Page 1

Manual Supplement

Refer to this Instruction Manual Supplement

for initial assembly of your Calypso ARF.

After completing the assembly steps in

this supplement, continue with the twentypage RTF/Rx-R /Tx-R Calypso instruction

manual booklet.

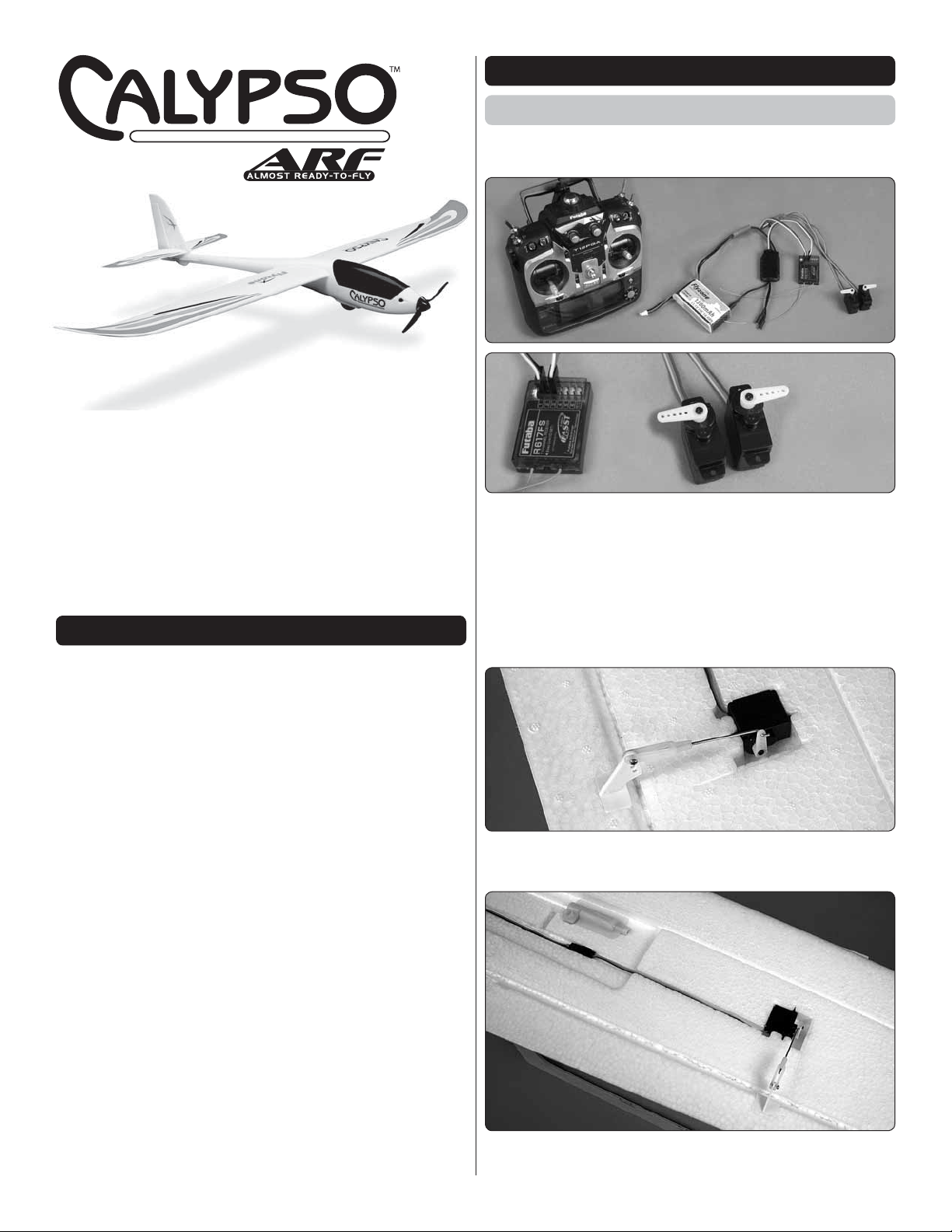

REQUIRED FOR COMPLETION

In addition to the items listed in the instruction manual for the

Rx-R edition, the Calypso ARF also requires the following items:

❍ 18A ESC (Electronic Speed Controller) (FLZA6011)

❍ C28-30 1300kV brushless motor (FLZA6012)

❍ Spinner, folding propeller set (FLZA6006)

❍ (4) Calypso micro servos (FLZA6013), or any of the

Futaba® micro servos that have the same case as the

S3117 such as the following:

◗ S3117 (FUTM0417)

◗ S3157 (FUTM0657)

◗ S3156 (FUTM0656)

❍ (2) 18"–24" [460 mm – 610 mm] servo wire extensions

for aileron servos (HCAM2200 for Futaba J)

❍ The ailerons may be mixed electronically through the

mixing in your transmitter, or “hard-wired” together into

the same channel with a Y-harness (FUTM4130).

