Page 1

INSTRUCTION MANUAL

™

SPECIFICATIONS

Wingspan:

™

Wing Area:

48.5 in [1230mm]

2

426 in

[27.5 dm2]

Wing

Loading:

Length:

16 oz/ft

[49 g/dm2]

38.5 in

[980mm]

2

WARRANTY

Flyzone guarantees this kit to be free from defects in both

material and workmanship at the date of purchase. This warranty

does not cover any component parts damaged by use or

modification. In no case shall Flyzone’s liability exceed the

original cost of the purchased kit. Further, Flyzone reserves

the right to change or modify this warranty without notice.

In that Flyzone has no control over the final assembly or material

used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © 2013 Hobbico,® Inc. All rights reserved.

Weight:

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

3 lb [1360 g]

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Radio:

5+ channel

required for Tx-R

FLZA4032 Tx-R/ RTF Mn l 1.1

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

AMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . .2

Radio Control System . . . . . . . . . . . . . . . . . . . . . . . . .2

Battery and Charger. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Required Assembly Tool . . . . . . . . . . . . . . . . . . . . . . .3

ORDERING REPLACEMENT PARTS. . . . . . . . . . . . . . . .3

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ASSEMBLE THE MODEL . . . . . . . . . . . . . . . . . . . . . . . . .4

Charge the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Battery Charging Precautions . . . . . . . . . . . . . . . . . . .5

Battery Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Assemble the Corsair. . . . . . . . . . . . . . . . . . . . . . . . . .5

Check the Radio System . . . . . . . . . . . . . . . . . . . . . . .7

Adjust the Control Surfaces . . . . . . . . . . . . . . . . . . . . . 8

INTRODUCTION

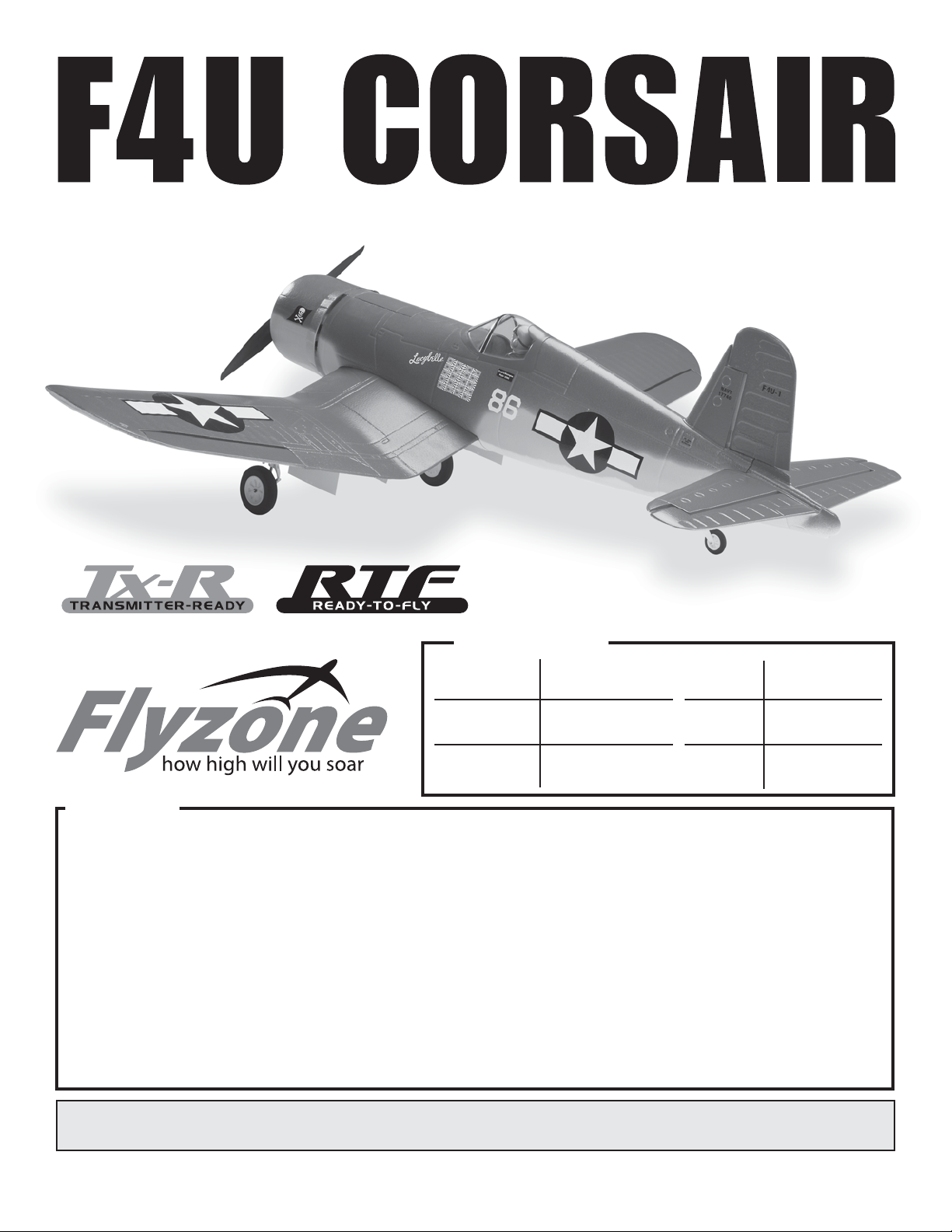

Congratulations on your purchase of the Flyzone F4U Corsair!

Following the success of the Flyzone Focke-Wulf Fw190, the

Corsair is the second World War II scale warbird release and

is equally as easy to fl y and loaded with scale details. Final

assembly and setup will take less than an hour as virtually all

of the components are already installed at the factory.

For the latest technical updates or manual corrections to the

Corsair, visit the Flyzone web site at www.fl yzoneplanes.

com. Open the Airplanes link, then select “Corsair”. Click

the Parts & Tech Info link at the right-hand side of the page.

AMA

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’ rights

and interests and is required to fl y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Ph. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

Check the Retracts . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Check the Control Throws . . . . . . . . . . . . . . . . . . . . . .9

Finish the Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Check the C.G. (Center of Gravity) . . . . . . . . . . . . . .11

Important ESC Information . . . . . . . . . . . . . . . . . . . .12

GET THE MODEL READY TO FLY. . . . . . . . . . . . . . . . .12

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . .12

FLYING THE CORSAIR. . . . . . . . . . . . . . . . . . . . . . . . . .12

Find a Suitable Flying Site . . . . . . . . . . . . . . . . . . . . . 12

Perform a Range Check . . . . . . . . . . . . . . . . . . . . . .12

Monitor Your Flight Time . . . . . . . . . . . . . . . . . . . . . .13

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

OPTIONAL 14.8V POWER SYSTEM . . . . . . . . . . . . . . . 14

TACTIC TTX600 2.4GHz 6-CHANNEL RADIO . . . . . . . . 14

the Corsair, if not assembled and operated correctly, could

possibly cause injury to yourself or spectators and damage

to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing

so may result in an unsafe or unfl yable model. In a few

cases the instructions may differ slightly from the photos. In

those instances the written instructions should be considered

as correct.

3. If you are not an experienced pilot or have not fl own this type

of model before, we recommend that you get the assistance

of an experienced pilot in your R/C club for your fi rst fl ights.

If you’re not a member of a club, your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

4. While this kit has been fl ight tested to exceed normal

use, if the plane will be used for extremely high stress fl ying,

such as racing, or if a more powerful motor is installed, the

modeler is responsible for taking steps to reinforce the high

stress points and/or substituting hardware more suitable for

the increased stress.

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

SAFETY PRECAUTIONS

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your Corsair should not be considered a toy, but rather a

sophisticated, working model that functions very much like

a full-size airplane. Because of its performance capabilities,

ADDITIONAL ITEMS REQUIRED

Radio Control System

The Corsair Tx-R (transmitter ready) comes with the servos

and a Tactic™ TR624 receiver installed, so all that is required is

a 5+channel transmitter. The Tactic TTX600 2.4GHz spread

spectrum 6-channel radio control system (TACJ2600) is

2

Page 3

included with the RTF (ready to fl y) version of the Corsair,

so this same radio system is ideal for your Tx-R version, too.

❍ Tactic TTX600 2.4GHz 6-channel system (TACJ2600)

❍ (4) AA batteries will be required to operate the

recommended transmitter (FUGP7300).

If you already own a transmitter that you plan to use with the

Corsair, fi rst make sure it is in the compatibility list at www.

Tx-Ready.com/anylink-chart.html. If so, you can purchase

the AnyLink 2.4GHz Universal Radio Adapter to allow your

transmitter to communicate with the pre-installed Tactic receiver.

❍ Tactic AnyLink™ 2.4GHz Universal Radio Adapter

(TACJ2000)

❍ Tactic AnyLink SLT™ 2.4GHz Adapter Cable Futaba®

Hitec® Round (TACM0003)

❍ Tactic AnyLink SLT 2.4GHz Adapter Cable Hitec

Aurora (TACM0004)

❍ Tactic AnyLink SLT 2.4GHz Cable Spektrum®

DX4e/5e/7s/8 (TACM0005)

❍ Tactic AnyLink SLT 2.4GHz Adapter Cable Futaba

12Z 14MZ (TACM0006)

❍ Tactic AnyLink SLT Cable Fut 12Z/14MZ/18MZ/4YF

2.4GHz (TACM0007)

Battery and Charger

The Corsair RTF comes complete with a motor battery and

charger. The Tx-R version requires a 2100mAh 11.1V LiPo

battery and LiPo Charger. The Corsair was designed for the

Flyzone 2100 mAh 11.1V LiPo battery (FLZA6173). Other LiPo

batteries similar in size with the same voltage and capacity

may also work, but they may not fi t properly in the battery

compartment or have the same type of battery connector. In

addition to a battery, a LiPo battery charger is also required and

there are several that will work (depending on your budget and

requirements). A safe, economical charger is the ElectriFly® 3S

(3-cell/11.1V) LiPo Smart Charger (GPMM3318). The Smart

Charger includes adapters to charge from a 110V wall outlet

or a 12V DC outlet from a car. The Smart Charger will take

approximately 4-1/2 hours to fully charge the battery. Some

pilots prefer to have several batteries and charge them faster

so they can fl y more. For charging up to four batteries faster at

the same time, the Great Planes PolyCharge4™ DC-powered

LiPo charger (GPMM3015) is recommended. But unlike the

Smart Charger, the PolyCharge4 does not have an internal

LiPo cell balancer which is a critical component in making sure

your LiPo batteries charge effi ciently and evenly. So, for each

LiPo battery you wish to charge simultaneously, one Great

Planes Equinox™ LiPo Cell Balancer (GPMM3160) will also be

required. Finally, the PolyCharge4 does not have AC capability,

so if wall charging is a priority, a separate AC 12-Volt power

source must also be purchased separately. A suitable power

supply for the PolyCharge4 is the Great Planes 12V 12A DC

power supply (GPMP0901).

