FLY SYNTHESIS

02

15/02/11

Placard updated

C. Cosatto

C. Cosatto

C. Cosatto

01

20/12/10

Propeller auto pitch contr.

C. Cosatto

C. Cosatto

C. Cosatto

00

18/11/10

New manual issue

C. Cosatto

C. Cosatto

C. Cosatto

Num.

Date

Description

Issued

Verified

Approved

REVISION

FlySynthesis s.r.l. Reserves in terms of law the exclusive ownership of this manual and also forbids the whole or partial reproduction of it.

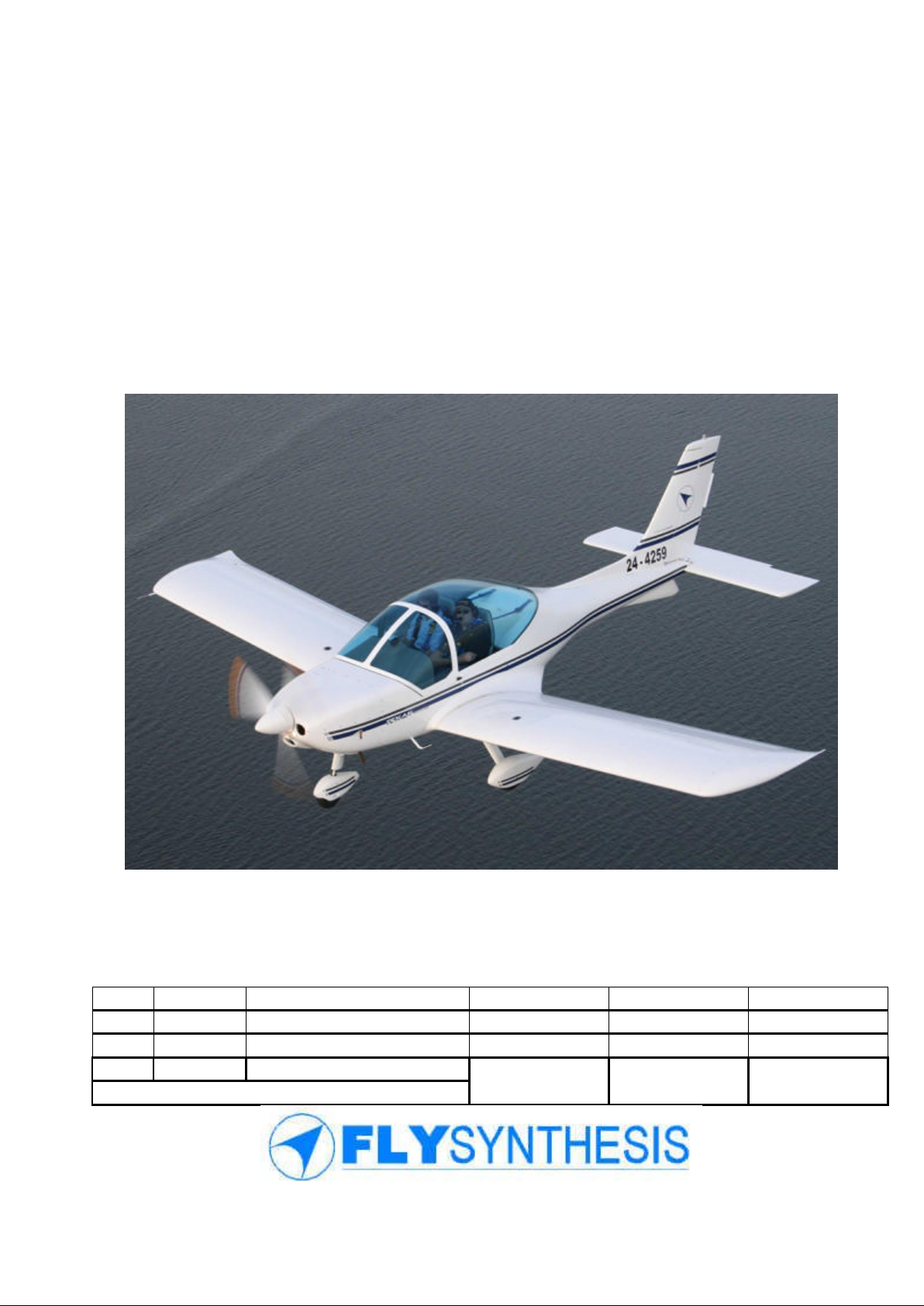

TEXAN TOP CLASS 580 ISR

MAINTENANCE MANUAL

(For Rotax 912 ULS)

2

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 2 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

WARNING

Procedures or instructions that if not followed correctly may result in injury or

death

CAUTION

Procedures or instructions that if not followed correctly may result in damage to

the aircraft or its parts

SCOPE

This manual contains the necessary information for safe and efficient Maintenance of the

FLYSYNTHESIS TEXAN TOP CLASS 580 ISR.

NOTE

This manual may be revised in the future and pages/or sections re-issued in part or whole.

Revisions will be available on the Fly Synthesis website www.flysynthesis.com. Any revisions

and/or sections should be printed and replaced in the manual at the earliest possible time for

flight safety. The revisions added to the manual should be logged and recorded in the table

under log of Revisions of this manual, by the owner/user.

DEFINITIONS

Definitions used in this handbook such as WARNING, CAUTION and NOTE are employed

in the following context.

NOTE: Procedures or instructions that is essential to highlight

INTELLECTUAL PROPERTY

The data and information contained in this document is the property of FLYSYNTHESIS

SRL. This document may not be reproduced or transmitted to a third party, in any form or by

any means. Any unauthorised copy or distribution is illegal as per international agreements

relating to property rights.

THIS AIRCRAFT WAS MANUFACTURED IN ACCORDANCE WITH THE FOLLOWING

LIGHT SPORT AIRCRAFT AIRWORTHINESS STANDARDS BCAR Section S, CS-VLA,

F2279, F2295 AND F2483 AND DOES NOT CONFORM TO STANDARD CATEGORY

AIRWORTHNESS REQUIREMENTS.

3

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 3 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

