FläktGroup CENTRIFLOW 3D PLUG FAN GMEC Operating Instructions Manual

FläktGroup DC_9942GB_20180604_R0

Specifications are subject to alteration without notice

OPERATING INSTRUCTIONS

CENTRIFLOW 3D PLUG FAN GMEC

CENTRIFLOW 3D PLUG FAN WITH EC MOTOR

CONTENT PAGE

1. Introduction............................................................................................ 2

2. Safety regulations and information .............................................. 2

3. Intended use ..........................................................................................4

4. Technical data ...................................................................................... 5

5. Connection and startup .................................................................... 6

6.

Integrated protective features

..............................................................12

7.

Maintenance, malfunctions, possible causes and remedies

........13

Plug fan GMEC with EC-motor - Operating instructions

2

FläktGroup DC_9942GB_20180604_R0

Specifications are subject to alteration without notice

1. INTRODUCTION

EC motor contains permanent magnet motor and integrated

speed controller which is called commutation unit. Speed can be

controlled with a 0-10V DC signal or Modbus RTU. Main voltage

requirement is 1-phase 230 VAC or 3-phase 400 VAC depending

on motor type.

Motors have 1 meter long supply and control cables or terminal

box depending on motor type. See Chapter 5.5 Connection dia

-

grams.

EC-motor is ready to be used. All parameters are set. Only power

from mains and control signals are needed.

2. SAFETY REGULATIONS AND INFORMATION

Read these operating instructions carefully before starting work

on the device. Observe the following warnings to prevent malfunc

-

tions or danger to persons.

These operating instructions are to be regarded as part of the de

vice. The device is only to be sold or passed on together with the

operating instructions.

These operating instructions may be duplicated and distributed to

inform about potential dangers and their prevention.

2 1. HAZARD LEVELS FOR WARNINGS

These operating instructions use the following hazard levels to

indicate potentially hazardous situations and important safety

regulations:

DANGER

Indicates an imminently hazardous situation which

will result in death or serious injury if the specified

actions are not taken. Compliance with the instruc

-

tions is imperative.

WARNING

ndicates a potentially hazardous situation which can result in

death or serious injury if the specified actions are not taken. Exer

-

cise extreme caution while working.

CAUTION

Indicates a potentially hazardous situation which can result in minor or moderate injury or damage to property if the specified actions are not taken.

NOTE. A potentially harmful situation can occur and, if not avoided, can

lead to property damage.

2.2 STAFF QUALIFICATIONS

The device may only be transported, unpacked, installed, operated, maintained and otherwise used by suitably qualified, trained

and authorized technical staff.

Only authorized specialists are permitted to install the device, to

carry out a test run and to perform work on the electrical instal

-

lation.

2.3 BASIC SAFETY RULES

The safety hazards associated with the device must be assessed

again following installation in the final product. Note the following

when working on the device:

Do not perform any modifications, additions or conversions on the

device without the approval of FläktGroup Oy.

2.4 VOLTAGE

Check the device’s electrical equipment at regular intervals; see

Chapter 6.2 Safety inspection.

Replace loose connections and defective cables immediately.

DANGER

Electrically charged device Risk of electric shock

• When working on an electrically charged device,

stand on a rubber mat.

WARNING

Live terminals and connections even with device switched off

Electric shock

• Wait five minutes after disconnecting the voltage at all poles

before opening the device.

CAUTION

In the event of a fault, the rotor and the impeller will be energized

The rotor and the impeller have basic insulation.

• Do not touch the rotor and impeller once installed.

CAUTION

If control voltage or a stored speed set value is applied, the motor

will restart automatically, e.g. after a power failure.

Risk of injury

• Keep out of the device danger zone.

• When working on the device, switch off the line voltage and en

-

sure that it cannot be switched back on.

• After working on the device, remove any tools or other objects

from the device.

Plug fan GMEC with EC-motor - Operating instructions

3

FläktGroup DC_9942GB_20180604_R0

Specifications are subject to alteration without notice

CAUTION

The motor restarts automatically when operating voltage is applied, e.g. after a power failure.

Risk of injury

• Keep out of the motor’s danger zone.

• When working on the motor, switch off the line voltage and en

-

sure that it cannot be switched back on.

• Wait until the motor comes to a stop.

2.5 ELECTROMAGNETIC RADIATION

Interference from electromagnetic radiation is possible, e.g. in

conjunction with open-and closed-loop control devices. If imper

missible radiation levels occur following installation, appropriate

shielding measures have to be taken by the user.

NOTE Electrical or electromagnetic interference after installing the

device in customer equipment.

• Verify that the entire setup is EMC-compliant.

2.6 MECHANICAL MOVEMENT

DANGER

Ejected parts

Missing protective devices may cause balancing

weights or broken fan blades to be ejected and cause injuries.