Required Assembly Tool

Other than common hobby tools this is the list of adhesives

and building supplies that are required to fi nish the Corsair.

❍ Phillips screwdriver

❍ Small crescent wrench

❍ Great Planes stick-on lead weight (Optional, GPMQ4485)

ORDERING REPLACEMENT PARTS

Replacement parts for the Flyzone Corsair are available using

the order numbers in the Replacement Parts List that follows.

The fastest, most economical service can be provided by your

hobby dealer or mail-order company.

To locate a hobby dealer, visit the Flyzone web site at www.

fl yzoneplanes.com. Click on the Storefront icon at the top

of the page to load the Flyzone Dealer Locator. Follow the

instructions provided on the page to locate a U.S., Canadian or

International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or fax at (217) 398-7721, but full

retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax.

If ordering via fax, include a Visa® or MasterCard® number

and expiration date for payment.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as listed in the

Replacement Parts List. Payment by credit card or personal

check only; no C.O.D.

If additional assistance is required for any reason, contact

Product Support by telephone at (217) 398-8970, or by e-mail

at productsupport@fl yzoneplanes.com.

REPLACEMENT PARTS LIST

Order No. Description

FLZA6290

FLZA6291

FLZA6292

FLZA6293

FLZA6294

FLZA6295

FLZA6296

FLZA6297

FLZA6298

FLZA6299

FLZA6300

FLZA6301

FLZA6302

FLZA6303

FLZA6304

FLZA6173

TACJ2600

TACL0624

Fuselage Set with Hardware

Wing Set with Retracts

Vertical Fin with Rudder

Horizontal Stabilizer

Retract Parts Set with Wheels & Gear Doors

40 Amp ESC

Pilot Figure with Clear Canopy

Prop Adapter with Spinner & Dummy Engine

Foam Battery Hatch

Motor Mount

Brushless Motor 35-36-920kV

Tail Wheel Set with Hardware

12x6 Propeller

Decal Set

Cowl

Flyzone LiPo Battery 3S 11.1V 2100mAh 20C

Tactic TTX600 6Ch SLT 2.4GHz Radio System No Servos

Tactic TR624 6-Channel SLT 2.4GHz Receiver

3

Page 4

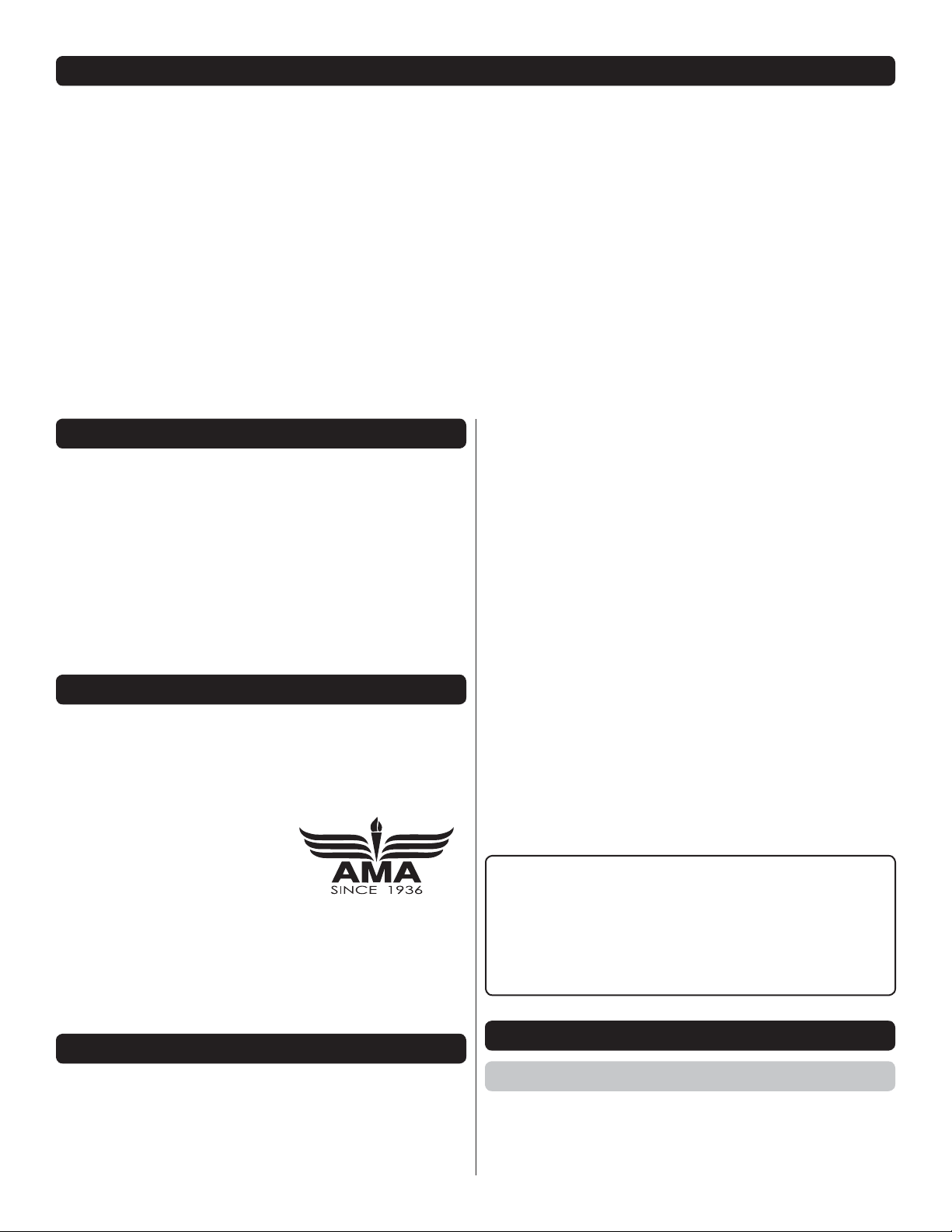

KIT INSPECTION

Before starting to build, inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not

of acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or missing

parts, use the part names exactly as they are written in the

Kit Contents list.

KIT CONTENTS

1

7

8

4

5

6

Flyzone Product Support

3002 N. Apollo Drive, Suite 1 Ph: (217) 398-8970, ext. 5

Champaign, IL 61822 Fax: (217) 398-7721

E-mail: airsupport@fl yzoneplanes.com

3

2

Kit Contents

1. Fuselage

2. Wing

3. Horizontal Stabilizers and Elevators

4. Vertical Fin and Rudder

ASSEMBLE THE MODEL

Before starting to assemble the Corsair, we recommend

charging the fl ight battery. Then, when you are ready to setup the radio system, the fl ight battery can be used to power

the receiver.

Charge the Battery

The following is an overview of how to charge your motor

battery using the ElectriFly Smart Charger. If you are using a

different LiPo charger, carefully follow the instructions included

with the charger.

1. Connect the input power to the charger. The GREEN LED

will be lit, indicating standby mode. The RED LED will be OFF.

5. Propeller and Prop Adapter

6. Prop Nut

7. Hook and Loop Material

8. Screws

2. Connect the battery to be charged to the balance plug.

The RED LED will also be lit, and remain RED during the

charging. Both LEDs should be lit solid while charging.

3. If the battery was completely discharged, the RED and

GREEN LEDs will start to fl ash after 2-hours and 40-minutes.

The charger has a built in safety timer.

4. Disconnect the battery from the charger, wait for the GREEN

LED to be lit, and then reconnect the battery to the charger.

5. It will take approximately 1-1/2 hours more to complete

the charge. When the battery is fully charged, the GREEN

LED will turn OFF. Remove the battery from the charger

at this time.

4

Page 5

6. Charging time depends on the level of discharge of the

battery and if the battery cells were unbalanced.

Assemble the Corsair

LED SCHEME

RED LED

OFF

OFF

Solid ON

Solid ON

Flashing

Possible sources of battery error may include a highly unbalanced

*

pack, charger timed out, or one cell of the pack which is low voltage.

In the case of a battery error, please remove the battery pack from

the charger and inspect it carefully for swelling or any other damage,

such as broken wires.

Use this table to determine charge action.

GREEN LED

Solid ON

Flashing

Solid ON

OFF

Flashing

No battery is connected

Conditioning battery

Battery charging

Charge complete

ERROR *

ACTION

Battery Charging Precautions

● Be careful to avoid overcharging the battery. Only use a LiPo

approved charger. Never use a NiCd/NiMH peak charger.

● Remember to check the temperature of the battery during

the charge. The battery should not get hot. If it does, unplug

the battery from the charger.

