Page 1

INSTRUCTION

MANUAL

SPECIFICATIONS

Wingspan:

™

Wing

Area:

Weight:

Wing

Loading:

59.5 in

[1510mm]

2

430 in

[27.7 dm2]

3–3.25 lb

[1360 –1470 g]

16–17 oz/ft

[49– 52 g/dm2]

2

Length:

Radio:

Motor:

38.5 in

[980mm]

5-channel

radio system

40mm dia.

850kV outrunner,

40A ESC,

12x6 propeller

WARRANTY

Flyzone guarantees this kit to be free from defects in both

material and workmanship at the date of purchase. This warranty

does not cover any component parts damaged by use or

modification. In no case shall Flyzone’s liability exceed the

original cost of the purchased kit. Further, Flyzone reserves

the right to change or modify this warranty without notice.

In that Flyzone has no control over the final assembly or material

used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

© 2012 Hobbico®, Inc. All rights reserved. FLZA4020 FLZA4022 Mnl

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Academy of Model Aeronautics . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

REQUIRED FOR COMPLETION . . . . . . . . . . . . . . . . . . . . 3

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LiPo Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . . 3

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . . . . 5

Mount the Floats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION

Thank you for purchasing the Flyzone 1/10th-scale de Havilland

DHC-2 Beaver RTF/Tx-R. For anybody who enjoys fl ying fl oat

planes or who aspires to do so for the fi rst time, the Flyzone

Beaver is the perfect choice because it maneuvers and fl ies

off the water so well—you virtually can’t mess up a takeoff or

landing unless you try! Of course, the Beaver is almost just

as much at home on dry land as it is in the water. And with

the fl aps extended you can set your Beaver down on water

or on land as light as a feather.

Mount the Horizontal and Vertical Stabilizer . . . . . . . . 6

Install the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hook Up the Rudder and Elevator . . . . . . . . . . . . . . . . 8

Mount the Wings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hook Up the Flaps and Ailerons . . . . . . . . . . . . . . . . 11

FINAL FLIGHT PREPARATION . . . . . . . . . . . . . . . . . . . 12

Check the Control Throws . . . . . . . . . . . . . . . . . . . . . 12

Check the C.G.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MOTOR SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . 14

MOTOR / ESC OPERATION . . . . . . . . . . . . . . . . . . . . . . 15

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SAFETY PRECAUTIONS

PROTECT YOUR MODEL, YOURSELF AND OTHERS...

FOLLOW THESE IMPORTANT SAFETY PRECAUTIONS

1. Your de Havilland Beaver should not be considered a toy, but

rather a sophisticated, working model that functions very much

like a full-size airplane. Because of its performance capabilities,

the Beaver, if not assembled and operated correctly, could

possibly cause injury to yourself or spectators and damage

to property.

For the latest technical updates or manual corrections to the

Beaver, visit the Flyzone site at www.fl yzoneplanes.com. Open

the “Airplanes” link, then select the Beaver ARF. If there is

new technical information or changes to this model a “tech

notice” box will appear in the upper left corner of the page.

Academy of Model Aeronautics

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’ rights

and interests and is required to fl y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

2. You must assemble the Beaver according to the instructions.

Do not alter or modify the model, as doing so may result in an

unsafe or unfl yable model. In a few cases the instructions may

differ slightly from the photos. In those instances the written

instructions should be considered as correct.

3. You must use an R/C radio system that is in good condition.

All components must be correctly installed so that the model

operates correctly on the ground and in the air. You must

check the operation of the model and all components before

every fl ight.

4. If you are not an experienced pilot or have not fl own this type

of model before, we recommend that you get the assistance

of an experienced pilot in your R/C club for your fi rst fl ights.

If you’re not a member of a club, your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

5. While this kit has been fl ight tested to exceed normal

use, if the plane will be used for extremely high stress fl ying,

such as racing, or if a motor or battery larger than ones in

the recommended range is used, the modeler is responsible

for taking steps to reinforce the high stress points and/or

substituting hardware more suitable for the increased stress.

2

Page 3

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends on how

you build it; therefore, we cannot in any way guarantee the

performance of your completed model, and no representations

are expressed or implied as to the performance or safety of

your completed model.

Remember: Take your time and follow the instructions to

end up with a well-built model.

REQUIRED FOR COMPLETION

Other than a #1 and #2 Phillips screwdriver and a few drops

of non-permanent threadlocker (GPMR6060), no adhesives

or anything extraordinary is required to assemble the Beaver.

