. For size 06 the heater is

duct mounted.

TOP RIGHT HAND CONFIGURATION RDSP, bb = 12 or 14 BOTTOM RIGHT-HAND CONFIGURATION RDSP, bb = 11 or 13

EXHAUST AIR UPWARDS RDSP, bb = 11 or 13 and c = 2

1 Outdoor air sensor GT3

2 Supply filter

3 Rotary heat exchanger with rotation sensor

4 Supply fan

5 Electrical heater including overheating

protection alternativelyhot water coil

with freeze protection GT5

6 Supply air sensor GT1

7 Extract air sensor GT12

8 Control equipment

9 Extract filter

10 Exhaust fan

11 Pressure guard

Outdoor air

Supply air

Extract air

Exhaust air

3 4 5 61 2

1011 8 79

64

8

5

3 79

10

1 211

eCO Side - Installation and Maintenance Manual

5

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

SOUND TRANSMISSION

When a unit is positioned next to a wall, low frequency sound can

generate vibrations in the wall, even if the sound level from the

unit is acceptable. Generally the unit should be positioned against

a wall adYescent to a room that is not sensitive for noise. When

this is not possible the unit should be positioned 400-500 mm

from the wall.

Duct lead-through must be designed with care so that rigid

connections between the duct and wall do not occur. In addition,

the seal around the duct must be carefully installed to prevent

the transmission of noise to adYescent areas. For sensitive in

stallations it may be a good idea to connect ducts using flexible

connections.

If the floor structure is weak, noise can be transmitted to other

areas in the building. Use of a heavy insulating mat can prevent

that problem.

TRANSPORT

Use a fork lift truck, pallet truck or platform trolley for transport on

site. The unit can be lifted from the front or from the side.

To move size 06 through a 900 mm opening remove the door and

the center strut. See section 13.3.

3. TRANSPORT AND PLACEMENT

UNIT WEIGHT

Size 03 = 260 kg

Size 04 = 300 kg

Size 06 = 400 kg

SPACE REQUIREMENTS

Make sure that it is enough space around the unit for routine

service work, such as replacing filters and cleaning the fan and

casing.

Consideration has to be taken for future replacement of

com ponents.

PLACEMENT

The unit can be placed directly onto the surface if this is flat and

horizontal, otherwise use adjustable feet.

Available as accessory RDTZ-13.

Size B1 S

03 1683 730

04 1782 780

06 1945 861

B1 = width with open doors

S = minimum space for service*)

* in front of the control cabinet there has to be enough space

according to local electrical regulations.

B1

S

eCO Side - Installation and Maintenance Manual

6

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

NOTE! The weight of the duct system

with components must not lay weight on the unit.

4. CONNECTIONS

4.1 DUCT CONNECTIONS

Size 03 (Ø250 mm) and 04 (Ø315 mm) have circular duct connections. Size 06 has rectangular duct connections (600 x 300 mm).

4.2 POST HEATER, ELECTRICAL

The electrical post heater for size 06 is duct mounted, see separate instruction. The rectangular connection is PG on the unit and

the accessories. If the unit is selected with flange connection the

unit is delivered with an adapter for flange. This can be placed on

the unit or on the accessories. If the accessories are not placed

directly at the unit more adapters are available with the code

RDTZ-25-06-1.