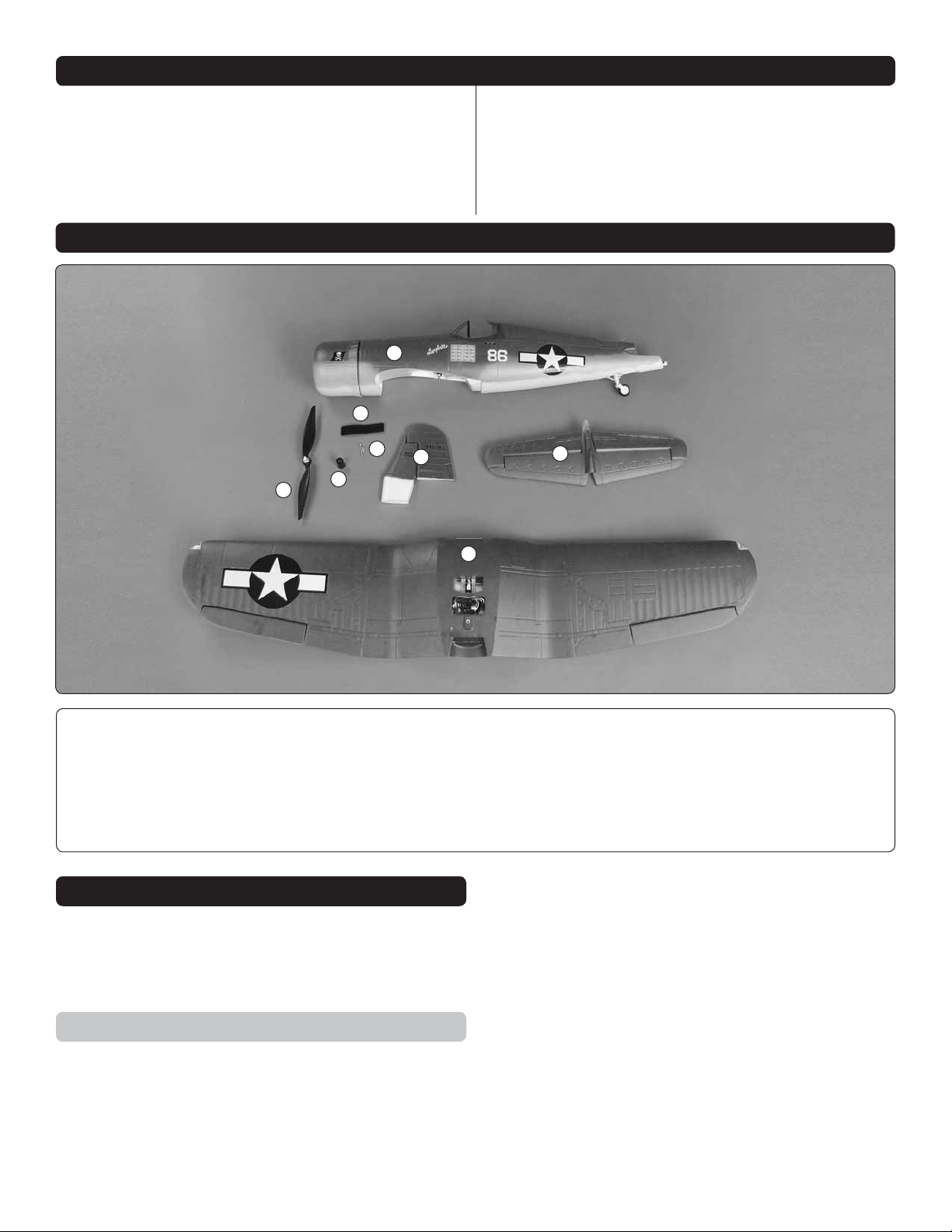

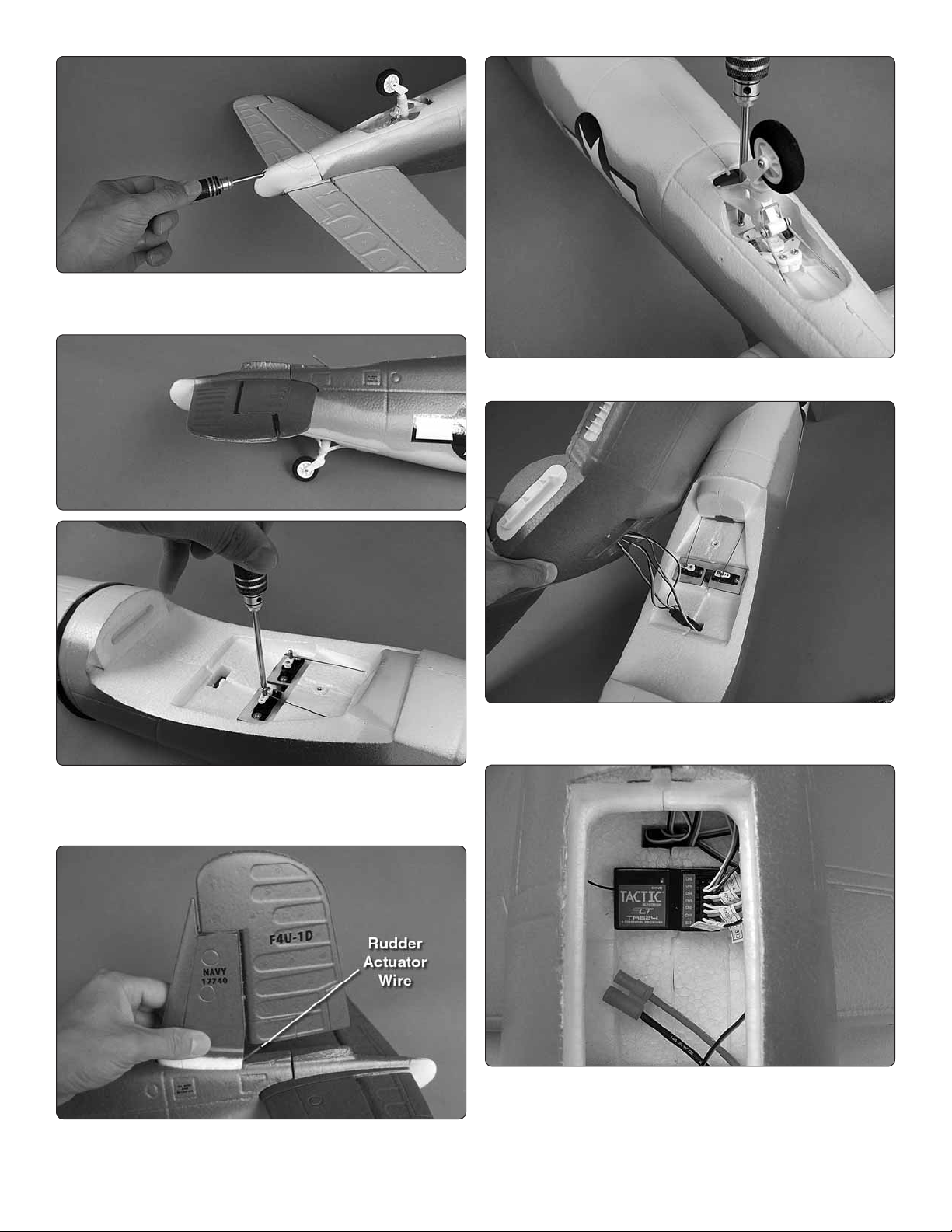

1. Slide the elevator pushrod out of the aft end of the

❏

fuselage and connect the Z-bend on the wire into the outer

hole of the elevator control horn.

● Charge the battery at a maximum charge rate of 1.8 amps.

A higher charge rate will cause the battery to get hot.

● Never place the battery on combustible material or leave it

unattended while charging.

● Never charge the battery in the plane.

● We recommend that a balancing charger be used to charge

the battery. A properly cared for battery will last a long time. If

the battery pack is continually charged without balancing the

individual cells, the life of the battery pack will be shortened.

Battery Recycling

ATTENTION: The Corsair is powered by a rechargeable battery.

At the end of the battery’s useful life, under various state and

local laws, it may be illegal to dispose of the battery into the

municipal waste system. Check with your local solid waste

offi cials for details in your area for recycling options or proper

disposal. We encourage contacting your local recycling center

for more information.

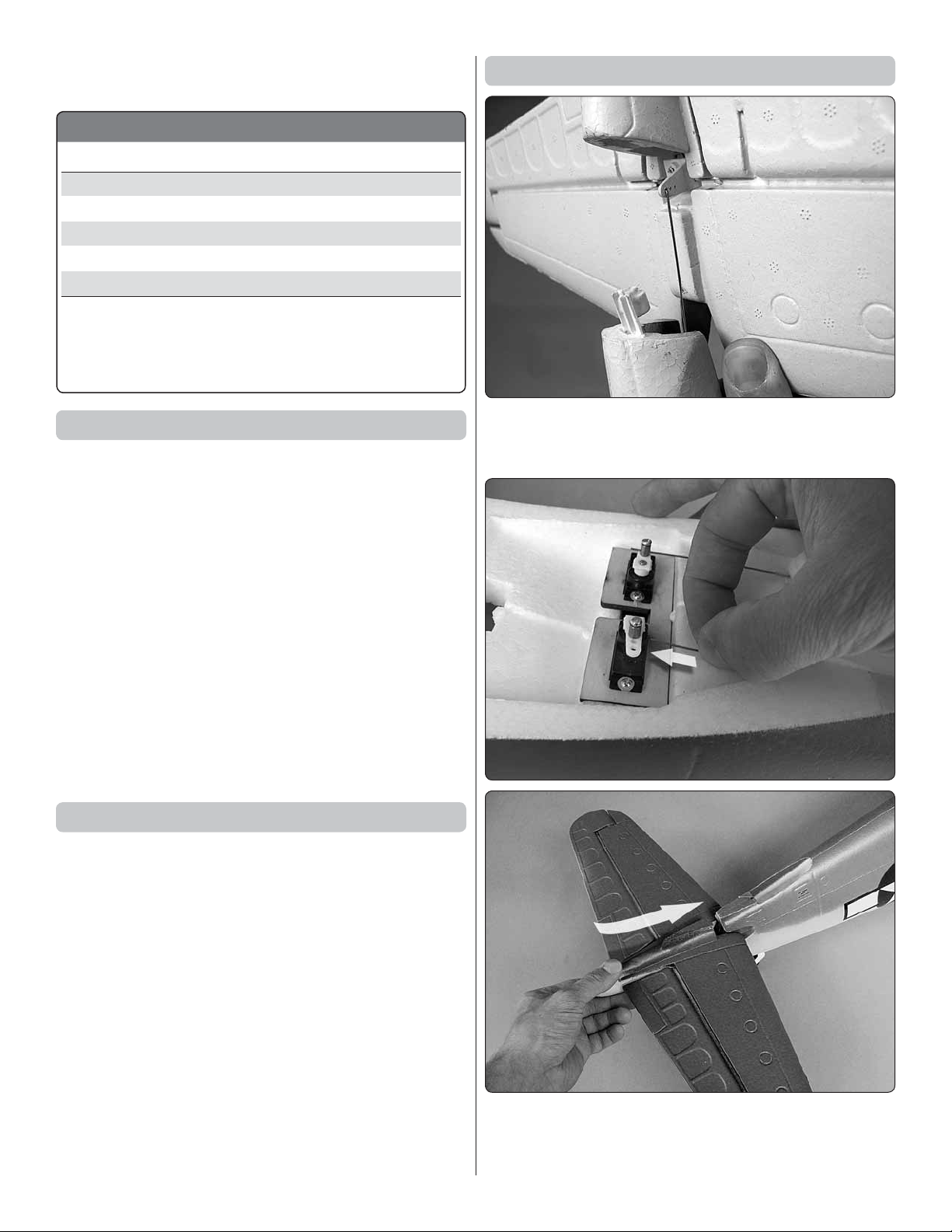

2. Guide the elevator pushrod into the screw-lock connector

❏

on the elevator servo arm as you slide the horizontal stabilizer

into place.

5

Page 6

3. Insert a 2.5x10mm screw into the hole at the aft end of

❏

the horizontal stabilizer and tighten it until snug.

6. Secure the vertical fi n in place with a 2.5x10mm screw.

❏

7. Fit the servo wires for the wing through the cutout in the

❏

fuselage as shown.

4. Center the elevators so they are in the neutral position

❏

with the horizontal stabilizer. Tighten the screw in the elevator

screw lock connector.

5. Insert the vertical fi n into the opening in the fuselage.

❏

Guide the rudder actuator wire into the slot in the rudder.

8. Connect the servo leads to the receiver. The leads are

❏

labeled as to which numbered channel slots they need to be

installed into.

6

Page 7

Check the Radio System

UP

DOWN

DOWN

DOWN

CAUTION: Do not install the propeller on the plane until

instructed to do so.