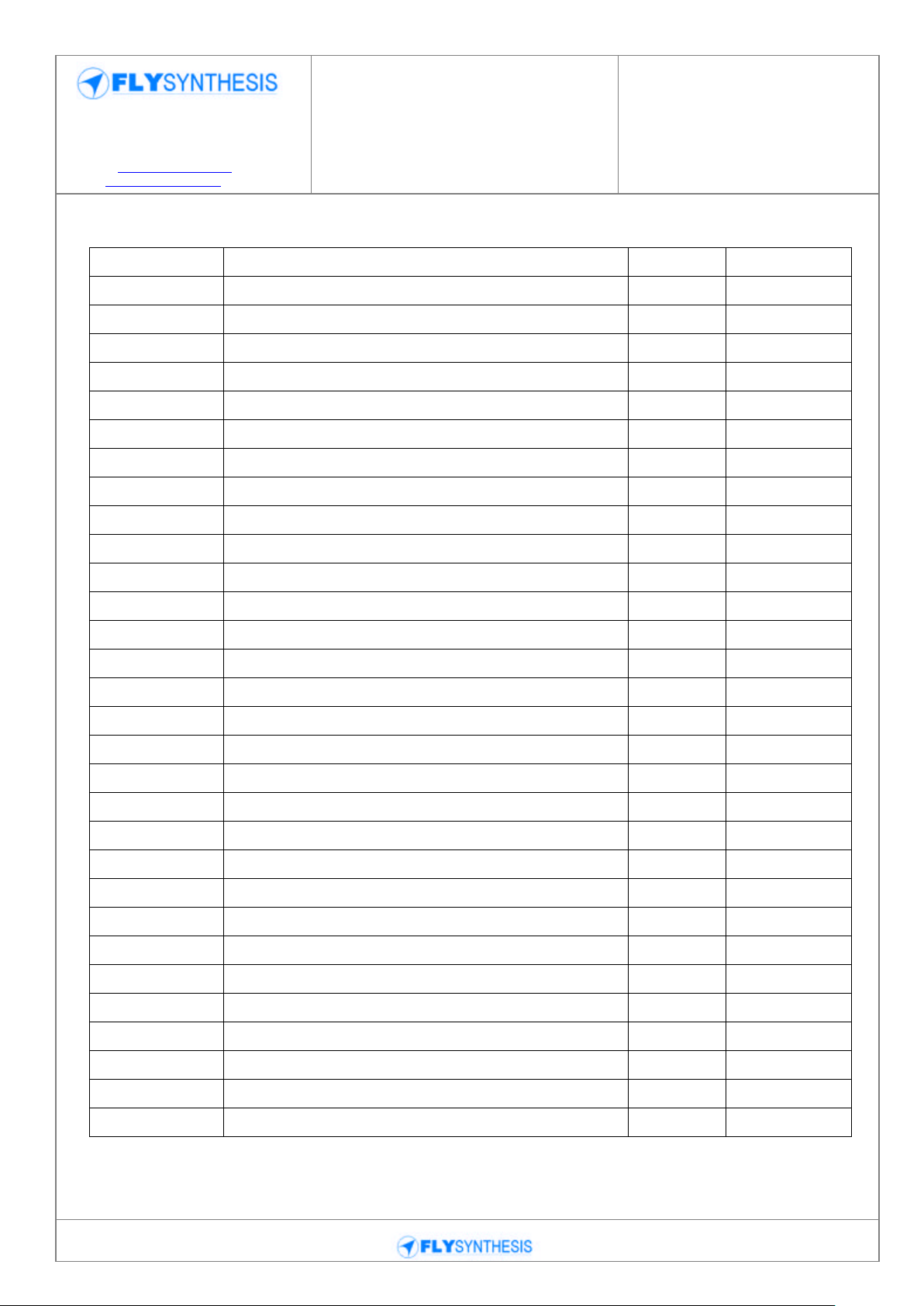

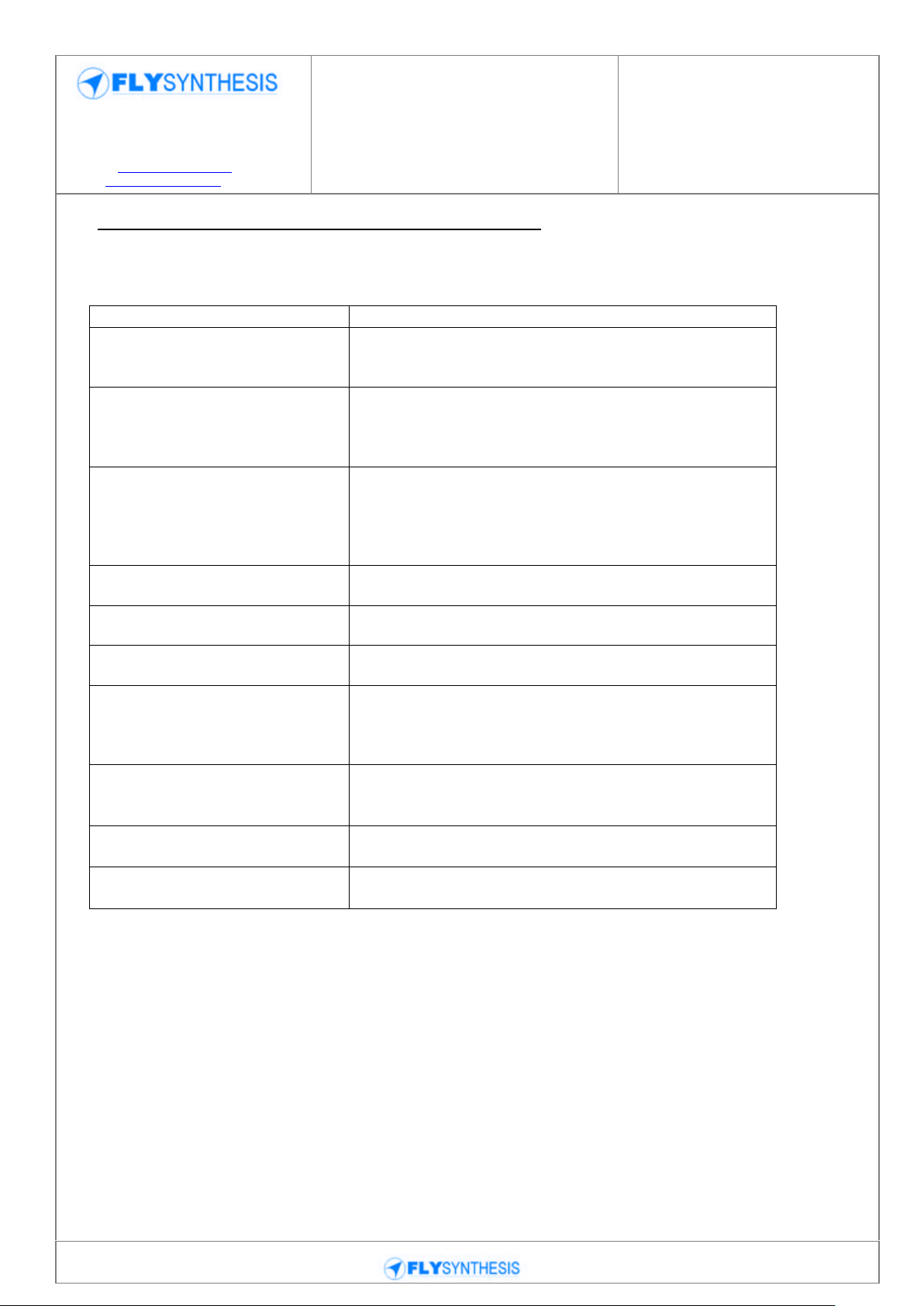

Revision No.

Revision

Date

Signature

01

Propeller automatic pitch control system

20/12/10

Cosatto C.

02

Limitations placard updated

15/02/11

Cosatto C.

LOG OF REVISIONS

4

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 4 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