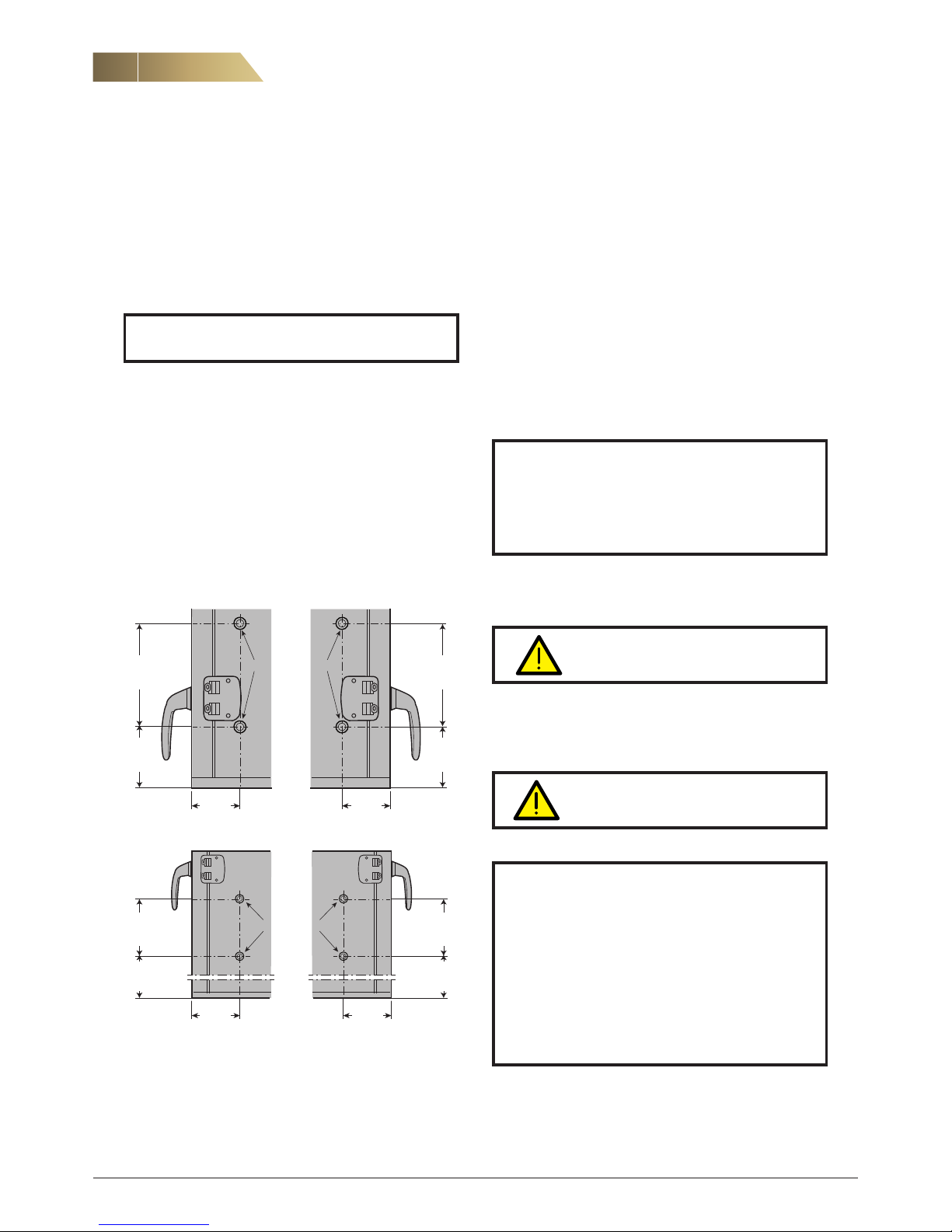

4.3 POST HEATER, HOT WATER

Connect the pipes for the heating coil inside the unit according to

pictures below. View from gables.

NOTE! To avoid freezing the temperatures for frost

protection must not be set too low. If the building

has to be left unheated for long periods during

winter, the water must be drained from both the

pipework and the heating coil.

WARNING! Wear protective gloves

when using a fin comb.

Warning - hot water!!

FläktGroup takes no responsibility neither for

the connection of air heaters to the heating

system, nor for damage or injury caused by

incorrect planning, installation or maintenance

of this system. Pipework, valves etc. are to be

designed due to pressure drop and function, not

the dimensions of the air heater connections. The

weight of the pipe work system with components

must not lay weight on the water coil.

PIPE CONNECTION

Size 03 = 3/8”

Size 04 = 12 mm

Size 06 = 12 mm

Maximum operating pressure 3.0 MPa

PREVENTING FREEZING

There is a risk of freezing in the hot water coil at low outdoor

temperatures. This can cause water damage. The risk can

appear:

1. if the temperature of the water is too high. The risk increases

in spring and autumn. Adjust the water temperature in relation

to the outdoor air temperature.

2. if the post heater is oversized. Decrease the temperature of

the water to increase the water flow.

FINS

Any deformed fins can be adjusted using fin comb EQAZ-14.

VENTING

The air must be properly vented from the system to ensure good

function. The venting is made through the pipe system.