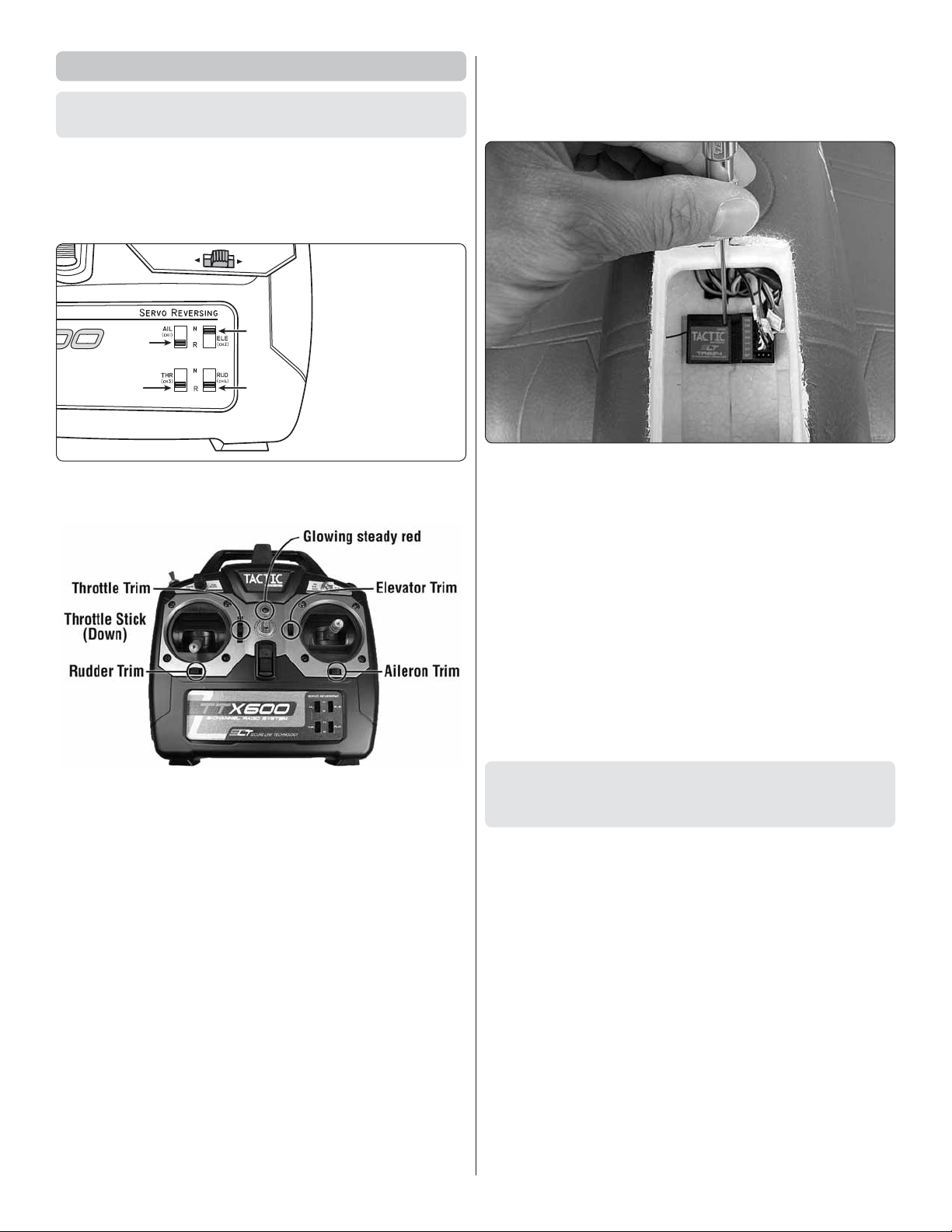

1. If using the Tactic TTX600 radio system read the Radio

❏

System Instructions section on page 14 in this manual. Then,

install four AA alkaline batteries in the transmitter with the

correct polarity.

2. Check that the servo reversing switches are confi gured

❏

as shown.

produce a low tone. Moving the right stick on the transmitter

up and down will move the elevator on the plane up and down.

If the motor does not beep and the elevator does not move,

the receiver will need to be bound to the transmitter.

6. The receiver does not need to be removed from the

❏

fuselage to bind it to the transmitter. Make sure the throttle

stick is down in the idle or off position and the transmitter is

switched on. Insert a small screwdriver or paperclip through

the hole marked “Bind” and press the pushbutton until the

LED on the receiver glows red and then turns off after about

one second. Then, release the bind button. If the binding is

successful, the LED on the receiver will fl ash once and then

remain ON.

3. Position the throttle stick (left stick) to idle (all the way

❏

down) and switch on the transmitter. The power indicator light

should be glowing a steady red. A fl ashing red light and an

audible tone indicates low voltage. If this happens, replace

the batteries before connecting the fl ight battery.

4. Center the aileron, elevator, throttle and rudder trims on

❏

the transmitter by listening to the beeps. You will hear a low,

short beep each time you bump the trim. When you hear one

high, short beep the trim is centered. Experiment running the

trim to the limits a few times to familiarize yourself with the

trims. When fi nished, return all the trims to center.

Before connecting the battery to the plane, be aware that

depending on the position of your landing gear switch

on the transmitter the gear in the wing may come down.

Place the wing upside down on your work surface or leave

the gear servo lead disconnected from the receiver until

you are prepared to test it.

7. Make sure the motor brake function in the ESC is

❏

deactivated. When you advance the throttle stick, the motor

should turn. When you bring the throttle stick all the way back

down, the motor should come to a coasting stop. If the motor

stops quickly, the brake is on. To deactivate the brake, follow

the instructions on page 12.

CAUTION: Perform the following steps without the propeller

mounted to the motor. Do not install the propeller until

instructed to do so.

5. With the transmitter still switched on, connect the LiPo

❏

motor battery to the electronic speed control. The motor will

7

Page 8

Adjust the Control Surfaces

1. Before mounting the wing, the control surfaces must be

❏

mechanically centered if they are not already. With the fl ight

battery plugged into the ESC and your transmitter on, confi rm

that the trims are centered on the transmitter. Move the left

control stick to the left and confi rm the rudder moves left. If

it moves right, fl ip the rudder (channel 4) reversing switch on

your transmitter if you are using the TTX600. If you are using

a different model transmitter, consult your radio manual. View

the model from behind to see if the rudder is aligned with the

vertical fi n (centered). If not, loosen the screw in the rudder

servo screw-lock connector and adjust the rudder pushrod

in the connector until the rudder is centered. When satisfi ed,

tighten the screw.

Check the Retracts

2. Move the right control stick down and confi rm that

❏

the elevators move up. If not, fl ip the elevator (channel 2)

reversing switch on your transmitter. As you did with the rudder,

mechanically center the elevator if necessary.

3. Moving the right control stick to the right should cause

❏

the right aileron to move up and the left aileron to move down.

If not, fl ip the aileron (channel 1) reversing switch on your

transmitter. Mechanically center the ailerons.

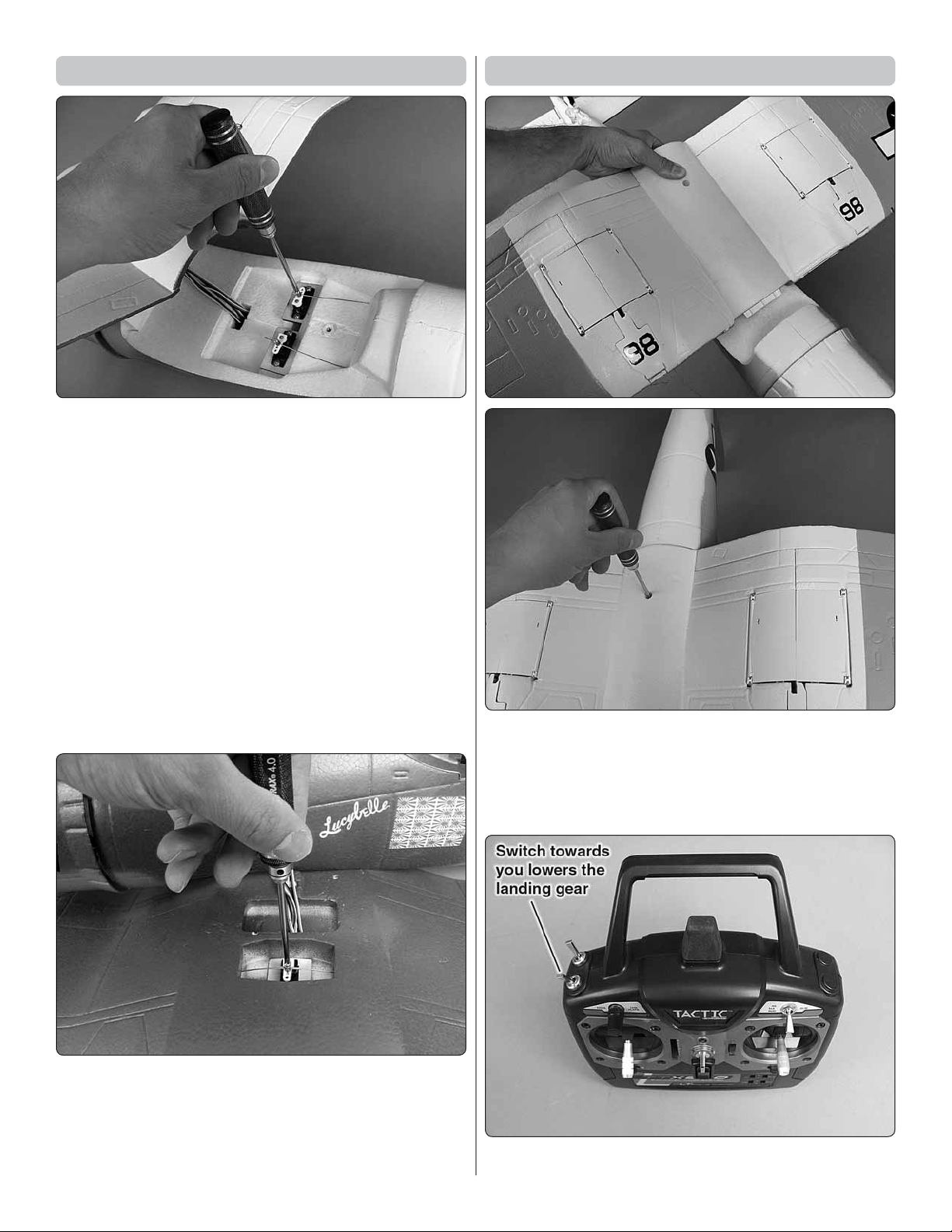

1. Mount the wing onto the fuselage using the 4 x 30mm

❏

screw. Be sure the excess servo leads are pulled out of the

way of tail servo arms and that they are not caught between

the wing and the wing saddle as the wing is seated onto

the fuselage.

8

Page 9

2. If the retract servo lead is not already connected to

FULL THROTTLE

RUDDER

MOVES RIGHT

ELEVATOR MOVES DOWN

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

4-Channel Radio Set Up (Standard Mode 2)

❏

channel 5 on your receiver, connect it now. Turn the plane

on its back (take care not to damage the rudder) to test the

operation of the retracts. Moving the retract switch towards

you on the transmitter will lower the gear.

3. With the gear down, check each landing gear leg and

❏

confi rm they are “locked” in place. The gear is set at the factory

so it lowers to the locked position. However, if adjustment is

required it can be done by loosening the small screws in the

screw-lock connectors shown. The wires can be shifted forward

or aft in the connectors to alter the actuation of the gear legs.

If you made adjustments to the gear wires, be sure to check

their operation afterwards.

4. Leave the gear in the down position for checking the

❏

center of gravity in a later section.

