Page 1

FLY SYNTHESIS

TEXAN TOP CLASS 550 LSA

24-7520

PILOT OPERATING HANDBOOK

(For Rotax 912 ULS and Jabiru 2200 engines versions)

00

14/05/07

New manual issue

M. Fiorindo

M. Fiorindo

C. Pinzana

Num.

Date

Description

Issued

Verified

Approved

REVISION

FlySynthesis s.r.l. reserves in terms of law the exclusive ownership of this manual and also forbids the whole or partial reproduction of it.

Page 2

Identification: POH_TC_LSA Rev.0

Page: 2 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

THIS DOCUMENT MUST BE CARRIED IN THE AIRCRAFT AT ALL TIMES

Page 3

Identification: POH_TC_LSA Rev.0

Page: 3 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

IDENTIFICATION:

Manufacturer

FLY SYNTHESIS SRL

Address

Provincial Rd 78 Km 12.150

Mortegliano 33050 (UD) ITALY

Model:

FLY SYNTHESIS TEXAN

Version:

TEXAN TOP CLASS 550 LSA

Airframe Serial

No:

Engine Model:

Engine Serial No:

Registration:

Date:

Signature:

Stamp:

Page 4

Identification: POH_TC_LSA Rev.0

Page: 4 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

NOTE

This manual may be revised in the future and pages/or sections re-issued in part or whole.

Revisions will also be available on the Fly Synthesis website www.flysynthesis.com. Any

revisions and/or sections should be printed and replaced in the manual at the earliest

possible time for flight safety.

The revisions added to the manual should be logged and recorded in the table under log of

ammendments of this manual, by the owner/user.

DEFINITIONS

Definitions used in this handbook such as WARNING, CAUTION and NOTE are employed

in the following context.

WARNING

Procedures or instructions that if not followed correctly may result in injury or death

CAUTION

Procedures or instructions that if not followed correctly may result in damage to the

aircraft or its parts

NOTE: Procedures or instructions that affect safety of flight are highlighted

INTELLECTUAL PROPERTY

The data and information contained in this document is the property of FLYSYNTHESIS

SRL. This document may not be reproduced or transmitted to a third party, in any form or by

any means. Any unauthorised copy or distribution is illegal as per international agreements

relating to property rights.

THIS AIRCRAFT WAS MANUFACTURED IN ACCORDANCE WITH THE FOLLOWING

LIGHT SPORT AIRCRAFT AIRWORTHINESS STANDARDS B CAR S, F2279, F2295

AND F2483 AND DOES NOT CONFORM TO STANDARD CATEGORY AIRWORTHNESS

REQUIREMENTS.

Page 5

Identification: POH_TC_LSA Rev.0

Page: 5 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

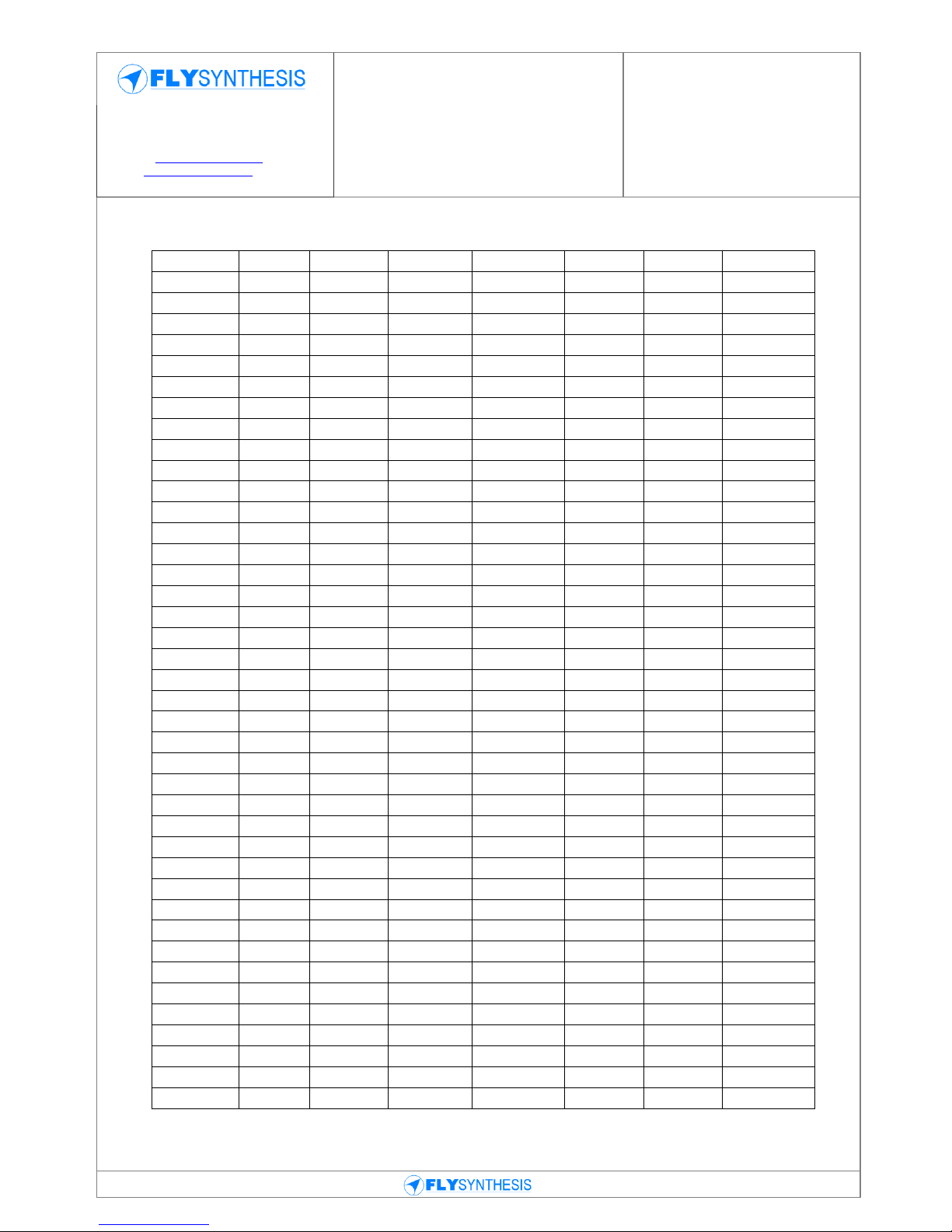

LOG OF REVISIONS

Revision No.