Supply air bottom, right-hand version Supply air bottom, left-hand version

Supply air top, right-hand version Supply air top, left-hand version

Ø22.5

Ø22.5

03=108

04= 93

06=111

03=108

04= 93

06=111

03=238

04=272

06=304

03=135

04=132

06= 93

03=238

04=272

06=304

03=135

04=132

06= 93

03=108

04= 93

06=111

Ø22.5

Ø22.5

03=108

04= 93

06=111

03=238

04=272

06=304

03=491

04=559

06=534

03=238

04=272

06=304

03=491

04=559

06=534

eCO Side - Installation and Maintenance Manual

7

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

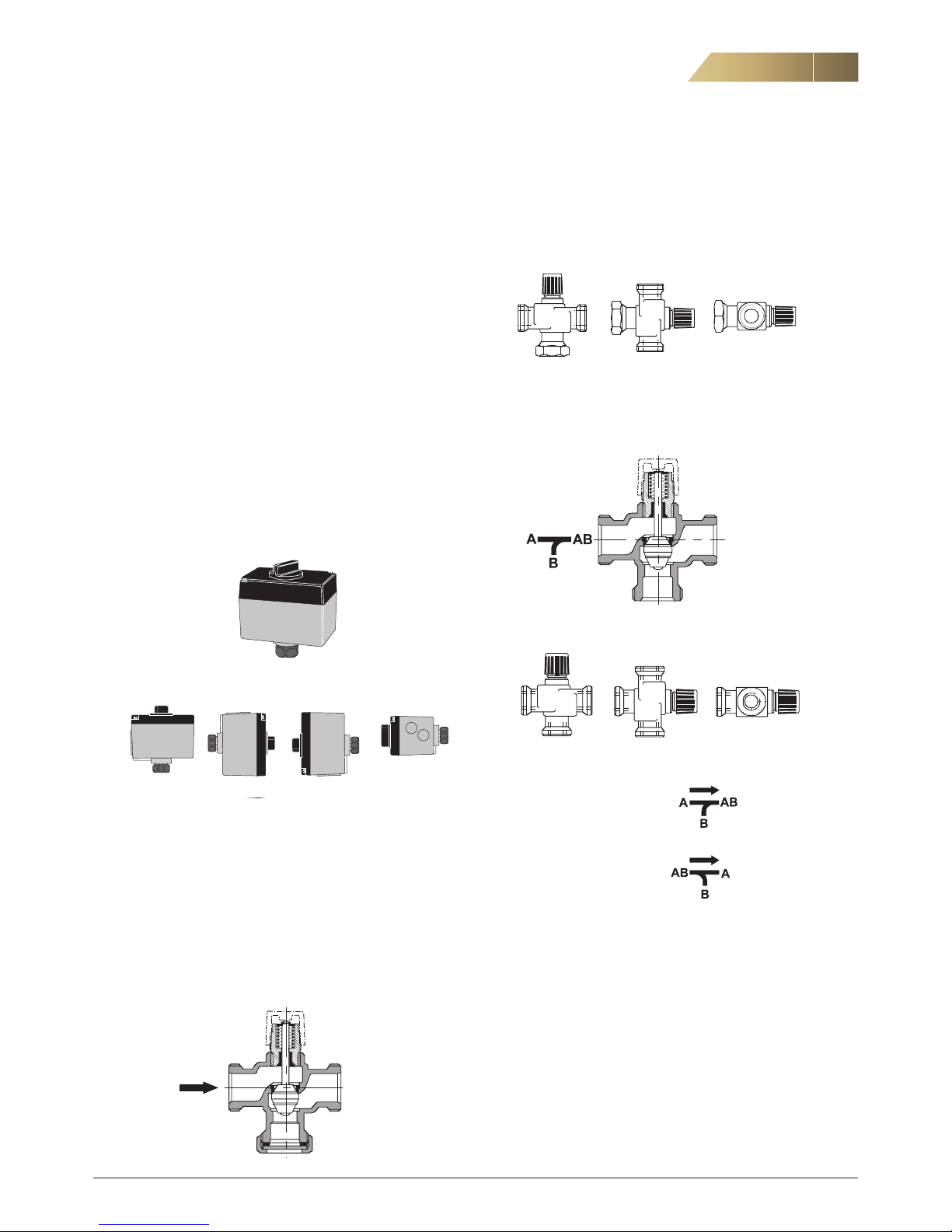

When installing a 3-way valve check as follows:

Mixture from A/B to AB

Splitting from AB to A/B

4.6 DAMPER

Duct mounted damper with a spring return on/off actuator. The

actuator has to be connected to the terminal block in the electri

cal cabinet. Size 03 and 04 have circular duct connections and

size 06 has rectangular. The damper is designed for duct insula

tion of up to 50 mm.

4.7 SILENCER, DUCT MOUNTED

Size 03 and 04 have circular duct connections and size 06 has

rectangular. Fire resistance rating EI30. The distance to the fan

has to be at least 300 mm.

4. CONNECTIONS

4.4 COOLING COIL, WATER

The cooling coils have circular duct connections with rubber

ring seals. For size 06 a converter from rectangular to circular

is available as an accessory (RDTZ-24). The cooler has to be

installed horizontally and the distance to nearest bend has to be

at least 600 mm. Venting and draining is carried out via the pipe

system. The pipe connection, Ø 22 mm, is located on the outlet

end, is smooth and is intended for a compression fitting. The

drainage tray is in stainless steel and has an R 1/2” connection.

Maximum operating pressure 1.0 MPa and maximum operating

temperature 150° C.

4.5 VALVE AND VALVE ACTUATOR

ACTUATORS FOR HEATING SV1 AND COOLING SV2

Connected to terminal in electrical cabinet. Stroke length 5.5 mm.

Intended for assembly on 2-way and 3-way valves of the type

VVG44 or VXG44.

ACCEPTED INSTALLATION METHODS

VALVE FOR HEATING AND COOLING

The valve and valve actuator can be easily installed without

special tools. A particle filter should be fitted before the valve to

extend its service life.

2-WAY VALVE VVG

The flow is increased by turning the spindle inwards, the flow is

reduced by moving the spindle outwards. Note that the 2-way

valve cannot be used as a 3-way valve.

The flow direction is indicated by an arrow.

ACCEPTED INSTALLATION METHODS

3 - WAY VA LVE V X G

The bypass is closed by turning the spindle inwards, the bypass

is opened by turning the spindle outwards.

ACCEPTED INSTALLATION METHODS

eCO Side - Installation and Maintenance Manual

8

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

5. ELECTRICAL CONNECTIONS

5.3 MAIN SUPPLY

NY BILD!

5.1 FUSE PROTECTION

Size Unit with Hot water coil Electrical coil

03

Supply 1 x 230 V 3 x 400 V

Fuse 10 A 10 A

04

Supply 1 x 230 V 3 x 400 V

Fuse 10 A 16 A

06

Supply 1 x 230 V 1 x 230 V

1)

Fuse 10 A 10 A

1)

Duct mounted heater size 06 has sparate supply.