Check the Control Throws

One major factor that determines how an airplane handles

in the air is the control surface throw, or how far each control

surface (aileron, elevator and rudder) moves up and down or

left and right. If the throw is too much, the plane will respond

too quickly. If the throw is too little, the plane will respond too

slowly. The control throws in the Corsair have already been

determined by where the pushrods are connected to the servo

arms and the control surfaces and by how far the servo arms

rotate. But, if you are using a radio control system different

than the one recommended, the servo arms could rotate more

or less than anticipated, changing the throws. Therefore, it’s a

good idea to double-check the throws just to make sure they

are acceptable. Follow the procedure below to make sure the

control throws are properly set.

1. Move the aileron, rudder, elevator and throttle sticks on

❏

the transmitter, making sure the controls respond in the correct

direction. Use the servo reversing function in the transmitter

to reverse any of the controls necessary.

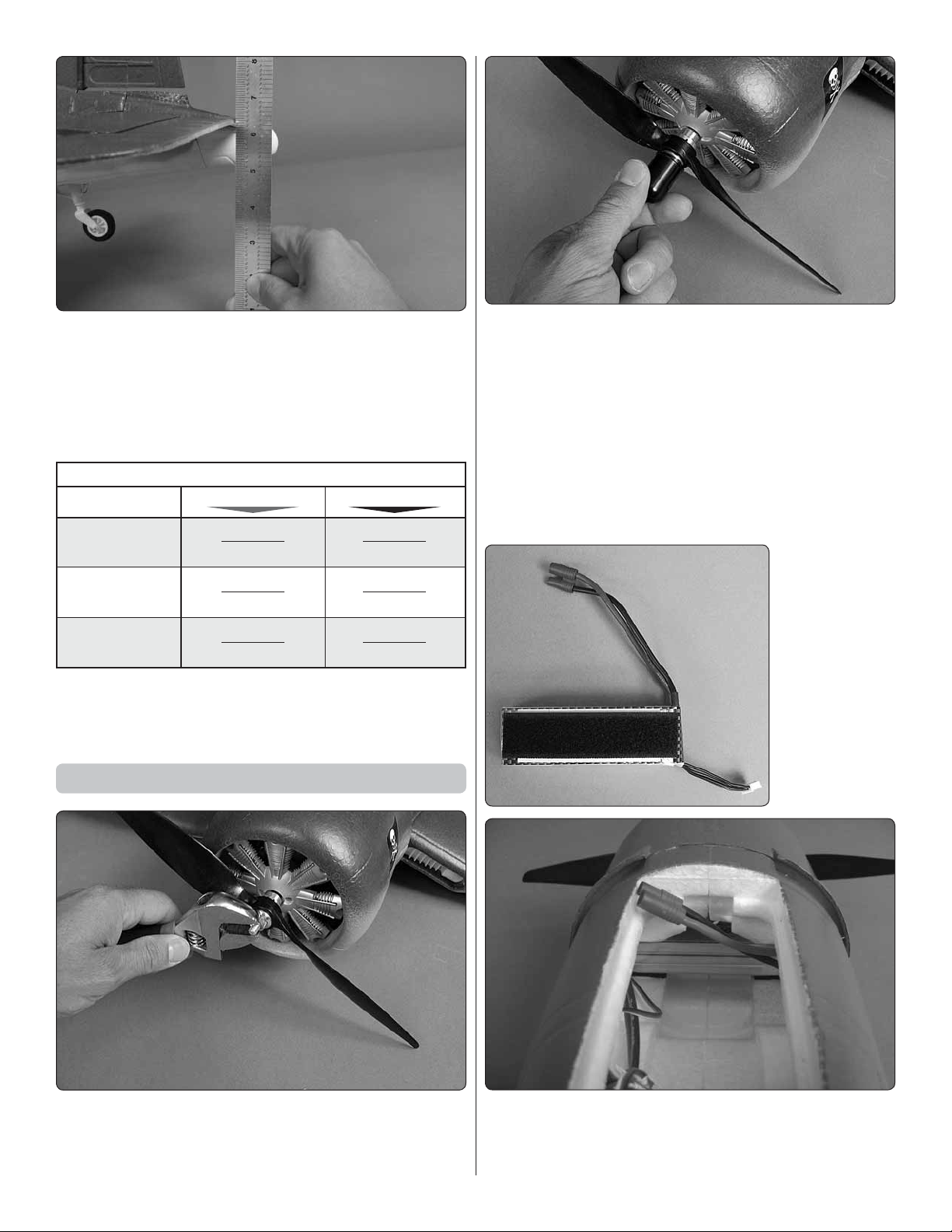

Measure the elevator throw fi rst:

2. Use a small box or something similar to prop up the aft

❏

end of the fuselage so the stabilizer will be level (or nearly level).

3. Still without the propeller mounted on the motor, switch

❏

on your transmitter and connect the motor battery. Place a

ruler next to the trailing edge of the elevator at the widest part

(from front-to-back).

9

Page 10

4. Use the transmitter to move the elevator up and measure

❏

the distance it moved from center. This is your “up” control

throw. Measure the down elevator control throw following the

same procedure. Compare the up and down elevator throw

to the recommended elevator throw below. Measure and

compare the rudder and aileron throws as well.

These are the recommended control surface throws:

ELEVATOR

RUDDER

AILERONS

LOW RATE

Up & Down

5/16" [8mm]

Right & Left

13/16" [ 21mm]

Up & Down

11/16" [17.5 mm]

HIGH RATE

Up & Down

7/16" [11mm]

Right & Left

1-1/4" [ 32 mm]

Up & Down

7/8" [22mm]

Note: If you ever install different servos in the plane or use a

different radio control system, make sure you check that you

still have the recommended control throws.

2. Thread the plastic spinner nut back onto the prop adapter

❏

until snug. It is not necessary to over-tighten the spinner nut

as doing so will strip out the hole in the nut. The spinner nut is

for scale detail only and does not aid in securing the propeller.

Note: With the propeller installed on the motor, you must

always be careful to stay clear of the prop blades whenever

the fl ight battery is plugged into the ESC! Always turn

on your transmitter fi rst and confi rm that the throttle stick

is all the way down before connecting the fl ight battery.

Always disconnect the battery fi rst before turning off the

transmitter.

3. Apply the

❏

piece of selfadhesive loop

material to your

fl ight battery.

Finish the Model

1. Remove the plastic spinner nut from the prop assembly by

❏

unthreading it. Loosen the aluminum prop nut on the assembly,

then slide the assembly onto the motor shaft. Thoroughly

tighten the prop nut with a wrench.

4. Test fi t the battery into the battery compartment. Do not

❏

connect the battery to the ESC until your transmitter is on,

the throttle stick is all the way down, and you are prepared

for the rotation of the propeller.

10

Page 11

Check the C.G. (Center of Gravity)

The C.G. (Center of Gravity) is the location on the wing

where the model balances and has a great effect on how

the plane will fl y. If the C.G. is too far aft (tail heavy), the

model will be too responsive. If the C.G. is too far forward

(nose heavy), the model will not be responsive enough. As

provided to you, your Corsair should already be properly

balanced, or very nearly properly balanced, but it’s a good

idea to check the balance just in case. Follow the instructions

to make sure the model is balanced properly and the C.G.

is in the correct location.

your fi ngers on these marks and lift the plane upside down.

The fuselage should remain level – it may be helpful to have

an assistant view the plane from the side. If the fuselage does

not rest level, try moving your fi ngers under the wing. Your

fi ngers can be moved forward up to 1/4" [6.4 mm] or aft up to

5/16" [ 8 mm]. As long as the fuselage is level with your fi ngers

within the range, the balance is acceptable, and the plane is

ready to fl y. However, even if after moving your fi ngers the

acceptable 1/4" [6.4 mm] forward, the nose remains low, tail

weight will be required. Or, even if after moving your fi ngers

the acceptable 5/16" [8 mm] aft, the tail remains low, nose

weight will be required. Balance the plane as instructed below.

Note: Even if your Corsair balances perfectly on the

recommended balance point, later you may wish to change

its fl ying characteristics by moving the C.G. forward or aft.

Moving the C.G. forward (nose heavy) will make the plane

more stable which may be better for windier days, but this will

also make it less maneuverable. Moving the C.G. back (tail

heavy) will make the plane more maneuverable which is good

for experienced pilots who wish to perform aerobatics. In any

regard, start at the recommended balance point and never

fl y the model with the C.G. outside the recommended range.

3. Determine the amount of weight required by placing

❏

segments of Great Planes stick-on lead (GPMQ4485) or similar

weight, over the cowl or tail, but do not attach it yet.

1. Install the battery hatch (the battery is still installed in

❏

the battery compartment).

2. On the top of the wing, place a mark 2-7/8" (73mm) from

❏

the leading edge or use the panel lines as a reference. Place

4. Once the plane balances and you know how much lead

❏

will be required, permanently stick it into position. The best

place to add nose weight is to remove the propeller and dummy

engine and place the weight inside the cowl. If tail weight is

required, simply attach it to the side of the fuselage, under the

horizontal stabilizer.

11

Page 12

5. Once the weight is attached, recheck the C.G. to make

❏

certain the plane still balances at the correct C.G. Once fi nished,

remove the battery. Never charge the battery while it is installed

in the model.

● The ESC has a soft cutoff. At 3.2V per cell the rpm of the motor

will slowly be reduced until it stops completely.

GET THE MODEL READY TO FLY

Important ESC Information

● The ESC included with the Corsair has a safe start. If the

motor battery is connected to the ESC and the throttle

stick is not in the low throttle or off position, the motor will

not start until the throttle stick is moved to the low throttle

or off position. Once the throttle stick is moved to the low

throttle or off position, the motor will give a short beep. The

motor is now armed and will start when the throttle

stick is moved.

● The motor and ESC come already connected and the motor

rotation should be correct. However, if you disconnected

the ESC from the motor and when you reconnected it, the

motor is rotating in the wrong direction, reverse any two of

the three motor wires.

● The motor has an optional brake setting. The ESC comes

with the brake switched off and we recommend that the

Corsair be fl own with the brake off. However, the brake could

be accidentally switch on if the motor battery is connected

to the ESC while the throttle stick is set at full throttle.

To toggle the brake function on and off, fi rst disconnect the

battery from the ESC if it is connected. Move the throttle

stick to full throttle. Connect the battery to the ESC. The

motor will fi rst make three incremental tones confi rming that

the battery voltage has been detected and is acceptable.

After two seconds the motor will emit two long beeps which

confi rms the throttle high position.

With the throttle stick still at full throttle the motor will emit

one short beep. Move the throttle to the lowest position

within two seconds of the beep to select BRAKE OFF, or

leave the throttle stick at full throttle to select BRAKE ON. If

the throttle stick is in the full throttle position, the motor will

emit two short beeps after two seconds. Move the throttle to

the lowest position within two seconds of the two beeps to

select BRAKE ON. If the throttle stick is left at full throttle for

more than two seconds after the two short beeps, then the

ESC will become disarmed and you will need to disconnect

the battery from the ESC and repeat this process.