Revision

Date

Signature

Page 6

Identification: POH_TC_LSA Rev.0

Page: 6 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

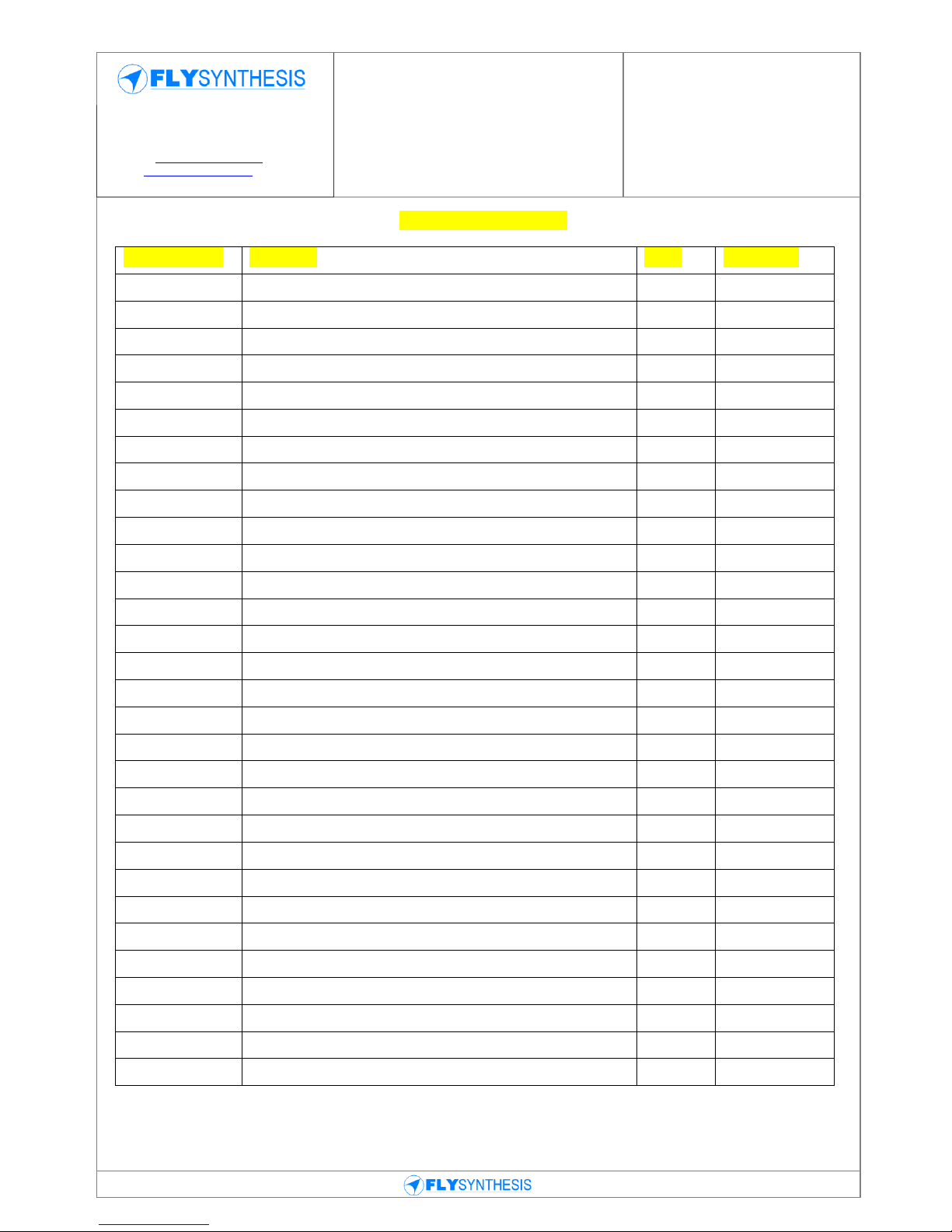

LOG OF EFFECTIVE PAGES

Section

Page

Date

Revision

Section

Page

Date

Revision

-

01

14/05/07

0 5 41

14/05/07

0 - 02

14/05/07

0 5 42

14/05/07

0 - 03

14/05/07

0 5 43

14/05/07

0 - 04

14/05/07

0 5 44

14/05/07

0 - 05

14/05/07

0 6 45

14/05/07

0 - 06

14/05/07

0 6 46

14/05/07

0 1 07

14/05/07

0 6 47

14/05/07

0 1 08

14/05/07

0 7 48

14/05/07

0 1 09

14/05/07

0 7 49

14/05/07

0 1 10

14/05/07

0 7 50

14/05/07

0 1 11

14/05/07

0 7 51

14/05/07

0 1 12

14/05/07

0 8 52

14/05/07

0 2 13

14/05/07

0 8 53

14/05/07

0 2 14

14/05/07

0 8 54

14/05/07

0 2 15

14/05/07

0 8 55

14/05/07

0 2 16

14/05/07

0 8 56

14/05/07

0 2 17

14/05/07

0 8 57

14/05/07

0 2 18

14/05/07

0 8 58

14/05/07

0 2 19

14/05/07

0 3 20

14/05/07

0 3 21

14/05/07

0 3 22

14/05/07

0 3 23

14/05/07

0 3 24

14/05/07

0 3 25

14/05/07

0 3 26

14/05/07

0 4 27

14/05/07

0 4 28

14/05/07

0 4 29

14/05/07

0 4 30

14/05/07

0 4 31

14/05/07

0 4 32

14/05/07

0 4 33

14/05/07

0 4 34

14/05/07

0 4 35

14/05/07

0 5 36

14/05/07

0

5

37

14/05/07

0

5

38

14/05/07

0 5 39

14/05/07

0 5 40

14/05/07

0

Page 7

Identification: POH_TC_LSA Rev.0

Page: 7 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

INDEX

Title Section Page

IDENTIFICATION 2

DEFINITIONS 3

LOG OF REVISIONS 4

LOG OF EFFECTIVES PAGES 5

INDEX 6

General informations 1 7

Limitations 2 13

Emergency procedures 3 20

Normal operations 4 27

Performances 5 36

Weight and balance 6 45

Aircraft ground handling and servicing 7 48

Aircraft check lists 8 52

Page 8

Identification: POH_TC_LSA Rev.0

Page: 8 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SECTION 1

General information

Title Page

1.1 Introduction 8

1.2 Warnings, suggestions and notes 8

1.3 Descriptive aircraft data 8

1.4 Aircraft three views 12

Page 9

Identification: POH_TC_LSA Rev.0

Page: 9 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

1.1 INTRODUCTION

This Operating Handbook contains the necessary information for a sure and efficient

employment of the aircraft FLY SYNTHESIS TEXAN TOP CLASS LSA ROTAX 912 ULS

100 HP and JABIRU 2200 85 HP. Unless indicated, all descriptive data are valid for both

engine versions. The POH has been prepared to comply with the requirements of B CAR S

and where relevant the ASTM standard.

The Pilot Operating Handbook is valid only for the particular aircraft identified on page 2,

the identification page.

Read this manual before your first flight!

1.2 WARNINGS, SUGGESTIONS AND NOTES

The observance of this manual is compulsory for the aircraft's use.

FLY SYNTHESIS S.r.l. declines every responsibility for any damage to person and property

derived by a missed or partial observance of the prescriptions contained in this manual.

FLY SYNTHESIS S.r.l. reserves it, to terms of law, the exclusive ownership of this manual

and also forbids the partial or integral reproduction of it and however to communicate it to

competing firms without a preventive written authorization.

1.3 DESCRIPTIVE AIRCRAFT DATA

TYPE OF AIRCRAFT

Texan Top Class LSA is a light sport aircraft with airframe; wings and control surfaces made

of laminate and honeycomb sandwich composite materials. The rectangular shape low wing

utilizes the laminar flow airfoil section. The ailerons are differential whilst the flaps are

electrically operated plain type, the vertical tail control surface is composed by a fixed fin and

by a mobile rudder, and the horizontal tail control surface is completely mobile, hinged in the

central part with integrated trim. The tricycle type landing gear is fixed, with dampened nose

wheel, with the main legs made in spring steel construction.

The Texan Top Class aircraft is approved for Day VFR only. Flight into bad weather with IFR

conditions by VFR pilots and aircraft is extremely dangerous. As the owner and operator of

an aircraft you are responsible for the safety of your passenger and yourself.