5.2 ELECTRICAL DATA

MOTORS

Size Power, kW Current, A

03 0,385 x 2 2,5 x 2

04 0,50 x 2 2,2 x 2

06 0,75 x 2 3,3 x 2

ELECTRICAL POST HEATER

Power, kW Current, A Voltage, V

4 10 2 x 400

6 15 2 x 400

9

1)

13 3 x 400

1)

Duct mounted heater size 06 has sparate supply.

Units with built-in electrical heater, main supply 3 x 400V.

Units with hot water coil can be supplied with 1 x 230V.

Units with duct mounted electrical heater can be supplied with 1

x 230V.

Units are not available for 3 x 230V..

The main supply cable must be fitted with an external safety

switch located close to the unit. Connect main supply to terminals

U, V, W, N and PE in the control box.

eCO Side - Installation and Maintenance Manual

9

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

5. ELECTRICAL CONNECTIONS

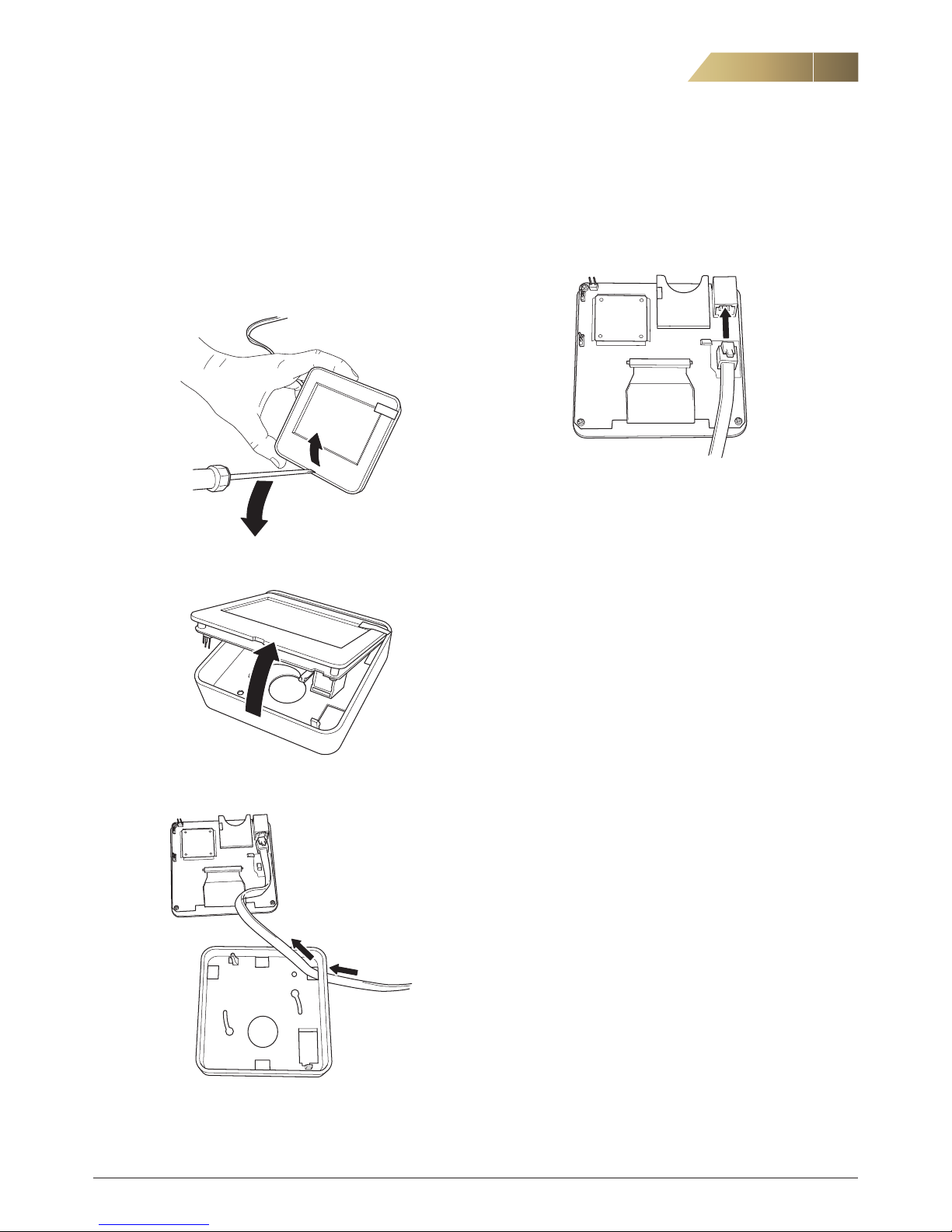

1. Open the control panel using a screwdriver.

5.4 CONNECTION OF CONTROL PANEL

The control panel is connected when delivered from factory and

provided with a magnet for easy handling. For wall mounting see

below.

2. Lift the display out of the enclosure.

3. Push the connection cable through a suitable hole and if

needed make an outlet for the cable in the side of the cover.