The RTF is fully equipped with a complete radio control

system, LiPo battery and charger, so no other accessories

are required, but the following items are required to complete

the Tx-R edition:

Transmitter

The Tx-R includes the Tactic™ TR624 6-Channel 2.4GHz

receiver, so you’ll need either a Tactic TX600 6-channel 2.4GHz

transmitter, or any other 5-channel (or more) transmitter

compatible with the Tactic AnyLink™ 2.4GHz radio adapter*.

Using the AnyLink allows any compatible transmitter to work

with the Tactic receiver.

❍ TX600 6-channel transmitter (TACJ2600)

❍ AnyLink radio adapter* (TACJ2000)

*In addition to the AnyLink radio adapter, some AnyLink-

compatible transmitters may also require additional adapter

cables. Visit Tx-Ready.com to see the AnyLink compatibility

chart or contact Product Support at the contact information

on this page.

LiPo Battery

The RTF edition of the Beaver includes a Flyzone 3S (11.1V)

1800mAh 20C LiPo battery and the same is recommended for

the Tx-R, but a 2100mAh battery is also an option for slightly

longer fl ight times (more about fl ying time on page 15).

❍ Flyzone 3S (11.1V) 1800mAh 20C LiPo battery

(HCAA6430)

❍ Flyzone 3S (11.1V) 2100mAh 20C LiPo battery

(HCAA6387)

replaced with a Deans Ultra Plug® male connector which will

require soldering (but is a simple task for those so equipped).

Charger

The RTF comes equipped with a Great Planes 3S LiPo

balancing Smart Charger, but the Tx-R requires a charger to

be purchased separately. The Smart Charger is a safe way to

charge your LiPo battery, but it’s very basic and just enough

to get you started. The Smart Charger charges at a rate of .8

Amps, so it will take at least one-and-a-half hours or more to

charge your battery. For those who have the RTF and wish

to upgrade their charger, or those with the Tx-R who must

purchase a charger anyway, the Duratrax® Onyx™ 235 AC/

DC Advanced Peak Charger (DTXP4235) is recommended.

The Onyx is perfect for 3S batteries used with the Beaver

and may be powered either by an external DC power source

(such as a 12V battery), or a 110V AC outlet. The Onyx also

has an adjustable charge rate to charge your batteries in as

little as a half-hour or less (depending on the condition of your

batteries and the manufacturer’s specifi ed charge rate). The

Onyx can also charge larger batteries and batteries other than

LiPos, so it is a versatile charger you can grow into. Finally, the

235 features an LCD digital display screen, so you can see

how much capacity it took to recharge the battery (required

for monitoring the condition of your batteries and calculating

how long you can fl y).

NOTE: For use with the Onyx 235, LiPo batteries that come

with a SuperTigre connector (such as the Flyzone batteries

recommended) require a banana plugs-to-SuperTiger charge

lead (SUPM0070). And batteries that come with a Deans Ultra

Plug connector require a Charge Lead with banana plugs/

Deans Ultra Plug Male charge lead (GPMM3148).

KIT INSPECTION

Before assembly, take an inventory of this kit to make sure

it is complete, and inspect the parts to make sure they are

of acceptable quality. If any parts are missing or are not of

acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or missing

parts, use the part names exactly as they are written in the

Contents list.

Flyzone Product Support Ph: (217) 398-8970 ext. 5

3002 N Apollo Drive Suite 1 Fax: (217) 398-7721

Champaign, IL 61822

E-mail: airsupport@fl yzoneplanes.com

ORDERING REPLACEMENT PARTS

Spare batteries may also be purchased and charged at home

ahead of time, eliminating the wait between fl ights for batteries

to charge at the fi eld.

NOTE: The Flyzone batteries suggested are equipped with

a SuperTigre® battery connector that fi t the connector on

the ESC. If using a different LiPo battery that has a Deans®

connector, a SuperTigre-to-Deans adapter (SUPM0040) will

be required, or the battery connector on the ESC may be

Replacement parts for the Flyzone de Havilland Beaver RTF/

Tx-R are available using the order numbers in the Replacement

Parts List that follows. The fastest, most economical service

can be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Flyzone web site at www.

fl yzoneplanes.com. Click on the Storefront icon at the top

of the page to load the Flyzone Dealer Locator. Follow the

instructions provided on the page to locate a U.S., Canadian or

International dealer.