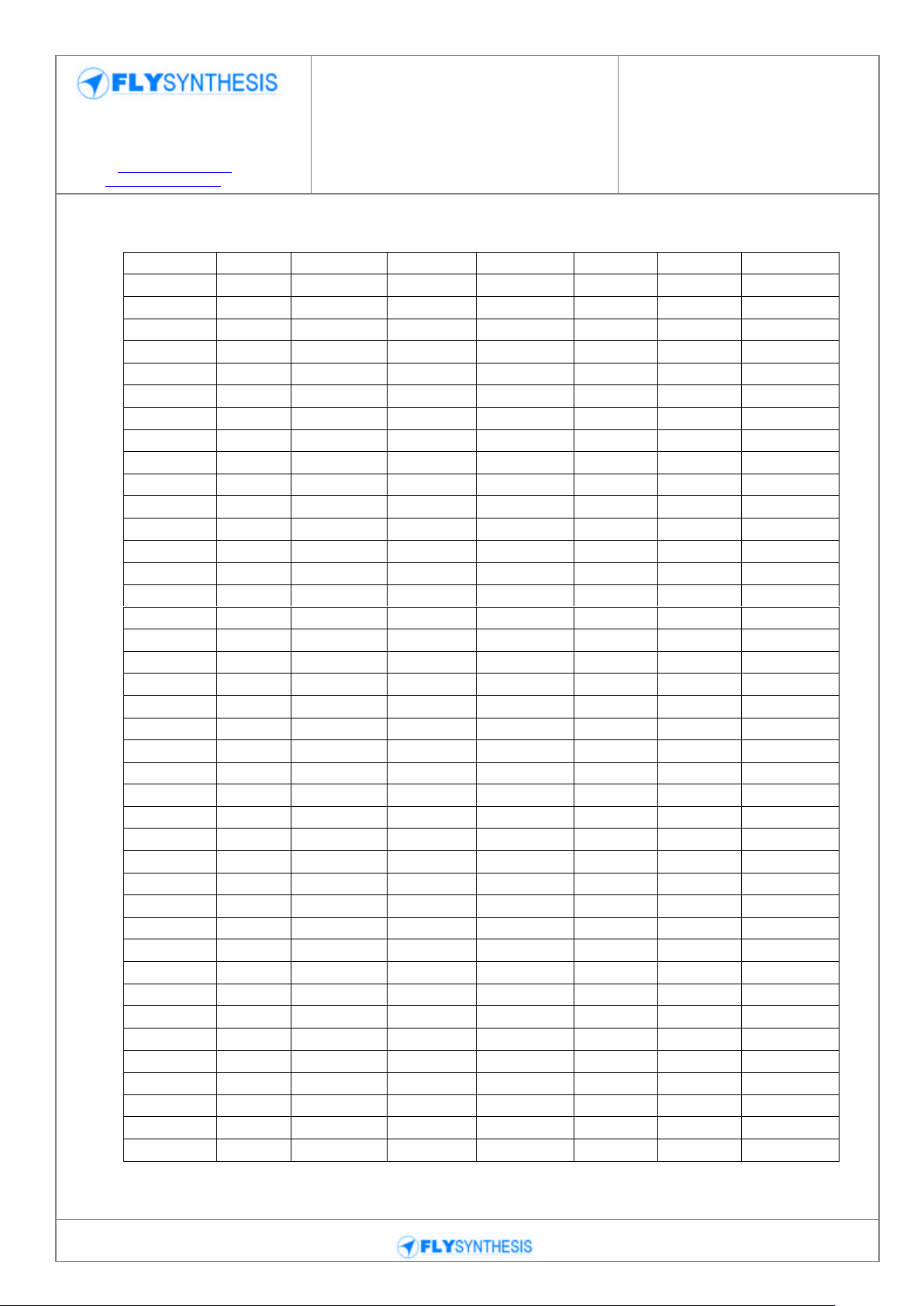

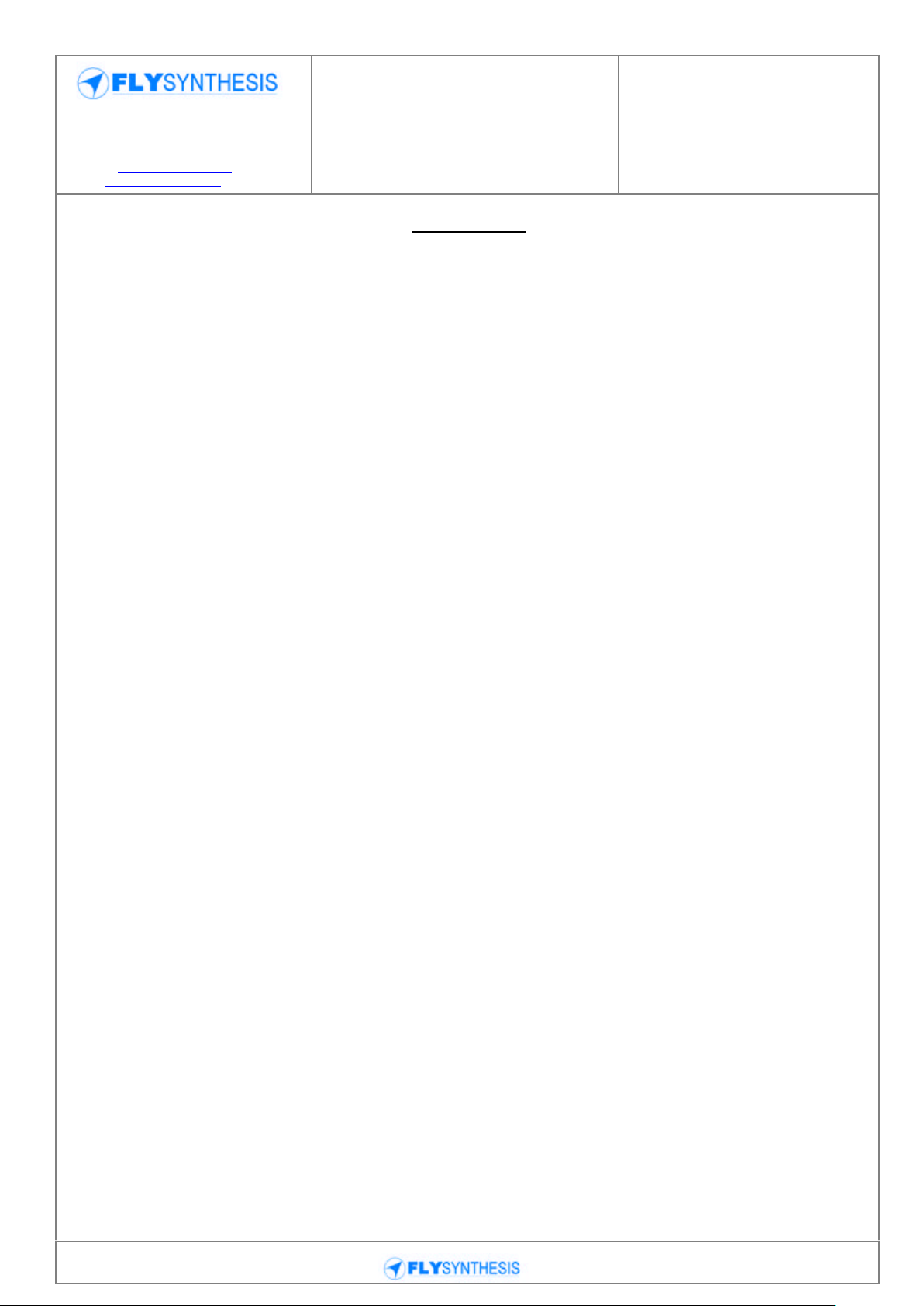

Section

Page

Date

Revision

Section

Page

Date

Revision

-

01

18/11/10

0 9 41

18/11/10

0

-

02

18/11/10

0 9 42

18/11/10

0

-

03

18/11/10

0 9 43

18/11/10

0

-

04

18/11/10

0 9 44

18/11/10

0

-

05

18/11/10

0

10

45

18/11/10

0

-

06

18/11/10

0

10

46

18/11/10

0

1

07

18/11/10

0

11

47

18/11/10

0

1

08

18/11/10

0

11

48

18/11/10

0

1

09

18/11/10

0

11

49

18/11/10

0

1

10

18/11/10

0

12

50

18/11/10

0

2

11

18/11/10

0

12

51

21/12/10

1

2

12

18/11/10

0

13

52

18/11/10

0

2

13

18/11/10

0

13

53

18/11/10

0

3

14

18/11/10

0

13

54

18/11/10

0

3

15

18/11/10

0

14

55

18/11/10

0

3

16

18/11/10

0

14

56

18/11/10

0

3

17

18/11/10

0

14

57

18/11/10

0

4

18

18/11/10

0

14

58

18/11/10

0

4

19

18/11/10

0

14

59

18/11/10

0

4

20

18/11/10

0

14

60

18/11/10

0

4

21

18/11/10

0

15

61

18/11/10

0

5

22

18/11/10

0

15

62

18/11/10

0

5

23

18/11/10

0

15

63

18/11/10

0

6

24

18/11/10

0

16

64

18/11/10

0

6

25

18/11/10

0

16

65

18/11/10

0

7

26

18/11/10

0

16

66

18/11/10

0

7

27

18/11/10

0

16

67

18/11/10

0

7

28

18/11/10

0

17

68

18/11/10

0

7

29

18/11/10

0

17

69

15/02/11

2

7

30

18/11/10

0

17

70

21/12/10

1

8

31

18/11/10

0

Appendix

71

18/11/10

0

8

32

18/11/10

0 A 72

18/11/10

0

9

33

18/11/10

0 B 73

18/11/10

0

9

34

18/11/10

0 B 74

18/11/10

0

9

35

18/11/10

0 C 75

21/12/10

1 9 36

18/11/10

0 C 76

21/12/10

1 9 37

18/11/10

0 D 77

18/11/10

0 9 38

18/11/10

0 9 39

18/11/10

0

9

40

18/11/10

0

LOG OF EFFECTIVE PAGES

5

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 5 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION PAGE

1. GENERAL SAFETY INFORMATION 6

1.1 GENERAL SAFETY INFORMATION 7

1.2 OWNERS MAINTENANCE 7

1.3 AIRFRAME 7

1.4 FLIGHT CONTROL SYSTEM 8

1.5 SEATS AND SAFETY BELTS 8

1.6 BAGGAGE COMPARTMENT 8

1.7 PLACARD REPLACEMENT 9

1.8 GROUND HANDLING 9

1.9 TIE DOWN 9

2. EQUIPMENT LIST 10

2.1 TOOLING 11

2.2 OTHER POSSIBLE REQUIRED ITEMS 11

2.3 SOURCES TO PURCHASE PARTS 11

2.4 LIST OF DISPOSABLE PARTS 12

3. ENGINE SPECIFICATIONS 13

3.1 ENGINE SPECIFICATIONS 14

3.2 ROTAX 912 S/ULS 14

3.3 ENGINE OVERHAUL 15

3.4 ENGINE CONTROLS 15

3.5 ENGINE INDICATIONS 15

4. WEIGHT AND BALANCE 17

4.1 INTRODUCTION 18

4.2 WEIGHT LIMITATIONS 18

4.3 CENTRE OF GRAVITY LIMITATIONS 18

4.4 WEIGHING PROCEDURE 18

5. TIRE INFLATION PRESSURE 21

5.1 INTRODUCTION 22

5.2 TIRE INFLATION PRESSURE 22

5.3 CHANGING THE TIRE AND TUBE REPLACEMENT 22

6. APPROVED OILS, FUEL AND QUANTITY 23

6.1 ENGINE OIL 24

6.2 FUEL 24

6.3 FUEL TANK CAPACITY 24

7. FASTENER TORQUE VALUES 25

7.1 RECOMMENDED FASTNER TORQE VALUES 26

7.2 FUSELAGE 26

7.3 ENGINE ASSEMBLY 27

7.4 PROPELLER ASSEMBLY 27

7.5 WING ASSEMBLY 28

7.6 RUDDER/STABILATOR ASSEMBLY 28

7.7 CANOPY ASSEMBLY 29

8. REPORTING POSSIBLE SAFETY OF FLIGHT CONCERNS 30

8.1 REPORTING INSTRUCTIONS 31

8.2 FEEDBACK FORM EXAMPLE 31

9. INSPECTION PROCEEDURES 32

9.1 INSPECTIONS 33

9.2 DAILY INSPECTIONS 33

9.2.1 REFUELING 33

9.2.2 FUEL DRAINING 34

9.3 SCHEDULED INSPECTIONS 34

9.3.1 TIME LIMITED COMPONENTS 34

INDEX

6

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 6 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

9.3.2 PROPELLER 34

9.3.3 MAIN LANDING GEAR 34

9.4 PRE-FLIGHT INSPECTIONS 35

9.4.1 NOSE WHEEL 35

9.4.2 PROPELLER 35

9.4.3 ENGINE 35

9.4.4 MAIN LANDING GEAR 35

9.4.5 WINGS 36

9.4.6 FUSELAGE 36

9.4.7 TAIL 36

9.4.8 STABILATOR 36

9.4.9 COCKPIT CHECKS 36

9.5 SCHEDULED INSPECTION CHART 37

10. LANDING GEAR SYSTEM 44

10. LANDING GEAR 45

10.1 BRAKE SYSTEM 45

11. FUEL SYSTEM 46

11.1 FUEL SYSTEM OPERATION 47

11.2 FUEL SYSTEM SCHEMATIC DIAGRAM 48

12. PROPELLER SYSTEM 49

12.1 PROPELLER 50

12.2 APPROVED PROPELLER TYPES 50

13. INSTRUMENTS AND AVIONICS 51

13.1 INSTRUMENTS AND AVIAONICS 52

13.2 BASIC MINIMUM FLIGHT AND ENGINE INSTRUMENTS. 52

13.3 INSTRUMENT PANEL LAYOUT AND LEGEND 53

14. ELECTRICAL SYSTEM 54

14.1 ELECTRICAL SYSTEM 55

14.2 ELECTRICAL POWER SYSTEM SCHEMATIC DIAGRAM 56

14.3 ELECTRICAL BUS SYSTEM SCHEMATIC DIAGRAM 57

14.4 FLAP SYSTEM 58

14.5 FLAP SYSTEM SCHEMATIC DIAGRAM. 59

15. PITOT-STATIC SYSTEM 60

15.1 PITOT-STATIC SYSTEM 61

15.2 PITOT-STATIC WATER TRAPS 61

15.3 PITOT-STATIC INSPECTIONS. 61

15.4 PITOT-STATIC SCHEMATIC DIAGRAM 62

16. STRUCTURAL REPAIRS AND ALTERATIONS 63

16.1 STRUCTURAL REPAIRS AND ALTERATIONS 64

16.2 DAMAGE TO THE COMPOSITE STRUCTURES 64

16.3 LINE MAINTENACE 64

16.4 HEAVY MAINTENANCE 64

16.5 MAJOR REPAIR, ALTERATION OR MAINTENACE 64

16.6 HEAVY LANDING 64

16.7 EXCEEDING ENGINE LIMITS 64

16.8 EXCEEDING AIRPLANE LIMITS 65

16.9 ENGINE MOUNT CHECKS 65

17 PAINTING AND COATINGS 65

17.1 PAINTINGS AND COATING 68

17.2 PLACARDS 68

18. APPENDIX 70

A. DEFINITIONS 71

B. ABBREVIATIONS 72

C. SUPPLEMENTRY APPROVED OPTIONAL EQUIPMENT 74

D. FEEDBACK FORM 76

7

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 7 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION 1

GENERAL SAFETY INFORMATION

Title Page

1.1 General Safety Information 8

1.2 Owner maintenance 8

1.3 Airframe 8

1.4 Flight control system 9

1.5 Seats and safety belts 9

1.6 Baggage compartment 9

1.7 Placard replacement 10

1.8 Ground handling 10

1.9 Tie down 10

8

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 8 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

1.1 GENERAL SAFETY INFORMATION

This manual contains recommended procedures and instructions for ground handling,

servicing and maintaining the TEXAN TOP CLASS 580 ISR. The procedures described

are to be used in addition to the particular governing body‘s regulations for each country

where the aircraft is being flown. Where a maintenance procedure contravenes local

regulations, the procedures of the local governing body will take precedence. This manual

may refer you to the engine manual(s) for maintenance required for the relevant engine.

Maintenance instructions are divided to scheduled and unscheduled tasks. Scheduled

tasks are carried at fixed intervals, either flight hours or periods of time, e.g. at each

100hrs, or once a year which ever comes first.

Unscheduled tasks are those required when the airplane condition if affected after

damage is discovered or some unusual event like a heavy landing.

1.2 OWNER MAINTENACE

The Texan Top Class 580 ISR has been designed as a simple aircraft that can be

maintained by owners. Fly Synthesis allows normal maintenance up to 100 hourly

servicing to be carried out by the owner. This includes:

Oil and Oil filter changes

Fuel filter changes

Brake pad changes

Spark plug changes

Tire changes

Fly Synthesis recommends that any aircraft being used for flight training or for hire/reward

operation be maintained by an approved maintenance person or organisation.

1.3 AIRFRAME

The fuselage, wings and tail are constructed from composite materials. Carbon fibre is

used in highly loaded parts of all the structure, like wing spars. The fuselage is made

using a composite skin, bulkheads and stringer construction. Sandwich honeycomb is

used where required, from the firewall to the tail. The engine is installed on a steel engine

mount connected to the firewall. The engine cowling is achieved with two composite

material parts, an upper and lower cowling, fixed together with the cam-lock system. The

engine compartment is made from steel firewall. The wings are made of a composite skin

and ribs with one main spar, connecting both wings together in the centre of the fuselage.