• Take appropriate safety measures.

WARNING

Rotating device

Long hair and dangling items of clothing, jewelry and the like can

become entangled and be pulled into the device. Injuries can re

sult.

• Do not wear any loose-fitting or dangling clothing or jewelry

while working on rotating parts. Protect long hair with a cap.

WARNING

Ejected parts

If the motor is operated with attached fan blades, missing protective devices may allow balancing weights or broken fan blades to

be ejected and cause injuries.

• Take appropriate safety measures such as installing guard

grilles.

• Keep out of the exhaust zone.

2.7 HOT SURFACE

CAUTION

High temperature on electronics housing

Risk of burns

Ensure sufficient protection against accidental contact.

2.8 TRANSPORT

CAUTION

Transporting the motor

Crushing hazard

• Wear safety shoes and cut-resistant safety gloves.

• Transport the motor in its original packaging only.

• Secure the device so it cannot slip, e.g. by using a lashing strip.

2.9 STORAGE

Store the device, partially or fully assembled, in a dry and weatherproof manner in the original packaging in a clean environment.

Protect the device against environmental effects and dirt until final

installation.

We recommend storing the device for no longer than one year in

order to guarantee trouble-free operation and the longest possible

service life.

Even devices explicitly intended for outdoor use are to be stored

as described prior to commissioning.

Maintain the storage temperature, see Chapter 4.2 Transport and

storage conditions.

Make sure that all cable glands are fitted with dummy plugs.

2.10 DISPOSAL

Comply with all relevant local requirements and regulations when

disposing of the device.

Item no. 55059-5-9970 · ENU · Change 88794 · Approved 201603-17 · Page 2 / 11

Plug fan GMEC with EC-motor - Operating instructions

4

FläktGroup DC_9942GB_20180604_R0

Specifications are subject to alteration without notice

3. INTENDED USE

The device is designed exclusively for use as a drive motor. Any

other usage above and beyond this does not conform with the

intended purpose and constitutes misuse of the device. Customer

equipment must be capable of withstanding the mechanical and

thermal stresses that can arise from this product. This applies for

the entire service life of the equipment in which this product is

installed.

Intended use also includes

• Using the device only in power systems with grounded neutral

(TN/ TT power systems).

• Using the device only in stationary systems.

• Performing all maintenance work.

• Using the device within the permitted ambient temperature

range; see Chapter 4.2 Transport and storage conditions and

Chapter 4.1 Nominal data.

• Operating the device with all protective devices.

• Following the operating instructions.

IMPROPER USE

In particular, operating the device in the following ways is prohibited and could be hazardous:

• Operation in medical equipment with a life-sustaining or lifesupport function.

• Operation with external vibrations.

• Conveying solids in the flow medium.

• Painting the device

• Connections (e.g. screws) coming loose during operation.

• Opening the terminal box during operation.

• Conveying air that contains abrasive particles.

• Conveying highly corrosive air, e.g. salt spray.

• Conveying air with high dust content, e.g. suctioning off

sawdust.

• Operating the device close to flammable materials or

components.

• Operating the device in an explosive atmosphere.

• Using the device as a safety component or to perform

safety-related functions.

• Operation with completely or partially disassembled or

manipulated protective devices.

• In addition, all applications not listed among the intended uses.