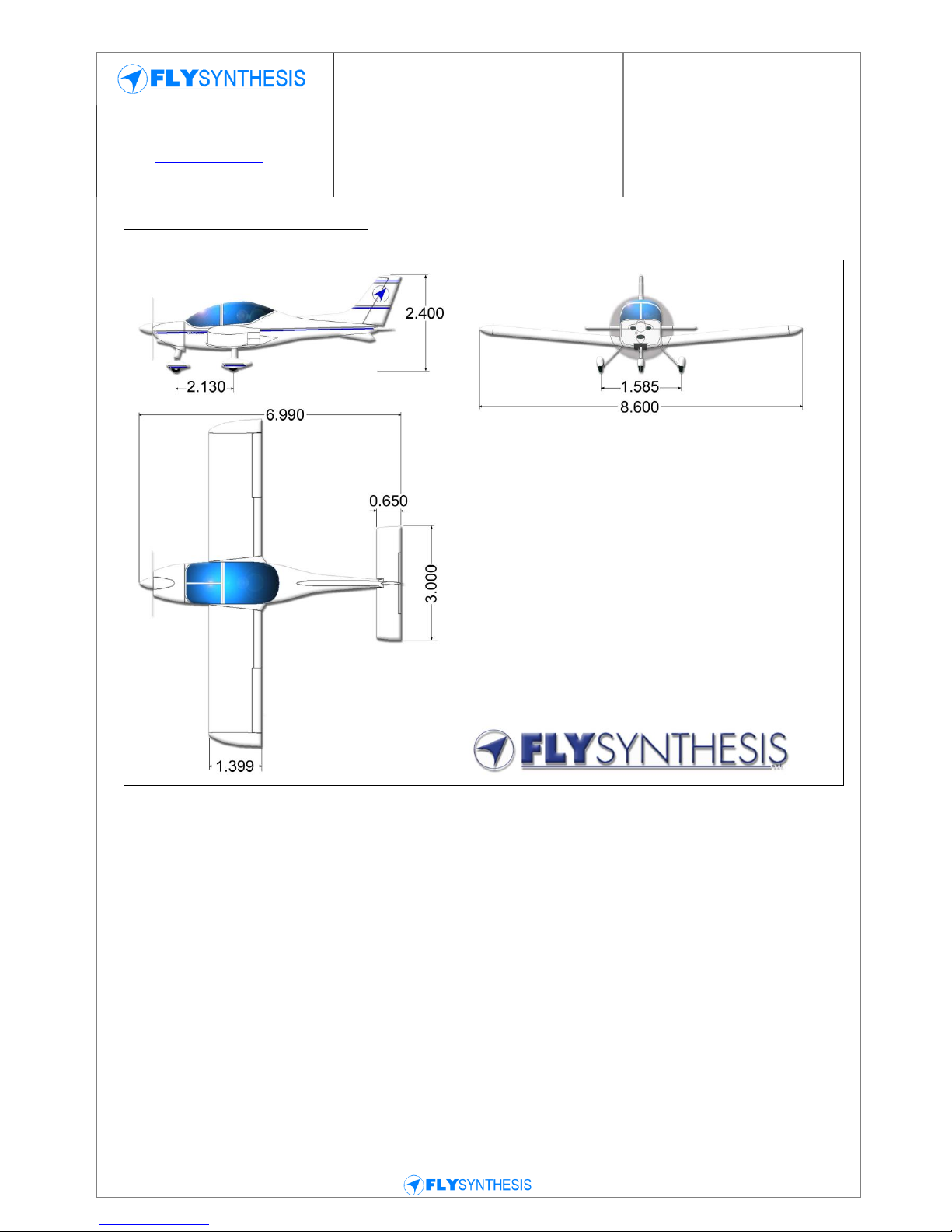

DIMENSIONS

General

Wing span: 8.600 m

Length: 6.990 m

Height: 2.400 m

Wing

Surface: 11.80 m2

Wing chord: 1.399 m

Page 10

Identification: POH_TC_LSA Rev.0

Page: 10 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Wing load: 46.6 kg/m2

Flap

Surface: 0.570 m2

Span: 1.700 m

Chord: 0.340 m

Travel: 0° - 45°

Aileron

Surface: 0.570 m2

Span: 1.700 m

Chord: 0.340 m

Travel: down 17° / up 22°

Stabilator

Surface: 1.950 m2

Span: 3.000 m

Chord: 0.650 m

Travel: down 11° / up 16°

Vertical fin (with rudder)

Surface: 1.150 m2

Height: 1.350 m

Mean chord: 0.850 m

Rudder

Surface: 0.600 m2

Height: 1.350 m

Mean chord: 0.440 m

Travel: +/-18°

WEIGHTS

Rotax 912 ULS

Empty weight 269 kg

Maximum allowed weight in baggage compartment 16 kg

Maximum Take Off Weight 550 kg

Minimum single pilot weight 70 kg

Maximum pilot and passenger weight 196 kg

LANDING GEAR

Type: Tricycle type landing gear with dampened nose wheel

Main gear track: 2.130 m

Wheelbase: 1.585 m

Tire: Main: 4.00x6"

Nose wheel: 4.00x4"

Tire pressure: Main: 2.2 - 2.4 bar

Nose wheel: 1.2 bar

Brakes: Main wheels hydraulic disc.

Page 11

Identification: POH_TC_LSA Rev.0

Page: 11 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

FUEL SYSTEM

Type: Two lines with mechanical and auxiliary electric fuel pump

Fuel plan draining system and fuel back system in the right tank

Tanks: Two integrated tanks with 50 liters of capacity for each tank

Televel and fuel reservoir sensor for each tank

Fuel tank caps with vent system

Non-usable fuel 2 liter for each tank

Fuel filter: Gascolator on firewall, filtered electric fuel pump

Fuel specification

Rotax 912ULS Premium Automotive Unleaded fuel min 95Ron.

Jabiru 2200A Avgas 100LL.

For complete fuel specifications see engine manufacturer manual.

ELETRICAL SYSTEM

Type: 12 V CC electric wiring with starting battery

Circuit breakers protected wiring

Provision for gyroscopic instruments, autopilot, radio and gps

AvMap EKP IV.

POWERPLANT

Engine: Rotax 912 ULS

Type: 4 stroke, 4 cylinders horizontally opposed, spark ignition engine,

liquid cooled cylinder heads, ram air cooled cylinders, two

constant depression carburetors, mechanical fuel pump, air box,

friction clutch geared reduction drive, radiator cooled oil, warm air

at carburetor system.

Ignition: increased electric ignition system HD

Engine: Jabiru 2200

Type: 4 stroke, 4 cylinders horizontally opposed, spark ignition engine,

ram air-cooled cylinders, two altitude compensated carburetors,

mechanical fuel pump, warm air at carburetor system.

Ignition: electric ignition system

Battery: Sealed Lead Acid Battery 12 Volts. (Applicable to both engines)

Standard propellers: DUC composite three blades propeller, diameter 1750 mm,

ground variable pitch. GT-2 wood two blades propeller, diameter

Page 12

Identification: POH_TC_LSA Rev.0

Page: 12 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

1730 mm, fixed pitch 1550 mm. Avtek two blades variable pitch

propeller, diameter 1760 mm. Other propeller types as approved

by the manufacturer and listed in appendix C of the maintenance

manual. (Applicable to both engines)

INSTRUMENTS

Standard instruments: Airspeed indicator, altimeter, vertical speed indicator, magnetic

compass, slip indicator, flap angle indicator, two fuel level tank

indicators with two low fuel level amber warning lamps, CHT,

EGT, RPM, oil temperature indicator, oil pressure indicator, fuel

pressure indicator, engine run time indicator, 12 Volt aux socket.

OTHER STANDARD EQUIPMENT

Main wheels and nose wheel fairings, main legs and nose leg aerodynamic fairing, depth

adjustable seats, four points safety belts, electric flap system (travel: 0° - 45°), manual trim

regulation system, fully upholstered cabin interior, canopy lock system with key, hooks for

ground anchorage, landing lights.