Wing-fuselage loads are transmitted through four bolts from the root ribs of each wing to

two cross antitorsional tubes in the fuselage construction. An aerodynamic fairing, called

Karman, covers the fuselage / wing root area. The cockpit canopy is made of two parts.

The forward fixed windshield is installed on the cockpit roll bar, designed to protect the

occupants in case of turn over. The aft part of the canopy is designed to move backwards

to open the cockpit. When closed, the canopy is held in place by two locks on each side,

four locks all together.

WARNING: The four locks must be engaged and locked during flight.

9

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 9 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

1.4 FLIGHT CONTROL SYSTEM

The airplane has standard three axis controls, with dual stick and dual rudder pedals.

All control surfaces are made from composite material. The control surfaces are mounted

on metal hinges and in-turn operated by metal mechanisms. All three control surfaces

mass weight balanced to prevent flutter. The pitch is controlled by the stabilator,

commonly known as flying tail. There is no fixed elevator section and a negatively geared

trim tab is used to position the stabilator in the correct pitch and also to trim the aircraft.

The two control sticks in the cockpit are inter-connected and push-pull aluminium rods

transfer the movement to the stabilator. The mechanical trim is achieved by changing the

zero position of the geared tab. The manual trim lever is positioned between the seats

and it moves the trim through a push-pull flexible cable, an optional electric trim is also

available. Roll control is by ailerons. Push-pull rods operate the ailerons. These are

differential ailerons where the angular movement up is greater then the angular

movement down. Directional control is by a rudder installed on the vertical fin stabilizer.

Rudder pedal motion is transmitted via flexible steel cables to the rudder bell-crank. The

rudder pedals are connected at the front of the aircraft to the steerable nose wheel, which

completes the rudder control loop. A spring system help to centralize the rudder and

improve pilot‘s control feel.

CAUTION

Do not operate rudder pedals whilst stationary. Excessive pressure applied to

rudder pedals may result in damage to the rudder control pedal structure.

1.5 SEATS AND SAFETY BELTS

Pilot and passenger seats are made from composite materials and installed on the cockpit

floor. The seat bottom can be removed to enable inspection of the controls below the

seat. Each seat vertical back is adjustable on the ground before flight in 1 of 5 positions,

to suit pilot and passenger‘s size. Seat covers are fastened via Velcro strips and easily

removed for cleaning and inspection.

Each seat is equipped with safety belts, which are locked together with a bayonet quick

release latching system. The safety belts are attached to the main structure and each can

be adjusted for occupant comfort. Belts should be replaced if frayed, cut, stitching is

broken or latching defective.

1.6 BAGGAGE COMPARTMENT

WARNING: Never try to change seat adjustment in flight!

The baggage compartment is located behind the seats. Maximum baggage weight when

distributed evenly is 16 kg. Loose Items stored in the baggage area must be secured to

prevent unwanted movement during flight in turbulent conditions. An optional bigger

baggage compartment is available on request.

10

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 10 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

1.7 PLACARD REPLACEMENT

If placards need to be replaced you can order them through Flysynthesis Srl at

www.flysynthesis.com or contact your local representative.

1.8 GROUND HANDLING

The TEXAN aircraft is very light and should always be moved by hand.

Moving the aircraft is accomplished by using the prop hub to pull the aircraft forward, it is

best to position the propeller in the horizontal position and hold the propeller close to the

hub. For rearward motion holding onto the rear vertical fin allows for easy rearward

motion.

WARNING

Do not spin the propeller whilst the engine is hot as it may fire when the propeller is

moved and result in injury.

Always ensure that master and Ignition are OFF.

Always treat the propeller as LIVE! IT KILLS!

Never approach the propeller when someone is in the aircraft.

Never use any of the control surfaces to move the aircraft for ground handling.

1.9 TIE DOWN

When mooring the aircraft in the open, head into wind if possible. Secure control surfaces

by tying the control stick back firmly with a latched seat belt.

Tie ropes to the designated wing attachment points located underneath the wing nearest

the wing tip. Anchor the rope approximately 30 degrees to the vertical, outboard of the

wing attachment point. Ensure sufficient slack as not to place strain on the wing in the

event of tire deflation whilst in the tied down position. A third rope is anchored around the

Stabiltator hinge and secured rearward in the same manner as the wings.

11

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 11 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION 2

EQUIPMENT AND PARTS LIST

Title Page

2.1 Tooling 12

2.2 Other possible required items 12

2.3 Sources to purchase parts 12

2.4 List of disposable replacement parts 13

12

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 12 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Component

Source

Composite airframe parts

Flysynthesis Srl or local distributor.

Non Composites hardware eg

Bolts screws etc.

Flysynthesis Srl or local distributor.

Other aircraft specialty hardware shops.

Avionics and Instruments

Flysynthesis Srl or local distributor.

Other aircraft avionic and instrument

specialty shops.

Propeller Parts

Flysynthesis Srl or local distributor.

Propeller manufacturer eg. DUC France, GT

Tonini (Italy) or Pipistrel (Slovenia).

2.1 TOOLING

Tooling required to do maintenance on this aircraft is listed below. Please note that the list

may not be comprehensive

Loctite (243, 567 and Antisieze Lubricant # 76764) for the frame section.

Open ended Metric Spanner set

Torque wrench

Air Pump

Various petroleum lubricants

Dry Lubricant – lubricant that doesn‘t attract dust after application.

UV Resistant Tie wraps, and tooling

Metric Hex key set

Gasoline resistant thread sealant tape

Various general care items

Metric Socket Wrench Set

Pliers and Wise Grips

Phillips and Regular Screw Driver Set

Flexible neck funnel

2.2 OTHER POSSIBLE REQUIRED ITEMS

Safety wire and Safety Pins

WD-40, CRC or another water displacement compound

Telescopic mirror

Good flash light

5x and 10x magnifying glass and or video inspection equipment

2.3 SOURCES TO PURCHASE PARTS

Parts can be purchased from the following sources

13

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 13 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Part

Comment

Fuel Filters

Disposable fuel filters or metal mesh non-disposable

ones specified by the respective engine

manufacture‘s manual must be used.

Air Filters

Disposable air and fuel filters are available from local

distributor. If soiled they will be replaced with new

ones and old ones discarded. Old filters should be

disposed of as per local laws

Tires

Standard front tires: 4x4-ply (100/75-5)

Standard rear tires: 13x5x6-ply

Large rear tires: 15x6x6-ply

Tires and tubes available from local distributor.

Worn tires should be disposed of as per local laws.

Oil Filters

Oil filters should be properly disposed of along with

the oil at each oil change, according to local laws.

Landing light

Automotive and auto-electrical shop.

Fuel Line

When fuel line has to be replaced, the old one should

be properly disposed of, according to local laws.

Water hoses

When hoses have to be replaced, the old one should

be properly disposed of, according to local laws.

Replacement hose should be of the same type and

grade as the original.

Battery

When the sealed maintenance free battery is to be

replaced, the older battery should be properly

recycled according to local laws.

Spark plugs

Spark plugs are available from Engine manufacturer

Or local distributor.

Brake pads

Brake pads are specially made and available from the

aircraft manufacturer or local representative.

2.4 LIST OF DISPOSABLE REPLACEMENT PARTS

Dispose of all disposable parts properly following local laws and regulations

14

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 14 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION 3

ENGINE

Title Page

3.1 Engine specification 15

3.2 Rotax 912 S/ULS 15

3.3 Engine overhaul 16

3.4 Engine controls 16

3.5 Engine indications 16

15

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 15 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

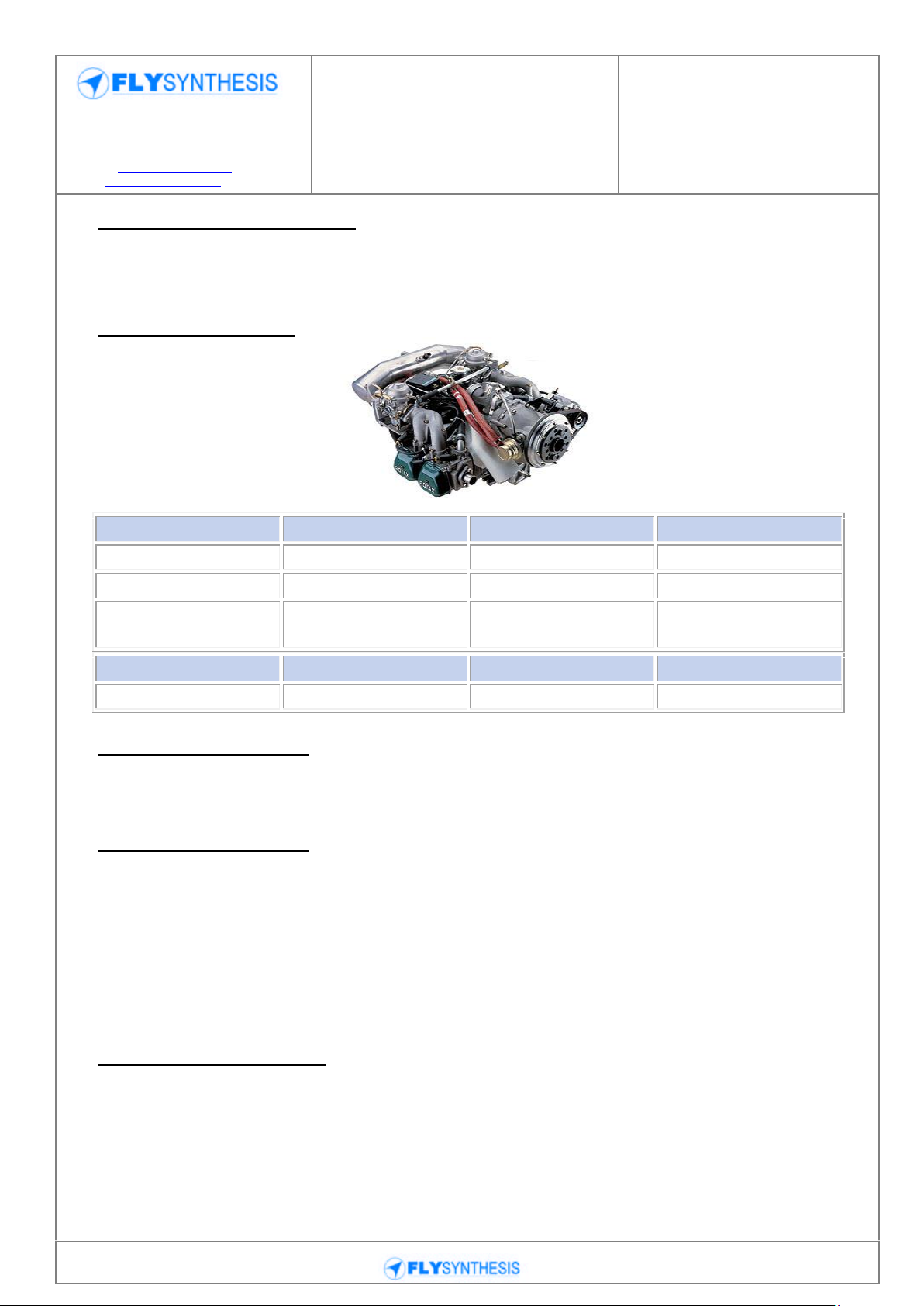

Version

Performance

Torque

Max.RPM

kw hp rpm

Nm ft.lb rpm

912 S/ULS

69.0 95.0 5500

128 94 5100

Continuous

max.5 min

73.5* 100* 5800*

*with Rotax air box and

exhaust system

5800

Bore

Stroke

Displacement

Compression ratio

84mm ( 3.31in )

61.0mm ( 2.4 in )

1352cm ( 82.6 cu.in.)