3

Page 4

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721, but

full retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax. If

ordering via fax, include a Visa® or MasterCard® number and

expiration date for payment.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as listed in the

Replacement Parts List. Payment by credit card or personal

check only; no C.O.D.

If additional assistance is required for any reason contact

Product Support by e-mail at productsupport@fl yzoneplanes.

com, or by telephone at (217) 398-8970.

REPLACEMENT PARTS LIST

ORDER NO. DESCRIPTION

FLZA6265

FLZA6266

FLZA6267

FLZA6268

FLZA6269

FLZA6270

FLZA6271

FLZA6272

FLZA6273

FLZA6274

FLZA6275

FLZA6276

Fuselage Set

Wing Set

Horizontal Stab

Vertical Fin

Main Landing Gear

Tail Wheel Set

Cowl

12x6 Propeller

Spinner

Prop Adapter

Float Set

Float Brackets

ORDER NO. DESCRIPTION

FLZA6277

FLZA6278

FLZA6279

FLZA6280

FLZA6281

FLZA6282

FLZA6283

FLZA6284

FLZA6285

FLZA6024

TACJ2600

TACL0624

GPMM3318

Water Rudders

Wing Clips

Hatch Set

41-19-850 Motor

40 Amp ESC

Main Wheels

Servo

Wing Strut Set

Decal Sheet

Flyzone LiPo Battery 3S 11.1V 1800mAh 20C

Tactic TTX600 6Ch SLT 2.4GHz Radio System No Servos

Tactic TR624 6-Channel SLT 2.4GHz Receiver

Great Planes AC/DC 3S LiPo Balancing Smart Charger

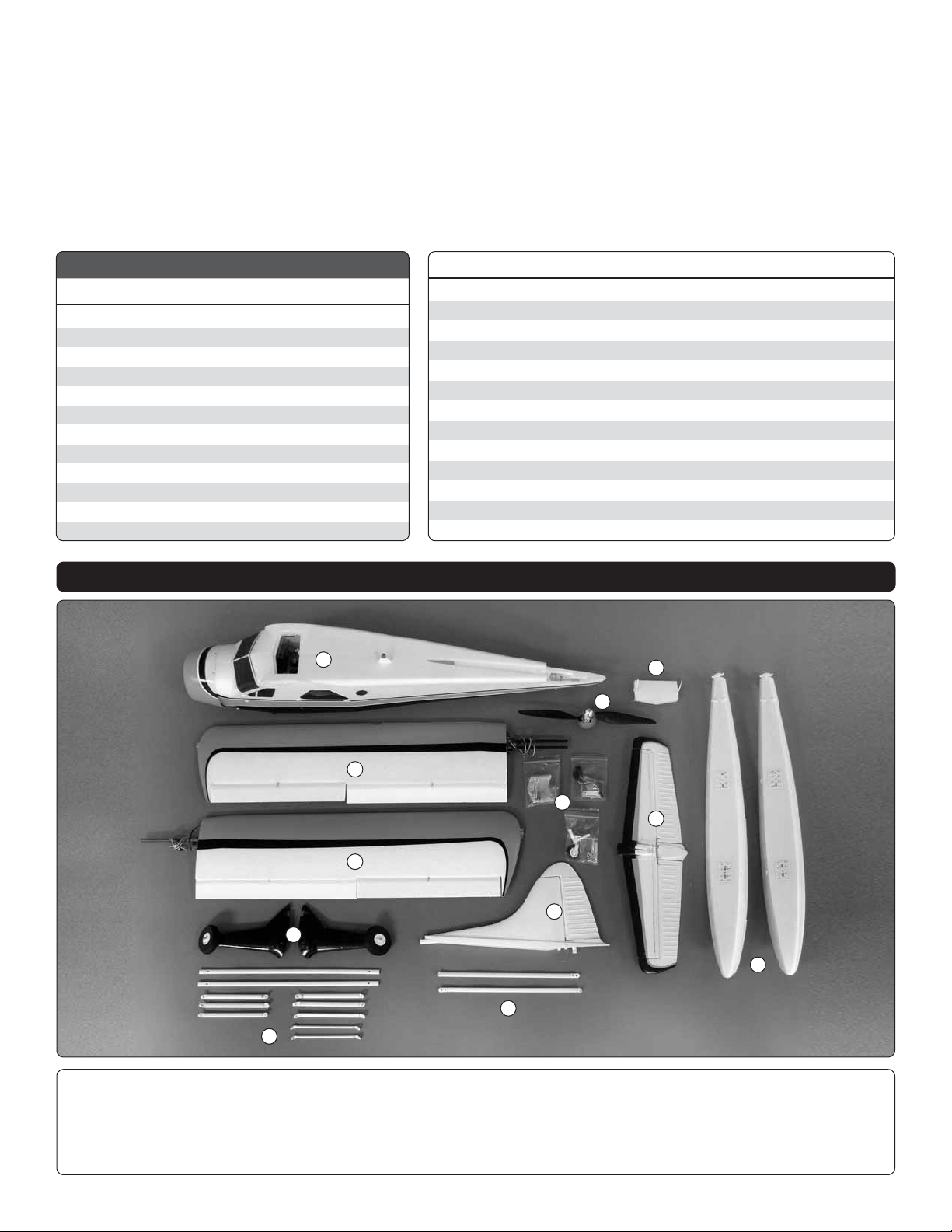

CONTENTS

1

9

10

1.

Fuselage

2.

Left Wing

3.

Right Wing

4.

Main Landing Gear

2

8

11

3

7

4

12

6

75

5.

Float Brackets

6.

Wing Struts

7.

Vertical Stabilizer

8.

Hardware

4

9.

Propeller/Spinner Assembly

10.

Top Hatch

11.

Horizontal Stabilizer

12.