Page 13

Identification: POH_TC_LSA Rev.0

Page: 13 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

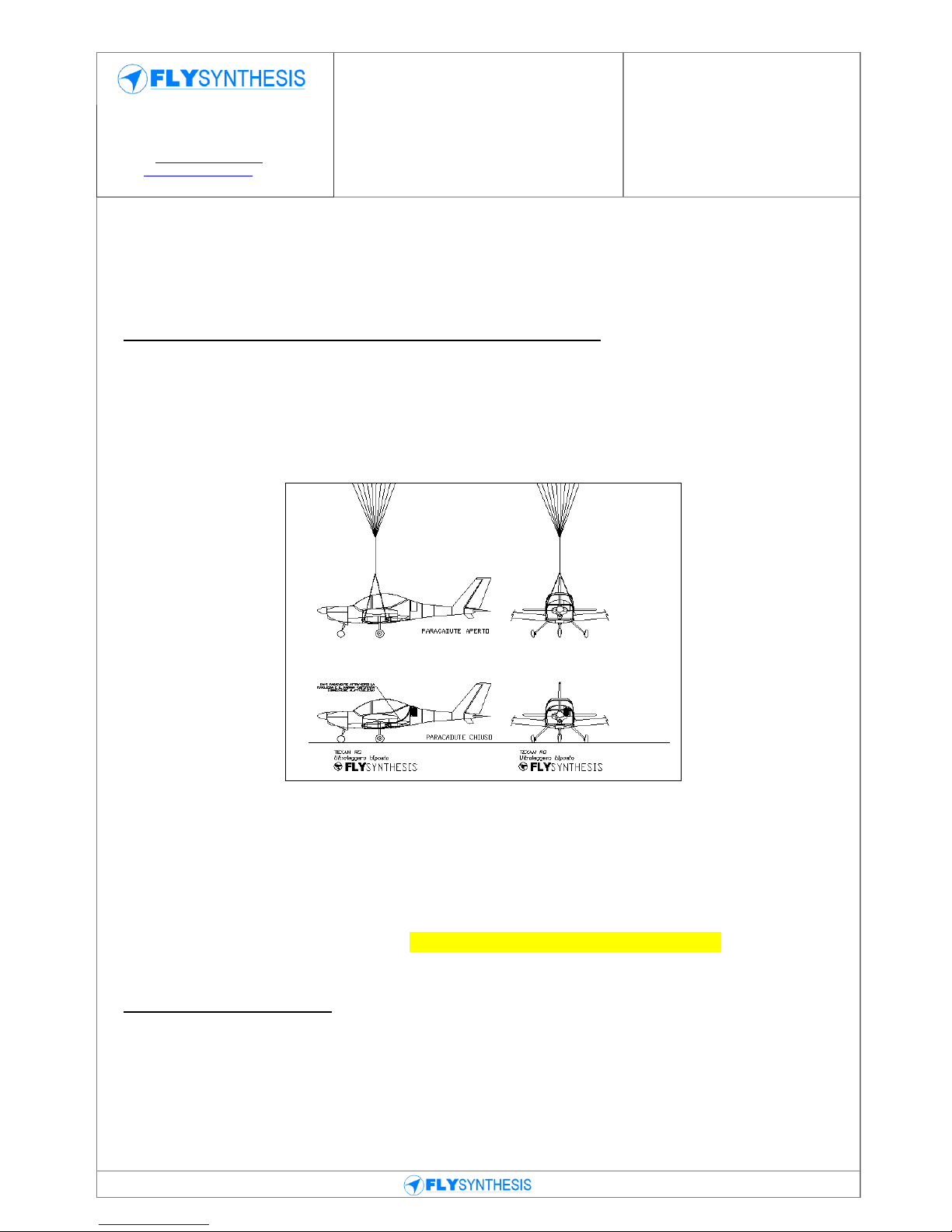

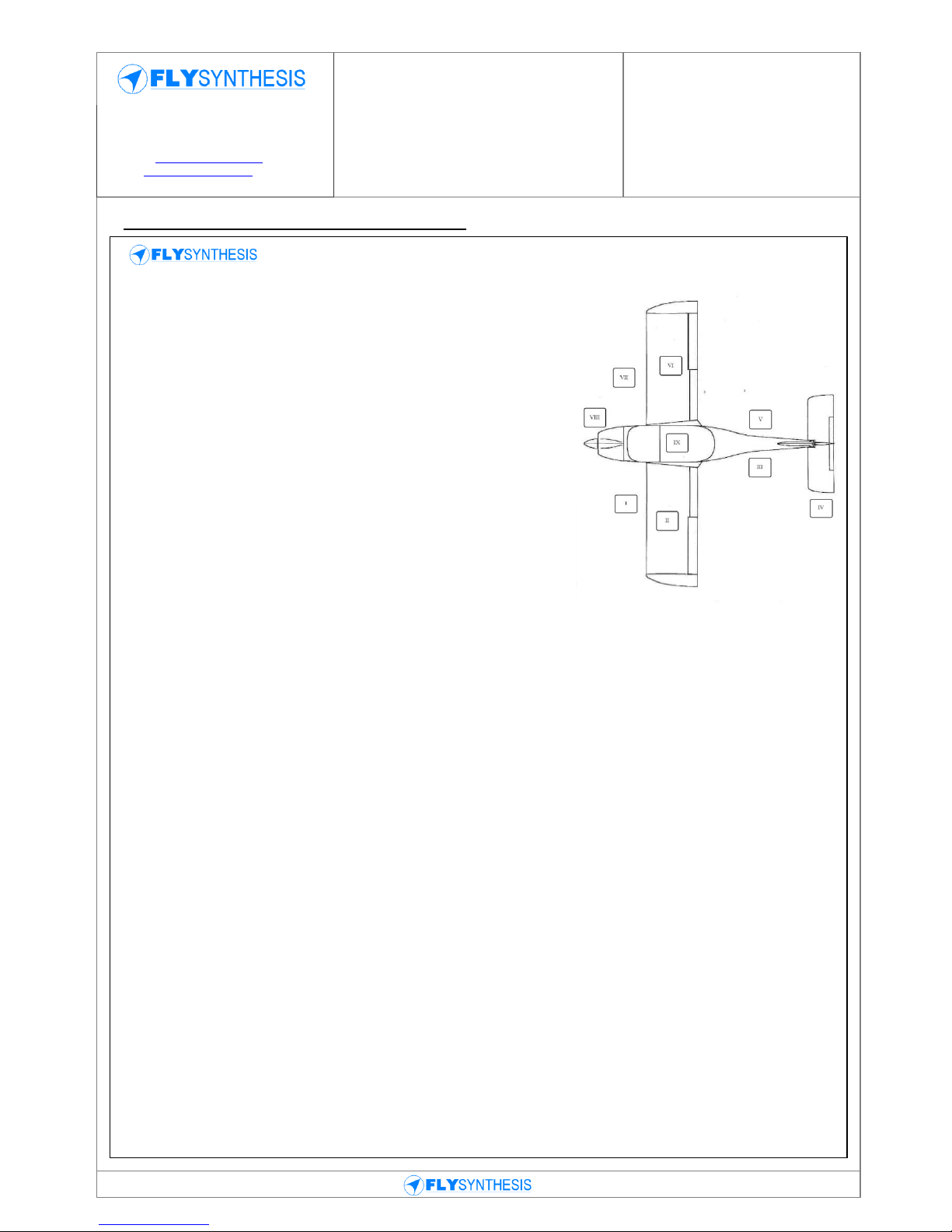

1.4 AIRCRAFT THREE VIEWS

Page 14

Identification: POH_TC_LSA Rev.0

Page: 14 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SECTION 2

Limitations

Title Page

2.1 Introduction 14

2.2 Airspeed limitations 14

2.3 Airspeed marking 14

2.4 Power plant and propeller limitations 15

2.5 Power plant instruments marking 15

2.6 Weight limitations 16

2.7 Center of gravity limitations 16

2.8 Maneuver limitations 17

2.9 Load factor limitations 17

2.10 Opening canopy limitations 17

2.11 Crew 18

2.12 Placards 18

Page 15

Identification: POH_TC_LSA Rev.0

Page: 15 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

2.1 INTRODUCTION

This section contains the operational limitations and instruments markings used for this

aircraft, the engine, and the standard equipment. The limitations of speed have been

calculated following the BCAR-S rules. The structure has been tested following the same

rules.