4. Mount the enclosure directly on the wall.

5. Connect the cable to the back of the display as shown above.

Note. Please do not touch the electronics.

6. Push back the display in the enclosure.

NOTE! The control panel is only for indoor use.

eCO Side - Installation and Maintenance Manual

10

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

6.1 ELECTRICAL POST HEATER (SIZE 06, 9 KW)

Duct mounted. Separate supply 3 x 400V, 16 A.

Connect alarm, start and control signal to the control box in the

unit. eCO Side is preconfigured for electrical post heater.

(Electrical heater for size 03 and 04 is built-in in the unit, no

further connections are needed).

Component Terminal Connection Remark

Electrical

heater

9 kW

CP1/SK1

Heater

1 – 2

C- NO

Start signal

ALM CP1

43 – 44

NO - C

Alarm, overheating (NC)

SV1 CTRL

35 – 36

Y - M

Control signal 0-10 V

Supply 3 x 400 V

Not from the unit

6.2 POST HEATER, HOT WATER

Circulation pump (CP1) and valve actuator (SV1) connects

according to table below.

Component Terminal Connection Remark

Circulation

pump CP1

CP1/SK1

Heater

1 – N – PE

Pump supply

(230 V max 2A

1)

CP1/SK1

Heater

2 - 3

NO – L1

Loop only with

circulation pump

ALM CP1

43 – 44

NO - C

Voltfree alarm input

(NO, configurable)

Valve

actuator SV1

SV1 CTRL

35 – 36 – 37 - 38

Y – M – G – G0

1)

The current consumption for CP1 and CP2 is limited to 2 A.

6. CONNECTION OF EXTERNAL COMPONENTS

6.3 COOLING COIL, WATER

Circulation pump (CP2) and valve actuator (SV2) connects

according to table below.

Component Terminal Connection Remark

Circulation

pump CP2

CP2/DX

Cooler

4 – N – PE

Pump supply

(230 V max 2A

1)

CP2/DX

Cooler

5 - 6

NO – L1

Loop only with

circulation pump

ALM CP2/DX45 – 46

NO - C

Voltfree alarm input

(NO, configurable)

Valve

actuator SV2

SV2 CTRL

39 – 40 – 41 - 42

Y – M – G – G0

1)

The current consumption for CP1 and CP2 is limited to 2 A.

6.4 COOLING COIL, DX

The unit can manage cooling DX, 1-step. Note that the coil is not

included in the delivery of the unit. For configuration see control

functions.

Component Terminal Connection Remark

DX-cooling,

1-step

CP2/DX

Cooler

4 – 5

C – NO

Start: 10 %

Stop: 0 %

ALM CP2/DX

45 – 46

NO - C

Voltfree alarm input (NO,

configurable)

6.5 DAMPER

On/off actuator with spring return, 15 Nm, 24 VAC.

Component Terminal Connection Remark

Damper ST1

29 – 30

G – G0

Exhaust air damper if used

is connected in parallel

(Maximum 2 dampers)

Use the cable flange on the top of the unit to connect all external

accessories.

For information about how to connect available accessories see

below.

eCO Side - Installation and Maintenance Manual

11

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

6. CONNECTION OF EXTERNAL COMPONENTS

6.6 TEMPERATURE SENSORS

The unit is provided with:

Supply air sensor GT1, located at supply air spigot.

Outdoor air sensor GT3, located at outdoor air spigot.

Frost protection sensor GT5 (when hot water coil is used), located

on the return pipe of the coil.

When using cooling coil or duct mounted post heater a supply

temperature sensor (GT1) is supplied for duct mounting. Then

there is no supply air sensor mounted in the unit.

Room sensor GT2 (accessory) is supplied when the unit is con

figured for room temperature control. Then there is no exhaust air

sensor mounted in the unit.

The room sensor is intended for wall mounting and needs to have

good air circulation and not direct sun light. Cable is not included.

Component Terminal Connection Remark

Supply air

sensor

GT1

25 – 26

B – M

Standard sensor is replaced

with a duct mounted sensor

when using cooling coil or duct

mounted heater

Room

sensor

GT2

27 – 28

B – M

Replaces exhaust air sensor

GT12 when room control is

selected

6.7 EXTENDED / FORCED VENTILATION

For external electronic timer, push button, PIR or other volt free

contact. Electronic timer and/or PIR if ordered is supplied

separately. When using a push button the time has to be set in

the control panel.

Component Terminal Connection Remark

Timer 1 TMR1

31 - 32

NO - C

Can also be used for PIR

Timer 2 TMR2

33 – 34

NO - C

Can also be used for PIR

Function of aux. inputs Timer 1 (T1) and Timer 2 (T2) can be

selected according to the following tables.