Floats

Page 5

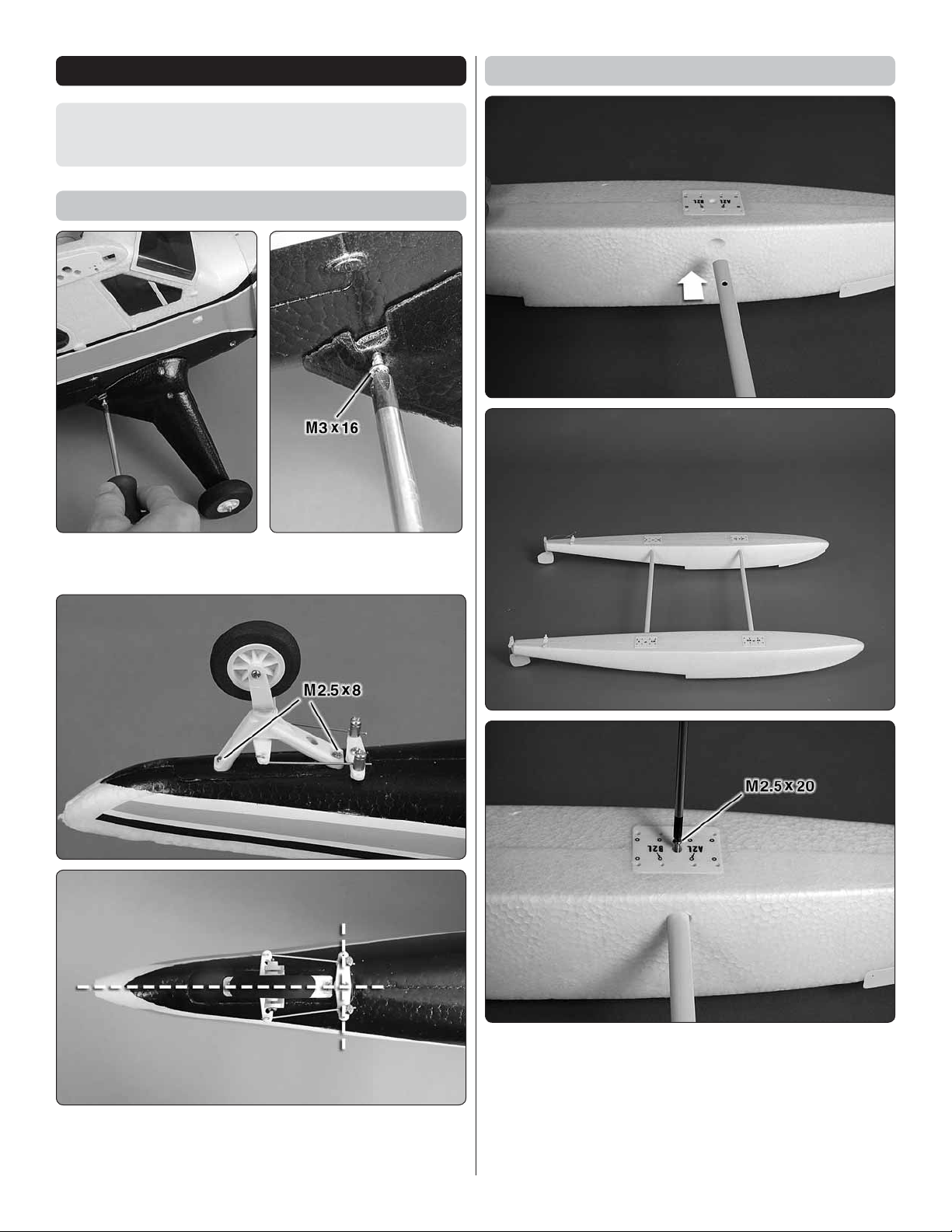

ASSEMBLY

NOTE: This instruction manual applies to both the RTF

and Tx-R editions of the de Havilland Beaver. If assembling

the RTF edition, simply skip steps that do not apply.

Mount the Landing Gear

Mount the Floats

1. Use a #2 Phillips screwdriver to fasten both main landing

❏

gears to the fuselage with three M3x16 screws in each side.

2. Mount the tail gear with two M2.5x8 screws, then fasten

❏

the pushrod wires as shown. Make sure the tail wheel is

perpendicular with the steering arm.

1. Connect the fl oats to each other with the horizontal struts

❏

and four M2.5x20 machine-thread screws.

5

Page 6

2. Use eight M2.5x8 screws to fasten the braces to the

❏

fl oats, matching the labels printed or molded into the end of

each brace to each mount location on each fl oat.

4. Connect a small rubber band to each fl oat and water

❏

rudder as shown.

5. Fasten the wire hooks on the end of each rudder line

❏

to the connectors in the steering arm. As best as you can,

adjust the tension in the lines to center the water rudders—the

rudders don’t have to be perfectly centered, because over

time they may drift anyway, and the rudders are forgiving and

overall water handling is easy.

3. Fasten the fl oat braces to the fuselage with one M3x16mm

❏

screw and two M2.5x8mm screws in each side of the fuselage.

Mount the Horizontal

and Vertical Stabilizer

1. Fasten the vertical stabilizers to each end of the horizontal

❏

stabilizer (stab) with M2x6 screws.

6

Page 7

2. Connect the elevator pushrod to the bottom hole in the

❏

elevator horn as shown.

3. Rotate the stab upward and key it into the fuselage.

❏

4. Key the rudder torque rod down into the receptacle while

❏