2.2 AIRSPEED LIMITATIONS

Speed

Rotax

912 ULS

IAS

Jabiru

2200

IAS

Notes

Vne

Never Exceed speed

240 km/h

129 KTS

Never exceed this speed in every

condition or configuration

Vno

Maximum Structural

Cruising Speed

175 km/h

94 KTS

Never exceed this speed in

turbulent air condition

Va

Maneuvering speed

145 km/h

78 KTS

Do not use full stick and full rudder

deflections above this speed

Vfe

Maximum speed with full

flaps

120 km/h

65 KTS

Do not exceed this speed with flap

extended

Vs

Stall speed without flap

93 km/h

50 KTS

Do not descend this speed without

flap to avoid undesired stall

conditions

Vs1

Stall speed in take off

position (15°)

81 km/h

44 KTS

Do not descend this speed with flap

in take off position to avoid

undesired stall conditions

Vs0

Stall speed in landing

position - full flap (45°)

74 km/h

40 KTS

Do not descend this speed with flap

in landing position to avoid

undesired stall conditions

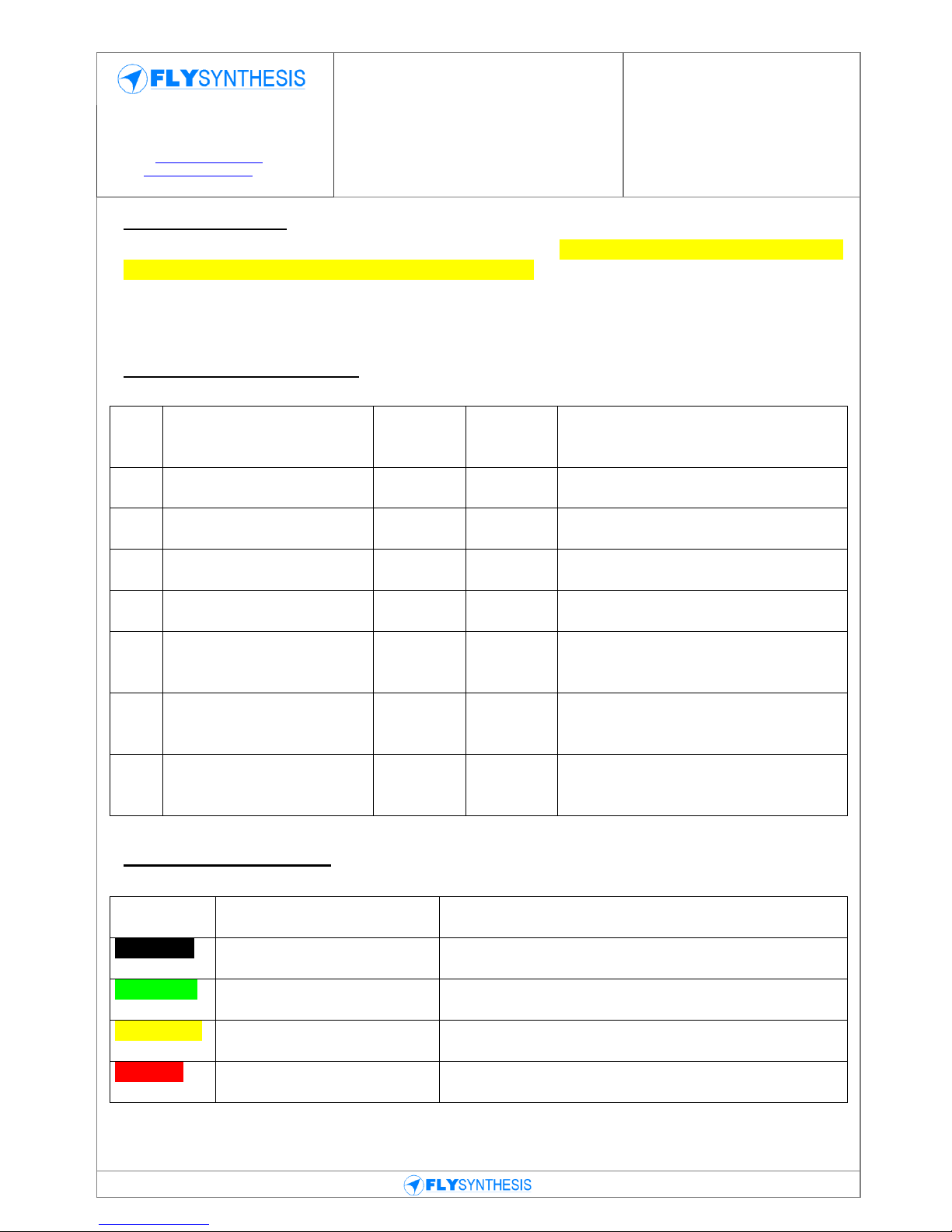

2.3 AIRSPEED MARKING

Marking

Speed range (IAS)