TIMER FUNCTION 1 (DEFAULT)

Timer 1 Timer 2

Manual/Automatic Mode 0 0

Trickle 1 0

Normal 0 1

Boost 1 1

TIMER FUNCTION 2

Timer 1 Timer 2

Manual/Automatic Mode 0 0

Trickle 1 0

Boost 0 1

Stop 1 1

TIMER FUNCTION 3

Timer 1 Timer 2

Manual/Automatic Mode 0 0

Normal 1 0

Boost 0 1

Stop 1 1

TIMER FUNCTION 4

Timer 1 Timer 2

Stop 0 0

Manual/Automatic Mode 1 0

Stop 0 1

Boost 1 1

TIMER FUNCTION 5

Timer 1 Timer 2

Stop 0 0

Manual/Automatic Mode 1 0

Stop 0 1

Normal 1 1

6.8 FIRE PROTECTION FUNCTION

External fire alarm to stop the unit can be connected to terminals

in the control box.

Smoke detectors and fire dampers cannot be connected directly

to the air handling unit, a separate fire system is needed.

Component Terminal Connection Remark

Fire protection

function

FIRE

23 – 24

NC – C

6.9 SUMMARY ALARM

The alarm output can be configured to indicate A-alarms or both

A- and B-alarms.

Component Terminal Connection Remark

Summary

alarm

ALARM

21 – 22

NO – C

Voltfree contact

Maximum load 24 V, 200 mA

eCO Side - Installation and Maintenance Manual

12

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

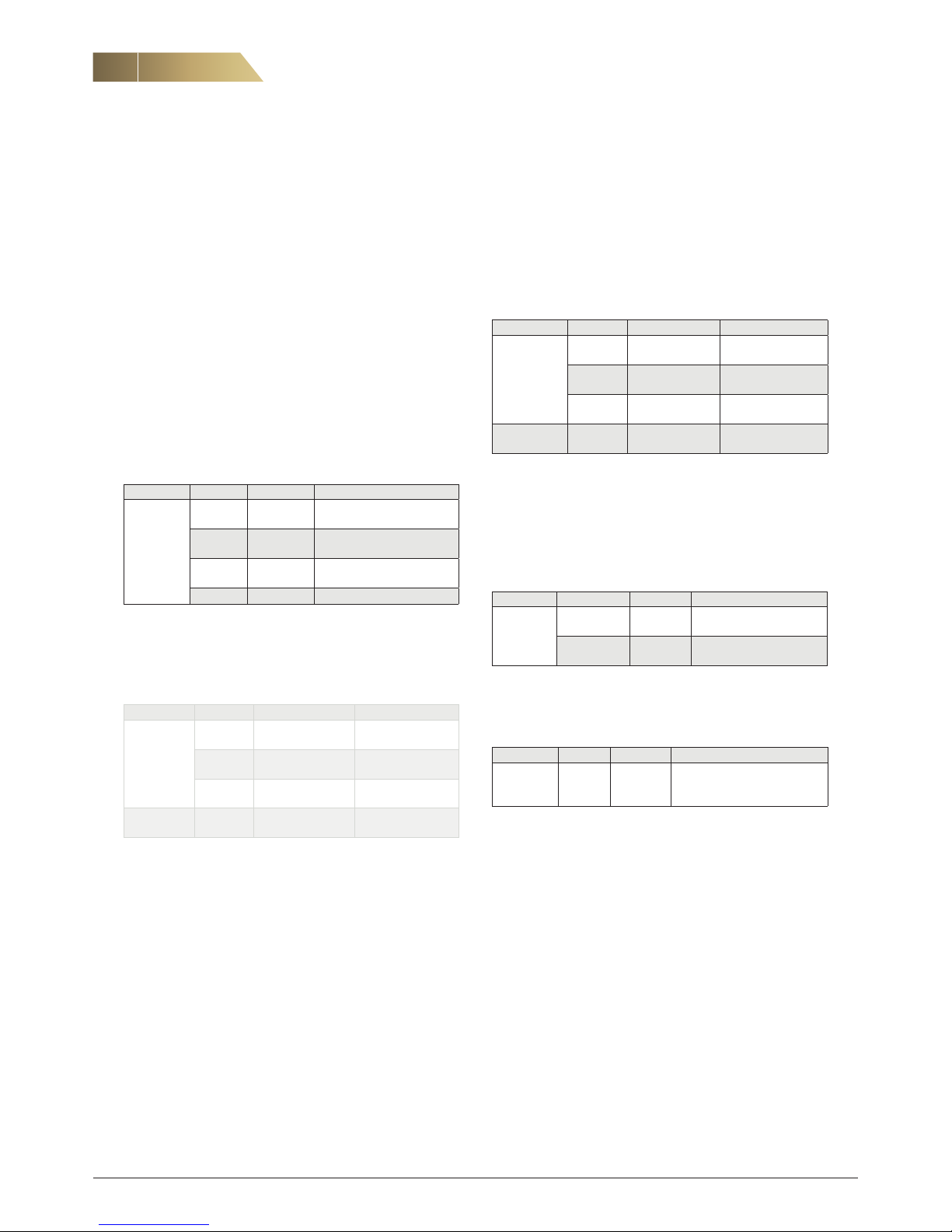

7. WIRING DIAGRAMS

Outside the AHU

Not in FläktGroup’s delivery

Outside the AHU

Not in FläktGroup’s delivery

eCO Side - Installation and Maintenance Manual

13

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

7. WIRING DIAGRAMS

Control panel

ISYteq Touch 3.5”

Control board

eCO Side - Installation and Maintenance Manual

14

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

7. WIRING DIAGRAMS

EXTERNAL CONNECTIONS DIAGRAM

230/400 V

EXTERNAL CONNECTIONS DIAGRAM 24 V

eCO Side - Installation and Maintenance Manual

15

FläktGroup DC_10176GB_20180924_R3 Specifications are subject to alteration without notice

STARTING THE UNIT

When the electrical connections are made and all the accessories are mounted the unit is ready to start up.