fi tting the vertical stabilizer (fi n) into the fuselage. Tightly press

the assembly down into position.

7

Page 8

5. Secure the stab and fi n with the M3x22 screw.

Centered

ON

Down

❏

Install the Battery

2. Cut a 3" [76mm] strip from the softer, “loop” side and

❏

attach it to the battery so the larger “discharge” wires will be on

the right side as shown. (This will position the wires opposite

the receiver for a better fi t.)

Hook Up the Rudder and Elevator

1. Turn on the transmitter, lower the throttle stick all the

❏

way, center the trims and make sure the throttle channel in

your transmitter is in the “reverse” position.

1. Cut two 1" [25mm] strips from the rougher, “hook” side

❏

of the included adhesive-back hook-and-loop material. Apply

the strips inside the fuselage where shown and press them

down tightly so they adhere.

2. Connect the battery to the ESC. If all is working properly,

❏

the ESC will send three, short, electrical pulses to the motor

causing it to chime three times (“ 1- 2- 3”) followed by a longer,

8

Page 9

single, lower tone beep (“BEEEP”) followed by a shorter, higher

tone beep (“beep”). If the chimes and beeps do not sound in

this manner refer to “MOTOR/ESC OPERATION” on page

15 to setup the transmitter and ESC correctly.

A magnetic screwdriver, or a small magnet stuck to a screw

driver to make it magnetic, will be helpful for the next couple

of steps.

5. Reinstall the screw, but do not tighten yet. With the

❏

transmitter and receiver on, center the elevator and tighten

the screw to lock the pushrod down.

3. Remove the screw from the connector on the elevator

❏

servo arm.

6. Repeat the same procedure for the rudder, making

❏

sure it is centered. Lock the pushrod down with the screw

and threadlocker.