With the throttle stick now at the lowest position the ESC

will emit one long beep confi rming the throttle low position.

It will then emit one short beep if the brake function is OFF

or two short beeps if the brake function is ON. The ESC is

now armed and ready to use.

If you do not hear any beeping from the ESC when the

battery is connected, the motor makes a repeated beeping

pattern, or the operation of the ESC does not coincide

with the procedure described, then check for the following

problems: The battery is not properly connected to the ESC,

the battery voltage is insuffi cient to operate the ESC, the

ESC is not receiving signal from the receiver (confi rm that

the transmitter and receiver are bound together and the

ESC is properly connected to the receiver), or the throttle

trim is set too high.

Identify Your Model

No matter if you fl y at an AMA sanctioned R/C club site or if you

fl y somewhere on your own, you should always have your name,

address, telephone number and AMA number on or inside your

model. It is required at all AMA R/C club fl ying sites and AMA

sanctioned fl ying events and simply a “good idea” even if fl ying

somewhere else. Write this information on a strip of masking

tape and place it on the inside of the battery hatch (or simply

write the information directly on the battery hatch).

FLYING THE CORSAIR

The Corsair is not intended for beginners. It is, however, easy

to fl y even for pilots with moderate experience. If you have not

previously fl own a trainer it is strongly suggested that you learn

to fl y with one fi rst. Or, get the assistance of an experienced pilot

to help you with the fi rst few fl ights.

Find a Suitable Flying Site

Find a fl ying site clear of buildings, trees, power lines and other

obstructions. Until you know how much area will be required and

have mastered fl ying your Corsair in confi ned spaces, a site at

least the size of two or three football fi elds should be adequate—a

fl ying fi eld specifi cally intended for R/C planes is best. Never fl y

near people—especially children who can wander unpredictably.

Perform a Range Check

As a precaution, an operational ground range test should be

performed before the fi rst fl ight each time you go out. Performing

a range test is a good way to detect problems that could cause

loss of control such as low batteries, defective or damaged

radio components or radio interference. This usually requires

an assistant and should be done at the actual fl ying site you

will be using.

First turn on the transmitter, then install the fully-charged battery

into the fuselage. Connect the battery and install the hatch.

Remember, use care not to “bump” the throttle stick.

Otherwise, the propeller will turn and possibly cause damage

or injury.

To range check the Tactic TTX600 radio control system, switch

on the transmitter and connect the motor battery to the ESC.

Set the model on the ground and have an assistant hold the

model. Walk 100’ (90m) from the model and while pointing

the transmitter at the plane, operate the controls ensuring

that the plane’s surfaces operate according to the transmitter

inputs. Operate the motor at different rpm. Have your assistant

alert you if the controls quit responding or move suddenly or

erratically. If you are using a different radio control system,

follow the instructions that came with your radio control system

to perform a ground range check.

12

Page 13

If the controls aren’t working correctly or if anything seems

wrong, don’t fl y the model until you fi nd and correct the problem.

Make certain all the servo wires are securely connected to the

receiver and the transmitter batteries are in good condition.

Monitor Your Flight Time

Monitor and limit your fl ight time using a timer (such as one on

a wrist watch or in your transmitter if yours has one). When the

batteries are getting low you will usually notice a performance

drop before the ESC cuts off motor power, so when the plane

starts fl ying slower you should land. Often (but not always), power

can be briefl y restored after the motor cuts off by holding the

throttle stick all the way down for a few seconds.

To avoid an unexpected dead-stick landing on your fi rst fl ight,

set your timer to a conservative 4 minutes (in most conditions

the Corsair will usually fl y for approximately 5 minutes, but this

can vary). When your alarm sounds you can either land right

away, or if you are an experienced pilot you may continue to fl y

until you notice the airspeed begin to slow. Then, glide it in for

a landing. If planning a “dead-stick,” circle your Corsair upwind

of the landing area until the motor quits and note the run time.

When you learn how much fl ight time you are getting you can

adjust your timer accordingly. Always be conservative so the motor

won’t quit unexpectedly and you will have enough battery to land

under power. Ending your fl ight before the ESC cutoff shuts off

power to the motor will help maximize the lifespan of the battery.

FLYING

The Corsair is a great-fl ying model that fl ies smoothly and

predictably. The Corsair does not, however, possess the selfrecovery characteristics of a primary R/C trainer and should be

fl own only by experienced R/C pilots.

CAUTION (THIS APPLIES TO ALL R/C AIRPLANES): If, while

fl ying, you notice an alarming or unusual sound such as a lowpitched “buzz,” this may indicate control surface fl utter. Flutter

occurs when a control surface (such as an aileron or elevator)

or a fl ying surface (such as a wing or stab) rapidly vibrates up

and down (thus causing the noise). In extreme cases, if not

detected immediately, fl utter can actually cause the control

surface to detach or the fl ying surface to fail, thus causing loss

of control followed by an impending crash. The best thing to do

when fl utter is detected is to slow the model immediately by

reducing power, then land as soon as safely possible. Identify

which surface fl uttered (so the problem may be resolved) by

checking all the servo grommets for deterioration or signs of

vibration. Make certain all pushrod linkages are secure and

free of play. If it fl uttered once, under similar circumstances it

will probably fl utter again unless the problem is fi xed. Some

things which can cause fl utter are; Excessive hinge gap; Not

mounting control horns solidly; Poor fi t of clevis pin in horn;

Side-play of wire pushrods caused by large bends; Excessive

free play in servo gears; Insecure servo mounting; and one of

the most prevalent causes of fl utter; Flying an over-powered

model at excessive speeds.

Takeoff

Before you get ready to takeoff, see how the model handles on

the ground by doing a few practice runs at low speeds on the

runway. Note the amount of rudder steering required to turn the

plane. If you need to calm your nerves before the maiden fl ight,

bring the model back into the pits, unplug the battery and top it off.

Remember to takeoff into the wind. When you’re ready, point

the model straight down the runway and gradually advance the

throttle. Gain as much speed as your runway and fl ying site will

practically allow before gently applying up elevator, lifting the

model into the air. Be smooth on the elevator stick, allowing the

model to establish a gentle climb to a safe altitude before turning

into the traffi c pattern.

Flight

For reassurance and to keep an eye on other traffi c, it is a good

idea to have an assistant on the fl ight line with you. Assistants

are great for helping make trim adjustments on the transmitter if

excessive trim is required.

Take it easy with the Corsair for the fi rst few fl ights, gradually

getting acquainted with it as you gain confi dence. Adjust the

trims to maintain straight and level fl ight. After fl ying around for

a while, and while still at a safe altitude with plenty of battery

power remaining, practice slow fl ight and execute practice landing

approaches with the fl aps, checking how the model handles at

slower speeds. Add power to see how she climbs as well. Continue

to fl y around, executing various maneuvers and making mental

notes (or having your assistant write them down) of what trim

or C.G. changes may be required to fi ne tune the model so it

fl ies the way you like. Mind your battery power. We recommend

setting the timer on your transmitter or using a separate timer

with an alarm to alert you when it is time to land. Electric motors

are very reliable, but if you fl y until the battery cutoff on the ESC

stops the motor, it’s still a dead stick landing, the same as with

a glow engine.

Landing

To initiate a landing approach, lower the throttle while on the

downwind leg. Lower the landing gear and the fl aps. Adjust

the throttle to allow the nose of the plane to pitch downward

to gradually bleed off altitude. Continue to lose altitude, but

maintain airspeed by keeping the nose down as you turn into the

crosswind leg. Make your fi nal turn toward the runway (into the

wind) keeping the nose down to maintain airspeed and control.

Level the attitude when the plane reaches the runway threshold,

adjusting the throttle as needed to maintain your glide path and

airspeed. Use the throttle to adjust the plane’s altitude. It may

require a couple of landing attempts to get the “feel” of how the

plane slows down. If you are going to be long on the landing,

slowly increase the throttle, gently applying up elevator. When the

plane is a foot above the runway, smoothly increase up elevator

until the plane gently touches down.

One fi nal note about fl ying your Corsair. Have a goal or fl ight plan

in mind for every fl ight. This can be learning a new maneuver(s),

improving a maneuver(s) you already know, or learning how the

model behaves in certain conditions (such as on high or low rates).

This is not necessarily to improve your skills (though it is never a

bad idea!), but more importantly so you do not surprise yourself

13

Page 14

by impulsively attempting a maneuver and suddenly fi nding that

you’ve run out of time, altitude or airspeed. Every maneuver should

be deliberate, not impulsive. For example, if you’re going to do

a loop, check your altitude, mind the wind direction (anticipating

rudder corrections that will be required to maintain heading),

remember to throttle back at the top, and make certain you are

on the desired rates (high/low rates). A fl ight plan greatly reduces

the chances of crashing your model just because of poor planning

and impulsive moves. Remember to think.

OPTIONAL 14.8V POWER SYSTEM

The modelers who are looking for hotter performance from their

Corsair can upgrade the battery to a 14.8V 2100mAh pack while

keeping the stock ESC and propeller. This will provide faster

airspeed and virtually unlimited vertical climb with only slightly

reduced fl ight time. The part number for the recommended

battery is:

❍ FlightPower LiPo EONX Lite 4S 14.8V 2100mAh 25C

(FPWP4197)

In addition to the battery, you will also need a SuperTigre to

Deans® Ultra Plug® adapter:

❍ SuperTigre Adapter Deans Ultra Male to SuperTigre

ESC (SUPM0040)

Although the optional FlightPower battery has a greater voltage

than the standard Flyzone 3S battery, the capacity is the same.

Because the increased voltage draws more current than the 3S

setup, the fl ight time will be reduced. We recommend setting your

fl ight timer for a conservative 3.5 minutes. This will allow time

to throttle back and circle around for land ing. This time can be

adjusted depending on your fl ying style. It’s also a great idea to use

a LiPo battery voltmeter (GPMM3205) to check the battery before

each fl ight (to make sure you haven’t inadvertently grabbed a

discharged battery) and to check the battery after each fl ight

to make sure you haven’t overdischarged your battery by fl ying

too long. A safe, conservative, minimum voltage is 3.65V- 3.7V

per cell right after a fl ight. Based on the post-fl ight voltage, adjust

your fl ight timer accordingly. The ESC has a built-in low voltage

cutoff of 3.2V per cell which will initiate a soft shutdown of power

to the motor when the cell voltages reach this level. Be sure to

allow enough time between fl ights for the motor to cool down

.

TACTIC TTX600 2.4 GHZ

6-CHANNEL RADIO

CH5 Switch

Trainer Switch

CH6 Dial

D/ R Switch

Neck Strap

Eyelet

Trim

Lever

Charge

Jack

Reversing

Switches

LED Power Indicator Power Switch

Transmitter Batteries

Four “AA” batteries are required to power the Tx (not included).

Non-rechargeable 1.5V alkaline, or 1.2V rechargeable nickel-

cadmium (NiCd) or nickel-metal hydride (NiMH) cells, can be

used. Do not mix cell types, or old and new cells, etc.

Have a ball! But always stay in control

and fl y in a safe manner.