Plug fan GMEC with EC-motor - Operating instructions

5

FläktGroup DC_9942GB_20180604_R0

Specifications are subject to alteration without notice

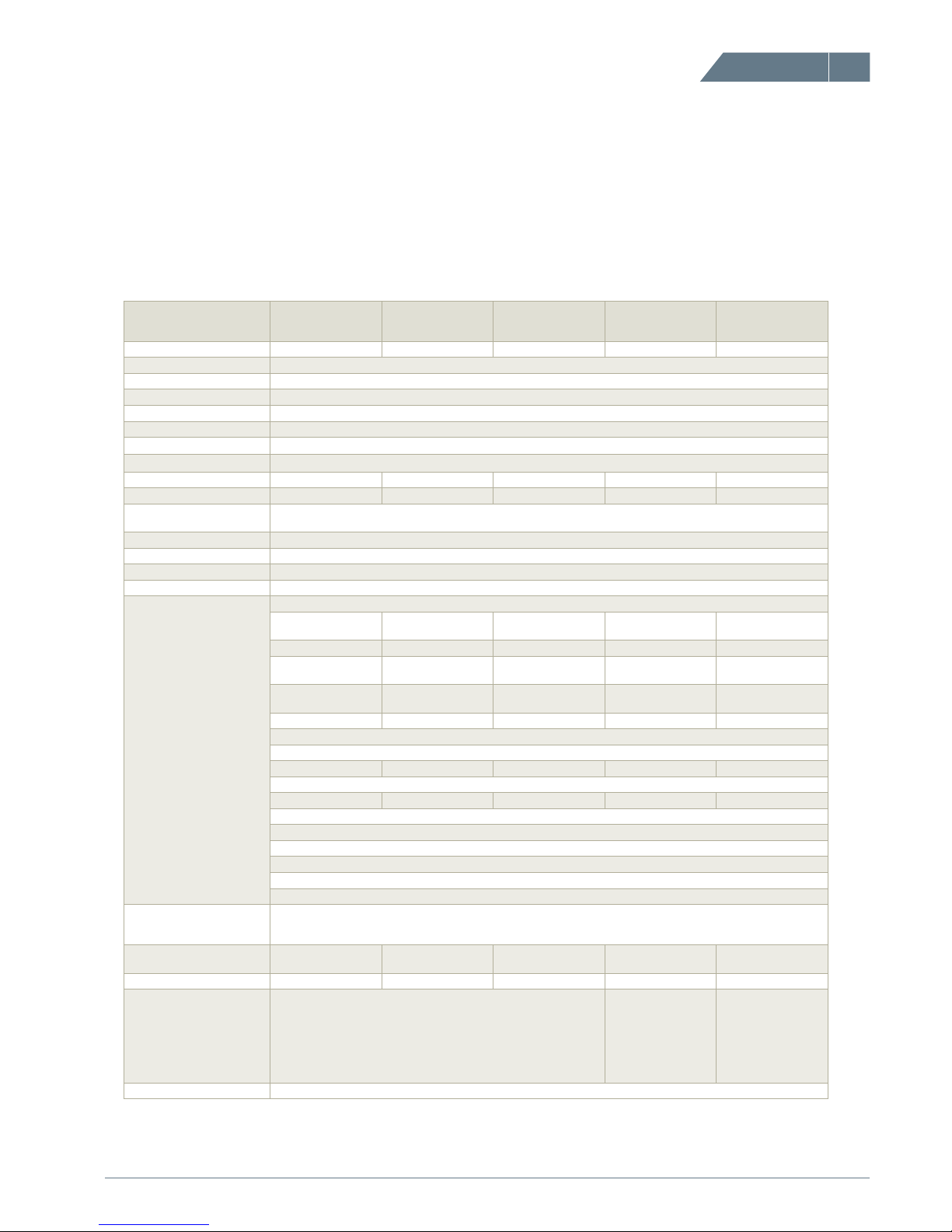

4. TECHNICAL DATA

4.1 NOMINAL DATA

Motor 1~230 V with cable 3~400V with cable

3~400 V with

plastic terminal box

3~400 V with

aluminum terminal box

3~400 V with aluminum

terminal box and

reduced terminals

Nominal voltage range / V AC 200...277 380...480 380...480 380...480 380...480

Frequency / Hz 50/60

Method of obtaining data Max. load

Min. ambient temperature / ° C –25

Max. ambient temperature / ° C At least +40 (See max. temperature from technical catalogue)

Rotor surface Painted black

Electronic housing material Die-cast aluminum

Direction of rotation Counterclockwise, viewed towards rotor

Degree of protection IP55 IP55 IP55 IP54 IP55

Insulation class “F” “F” “B” “B” “F”

Moisture (F) / Environmental (H)

protection class

H1

Installation position Shaft horizontal or rotor on bottom; rotor on top if no condensation

Condensation draining holes On rotor side

Mode S1

Motor bearing Ball bearing

Technical features

Output 10 VDC, max. 10 mA

Output 20 V DC,

max. 50 mA

Output for slave 0-10 V

Input for sensor

0-10 V or 4-20mA

External 24 V input

(parameter setting)

External 24 V input

(parameter setting)

External 24 V input

(parameter setting)

External 24 V input

(parameter setting)

External release input External release input

Alarm relay

Integrated PID controller

Power limiter

Motor current limitation

PFC, active PFC, passive PFC, passive PFC, passive PFC, passive

RS-485 MODBUS-RTU

Soft start

Control input 0-10 VDC / PWM

Control interface with SELV potential safely disconnected from the mains

Thermal overload protection for electronics/motor

Line under voltage / phase failure detection

Touch current according to IEC

60990 (measuring

circuit Fig. 4, TN system)

<= 3,5 mA

Electronic hookup

Via external terminal

box (not included)

Via external terminal

box (not included)

Via internal terminal box Via internal terminal box Via internal terminal box

Connection diagram, Chapter 5.5 A B C D E

Motor protection Thermal overload protector (TOP) internally connected

Thermal overload pro

tector (TOP) internally

connected (frame size

112)

Reverse polarity and

locked rotor protection

(frame size 150)

Reverse polarity and

locked rotor protection

Protection class I (with customer connection of protective earth)

Loading...

Loading...