7. Disconnect the battery and turn off the transmitter.

❏

Mount the Wings

4. Lightly wet the threads of the screw with threadlocker.

❏

1. Fasten the wing clips to both sides of the fuselage with

❏

four M3x10 screws.

9

Page 10

3. Mount the left wing the same way.

❏

4. Mount the top of each wing strut to the wing with a

❏

M2.5x8 machine-thread screw.

2. Guide the wires from the right wing into the fuselage, then

❏

slide the wing joiner tube and the fl ap pushrod wire through

the corresponding holes. Also guide the fl ap pushrod wire into

the screw-lock connector on the fl ap servo. Guide the joiner

tube through the hole in the left side of the fuselage, then

tightly “CLICK!” the wing onto the wing clips.

5. Mount the bottom of each strut to the fuselage over the

❏

fl oat strut (or over the main landing gear) with a M3x16 screw.

10

Page 11

Hook Up the Flaps and Ailerons

1. Connect the wing lighting wires and the aileron servo

❏

wires to the lighting and fl ap wiring harnesses coming from

the receiver.

2. Turn on the transmitter and install and connect the battery.

❏

Then install and secure the hatch.

3. Move the dial or switch on your transmitter that controls

❏

the fl aps to the “up” position, rotating the fl ap servo arm

clockwise. Remove the screw in the fl ap servo arm, wet the

threads with threadlocker, and then reinstall and tighten the

screw so the fl aps will be in their fully retracted (“up”) position.

11

Page 12

FINAL FLIGHT PREPARATION

FULL

THROTTLE

RUDDER

MOVES

RIGHT

ELEVATOR

MOVES DOWN

RIGHT AILERON MOVES UP

LEFT AILERON

MOVES DOWN

4-Channel Radio Set Up (Standard Mode 2)

Check the Control Throws

Because the servos and pushrods are factory-installed

the control throws should already be correct, but because

of the effect the control throws can have on a model, it’s

always a good idea to check them anyway.

4. With the system still on, make sure the ailerons are

❏

centered and aligned with the wing tips. If necessary, apply a

few clicks of aileron trim to get the ailerons centered. If more

than a few clicks of trim are required, or if you cannot get both

ailerons neutralized, a small screwdriver may be used to pop

off one or both fl ap servo covers to access the pushrods.

Adjust the pushrods in the connectors to get the ailerons

centered. When fi nished, replace the cover, press into position,

and hold in place with tape or a dab of glue.

1. Confi rm that the controls are responding in the correct

❏

direction according to control inputs from the transmitter. If

necessary, use the servo reversing program in your transmitter

to change the servo direction of any controls that are moving

the wrong way.

2. If your de Havilland Beaver is confi gured with wheels,

❏

use a small box or something similar to prop up the bottom

of the fuselage under the tail so the wings and stab are level

(or nearly level).

3. Measure and set the control throws according to the

❏

measurements below. The throws are measured at the widest

part (front-to-back) of each surface.

12

Page 13

Recommended Control Surface Throws

More Control Throw

Pushrod

Farther Out

Pushrod

Farther In

Less Control Throw

64 mm

51mm

2-1/2"

2"

English Metric

INCHES

ELEVATOR

Up

7/16"

Down

7/16"

LOW RATEHIGH RATE

Up

5/16"

Down

5/16"

4. If any of the control throws require adjustment use the

❏

programming in your transmitter to increase or decrease the

throws accordingly. If the programming isn’t enough or if your

radio doesn’t have adjustable throws, the pushrod connectors

on the servo arms can be relocated in different holes inward

or outward to increase or decrease the throw—moving the

pushrods inward on the servo arms decreases the throw and

moving the pushrods outward on the servo arms increases

the throw.

AILERONS

RUDDER (R&L)

FLAP

Recommended Control Surface Throws

MILLIMETERS

ELEVATOR

11mmUp11mm

7/16"

Down

AILERONS

RUDDER (R&L)

FLAP

Recommended Control Surface Throws

DEGREES

ELEVATOR

Up

10 º

11mm

Down

10 º

3/8" 3/8"1/2" 1/2"

7/8" 7/8"1-1/4" 1-1/4"

LOW RATEHIGH RATE

Up

8mm

10 mm 10 mm13 mm 13 mm

22 mm 22 mm32mm 32mm

LOW RATEHIGH RATE

Up

8º

Down

8mm

Down

8º

Check the C.G.