1. Turn the safety switch to 1 (ON).

2. Start the unit.

DAMPERS

Check that all dampers opens and closes correctly.

VALVE ACTUATORS

Check that valve actuators for heating and cooling works correctly.

DIRECTION OF ROTATION

Check that the direction of rotation for the heat exchanger corresponds to the alternatives below.

LEFT-HAND VERSION:

The rotor should rotate upwards when looking from the front.

RIGHT-HAND VERSION:

The rotor should rotate downwards when looking from the front.

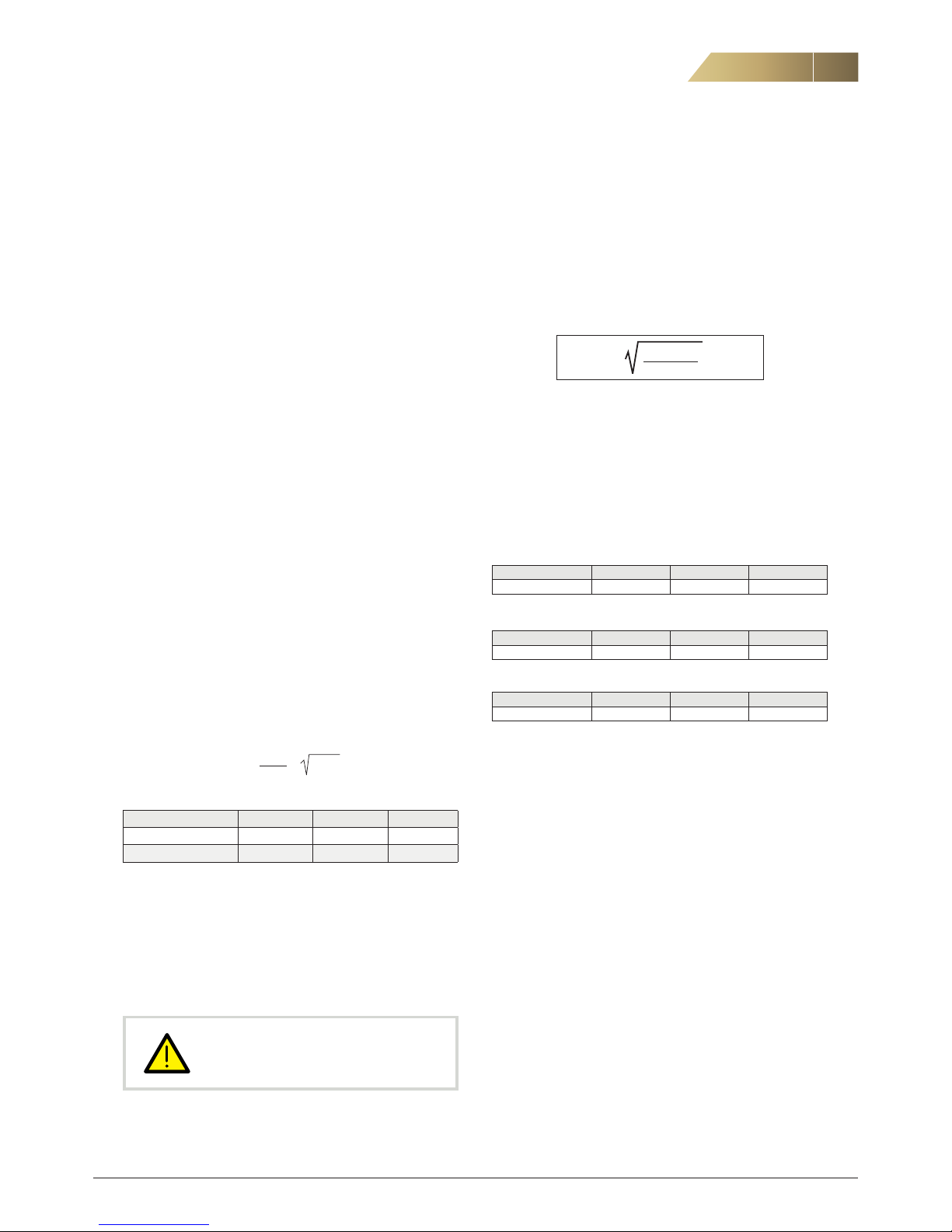

AIR FLOW MEASUREMENT

The eCO Side has measuring nipples for air flow measurement.

Using a measuring pressure Dpm (Pa) and a constant (k) the air

flow q (R/W) can be calculated using the following equation:

NOTE! When the unit is supplied with

Constant Air Volume Control there will be

no measuring nipples on top of the unit.