GOOD LUCK AND GREAT FLYING!

To install the batteries, slide the battery door down. Insert the

cells as shown in the diagram, making sure to note proper

polarity for each cell. Close the battery door.

POWER SWITCH, LED, and LOW BATTERY ALARM

The red power LED should light when the power switch is

moved upwards to the “ON” position. The Tx should have

adequate power for fl ight when the LED is on constantly.

Anytime the LED begins to fl ash, accompanied by the

sounding of an audible tone, the Tx battery voltage has

dropped too low and operation of the model should NOT

be attempted!

WARNING! Never operate an R/C model

with weak Tx batteries! Reduced operational

range and/or possible loss of control of the

14

Page 15

aircraft could result. Replace weak alkaline batteries,

or re-charge NiCd or NiMH batteries, before attempting

a fl ight!

If during a fl ight the Tx LED starts to fl ash, accompanied

by the sounding of audible tones, it’s a warning that the

Tx batteries have become weak and the aircraft should be

landed as soon as possible!

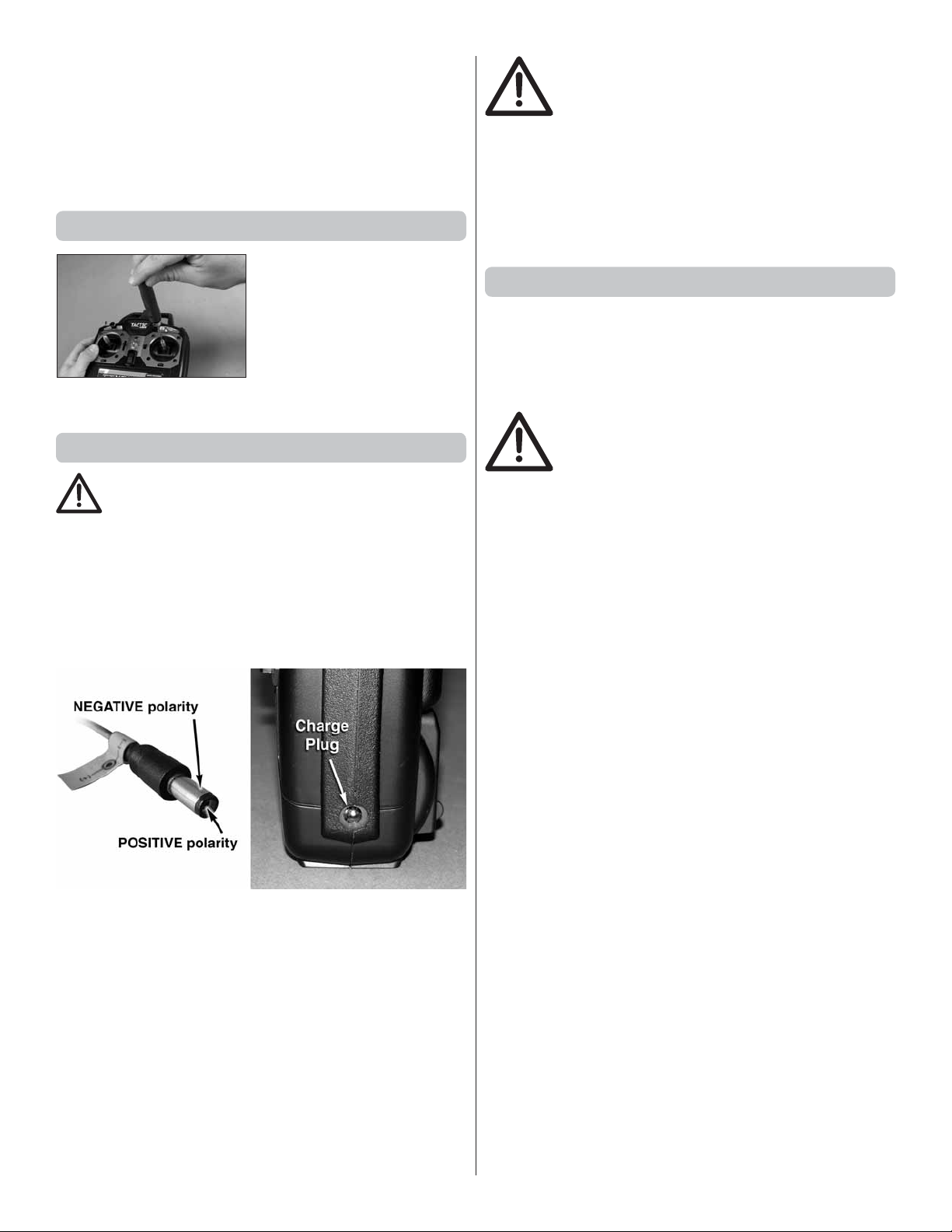

Adjustable Sticks

The length of both gimbal

sticks can be adjusted as

desired. Loosen the set

screw inside the center of the

stick with a 2mm hex wrench.

Rotate the stick end counter-

clockwise to lengthen the stick,

or clockwise to shorten the stick. Once the desired stick

length is found, tighten the set screw with the hex wrench.

Charge Jack

WARNING!! Do NOT attempt to recharge

alkaline batteries! The charge jack should

ONLY be used if rechargeable cells are used in the

transmitter.

The TTX600 includes a built-in charge jack for convenient

recharging of NiCd or NiMH batteries, and is compatible

with charge leads designed for Futaba® brand transmitters

(HCAP0101). This jack is NOT compatible with charge leads

for Hitec®, Airtronics®, JR® or Spektrum® radios.

To use the charge jack with optional rechargeable batteries,

fi rst remove the sticker that covers the charge jack on the

side of the Tx – making sure not to allow any object to be

inserted inside the jack itself. Next, insert the cells inside

the Tx’s battery compartment noting proper polarity. Make

sure the transmitter’s power switch is in the OFF position.

Connect a compatible charge lead to the jack and follow the

instructions included with the charger for charging of NiCd or

NiMH batteries that are rated at 4.8V.

Tactic’s optional TACP1000 rechargeable battery and wall

charger kit includes eight “AA” size rechargeable NiMH cells

and 110V AC wall charger, which is compatible with this Tx

and can be found at local retailers. Make sure to follow the

instructions included with the charge kit.

WARNING!! It’s not recommended to charge

batteries at greater than 1 amp through this

charge jack. Fast charging of NiCd and

NiMH batteries should ONLY be done with

chargers that are specifi cally designed to include the

peak-detection function which can automatically stop

charge when full charge is detected. Misuse, improper

charging, or over-charging of rechargeable cells can

result in damage to the cells that could include cell

rupture, explosion, or fi re!!

Trainer Function

The TTX600 Tx includes a built-in wireless trainer function

– no trainer cable required! This trainer system connects a

teacher’s Tactic Tx to a student’s Tactic Tx by wireless

connection. Tactic’s wireless trainer function is not compatible

with trainer systems in any other brand radios.

IMPORTANT! Before attempting to fl y the

airplane, it’s very important to make sure all

reversing switches and trim lever adjustments

on the student’s Tx match the settings on the

teacher’s Tx! Otherwise, the airplane could suddenly veer

off in an unwanted manner when the teacher’s trainer switch

is pressed. Proper matching of the student and teacher’s

Tx settings should ensure that no unexpected movements

occur when the trainer switch is pressed. This is especially

true of the throttle control!

1. The Tx that was used to set up the controls on the

aircraft must be used by the TEACHER.

2. The student must use a separate Tactic Tx with

wireless trainer function.

3. Place the teacher’s and student’s transmitters within

1 meter of each other, and make sure the throttle

stick for each Tx is set to idle.

4. Turn ON the power switch for the Tx being held by

the student.

5. Pull and hold the trainer switch on the teacher’s Tx,

and then turn ON the teacher’s Tx power switch.

6. The LED on the teacher’s Tx will fl ash 3 times to

indicate it has become bound with the student’s Tx.

7. The teacher can then release his trainer switch.

8. Once both transmitters are bound together, power

can be applied to the receiver to prepare for fl ight.

When the training session has ended, with the model on the

ground and all power removed from the model, place both

transmitters within 1 meter of each other and simply turn the

power switch for both transmitters to the OFF position. This

will terminate the wireless link between both transmitters. If

additional training will be performed again, return to step 1

above to re-establish the wireless link between the teacher

and student’s transmitters.

15

Page 16

Failsafe Function

The included TR624 receiver has a failsafe feature which

engages in the event that the radio signal from the transmitter

somehow becomes interrupted. If radio contact is broken,

this safety feature causes the servos to automatically move

either to a certain position, or hold their last position to prevent

the model from moving in an erratic manner. Channels 1, 2,

4, 5, and 6 will enter a “hold” mode, whereby the servos will

lock in their last recognized position.

The servo connected to channel 3, normally being the throttle

control, will move to a pre-set position. The factory default

failsafe position for channel 3 is to move to 0% throttle.

Motor/prop movement should stop if the receiver loses signal

from the transmitter. The throttle servo’s failsafe position can

be manually re-set to any other position if desired, as follows:

IMPORTANT NOTE: Before manually resetting the

failsafe, make sure the servo reversing switches are in the

correct position for the application.

1. Apply power to the Tx and Rx.

2a. If using an ESC, do NOT arm the ESC. Do NOT

attempt to adjust the throttle’s failsafe position if the

ESC is armed.

2b. If using a gas or glow powered engine, do NOT

attempt to adjust the throttle’s failsafe position while

the engine is operating.

3. Move the Tx throttle stick to the desired position for

the throttle control to move if the Rx goes to failsafe.

4. Press and hold the “Bind” button on the receiver, and

the Rx’s LED should blink twice. Release the Bind

button, and the receiver’s LED should turn on (stop

fl ashing). The Tx and Rx should now be bound, with

the throttle failsafe in the new position as set above.

NOTE: If you’re using an ESC which has a signal loss

feature, the pre-set failsafe position is irrelevant as the

signal loss feature will cease the throttle operation if the

signal is lost.

System Check and Operation

WARNING! During all pre-fl ight preparations with the

aircraft on the ground, make sure the throttle stick remains

at the minimum position and do not stand the Tx upright on

the ground. Carefully lay the Tx on its back on the ground to

prevent it from falling over and possibly dislodging the throttle

stick from the low position which would create a safety

hazard. Make sure all devices are properly mounted inside

the model, and all wiring connections are solid to prevent

them from easily becoming dislodged during normal fl ight.

It’s best to check the system with the propeller removed from

the aircraft.

1. Once all connections are made, check the general

operation of the radio and all other components before

attempting a fl ight.

2. Move the Tx throttle stick to the minimum (idle) position.

3. Turn on the Tx, and then the Rx.

4. Make sure all controls are operating in the proper direction.

If any servo is turning in the wrong direction, change the

position of the reversing switch for that particular channel.

5. With both sticks at center position, move the trim levers

for the aileron, elevator, and rudder channels so each

respective control surface is perfectly aligned with the

main surface. For example: When the aileron trim lever is

in the center position, it’s best that the trailing edge of the

aileron is aligned with the trailing edge of the wing itself

(not above or below the wing’s trailing edge).