Definition

White arc

[Vs0 - Vfe] 40 - 65 KTS

Speed range where flap may be extended

Green arc

[Vs - Vno] 44 - 94 KTS

Speed range of normal operation

Yellow arc

[Vno- Vne] 94 - 129 KTS

Maneuver the aircraft with great caution

Red line

[Vne] 129 KTS

Maximum speed allowed

Page 16

Identification: POH_TC_LSA Rev.0

Page: 16 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

2.4 POWERPLANT AND PROPELLER LIMITATIONS

Refer always to Rotax or Jabiru operator manual

Engine manufacturer: Rotax Jabiru Aircraft

Engine model: 912 ULS 2200

Maximum take off power: 73.5 kW 63.4 kW

Maximum continuous power: 69 kW 63.4 kW

Maximum take-off RPM: 5800 rpm 3300 rpm

Maximum continuous RPM: 5500 rpm 3300 rpm

Minimum cylinder head temperature: 135°C 200°C

Maximum oil temperature: 130°C 118°C

Minimum oil pressure: 0.8 bar 2.2 bar

Maximum oil pressure: 7 bar 5.25 bar

Minimum fuel pressure: 0.15 bar 0.05 bar

Maximum fuel pressure: 0.4 bar 0.2 bar

Usable type of fuel: minimum 95 RON Avgas or minimum 95 RON

Usable type of oil: See engine manual specifications

________________________________________________________________________

Propeller manufacturer: DUC Hélices GT Propellers Avtek Idrovario

Propeller model: Carbon 3-blades Wood 2-blades Composite 2- blade

Ground variable pitch Fixed pitch Variable pitch

Maximum diameter: 1750 mm 1730 mm 1760 mm

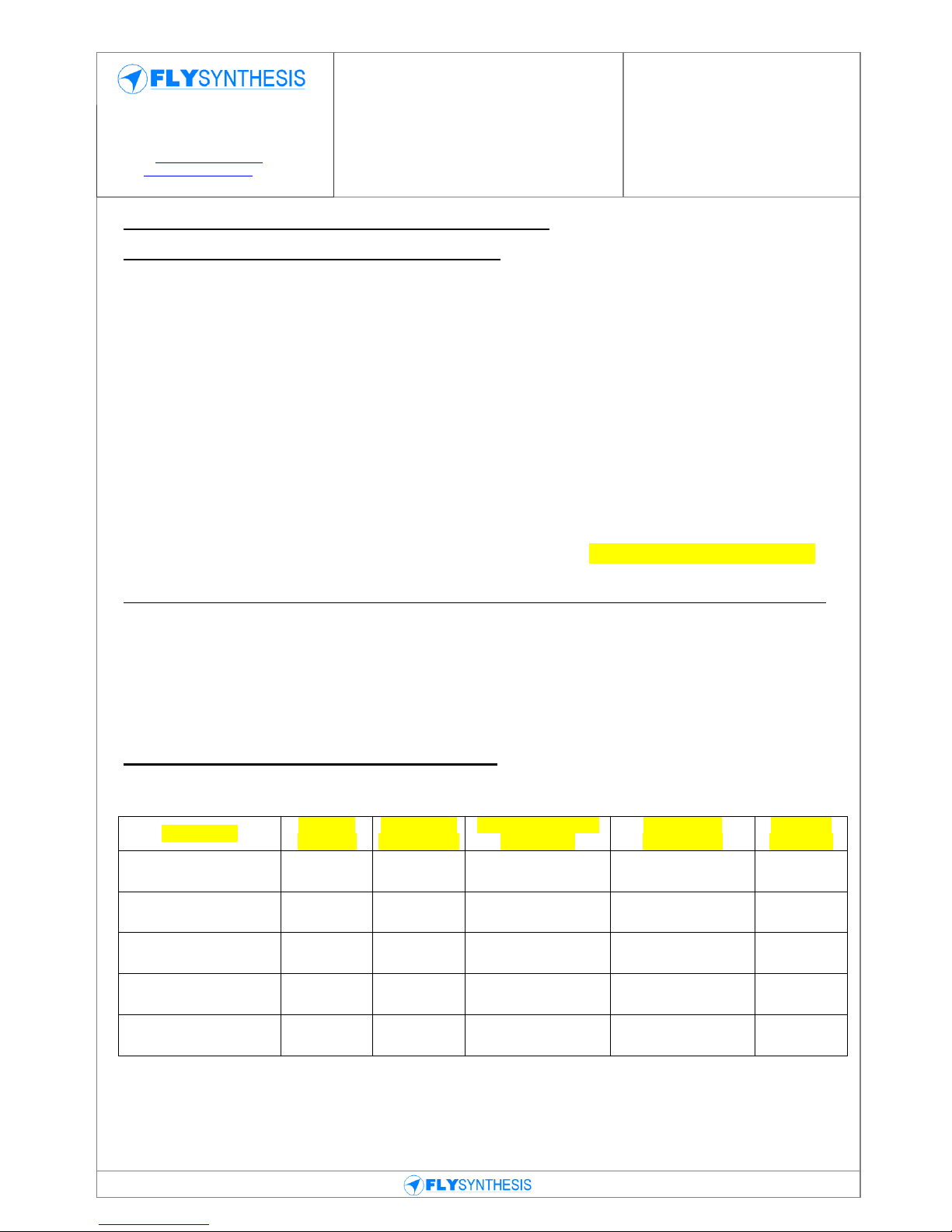

2.5 POWERPLANT INSTRUMENTS MARKING

Rotax 912 ULS engine version

Instrument

Min Red

line limit

Min Yellow

arc Caution

Green arc-normal

operations

Max Yellow

arc Caution

Max Red

line Limit

RPM indicator

nd

nd

1.400 - 5.500

rpm

5.500 - 5.800

rpm

5.800 rpm

Fuel pressure

gauge

0.15 bar

nd

0.15 - 0.4 bar

nd

0.4 bar

Oil pressare gauge

0.8 bar

0.8 - 2

rpm

2 - 5 bar

5 - 7 rpm

7 bar

Oil temp. gauge

50°C

50° - 90°C

90° - 100°C

110° - 130°C

130°C

CHT

50°C

nd

50° - 100 °C

110° - 135°C

135°C

Page 17

Identification: POH_TC_LSA Rev.0

Page: 17 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Jabiru 2200 engine version

Instrument

Min Red

line limit

Min Yellow

arc Caution

Green arc-normal

operations

Max Yellow

arc Caution

Max Red

line Limit

RPM indicator

nd

nd

900 - 3.300 rpm

nd

3.300 rpm

Fuel pressure

gauge

0.05 bar

nd

0.05 - 0.2 bar

nd

0.2 bar

Oil pressare gauge

0.8 bar

nd

2.2 - 5.25 bar

nd

5.25 bar

Oil temp. Gauge

15°C

15° - 80°C

80° - 100°C

100° - 118°C

118°C

CHT

50°C

nd

50° - 180 °C

180° - 200°C

200°C

Below 70% of power

Above 70% of power

EGT

680° - 750°C

640° - 780°C

2.6 WEIGHT LIMITATIONS

Rotax 912 ULS

Empty weight 269 Kg applies to 24-7520 only

Maximum fuel weight 77 Kg

Maximum allowed weight in baggage compartment 16 Kg

Maximum Take Off Weight 550 Kg

2.7 CENTER OF GRAVITY LIMITATIONS

With the purpose to achieving the best performances of flight and operations in complete

safety, according to the procedures described in this manual, the aircraft must have

employed respecting all the schemes of load and balancing pointed out in the following

pages.

Pilot must consider the limit of weighing and all correlated parameters.

Before the delivery of the airplane, center gravity position and weight of the airplane are

verified.

NOTE: Empty weight & Center gravity position must be updated after a new weighing, in the

following case:

- Substitution and/or modify of one or plus accessories and equipment;

- After painting or reparations of fuselage.

Weight and Center Gravity position must be recorded after every change to the weighing

report inside this manual only by authorized personnel. The weighing report must be

recalculated and reissued if the empty weight changes by more than 0.5% of MTOW or 10

kg whichever is greater of the empty weight or CoG position has changed by more than 2%

of the maximum permissible CoG range or 5mm whichever is greater.

Page 18

Identification: POH_TC_LSA Rev.0

Page: 18 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

The location of the CG can be defined by reference to the % MAC.

Maximum anterior limit: 27% M.A.C. correspondent to 378 mms

Maximum back limit: 36% M.A.C. correspondent to 504 mms

For methodology and conditions for weight and balance procedure, see section 6.

2.8 MANOEUVRE LIMITATIONS

All aerobatics maneuvers are prohibited.

The normal flight operations permitted are as follows:

- Every connected maneuver to the normal flight operation,

- Stalls, with exclusion of the accelerated stall (superior to 1 g)

- Low speed figure eight, chandelle, turns below 60°

The use of the aircraft has to conform with the Rules of the State within it flies

WARNING: Flight in known icing conditions, snow and heavy rain is prohibited.

The pilot is responsible for determining the airworthiness of the aircraft before each flight

including on board fuel level verification.

All maneuvers at load factor less than - 0.5 g must be performed for no longer than 5

seconds.

In single pilot operation, belt and shoulder harness of the vacant seat must be secured to

avoid uncontrolled movement of seat back and belt.

2.9 LOAD FACTOR LIMITATIONS

The load factors limit used for the calculation of the structures are conforming to BCARSection S rules:

Flap retracted Flap extended

- Maximum positive load factor 3.8 (+) - Maximum positive load factor 2.0 (+)

- Maximum negative load factor 1.9 (-) - Maximum negative load factor 0.0 (+)

2.10 OPENING CANOPY LIMITATIONS

During flight, engine operation and taxi operation the canopy must remain closed and

securely locked via the 4-point hook locking system. The only exception is if the optional

"taxi open system", safety locking mechanism has been fitted, in this case it is possible to

slightly maintain the canopy open only during taxi and ground operations.