❍ The Calypso may be assembled with just about any kind

of glue including foam-safe or regular CA, but for gluing

in the servos something thicker and fl exible is preferred

such as Zap Goo or similar (PAAR3200).

❍ A 1.5mm Allen wrench is required for tightening the set

screws in the folding propeller hub (DTXR0288).

❍ Non-permanent threadlocker for all metal-to-metal screws

(GPMR6060)

ASSEMBLY

Assemble the Wings

First, let’s center the aileron servo arms before gluing the

servos into the wing…

1. Temporarily connect the aileron servos and ESC to your

❏

receiver and turn on your transmitter. Making sure the trims

on your transmitter are centered, connect the battery to the

ESC. If necessary, remove and re-mount the servo arms so

they will be perpendicular as shown. Be certain to replace

the servo arm screws.

You may work on both wings simultaneously, or do one

wing at a time.

2. Without using any glue, temporarily fi t the servos into the

❏

pockets in the wing. Hook up the ailerons with the hardware shown.

3. Connect a 18" – 24" [460mm – 610mm] servo extension

❏

to the aileron servo wires and secure the connection with tape,

Page 2

heat shrink tubing or a dab of glue. Lay the servo wires down

inside the channels.

4. If you plan to hook up the optional fl aps, it will be a

❏

little easier to cut the fl ap servo openings in the bottom wing

covers and fi t the fl ap servos at this time, so go ahead and

do so—but fi rst refer to the illustration at step 13 on page 11

of the Calypso instruction manual for the correct orientation

of the fl ap servos and servo arms. If unsure whether or not

you will be using fl aps, the servo installation and hookup is

easy enough to retrofi t later (as illustrated on page 8 of the

instruction manual).

6. Glue the aileron servos (and fl ap servos if installed) into

❏

position—thick or medium CA is suitable, but if ever necessary,

the servos will be easier to extract later if something more

fl exible such as Zap Goo or similar is used.

5. Without using any glue, test-fi t the bottom wing cover to

❏

the wing. Make sure the cover lays all the way down fl at into

the cavity and make any adjustments necessary.

7. Glue the bottom wing cover into position—thick or medium

❏

CA is okay here, but use care not to allow any glue to leak into

the channel or into the clamp for the joiner tube. If necessary,

use tape or weights to hold the cover down until the glue

hardens.

8. Glue the spars and optional aileron pushrod covers into

❏

position. Also apply a strip of white or clear tape over the

channel for the aileron servo wire.

2

Page 3

Assemble the Fuselage

Non-permanent threadlocker

should be used on all screws

that thread into metal such as

the motor mount screws, the

set screws in the propeller hub

and the screws that secure the

spinner—a large amount of

threadlocker is not required—

just enough to “wet” the fi rst few

threads.

1. Guide the motor wires through the oval hole in the bottom

❏

of the motor mount. Then, mount the motor with the two 3 x

5mm screws (don’t forget to use threadlocker on the screws).

2. Fasten the propeller hub onto the motor shaft using a

❏

1.5mm hex wrench to tighten the set screws. Then, mount the

spinner with the 3 x 12mm screws.

3. Connect the ESC to the motor and mount the ESC to the

❏

inside of the fuselage with strips of the included adhesive-back

hook-and-loop material. Note: If, while running up the motor

later, the propeller turns backward, simply switch any two of

the three motor wires with each other to make the motor turn

the other direction.

3

Page 4

4. Apply a strip of the rougher, "hook-side" of the hook-

❏

and-loop material to the bottom of the radio compartment for

the battery. Apply thin or medium CA all the way around the

edges of the strip to make certain it is adhered permanently.

5. Same as was done with the aileron servos, temporarily

❏

power up the elevator and rudder servos with your radio system

and make sure the arms are perpendicular.

6. Install the pushorods through the guide tubes in the

❏

fuselage. Then, connect the pushrods to the outer holes in

the servo arms. Glue the servos into position.

7. Thread the clevises onto the pushrods until the end of

❏

each pushrod protrudes through the clevis just enough to

become visible.

Congratulations! Your Calypso ARF

is now a Calypso Rx-R and you may

continue assembly using the full Calypso

instruction manual.

™

Champaign, Illinois (217) 398-8970

E-mail: airsupport@hobbico.com

FLZA3006 MnlEntire Contents © 2012 Hobbico,® Inc. All rights reserved.

4

Loading...

Loading...