Same as the control throws, the C.G. has a great effect on how

every model fl ies, so do not skip this procedure. If the model

is tail-heavy it may be too instable and respond too quickly to

the controls. If the model is nose-heavy it may be too stable

and not respond fast enough—in either case possibly causing

a crash. Do not overlook this important procedure.

AILERONS

RUDDER (R&L)

FLAP

34º

14º 14º20 º 20 º

18º 18º26 º 26 º

13

Page 14

1. Mark the forward and aft C.G. limits on both sides of

❏

the bottom of the wing 2" and 2-1/2" [51mm and 64mm] back

from the leading edge where shown—using narrow strips of

tape will allow you to feel the marks when lifting the model

with your fi ngertips to balance.

3. Install the battery, battery hatch and cabin hatch. At

❏

this point the Beaver must be in ready-to-fl y condition with

everything attached and installed including the fl oats or wheels

and battery and propeller.

4. Lift the model by your fi ngers between the lines indicating

❏

the balance range. As long as the Beaver sits level with your

fi ngers on the forward or aft lines or anywhere between the

lines it is properly balanced and ready to fl y. If you have to

move your fi ngertips outside the lines the Beaver is out of

balance and should not be fl own. If necessary, add squares

of stick-on lead to the nose or tail to get the Beaver to balance

within the specifi ed range.

2. Mount the propeller and spinner.

❏

MOTOR SAFETY PRECAUTIONS

Failure to follow these safety precautions may result in

severe injury to yourself and others.

● Seek the assistance of an experienced pilot if new to

electric motors.

● Wear safety glasses whenever in the proximity of a

spinning propeller.

● Do not operate the motor in an area of loose gravel or

sand; the propeller may throw such material in your face

or eyes.

● Keep spectators as well as your own face and body out

of the plane of rotation of the propeller.

14

Page 15

● Keep all loose clothing, long hair or any other loose objects

such as pencils or screwdrivers that may fall out pockets

away from the propeller.

MOTOR / ESC OPERATION

Turning on the transmitter and running the motor is intuitive

for most pilots who already have experience with electric

motors, but for those who may have little or no experience

with electric motors here are basic operating instructions for

the ESC and motor:

When ready to fl y and running the motor, fi rst turn on the

transmitter and make sure the throttle stick is all the way down.

Always securely hold onto the model when connecting the

battery. The propeller should not turn, but expecting it to do so

anyway will prevent an accident or injury. Connect the battery

to the ESC. The ESC will send three short electrical pulses to

the motor, causing it to chime three times (“ 1- 2- 3”) followed

by a longer, single, lower tone beep (“BEEEP”), followed by

a shorter, higher tone beep (“beep”). The model is ready to

fl y and the propeller will turn when the throttle is advanced.

If the transmitter is not turned on before the battery and

ESC are connected (so the receiver is not receiving a signal)

the motor will still chime three times (“ 1- 2- 3”), but then it

will sound consecutive, higher tone beeps (“beep,” “beep,”

“beep,”….) until the transmitter is turned on at which time it

will emit a single, lower tone beep (“BEEEP”) followed by the

single higher tone beep (“beep”).

If, when the battery is connected to the ESC the throttle stick

is not all the way down the motor will beep rapidly (“beep beep

beep beep beep…”) until either the battery is disconnected or

the throttle stick is returned to the off position at which time it

will emit a single, lower tone beep (“BEEEP”) followed by the

single higher tone beep (“beep”).

FLYING

The Beaver fl ies mostly the same as any similar-type, high-wing

airplane, but you may fi nd that the roll rate is a little slower.

This suits the Beaver well as it is a scale-like, STOL (Short

TakeOff and Landing) craft. Just give yourself more time and

altitude before trying your fi rst full roll.

The only peculiarity arises when the fl aps are extended—if you

extend the fl aps too soon before the Beaver has lost enough

fl ying speed the nose will pitch up. The way to avoid this is

fi rst by making sure you have given the Beaver enough time

to slow after cutting the throttle. You can also roll in the fl aps

gradually. If you have a computer radio you could also mix in

some down elevator with fl aps. In any regard, once the Beaver

reaches “equilibrium” and has initiated a gliding descent the

nose will resume a normal, downward glide angle. Similarly,

when powering up the throttle with the fl aps extended the

nose will pitch up, so be ready to counter with down elevator.

Unless weather conditions are terrible, you should have no

trouble fl ying the Beaver from either rough or calm water.