WARNING: during the flight is absolutely forbidden to hold the canopy in any position other

than in the securely locked mode. Never try to open the canopy during the flight!

Page 19

Identification: POH_TC_LSA Rev.0

Page: 19 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

2.11 CREW

The minimum crew for flight operations is a person. The pilot can choose the place of

command either the right or the left. The maximum number of people permitted on board is

two.

2.12 PLACARDS

The following placards are to be located and visible to the pilot where an inspection or

function is relevant and required in the designated area.

Located on the Instrument panel

Located on Nose Leg fairing Located on both Main Leg fairing

Located next to fuel each filler cap Located in baggage compartment

Located in baggage compartment

WARNING

THIS AIRCRAFT WAS MANUFACTURED IN ACCORDANCE WITH LIGHT SPORT

AIRCRAFT AIRWORTHINESS STANDARDS AND DOES NOT CONFORM TO STANDARD

CATEGORY AIRWORTHINESS REQUIREMENTS.

INFLATE NOSE WHEEL TO

2.2 – 2.4 bar ( 32 – 35 psi )

INFLATE MAIN WHEEL TO

1.8 bar ( 18 psi )

FUEL CAPACITY 50L

MINIMUM 95 OCTANE AUTO FUEL

OR 100 LL AVGAS

TEXAN TC 550 LSA

Speed: KTS Weight: Kg

Vne (Not Exceeded) 129 Maximum Take-off 550

Vmo (Max Operating) 94 Empty Weight 305

Va (Min Maneuvering) 78 Minimum Pilot 70

Vfe (Max Full Flap) 59 Maximum Pilot +

Vs (Stall) 50 passenger 196

Vso (Stall with flap) 45

AEROBATIC MANOEUVRES AND

BAGGAGE COMPARTMENT

Maximum 16 KG

Evenly distributed

Page 20

Identification: POH_TC_LSA Rev.0

Page: 20 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Located in baggage compartment

Located interior port side of canopy

Located interior starboard side of canopy

Located in exterior port side latch Located in exterior starboard side latch

TEXAN TC 550 LSA DATA PLATE

Fuselage s/n ____________________

Date of Manufacture ____________________

Engine Type ____________________

Engine s/n ____________________

Propeller type ____________________

Propeller s/n ____________________

Hub s/n ____________________

EXIT

CLOSED OPEN

EXIT

OPEN CLOSED

OPEN

CLOSE LHS

CLOSE

OPEN RHS

Page 21

Identification: POH_TC_LSA Rev.0

Page: 21 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SECTION 3

Emergency procedures

Title Page

3.1 Introduction 21

3.2 Ground emergency procedures 21

3.3 Take off emergency procedures 21

3.4 During flight emergency procedures 22

3.5 Electric plant failure 23

3.6 Landing emergency procedures 24

3.7 Opening parachute procedure 25

3.8 Other emergency 25

Page 22

Identification: POH_TC_LSA Rev.0

Page: 22 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

3.1 INTRODUCTION

An emergency situation is extremely rare; even so, the pilot responsible for the aircraft

should meticulously carry out daily pre-flight controls checks. A safe airworthy aircraft should

be maintained according to the requirements of the accompanying maintenance manual.

This section contains the recommended procedures should an emergency arise. It is

strongly advised that Pilots become familiar with these procedures.

3.2 GROUND EMERGENCY PROCEDEDURES

ENGINE ON FIRE

1. Fuel tank faucet - Close

2. Electric fuel pump - Off

3. Cabin heating - Off

4. Throttle - All forward

5. Master switch - OFF

6. Ignition magnets key - OFF

7. Get out of the aircraft immediately

8. If possible, use an extinguisher to extinguish the fire.

WARNING: Not remove the engine cowling until the complete extinction of the fire.

Don't use water to extinguish the fire.

3.3 TAKE OFF EMERGENCY PROCEDURES

TAKE OFF INTERRUPTION (during take off run)

1. Throttle - All rearward (reduce to minimum RPM)

2. Brakes - Brake and avoiding skidding the wheels

3. Flap - Retract

4. Ignition magnets key - OFF

5. Master switch - Off

6. Fuel tank faucet - Off

ENGINE FAILURE DURING TAKE OFF (after rotation - below 50 mt)

1. Fuel tank faucet - Close

2. Electric fuel pump. - Off

3. Master switch & ignition magnets key - Off

4. Safety belts - Tighten well

5. Maintain a linear line of flight, without turning if possible, and if the area allows it, get

ready for a forced landing (see relative paragraph)

ENGINE FAILURE DURING TAKE OFF (during climb)

If the height allows it, proceed in the following way:

1. Best glide speed - (59 KTS)

2. Electric fuel pump - Verify ON

3. Fuel tank faucet - Verify RH tank faucet open

4. Fuel tank level - check fuel quantity

5. Fuel pressure - Verify within limits

Page 23

Identification: POH_TC_LSA Rev.0

Page: 23 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

6. Ignition magnets key - Verify ON

7. Throttle - Position warm engine starting

8. Engine start procedure

- If the engine immediately starts up climb to a safe height and land ASAP for a check.

- If the engine doesn't start up prepare for an emergency landing & proceed as follows:

9. Flap - As necessary (30° or 45°)

10. Fuel tank faucet - Close

11. Electric fuel pump - Off

12. Master switch & ignition magnets key - Both Off

WARNING: Land AS SOON AS POSSIBLE in case of fire on board.

- Never perform a 180° turn from too low a height in an effort to return to the runway.

3.4 DURING FLIGHT EMERGENCY PROCEDURES

ENGINE ROUGHNESS/ ENGINE SHUTDOWN

1. Throttle - Check position and friction

2. Check engine instruments - Check parameters

3. Choke lever - OFF / All rearward

4. Fuel tank faucet - Select tank with maximum fuel

5. Electric fuel pump. - ON

6. Fuel pressure - Verify within limits

7. Warm air to carburetors - ON

8. Ignition magnets key - Both / Verify

9. Master switch - Verify / ON

10. Throttle - Position warm engine starting

11. Start - Operate start procedure

12. Check all the engine parameters and land as soon as possible for a full check

WARNING: If the engine doesn't start up choose a proper zone for an emergency landing.

ENGINE ON FIRE

1. Fuel tank faucet - Close

2. Electric fuel pump - Off

3. Throttle - All forward

4. Vent system - All closed

5. Cabin heating system - Off

6. Master switch & ignition CDI’s key - Off

7. Best glide speed - (59 KTS)

9. Landing ASAP

WARNING: Do not attempt to re-start the engine even if engine fire has ceased, but prepare

for an emergency landing.

Page 24

Identification: POH_TC_LSA Rev.0

Page: 24 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

STALL RECOVERY PROCEDURE

1. Apply full power to reduce the loss of height.

2. Push softly forward the control stick to eliminate the stall conditions.

NON-INTENTIONAL SPIN RECOVERY PROCEDURE

WARNING: don't try to stop the rotation using the opposite ailerons

1. Throttle - At minimum RPM

2. Rudder pedals - All opposed to the sense of rotation

3. Control stick - Neutral, softly to dive

4. When the rotation stops and the aircraft is under control, return to level flight,

WARNING: do not exceed the Vne speed.

3.5 ELETRICAL WIRING FAILURE

GENERATOR WARNING LAMP LIGHTING

1. Voltmeter - Check voltage (if installed)

2. Non essential electric equipment - Off

3. Land ASAP

A fully charged and functional battery should permit the operation of trim, flap and aux

electric fuel pump for about 20 minutes.