10.5 : 1

3.1 ENGINE SPECIFICATION

The approved power plant installations for the TEXAN TOP CLASS 580 ISR is the

ROTAX 912 ULS. For full detail of engine construction see ROTAX manuals.

3.2 ROTAX 912 S/ULS

3.3 ENGINE OVERHAUL

Rotax: After 1500 hours for Rotax 912ULS

3.4 ENGINE CONTROLS

Engine control is by one throttle control, operating both carburettors simultaneously. A

choke is provided for starting a cold engine. The twin-magneto ignition system is

controlled by the Master Key.

The engine starter is actuated by the Master Key, that control the starter relay, when the

master switch is ON. With master switch OFF the starter will not operate.

An Electric fuel pump supplies fuel pressure prior to the engine starting and running and is

used as back up for the engine driven fuel pump in case of failure.

3.5 ENGINE INDICATIONS

The rpm indicator indicates engine speed (RPM). This is an electronic unit.

The cylinder head temperature (CHT) indicator shows engine temperature.

The oil pressure indicator indicates oil pressure.

A separate indicator indicates the oil temperature. An Exhaust Gas Temperature system

(EGT) is also installed.

16

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 16 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

The fuel pressure indicator indicates fuel pressure with the engine pump and/or aux

electric fuel pump in use. This fuel pressure indicator is a mechanical unit.

A standard sealed accumulating hours-meter (Hobbs meter), counts the total time the

ignition key is switched on. An optional air switch may be fitted that accumulates time on

an air switch clock when the aircraft attains a speed greater than 30 knots. The air switch

time can be used for purposes of airframe and engine maintenance.

17

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 17 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Intentionally left blank

18

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 18 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION 4

WEIGHTS AND BALANCE

Title Page

4.1 Introduction 19

4.2 Weight Limitations 19

4.3 Center of Gravity Limitations 19

4.4 Weighing Procedure 19

19

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 19 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Exceeding the Centre of Gravity limits is

PROHIBITED

Exceeding the maximum weights is

PROHIBITED

4.1 INTRODUCTION

In order to obtain the best flight performance, safety, stability and control, the airplane

must be loaded within the Centre of Gravity (balance) inside the prescribed limits.

Operation beyond the prescribed limits may cause instability and loss of control, or too

much stability with not enough control. Both cases will lead to unsafe conditions and could

result in an accident, with serious or fatal personal injury.

Weight limitations are important as the performance and the integrity of the structure will

decrease to below acceptable values when exceeding the maximum Take-Off Weight.

Operation at weights above the limits may thus lead to unsafe conditions and could result

in a serious accident.

4.2 WEIGHT LIMITATIONS

Rotax 912

Maximum Take-Off Weight 580 kg

Maximum Pilot and Passenger Weight 180 kg

Minimum Solo Pilot Weight 70 kg

Luggage Compartment, 16 kg

Minimum Empty Weight 330 kg

4.3 CENTER OF GRAVITY LIMITATIONS

Forward Limit: 377 mm behind the reference datum (27% MAC)

Aft Limit: 504 mm behind the reference datum (36% MAC)

The longitudinal location of the Centre of Gravity (CG) is measured as the distance behind

a reference datum (RD).

The reference datum is defined as the vertical plane of the leading edge of the wing, when

the airplane is level.

The mean Aerodynamic Chord (MAC) is the average chord of a wing, for this airplane it is

1400 mm.

The 0% of the MAC is the reference datum (RD).

The location of the CG can be defined by reference to the % MAC.

4.4 WEIGHING PROCEDURE

Weighing must be done in a closed hangar with no chance of wind affecting the

measurements.

The floor must be level, preferably smooth concrete or any other smooth hard surface.

20

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 20 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

The airplane is complete, painted and all instruments and accessories installed.

The airplane is serviced with full engine oil, full engine coolant fluid, full brake fluid, fuel

tank drained and filled with the specified amount of the unusable fuel (TEXAN-2 litres-with

dual tanks).

In order to achieve an acceptable accuracy, the scales used for weighing should have the

following capacities:

Nose wheel - Up to 100 kgs

Main wheel – each - Up to 120 kgs

1. Put the airplane on the three scales,

2. Block the wheels to prevent the airplane from rolling off the scales,

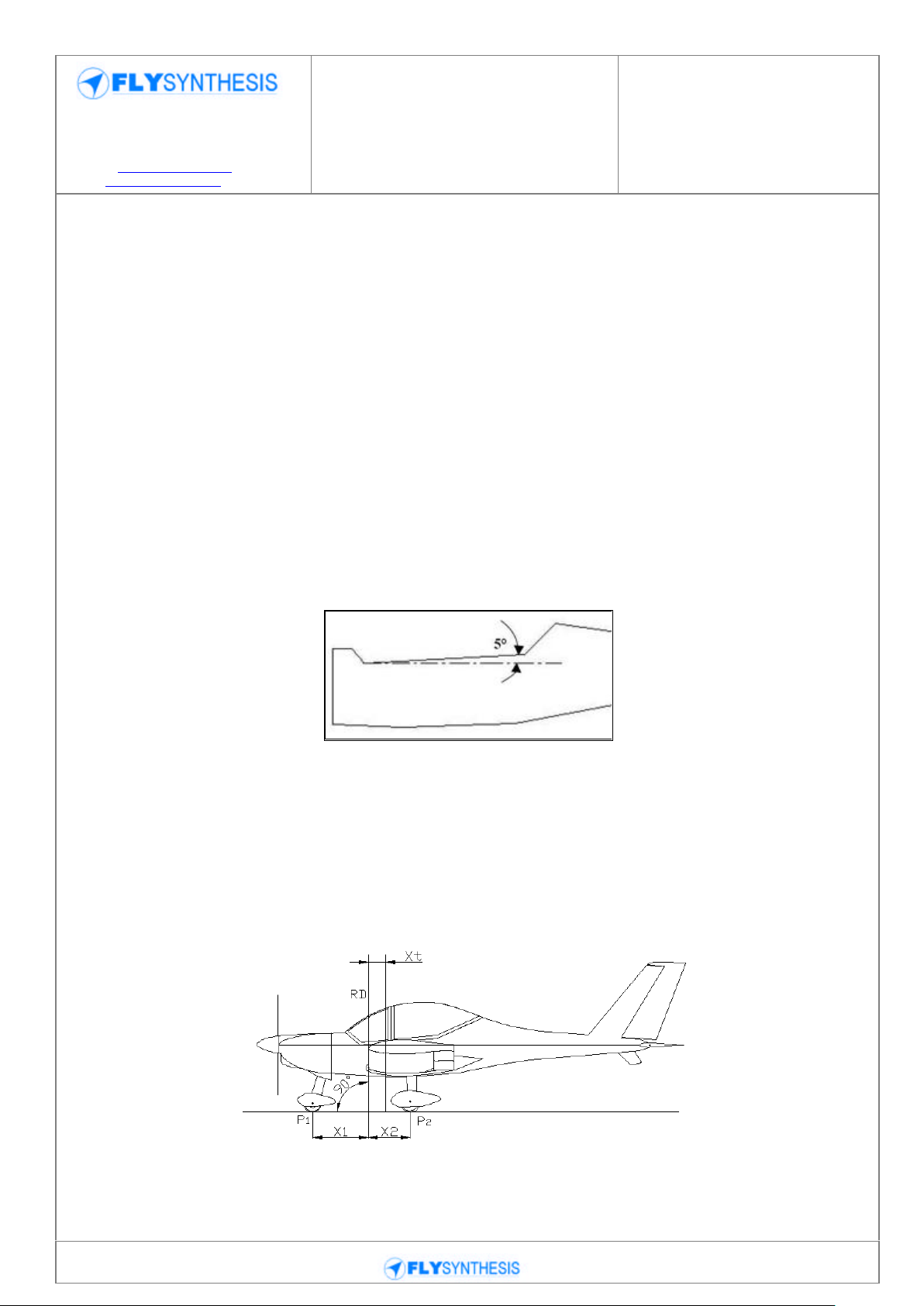

3. Check that the airplane is level. The check is done by measuring on the cockpit

sidewall top, which should be 5º nose down when the airplane is level. Place

pieces of wood with different thickness under the wheels, as required to have the

airplane level. Close the canopy before reading the scales.

4. Lower two plumb lines from the leading edge of the inboard wing section, left and

right wings. Mark the points on the floor and draw a straight line on the floor

(parallel to the wing span). This is the reference datum (RD),

5. Measure the longitudinal distance from the RD to the axle of the nose wheel. This

is the value X1. Record the value in the weight report. This value should be with a

minus sign,

6. Measure the longitudinal distance from the RD to the axle of the main wheels. This

is the value X2. Record the value in the weight report,

7. Note the weight of each scale and record in the weight report,

21

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 21 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

8. Remove the airplane from the scales, record the weight of the supporting wood

pieces of each scale as tare weight for that scale,

9. Change the left and right scales for the main wheels, and repeat the weighing

procedure again. Record results in the weight report,

10. Calculate the average weight value for each wheel.

11. Calculate the Empty Weight and the Empty Centre of Gravity position for the

airplane.

X1 is the distance from nose wheel axle centerline to projection of RD.

X2 is the distance from main wheel axle centerline to projection of RD.

The standard distance is:

X1 = 925mm (±0.5%)

X2 = 655mm (±0.5%).