6. Make sure that movements of the throttle stick result in

an equal adjustment of the throttle in the model. Confi rm

that when the throttle stick is at maximum position the

electronic speed control gives the appropriate indications

(LED and/or audible indicators) for full forward fl ight. When

the throttle stick is at minimum position, the electronic

speed control should give the appropriate indications for

“off” or no motor rotation.

7. Anytime power is to be removed from the radio system,

it’s important to shut down power in the aircraft fi rst.

Otherwise, the aircraft could become out of control and

cause a safety hazard! Move the throttle stick and throttle

trim lever to minimum position to stop the glow engine

or shut down the ESC. Once the propeller has stopped

rotating, shut off the ON/OFF power switch in the model,

and disconnect the power battery from the ESC in electric

airplanes. Then turn off the power switch in the Tx.

AMA Safety Code (Excerpts)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model Aviation magazine, the AMA web site or

the Code that came with your AMA license.

GENERAL

1. I will not fly my model aircraft in sanctioned events, air shows,

or model flying demonstrations until it has been proven to

be airworthy by having been previously, successfully flight

tested.

2. I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid flying

in the proximity of full-scale aircraft. Where necessary,

an observer shall be utilized to supervise flying to avoid

having models fly in the proximity of full-scale aircraft.

3. Where established, I will abide by the safety rules for the

flying site I use, and I will not willfully and deliberately

fly my models in a careless, reckless and/or dangerous

manner.

5. I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model. Note:

This does not apply to models while being flown indoors.

16

Page 17

7. I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

RADIO CONTROL

1. I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2. I will not fly my model aircraft in the presence of spectators

until I become a qualified flier, unless assisted by an

experienced helper.

3. At all flying sites a straight or curved line(s) must be

established in front of which all flying takes place with the

other side for spectators. Only personnel involved with

flying the aircraft are allowed at or in the front of the flight

line. Intentional flying behind the flight line is prohibited.

4. I will operate my model using only radio control frequencies

currently allowed by the Federal Communications

Commission.

5. I will not knowingly operate my model within three

miles of any pre-existing flying site except in

accordance with the frequency sharing agreement

listed [in the complete AMA Safety Code].

9. Under no circumstances may a pilot or other person touch

a powered model in flight; nor should any part of the

model other than the landing gear, intentionally touch

the ground, except while landing.

Tactic TR624 Receiver

Channels 6

Frequencies 2.403 – 2.480GHz

Modulation FHSS spread spectrum

Input power Four “AA” alkaline,

NiCd or NiMH cells (4.0 – 6.0V, not included)

Failsafe Programmable throttle, all other channels hold

Dimensions 1.77 × 0.98 × 0.5" (45 × 25 × 13mm)

Weight 0.28 oz (8g)

Important Warnings and Precautions

● NEVER allow water or moisture to make

contact with the electronic components

inside the transmitter, receiver, servos, switch

harness, etc.! This could lead to failure or

improper functionality of components and poor control of

aircraft which could pose a safety hazard.

● NEVER operate R/C model aircraft near power lines, radio

or cell phone towers, roads or automobiles, buildings, or

pedestrians. Be very careful in locations where many R/C

aircraft are being used simultaneously.

Specifi cations

TTX600 6-Channel Transmitter

Channels 6

Frequencies 2.403 – 2.480GHz

Modulation FHSS spread spectrum

Input power Four “AA” alkaline, NiCd,

or NiMH cells (3.8 – 8.0V, not included)

Output power < 0.1W

Power indicators LED, with low voltage alarm

Reversing switches Slide switches, four channels

Trims Analog for throttle,

digital for aileron, elevator, rudder

Antenna Built-in non-removable

Charge jack Built-in (Futaba

for use with optional NiCd or NiMH cells)

Trainer function Wireless

(compatible with Tactic brand transmitters only)

Optional mixes Elevon, V-Tail

Dual rates 100/60 % for aileron/elevator/rudder

Channel 5 Non-proportional on/off

Channel 6 Proportional

®

compatible,

● NEVER operate R/C equipment if you are physically

impaired as it could pose a safety hazard to yourself or

others in the area.

● NEVER allow small children to operate/control model R/C

equipment without the supervision of an adult.

● NEVER allow the transmitter’s throttle stick to accidentally

be moved away from the “off” or minimum position while

the model’s engine/motor is moving.

● ALWAYS range check the radio system before use.

● ALWAYS make sure that all transmitter stick movements

operate all servos properly in the model. Check the proper

operation of control surfaces before and after starting the

engine/motor.

● ALWAYS make sure the transmitter antenna is unfolded

entirely so that it’s pointing upright to ensure max. range

and control of the aircraft.

● Do not store your radio equipment in extremely hot or

cold locations, in direct sunlight, or in locations with high

humidity. Store R/C equipment in cool and dry locations.

● Do not allow chemicals to come in contact with any

parts of the radio system. Substances such as glow fuel,

gasoline, CA glue, etc. could permanently damage plastic

parts of the radio system.

● If NiCd batteries were installed in the transmitter, remove

the batteries before placing the radio in long-term storage.

17

Page 18

Troubleshooting

FCC Statement

RANGE IS SHORT

Interference – check Rx installation and servo connections.

Low Tx or Rx battery – replace the batteries or recharge

if applicable. Rx may need to be located to a different

position in the model for better reception. Crash damage –

send the radio to Hobby Services for repair.

RUN TIME IS SHORT

Low Tx or Rx batteries – replace or recharge the batteries.

Obstructed servo linkages causing excess battery drain –

free the linkages / pushrods.

Tx POWER SWITCH ON BUT SERVOS DO NOT FUNCTION

Tx or Rx batteries are low – replace or recharge the

batteries. Rx switch is in the off position – turn on the

ESC or switch harness. Switch harness or ESC is

connected incorrectly – check all connections and the

ESC instruction manual. Rx is not binded to the Tx

properly – perform binding process again. Check Tx or

Rx battery polarity.

INTERFERENCE OR SERVOS GLITCHING

Out of range – operate the model more closely to the

transmitter. Outside radio interference from pagers, strong

industrial or other commercial transmitters in the area

- check your local R/C club regarding local operation. Rx

located too closely to engine, motor, or servos or other

moving mechanical parts which might be creating unwanted

electrical noise – relocate the Rx inside the model or

relocate the ESC.

CONTROL SURFACE MOVES IN THE WRONG DIRECTION

Reverse the position of the reversing switch for the

appropriate channel.

ONLY ONE SERVO GLITCHES

Servo is bad – replace the servo or send to Hobby Services

for repair.

FAILSAFE NOT WORKING CORRECTLY

Receiver is not properly binded to the transmitter – bind

the Rx to the Tx and re-try. Contact Hobby Services for

further details.

WIRELESS TRAINING FUNCTION NOT BINDING

Check to see that another Tactic 2.4GHz system is not on

in your area. The teacher’s and student’s transmitters were

not powered in the proper sequence. Carefully follow the

instructions on page 15 for proper binding and operation

for training.

RECHARGEABLE BATTERIES WON’T ACCEPT CHARGE

THROUGH THE TRANSMITTER

Check the charger for proper setup and operation. Make

sure the charge plug is inserted fully into the charge

jack. Make sure the transmitter’s power switch is in the

OFF position. Make sure the cells are inserted inside the

battery compartment in the proper direction.

This device complies with part 15 of the FCC rules. Operation

is subject to the following two conditions.

(1) This device may not cause harmful interference.

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

FCC Rf Radiated Exposure Statement: The

equipment complies with FCC Rf radiation exposure limits

set forth for an uncontrolled environment. This equipment

should be installed and operated with a minimum distance of

20 centimeters between the radiator and your body.

Note: The manufacturer is not responsible for any radio

or TV interference caused by unauthorized modifi cations

to this equipment. Any changes or modifi cations

not expressly approved by the party responsible for

compliance could void the user’s authority to operate

the equipment.

FCC ID: IYFTTX600

CE Compliance Information

for the European Union

Instructions for Disposal of Waste Equipment

by Private Users in the European Union:

This symbol on the product or its packaging

indicates this product must not be disposed of

with other household waste. Instead, it is the user’s

responsibility to dispose of their waste equipment by

handing it over to a designated collection point for the recycling

of waste electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the time

of disposal will help to conserve natural resources and ensure

that it is recycled in a manner that protects human health and

the environment. For more information about where you can

drop off your waste equipment for recycling, please contact

your local city offi ce, your household waste disposal service

or location where you purchased the product.

Declaration of Conformity:

Product: Tactic TTX600 2.4GHz

6-Channel Tx Rx

Item number: TACJ2600

Equipment class: 1

Tactic TTX600 transmitter and Tactic TR624 receiver:

The objects of the declaration described here are in conformity

with the requirements of the specifi cations listed below,

following the provisions of the European 2006/95/EC Low

Voltage Directive:

EN 60950-1:2006 Safety

18

Page 19

The objects of the declaration described here are in conformity

with the requirements of the specifi cations listed below,

following the provisions of the European R&TTE directive

1995/5/EC:

ETSI EN 300 328 V1.7.1 Technical requirements

for radio equipment

ETSI EN 301 489-1 V1.8.1, General EMC requirements

301 489-17 V1.3.2 for radio equipment

Tactic

c/o Hobbico, Inc.

2904 Research Road

Champaign, IL USA 61826

CE COMPLIANCE INFORMATION

FOR THE EUROPEAN UNION

The associated regulatory agencies of the following countries recognize the noted

certifications for this product as authorized for sale and use.

UK DE DK BG SE FI

EE LV LT PL CZ SK HU

RO SI AT IT ES PT IE

NL LU MT CY GR

TTX600 One Year Limited Warranty

*U.S.A and Canada

Tactic warrants this product to be free from defects in

materials and workmanship for a period of one (1) year from

the date of purchase. During that period, Tactic will, at its

option, repair or replace without service charge any product

deemed defective due to those causes. You will be required to

provide proof of purchase (invoice or receipt). This warranty

does not cover damage caused by abuse, misuse, alteration

or accident. If there is damage stemming from these causes

within the stated warranty period, Tactic will, at its option,

repair or replace it for a service charge not greater than 50%

of its then current retail list price. Be sure to include your

daytime telephone number in case we need to contact you

about your repair. This warranty gives you specifi c rights. You

may have other rights, which vary from state to state.

For service on your Tactic product, send it post paid and

insured to:

HOBBY SERVICES Ph: (217) 398-0007

3002 N. Apollo Dr., Suite 1 (9:00am – 5:00pm CST, M–F)

Champaign, IL 61822

E-mail: hobbyservices@hobbico.com

tacticrc.com

● This product is suitable only for people of 14 years and

older. This is not a toy!

● WARNING: CHOKING HAZARD - May contain small

parts. Keep away from children under 3 years. Please

retain packaging for future reference.

● No part of this manual may be reproduced in any form

without prior permission.

● The contents of this manual are subject to change without

prior notice.

● Tactic is not responsible for the use of this product.

19

Page 20

Loading...

Loading...