TEMPERATURE CORRECTION

The air flow formula above applies to air with a temperature of

+20 °C. At other air temperatures the air flow must be corrected

using the formula:

The value of the constant (k) is shown in the table below.

q =

1000

k

Dp

m

x

Size

03 04 06

k-value extract air fan

58,4 51,5 49,2

k-value supply air fan

62,5 52,1

51,4

The measuring pressure, Dpm, is the difference between the

pressure in the empty section at the fan inlet and the pressure

inside the inlet cone. A manometer (RDTZ-56) can be connected

to view the measuring pressure. This is used as a reference for

monitoring the unit.

If the unit is supplied with Constant Air Volume control the air

flow can be read in the control panel.

q = q

20

(273 + t)

293

, m

3

/s

8. TESTING OF FUNCTIONS

q = actual air flow

q

20

= calculated air flow in formula abowe

t = current temperature in ° C

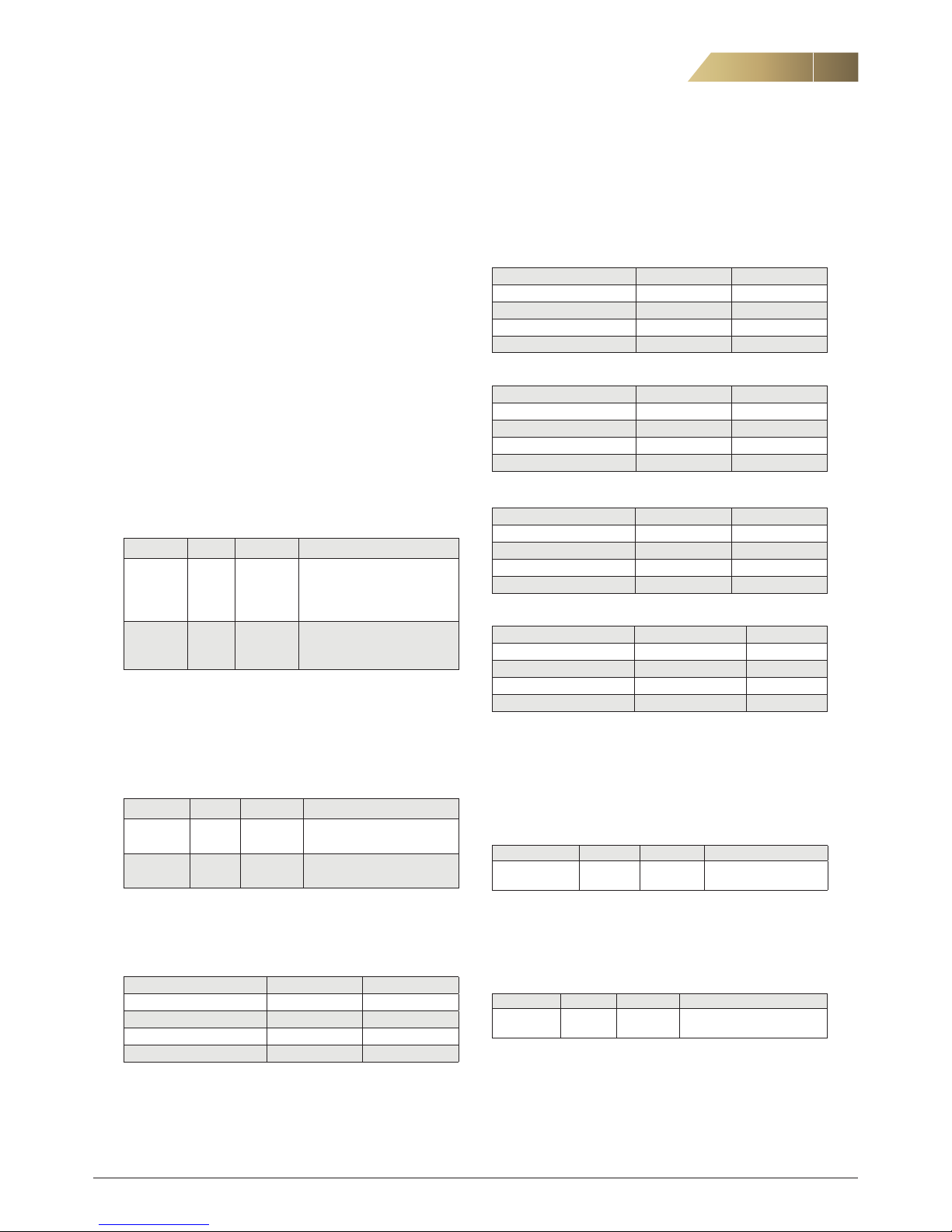

FILTER, FINAL PRESSURE DROP

It is time to replace the filters when the final pressure drop is

reached, see table below.

SIZE 03

Air flow m3/s 0,15 0,25 0,35

Supply air/Extract air 119 148 177

SIZE 04

Air flow m3/s 0,15 0,25 0,35

Supply air/Extract air 125 142 159

SIZE 06

Air flow m3/s 0,15 0,25 0,35

Supply air/Extract air 121 139 157

FILTER MONITOR

When using filter monitors use the values in the table above. If

the unit is supplied with Constant Pressure control increase the

final pressure drop with 50 Pa.

Loading...

Loading...