The formula for CG calculation is as follows:

Xt = ML / PT . [CofG position in mm on the wing chord]

Where:

ML = (P2DX + P2SX) x X2 - P1 x X1

Xt% = (Xt / MAC) x 100 [CG position in percentage to the wing chord]

ML = Empty weight moment

P2DX , P2SX = Weight measured on main wheel

P1 = Weight measured on nose wheel

NOTE: DX = RHS SX = LHS

The first recording of the Weighing Report & the Center of Gravity Position of the aircraft

is taken at the factory before the delivery of the same aircraft. The Factory Weight and

Balance report will accompany the Aircraft on delivery.

Every variation due to the installation of new components or repairs and painting,

implicate a new calculation of the empty weight and the relative positioning of the center

of gravity.

Any weight and Balance changes should be recorded into the aircraft log book.

22

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 22 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Title Page

5.1 Introduction 23

5.2 Tire Inflation pressure 23

5.3 Tire and tube replacement procedure 23

SECTION 5

TIRE INFLATION PRESSURE

23

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 23 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

5.1 INTRODUCTION

It is essential to maintain your tires in good condition. When checking tire pressure,

examine for tire wear, cuts, bruises and slippage. Remove oil, grease and mud from tires

with soap and water.

NOTE: Recommended tire pressures should be maintained, especially in cold weather.

Any drop in temperature of air inside the tire causes a corresponding drop in tire pressure.

5.2 TIRE PRESSURES

Main wheel tire 4.00x6‖ or (13x5x6), inflation pressure 2.2 – 2.4 bar (32 – 35 psi)

Large main wheel tire 15x6x6, inflation pressure 2.2 – 2.4 bar (32 – 35 psi)

Nose wheel tire 4.00x4‖,(100/75-5) inflation pressure: 1.8 bar (26.1 psi)

5.3 CHANGING THE TIRE AND TUBE REPLACEMENT.

The wheel rims used in this aircraft are of the split rim type and as such generally require

an inner tube. Should the tube or tire require replacement the following procedure will be

of assistance.

Raise the aircraft to suspend the wheel off the ground

Remove the wheel fairing

Remove axle from wheel housing

Unbolt the disk brake from rim ( rear wheel only)

Remove wheel from axle assembly

Split rim by undoing the rim bolts

NOTE: ensure no pressure is left in tire prior to splitting the rim.

Replace defective tire or tube

Re bolt the rim being careful not to pinch the inner tube

Inflate the tire to correct tire pressure

Check bearing for smoothness in rotation

Submerse the inflated tire in water and check for leaks

Re-assemble the wheel to the axle in reverse order.

24

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 24 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION 6

APPROVED OILS, FUELS AND QUANTITY

Title Page

6.1 Engine Oil 25

6.2 Fuel 25

6.3 Fuel tank capacity 25

25

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 25 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

6.1 ENGINE OIL

For detailed information on recommended oil grades refer to the ROTAX operator‘s

manual.

Recommended engine oils for Rotax engines running on Unleaded Auto Fuel

Oil Capacity: 3.0 Litres

MOBIL 1 (5w- 30) or (15W-50)

SHELL Advance VSX 4 (10W-40) or (15W-50)

SHELL Advance Ultra 4 (10W-40)

VALVOLINE Dura blend Synthetic (10W-40)

PENNZOIL Motorcycle Motor Oil (20W-50)

Recommended engine oils for Rotax engines running on AVGAS fuel

SHELL Advance VSX 4 (10W-40) or (15W-50)

SHELL Formula (10W-30) or (20W-50)

SHELL Formula Synthetic Blend (10W-30)

VALVOLINE Dura blend Synthetic (10W-40)

6.2 FUEL

For detailed information on the approved fuels, refer to the ROTAX operator‘s manual.

Do not use fuel additives such as Octane boosters or MOGAS with any level of added

Alcohol.

6.3 FUEL TANK CAPACITY:

- Fuel tank capacity 2 x 50 L

- Unusable fuel 2 L

- Usable fuel 98 L

NOTE: for fuel system schematic drawing see section 11 in this manual.

26

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 26 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Title Page

7.1 Recommended Fastener torque values 27

7.2 Fuselage 27

7.3 Engine assembly 28

7.4 Propeller assembly 28

7.5 Wing assembly 29

7.6 Rudder and Stabilator assembly 29

7.7 Canopy assembly 30

SECTION 7

FASTENER TORQUE VALUES

27

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 27 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

7.2 FUSELAGE

Quantity

TORQUE

MAIN LANDING GEAR STRUCTURE ON FUSELAGE

N°24

screws M6

Kg*mt 0,75

MAIN LANDING GEAR LEG ATTACH ON GEAR STRUT

N°2 screws

M8

Kg*mt 1,6

WHEEL AXLE ATTACH ON MAIN LANDING GEAR LEG

N°2 screws

M6

Kg*mt 0,75

PLATE ATTACHMENT TO FIREWALL

N°7 screws

M8

Kg*mt 1,6

PLATE ATTACHMENT TO SHOCK ABSORBER SYSTEM

N°2 screws

M8

Kg*mt 2,4

FLAP CONTROL SHAFT ATTACHMENT TO FUSELAGE

N°1 screw

M6

Kg*mt 0,75

AILERON CONTROL STICK UNDER SEATS FLOOR IN

FUSELAGE

N°16

screws M5

Kg*mt 0,42

FLAP ACTUATOR HINGES

N°2 screws

¼‖

Kg*mt 0,9

FLAP CONTROL STICKS (INSIDE FUSELAGE)

N°8 screws

M6

Kg*mt 0,75

CLOCHE SYSTEM

N°8 screws

M6

Kg*mt 0,75

BOWDEN CABLE ATTACHMENT

N°6 screws

M5

Kg*mt 0,42

ENGINE MOUNT ATTACHMENT AT FIREWALL

N°4 screws

M8

Kg*mt 2,4

PINCER DISCK BRAKE ATTACHMENT INTO WHEEL AXLE

N°4 screws

M6

Kg*mt 0,75

PINCER TO PINCER SUPPORT GROUP

N°8 screws

M6

Kg*mt 0,75

FAIRING TO WHEEL AXEL

N°6 screws

M6

Kg*mt 0,75

PULLEY TO PULLEY SUPPORT

N°1 screw

M8

Kg*mt 1,6

SUPPORT ROD TO PULLEY

N°1 screw

M6

Kg*mt 0,42

7.1 RECOMMENDED FASTENER TORQUE VALUES

*The following table presents the required torque values of the different assemblies in the

airplane. It is assumed that the bolts and nylon locknuts are in new condition and are

made from standard finish 8.8 coarse metric hardware. Final tightening sequence is

achieved smoothly and slowly until full torque has been obtained.

28

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 28 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

7.3 ENGINE ASSEMBLY

Quantity

TORQUE

ALTERNATING CURRENT RECTIFIER ON FIRE BULKHEAD

N°2 screws

M5

Kg*mt 0,42

START RELAY ON FIRE BULKHEAD

N°2 screws

M5

Kg*mt 0,42

CAPS BULKHEAD ON FIRE BULKHEAD

N°8 screws

M5

Kg*mt 0,42

DECANTER FILTER ON RIGHT COVER

N°2 screws

M5

Kg*mt 0,42

TAKE OFF PUMP ON FIRE BULKHEAD

N°1 screw

M6

Kg*mt 0,75

OIL RADIATOR SUPPORT ON FIRE BULKHEAD

N°2 screws

M5

Kg*mt 0,42

AIR FILTER SUPPORT ON FIRE BULKHEAD

N°2 screws

M5

Kg*mt 0,42

ENGINE TO ENGINE MOUNTING PYLON

N°4 screws

M10

Kg*mt 3,5

WATER MANIFOLD ASSEMBLY

N°2 screws

M6

Kg*mt 1

CAP PUMP

N°5 screws

M6

Kg*mt 1

HEAD AIR INTAKE

N°8 screws

M6

Kg*mt 1

INDUCTION MANIFOLD

N°8 screws

M6

Kg*mt 1

FUEL PUMP

N°2 dadi M8

Kg*mt 2,4

AIRBOX SUPPORT

N°2 screws

M6

Kg*mt 1

OVERFLOW BOTTLE SUPPORT TO ENGINE MOUNTING

PYLON

N°1 screw

M6

Kg*mt 0,75

OIL MANIFOLD SUPPORT TO ENGINE MOUNTING PYLON

N°2 screws

M6

Kg*mt 1

WATER RADIATOR

N°4 screws

M6

Kg*mt 0,75

FASCETTE TUBI ACQUA

N°8

Kg*mt 3,5

EXHAUST MANIFOLD

N°8 dadi M8

Kg*mt 2,4

FUEL DEVICE SUPPORT TO ENGINE

N°2 screws

M6

Kg*mt 0,75

FUEL DEVICE TO SUPPORT

N°2 screws

M4

Kg*mt 0,2

7.4 PROPELLER ASSEMBLY

Quantity

TORQUE

PROPELLER TO ENGINE (STANDARD WOOD PROPELLER)

N°6 screws

M8

Kg*mt 1,6

PROPELLER TO ENGINE (CARBONFIBRE PROPELLER)

N°6 screws

M8

Kg*mt 2,4

SPINNER TO PLATE (STANDARD)

N°6 screws

M5

Kg*mt 0,42

29

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 29 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SPINNER TO PLATE (IDROVARIO TWOBLADES PROPELLER)

N°6 screws

M5

Kg*mt 0,42

SPINNER TO PLATE (IDROVARIO THREEBLADES

PROPELLER)

N°9 screws

M5

Kg*mt 0,42

SPINNER TO PLATE (PIPISTREL THREEBLADES PROPELLER)

N°9 screws

M5

Kg*mt 0,42

SPINNER TO PLATE (QUINTI AVIO THREEBLADES

PROPELLER)

N°9 screws

M5

Kg*mt 0,42

7.5 WINGS ASSEMBLY

Quantity

TORQUE

COMB HINGES ON SPARE

N°16

screws

M10

Kg*mt 4,6

ANGLE SUPPORT OF MECHANISM PIN ON WING PYLONS

N°8 screws

M5

Kg*mt 0,42

PIN AIRELONS MECHANISM

N° 2 screws

M6

Kg*mt 0,75

PYLON TO WING(FLAP AND AIRELONS)

N° 32

screws M5

Kg*mt 0,42

FLAP/AIRELONS ALLIGNMENT REGULATION BLADES ON

WING PYLONS

N°16

screws M6

Kg*mt 0,75

FLAP/AIRELONS MECHANISM BUSH ON WING PYLONS

N° 8 screws

M6

Kg*mt 0,75

UNIBALL OF AIRELONS CONTROL BAR INSIDE THE WINGS

N° 6 screws

Kg*mt 0,75

FUELTANK CONTROL LEVEL

N°10

screws M5

Kg*mt 0,42

FUELTANK FRAME ON ROOT WING RIB

N°24

screws M5

Kg*mt 0,42

OPENING FUELTANK ON WING

N°12

screws M5

Kg*mt 0,42

TIP ON WING

N°38

screws M4

Kg*mt 0,2

FLAP CONTROL BAR ON FLAP SURFACE

N°4 screws

M6 N.C.S.