The water rudders direct the Beaver well and they don’t have

to be perfectly centered to be effective (so don’t spend an

exorbitant amount of time on the work bench working on

them!). The Beaver turns more tightly at idle speeds, so if you

need to do a U-turn throttle back to bring the Beaver around.

At higher speeds during a takeoff run the water rudders have

the correct amount of effectiveness to steer the Beaver on its

intended path. Takeoffs can be long and graceful or short and

steep—either way the fl oats handle the water well. If the winds

are really high the Beaver can still be fl own from water, but

avoid turning it directly across the wind. Otherwise, the wind

can get under the wing and fl ip the Beaver over. In the air, the

only effect of the fl oats is that the Beaver fl ies slightly slower.

Flying “normally” (using half-throttle for general cruising and

full-throttle only when required) the Beaver consumes about

200mAh/minute for recommended fl ight times of about 7

minutes with an 1800 mAh battery and about 8.5 minutes with

a 2100 mAh battery. Flying more aggressively using higher

throttle settings, the current draw increases closer to 260mAh/

minute for recommended fl ight times of 5.5 minutes with an

1800 mAh battery and 6.5 minutes with a 2100mAh battery.

To fi nd out for yourself how long you can fl y, set your timer

to a conservative 5 minutes. Fly until the timer sounds, then

land. Use a charger with a digital display to fi nd out how

much capacity it took to recharge the battery (indicating how

much capacity was used). To avoid over discharging your

LiPos use only 80% of your battery’s capacity, so multiply

your battery’s capacity by .8 to fi nd out how much you have

available. Compare the capacity used to 80% of your battery’s

capacity and adjust your fl ight time accordingly.

For example: If using the recommended 1800mAh battery,

your target capacity to use for a fl ight is 1440 mAh (1800mAh x

.8 = 1440 mAh). If you fl y for fi ve minutes and it takes 1000mAh

to recharge your battery, you still have 440mAh to go before

you should land, so adjust your timer to increase your fl ight

time accordingly until you reach your 1440mAh target. (You

could also divide 1000 mAh by fi ve minutes to fi gure a current

consumption rate of 200mAh/minute. Divide 1440mAh by

200 mAh/minute to conclude that you can fl y for 7.2 minutes

[7 min. 12 sec.]—but round down to 7 minutes.)

Taken verbatim from our fl ight log book… “Flying the Beaver

from water with fl oats can be described with many adjectives

including astonishing, easy, fun, smooth, remarkable, etc.”

15

Page 16

It’s also a great idea to use a LiPo battery checker (HCAP0275)

to check the battery before each fl ight (to make sure you

haven’t inadvertently grabbed a discharged battery) and to

check the battery after fl ight to make sure you haven’t over

discharged your battery by fl ying too long. A safe, conservative,

minimum voltage is 3.65V – 3.7V per cell right after a fl ight.

REPAIRS

The Beaver is made from injection-molded EPO (expanded

polyolefi n) foam which can be glued with just about anything.

Most people use regular CA. With CA no clamping is required,

but some prefer softer, more fl exible adhesives such as white

glue or canopy glue. These will require clamps or tape to hold

the parts together while the glue dries.

One fi nal note about fl ying your model. Have a goal or fl ight

plan in mind for every fl ight. This can be learning a new

maneuver(s), improving a maneuver(s) you already know,

or learning how the model behaves in certain conditions

(such as on high or low rates). This is not necessarily to

improve your skills (though it is never a bad idea!), but more

importantly so you do not surprise yourself by impulsively

attempting a maneuver and suddenly fi nding that you’ve run

out of time, altitude or airspeed. Every maneuver should be

deliberate, not impulsive. For example, if you’re going to do a

loop, check your altitude, mind the wind direction (anticipating

rudder corrections that will be required to maintain heading),

remember to throttle back at the top, and make certain you

are on the desired rates (high/low rates). A fl ight plan greatly

reduces the chances of crashing your model just because

of poor planning and impulsive moves. Remember to think.

Parts damaged beyond repair can be purchased separately.

The full replacement part list is printed in the front of the manual

on page 4. Often though, parts can be repaired and you can

get your Beaver back into the air with a little glue and ingenuity.

Have a ball! But always stay in control

and fl y in a safe manner.

GOOD LUCK AND GREAT FLYING!

Name

Address

City, State, Zip

This model belongs to:

AMA Number

Phone Number

16

Loading...

Loading...