Kg*mt 0,75

SEMIWING JOINT PIN TO FUSELAGE

N°4 screws

M8 N.C.S

Kg*mt 2,4

JOINT PIN

N°2 perni

M12

Kg*mt 9,0

AILERON BALANCING WEIGHT TO AILERON PYLON

N°8 screws

M5

Kg*mt 0,42

7.6 RUDDER / STABILATOR ASSEMBLY

Quantity

TORQUE

RUDDER HINGE - FUSELAGE

N° 2 screws

M6

Kg*mt 0,75

RUDDER HINGE – RUDDER

N° 8 screws

M5

Kg*mt 0,42

TRIM BALANCING WEIGHT

N° 2 screws

M5

Kg*mt 0,42

HORIZONTAL STABILIZER HINGE-HORIZONTAL STABILIZER

N° 3 screws

M6

Kg*mt 0,75

30

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 30 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

7.7 CANOPY ASSEMBLY

Quantity

TORQUE

PLEXIGLAS ON ROLL BAR

N°12

screws M5

Kg*mt 0,42

OPENING AND CLOSING ANGLE SYSTEM ON ROLLBAR

N°10

screws M4

Kg*mt 0,2

CLOSING POINT ON ROLLBAR

N°12

screws M4

Kg*mt 0,2

CLOSING POINT PIN

N°4 screws

M6

Kg*mt 0,75

BACK HINGE ON ROLLBAR

N°3 screws

M4

Kg*mt 0,2

OPENING CENTRAL HANDLE ON ROLLBAR

N°4 screws

M5

Kg*mt 0,42

31

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 31 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

REPORTING POSSIBLE SAFETY OF FLIGHT CONCERNS

Title Page

8.1 Instructions for reporting 32

8.2 Feed back form example 32

SECTION 8

32

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 32 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

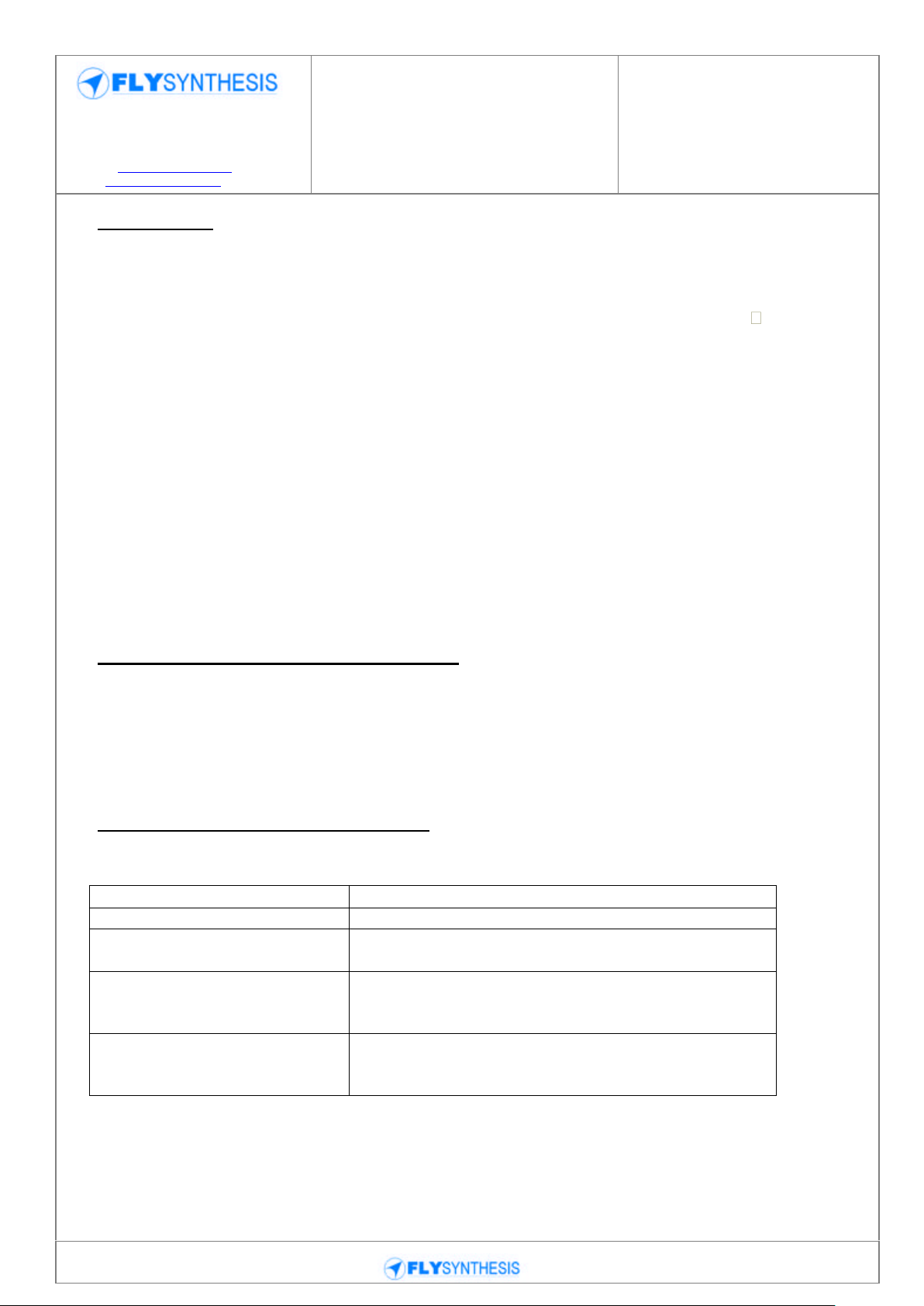

Model Aircraft

Registration No

Texan Top Class 580 ISR Registration No 4X- XXXX

Engine type and

Serial number

Rotax 912 ULS xxxx xxxx xxxx

Date of

Manufacture

Enter Day, Month and year of manufacture

Number of hours

Enter number of flight hours

Name of part/area

eg, Engine mounts, landing gear leg etc.

Description

Describe the issue as best you can

Images/pictures

Please attach pictures or sketch of the problem area

Suggested remedy

Enter any suggested remedy if you have one

Your Name

Enter your full name here

Your Title

Enter your title here (owner, mechanic, inspector etc.)

Your Qualification

Enter your Qualification e.g. Owner, Level 2 authority – LAME.

Address

Enter your address here

Phone number

Enter your Telephone number here

Fax Number

Enter your fax number here

Email address

Enter your email address here

8.1 REPORTING INSTRUCTIONS

If you discover any problems during maintenance of this aircraft that in your opinion can

cause safety of flight issues, please report that concern to FlySynthesis Srl in the following

way. If your concern relates to engine internals you should notify the engine manufacturer.

8.2 FEED BACK FORM EXAMPLE ONLY

Note: Contact details for notifiying the manufacturer are found on Actual

forms.Blank forms found on rear pages of this manual APPENDIX D

33

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 33 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

SECTION 9

INSPECTION PROCEEDURES

Title Page

9.1 Inspections 34

9.2 Daily Inspections 34

9.2.1 Refueling 34

9.2.2 Fuel draining 35

9.3 Scheduled Inspection 35

9.3.1 Time limited components 35

9.3.2 Propeller 35

9.3.3 Main landing gear 35

9.4 Pre flight inspections 36

9.4.1 Nose wheel 36

9.4.2 Propeller 36

9.4.3 Engine 36

9.4.4 Main landing gear 36

9.4.5 Wings 37

9.4.6 Fuselage 37

9.4.7 Tail 37

9.4.8 Stabilator 37

9.4.9 Cockpit checks 37

9.5 Scheduled Inspection chart 38

34

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 34 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

Flight Time

25

50

100

150

200

250

300

350

400

Inspection Type

25

50

100

50

200

50

100

50

200

Flight Time

450

500

550

600

650

700

750

800

Inspection Type

50

100

50

200

50

100

50

200

Flight Time

850

900

950

1000

1050

1100

1150

1200

Inspection Type

50

100

50

200

50

100

50

Overhaul

9.1 INSPECTIONS

Inspections are composed of daily and scheduled inspections.

1. Daily Inspections, includes refuelling, fuel system draining and pre flight

inspection.

2. Scheduled Inspections per flight time are planed in a cycle of 50 flight hours,

to match the engine manufacturer requirements, these are composed of the

following inspection types: First 25 hour inspection; 50 hourly inspection; 100

hourly/Annual inspection and 200 hourly inspection.

The normal cycle repeats itself per following table:

The 25 hours inspection should be carried out only once after the first 25 flying hours

of the airplane. It is also done once after an engine change, engine or airplane overhaul or

major repair due an accident or other major damage.

Other limited maintenance periods for certain equipment are listed separately.

9.2 DAILY INSPECTION

Daily inspections can be carried out by either the owner or by the maintenance person.

9.2.1 REFUELING

1. Magnetos Check OFF

2. Master switch ON

3. Fuel quantity Check

4. Master switch OFF

5. Tank filler cap clean, and then open

6. Fill the required amount of fuel per flight plan

7. Tank filler cap Close, check flush with top of wing

8. Master switch ON, check fuel quantity

9. Master switch OFF

10. Record amount of fuel in airplane log

NOTE: For Rotax engines, the recommended fuel is 95 Octane or higher unleaded

motor fuel. If leaded fuel is used, or 100LL Fuel, engine maintenance checks including

spark plugs change, must be carried out more often. Consult ROTAX Maintenance

Manual.

35

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 35 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

9.2.2 FUEL DRAINING

Fuel drainage should be carried out once a day before the first flight, and 10 minutes after

each and every refuelling of the tank. Fuel drainage should also be repeated if the

airplane was parked for more than three hours.

CAUTION

Before attempting any service or inspection on the airplane, check that the Magnetos and

Master Switch (key) are OFF. Draining is accomplished by operating the cock located on

the gascolator in the lower engine compartment, just in front of the firewall frame.

Draining 80 to 100 cc (5-6 cubic inches) is considered sufficient to eliminate the water in

the tank. Use transparent container to drain into. If water is found in the drained fuel,

repeat fuel drain operation until the water is completely drained and any trace of water in

the fuel is completely eliminated.

Fuel drainage should be performed before moving the airplane from its parking place, to

avoid condensation or water present on tank bottom mixing and emulsifying with fuel,

making detection difficult.

9.3 SCHEDULED INSPECTION

If the airplane does not reach 100 flight hours within consecutive 12 months, a 100 hours

inspection must be carried out before renewal of its permit to fly.

If the airplane did not reach 200 flight hours within 24 months, a 200 hours inspection

must be carried out before renewal of its permit to fly.

9.3.1 TIME LIMITED COMPONENTS

The following components must be removed for inspection and complete overhaul after

the time specified have expired:

Engine ROTAX 912 ULS 1500 hours, or 10 years, whichever comes first, refer to the

ROTAX manual.

9.3.2 Propeller

See manual supplied with the fitted propeller.

9.3.3 Main landing gear strut

The spring steel tubular legs model 2E1000024 do not require replacement unless bent or

damaged.

36

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 36 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

9.4 PRE - FLIGHT INSPECTION

The pre flight inspection should be carried out BEFORE EACH FLIGHT, even if the

previous flight was very short. The pilot in charge should carry out the inspection.

The inspection does not require any tools only a clean rag is needed. It is important to

verify by sight and touch that there are no failures, defects, excessive clearances or play.

9.4.1 NOSE WHEEL

Axle locking nuts Check Tightness.

Wheel fairings Undamaged with correct clearance between

fairing and tire.

Tire and wheel Undamaged, not worn excessively, inflated

properly.

Gear strut No distortion.

Gear support frame Locking nuts tightened, No distortion, with

pedals centred rudder aligned with nose..

Shock absorber Undamaged and serviceable,

9.4.2 PROPELLER

Blades and hub Undamaged and clean.

Spinner Undamaged, fixed tight.

9.4.3 ENGINE

Upper cowlings Remove cowling or open inspection port

Oil Check level

Cooling fluid Check level.

Radiators and air scoop Undamaged and free of obstruction

Crankcase and cylinder block Clean, no oil or cooling fluid leak

Exhaust and mufflers No damage or cracks, retaining spring

mounted and hooked in place.

Fuel, oil and water pipes Undamaged.

Electric and ignition line Undamaged.

Throttle and choke Function properly, smooth movement.

Close upper cowling When refitted, checked security of cowl or

9.4.4 MAIN LANDING GEAR

Strut No distortion, locking nuts tightened, and

Tire Undamaged, not worn excessively, inflated

Fairing Undamaged fixed tight and clean.

inspection port.

No visible welding cracks are evident.

properly.

37

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 37 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

9.4.5 WINGS

Skin Undamaged-absence of major gel coat chips,

swellings depressions, no delamination.

Wing-fuselage fairing Secure.

Airspeed probe Undamaged, clean, aligned, pressure tubes

securely connected.

Leading edge Undamaged.

Wings tip Undamaged, fixed tight.

Trailing edge Undamaged.

Aileron and flap Undamaged, freedom of movement, no

Excessive hinge slack, all split pins in place

Hinges securely connected to the wing,

Mass weight balance fixed tight, NO PLAY.

9.4.6 FUSELAGE

Skin Undamaged, no sign of serious chipping,

swellings or

Delamination, Inspection doors closed.

9.4.7 TAIL

Vertical fin Undamaged, no serious chipping, depressions

or delamination.

Rudder structure and skin Undamaged, hinges secured.

Lower the aircraft tail in order to lift the nose wheel from the ground, check rudder

free movement, no play on lower hinges.

Control cables Secured, freedom of oscillating eye-ends.

Balance weights Fixed tight, no play.

9.4.8 STABILATOR

Structure and skin Undamaged, no serious chipping, delaminating,

especially on leading edges. Attached firmly

through out its length.

Elevator Free movement up and down.

Elevator hinge plate Undamaged, attached firmly, no play.

Balance weights Fixed tight, no play.

Hinges pins Tight and with all safeties.

Trim tab Undamaged, attached properly, correct

operation.

9.4.9 COCKPIT CHECKS

Instrument panel Fixed tight, limitation markings in place.

Master switch (key) ON All instruments operate as required.

Master switch OFF Instruments indicate zero or as required.

38

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 38 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

TEXAN ISR - SCHEDULED INSPECTIONS – PROGRAM

INSPECTION

TYPE

TYPE

TASKS TO BE PERFORMED

25

50

100

200

GENERAL

Ensure that ignition switches are OFF and master switch

(key) is REMOVED

X X X

X

Open all inspection panels in the fuselage and wings.

X X

X

Remove seats and seat back

X X X

X

Remove floor below the seats (part TB0200) unless

suitable special video equipment is used for inspection.

X X

Remove floor below the seats (part TB0200)

X

Remove Engine cowling, top and bottom.

X X X

X

Expose underside fuselage wing root fairing both sides

X X

X

Check all rivets to detect loose rivets. Any loose rivet

shall be replaced with oversize rivet

O O

O

Control sticks Control rods connected securely (visible part

only) free and full movement.

Rudder pedals No distortion, rudder and nose wheel aligned,

Nose wheel control rods and rudder control

cables securely attached, condition, rubber

(shock cord)

centering cables condition good.

Throttle and choke Free and smooth movement, installed

securely.

Brake lever and parking brake Release parking, brake lever operates

smoothly, correct feel. Engage parking.

Trim lever Installed securely, free and smooth movement.

Seat belts Undamaged, locking device locks and

releases freely.

Seats Fixed Correctly located in required position.

Canopy Clean, undamaged, freedom of movement.

four locks operate correctly,

Windshield Clean, fixed securely.

Baggage Not exceeding weight limit, weight distributed and

load secured.

Weight and balance Calculate.

Aircraft log book Record the Daily Inspection in the book.

9.5 SCHEDULED INSPECTION CHART

Legend: O = only requires a visual check X = complete check, may require tools.

NOTE: Prior to working around the cockpit area, place a suitable protective covering over

the wing surface such as a rubber mat. Prolonged kneeling on the wing surface without

protection may cause indentation or even delamination.

39

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 39 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

TYPE

TASKS TO BE PERFORMED

25

50

100

200

PROPELLER

Remove spinner

X X

X

Inspect the prop blade for cracks, stone damage and

other defects. For small defects, smooth with fine glass

paper and apply lacquer or epoxy as required.

X X X

X

Check propeller bolt tightness, see propeller manual for

Torque value, check safe tying if required.

X X

X

Install spinner

X X

X

FUSELAGE

Inspect fuselage for condition and other sign of defect.

Check skin for delamination, inner structure bulkheads

seen to be to be glued to skin with no cracks or

separation between them.

O O O

O

Exterior check main landing gear frame (steel tube spar)

for condition, no cracks. Check four points of connection

to fuselage structure, no delamination or skin separation,

check retaining bolts and nuts tightness

(this check can be made with special video equipment)

X X

Internal check main landing gear frame (steel tube spar)

to fuselage for condition, no cracks. Check four points of

connection to fuselage structure, no delamination or skin

separation, bolts and nuts tightness (floor below the

seat must be removed, part TB0200, unless suitable

special video equipment is used for inspection).

X X

Internal check main landing gear frame (steel tube spar)

to fuselage for condition, no cracks. Check four points of

connection to fuselage structure, no delamination or skin

separation, bolts and nuts tightness (floor below the

seat must be removed, part TB0200)

X

Check antenna attachment, check for cracks, loose Bolt,

connecting cable condition and security and antenna

condition.

O O O

O

Check wing main spar connection in centre fuselage for

bolts tightness, no cracks (floor below the seat must

be removed, part TB0200, unless suitable special

video equipment is used for inspection).

X X

Check wing main spar connection in centre fuselage for

bolts tightness, no cracks (floor below the seat must

be removed, part TB0200).

X

Check four wing fuselage connections for bolts tightness,

condition of fuselage spars

X X

X

Front windshield, clean and check condition, check

attachment to the structure

O O O

O

Canopy, clean & check condition check connection to the frame,

check locks operation, lubricate lightly locks mechanism

O O O

O

40

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 40 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

TYPE

TASKS TO BE PERFORMED

25

50

100

200

FLIGHT CONTROLS

Check aileron surfaces for condition, smooth and free

movement, no play up or down, side play acceptable.

O O O O

Check bolts and nuts attaching the aileron hinges for

tightness. Check hinge pin tightness (use Loctite).

X X X

Check elevator surface for condition, smooth and free

movement, no play up or down, side play acceptable.

X X

X

Check bolts and nuts attaching the elevator support plate

mechanism for tightness, no play.

X X

X

Check rudder control surface for condition, smooth and

free movement, no side play, up and down play

acceptable.

X X

X

Check bolts and nuts attaching the rudder hinges for

tightness, no play.

X X

X

Note: The max side play in flight control surfaces (up or down in rudder) is 0.6 mm

Check aileron push pull rods and rod ends for condition

no distortion, free clearances all around in full movement

X

X

Check elevator push pull rods and rod ends for condition

no distortion, free clearances all around in full

movement.

X

X

Check rudder control flexible cables and cable ends for

condition, replace if necessary. Check tension.

O O

O

Check trim lever for secure installation.

O O

O

Check trim push pull cable for condition, smooth and free

movement, end connections, irreversible movement.

X X

X

Check flaps for normal smooth operation

0 0

0

Check flap mechanism, no distortion, free clearances all

around in full movement. Check flap hinge pin tightness.

X X

X

Check trim surface for secure installation, no bending

O O

O

Check ailerons surface angles both left and right sides,

should be: up 22º/down 17º

O O O

Check elevator surface angles, should be trailing edge

up 16º /down 11º

O O O

Check rudder surface angles, left and right, should be

trailing edge left 18º ; right 18º, +0º/-1º each side

O O

O

Check geared trim surface angles, should be for trim

zero, trailing edge up or down twice the elevator

movement + /- 5%

O O O

Check trim surface angles, should be for elevator zero,

trailing edge up 3º+/-1º (lever forward), down 3º+/-1º

(lever back)

O O

O

Check flap angles, compare to indicator readings. 0º to

45º +2º/-3º

O O

Lubricate lightly all movable part and hinges.

O O

O

41

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Maintenance Manual

FLY SYNTHESIS TEXAN

TOP CLASS 580 ISR

(For Rotax 912 ULS

versions)

Identification: MM_TC_580_Rev.2

Page: 41 of 77

Date: 15/02/11

Issued: C. Cosatto

Verified: C. Cosatto

Approved: C. Cosatto

Revision Description:

Placard update

TYPE

TASKS TO BE PERFORMED

25

50

100

200

Check tightening of nuts securing aileron and flap hinges

(support plates) in wings.

O O

O