OVERVOLTAGE (Voltmeter indication [if installed] over 16 V)

1. Master switch - Off

2. Voltmeter - Verify the decrease of voltage

3. Master switch - On

4. Voltmeter - Verify the increase of voltage (within limits)

If the voltage does not return within limits, proceed as follows

5. All non-essential electrical equipment must be switched off

6. Land ASAP

A fully charged and functional battery should permit the operation of trim, flap and aux

electric fuel pump for about 20 minutes.

LOW VOLTAGE IN FLIGHT

1. Possible causes - Excessive consumption (Too many appliances on)

- Damage of the alternator

- Interrupted fuse

2. Landing ASAP

LOW VOLTAGE ON GROUND

1. RPM - Reduce

2. Navigation and landing lights - Off

3. Voltmeter - Verify within limits

4. If the check has negative result - Shutdown engine

Page 25

Identification: POH_TC_LSA Rev.0

Page: 25 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

ELECTRICAL WIRING or EQUIPMENT ON FIRE

An electrical fire is recognizable by the distinct odor of burning plastic and white smoke.

1. Master switch - Off

2. Vent systems - All open

3. Cabin heating - Off

4. Landing ASAP

WARNING: get ready to possibly land without the use of flaps and trim (if electric).

SMOKE ELIMINATION FROM CABIN

1. Vent systems - All open

2. Cabin heating - Off

3. Master switch - Off

4. If the smoke remains dense land immediately.

WARNING: absolutely DO NOT open the canopy.

3.6 LANDING EMERGENCY PROCEDURES

LANDING WITHOUT FLAPS

1. Verify flap/trim circuit breaker is in the ON position.

2. Verify the position of both the flaps visually

With flaps in symmetrical position (both retracted or extracted at the same angle)

3. Try to retract the flaps

4. Verify that there is enough free space from obstacles for a safe landing

5. Land as normal but maintain a landing speed not less than 48 Knots

LANDING WITH A DEFLATED TIRE

1. Landing as per normal condition

2. Before contacting the ground shutdown the engine and turn off electrical equipment.

3. When landing hold-off contact with the ground on the side of the deflated tire for as

long as possible

4. Get ready for a tendency to yaw on the side of the deflate tire

5. Maintain the directionality with rudder and nose wheel steering

6. If nose wheel is deflated maintain backpressure on control stick and keep the nose

wheel in a central position.

FORCED LANDING

1. Best glide speed - (59 KTS)

2. Safety belts - Tighten well

3. Throttle - All rearward (minimum position)

4. Fuel tank faucet - Closed

5. Electric fuel pump. - Off

6. Master switch & ignition magnetos key - Off

CAUTION: Choose a suitable area for an emergency landing.

7. Flap - As necessary

8. Trim - As necessary

Page 26

Identification: POH_TC_LSA Rev.0

Page: 26 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

9. Final - Check velocity (at least 55 KTS, flap with 45°)

10. Landing - Check velocity (at least 55 KTS, flap with 45°)

The contact with the ground should happen at the minimum possible speed, maintain lifted

the nose wheel for the longest possible time.

3.7 OPENING PARACHUTE PROCEDURE (IF INSTALLED)

The emergency parachute is located in the left back part behind the canopy, situated in a

special container drawn inside the fuselage. The emergency parachute is fixed to the aircraft

through four Kevlar ropes, passing in the external part of the fuselage, attached to antitorsion tube of the wing. The emergency parachute must be used only incase of complete

loss of the control of the aircraft.

a. Shutdown the engine (magnetos OFF)

b. Pull red handle between the two seats, at least 20 centimeters,

c. Close both fuel faucets

d. Tighten the safety belts

e. Shutdown the electric plant (Master OFF)

f. Do crouch and to protect the face with the hands

For further information and notes on function and maintenance, consult the parachute

manual.

3.8 OTHER EMERGENCY

OIL TEMPERATURE & PRESSURE IN YELLOW ARC OR REL LINE

If the oil pressure is low (yellow arc) but the oil temperature is in normal operation range

(green arc)

- Land ASAP as per normal procedure.

If the oil pressure indication is too low or too high (red arc)

- Land ASAP and get ready for a forced landing (see relative paragraph)

Page 27

Identification: POH_TC_LSA Rev.0

Page: 27 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

LOW FUEL PRESSURE

1. Electric fuel pump - On

2. Fuel tank faucets - Open alternately the faucets to check the fuel circuit

3. Fuel pressure - Check within limits

4. If the fuel pressure does not reach the normal operating range, land ASAP

UNINTENTIONAL FLIGHT WITHIN ICING CONDITIONS

WARNING: Flight in known icing conditions, snow and heavy rain is prohibited.

If you meet unintentional icing condition during the flight, descend as soon as possible to a

lower height. If the wing leading edge and the stabilator leading edge are covered by ice

formations, remember that stall speed will increase, you will need more engine power to

maintain the same velocity and the maneuverability of the airplane will decrease.

1. Carburetor heating system (if installed) - On

2. Engine RPM - Maintain the maximum continuous engine

power

3. Cabin heating (if installed) - On

4. Move all control surfaces to break potential icing formations.

ICING FORMATIONS ON CARBURETTORS

You can recognize icing formations on carburetors if RPM decreases without moving the

throttle. You can find this phenomenon during a descent with low RPM in a day with a lot of

humidity.

1. Carburetor heating system (if installed) - On

2. Throttle - All forward when RPM starts to increase

3. Carburetor heating system (if installed) - Off

4. Reinstate normal flight conditions

ABNORMAL ENGINE VIBRATIONS

1. Verify the reduction of the vibrations with a reduction of the RPM’s

2. Land as soon as possible

3. Be prepared for a possible engine failure and to commence a forced landing

LANDING WITH BRAKE SYSTEM FAILURE

1. Look for a long grassy runway with absence of obstacles (the grass has a light braking

action)

2. Land with the flaps to the maximum extension and reduce speed to the minimum safe

speed

(After touching the ground)

3. Master switch & ignition magnets key - Off

Page 28

Identification: POH_TC_LSA Rev.0

Page: 28 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SECTION 4

Normal procedures

Title Page

4.1 Introduction 28

4.2 Speed for normal employment 28

4.3 Fuel circuit draining procedure and refueling operations 28

4.4 Pre-flight Inspection 29

4.5 Flight inside heavy rain 35

Page 29

Identification: POH_TC_LSA Rev.0

Page: 29 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

4.1 INTRODUCTION

This section contains the information for normal flight conditions and the checklist to follow

before every flight.

4.2 SPEED FOR NORMAL EMPLOYMENT

Except otherwise suitable, the following speeds refer to the maximum take-off weight equal

to 550 Kg and can be used for any inferior weight.

Take off (Flap 15°) Rotax 912 ULS Jabiru 2200

Rotation (50 KTS) ()

Speed at 50 ft (15 m) obstacle (55 KTS) ()

Climb

Best angle of climb speed Vx, (5° flap), (60 KTS) ()

Best rate of climb speed Vy, (0° flap) (70 KTS) ()

Cruise

Maneuvering speed (Va) (78 KTS) ()

Max speed in turbulent air conditions (Vmo) (94 KTS) ()

Never Exceeding Speed (Vne) (129 KTS) ()

Landing approach (65 KTS) ()

Landing (Flap 45°) (55 KTS) ()

Touch & go (Maximum power, flap 15°) (55 KTS) ()

Maximum demonstrated crosswind velocity (17 KTS) ()

4.3 FUEL CIRCUIT DRAINING PROCEDURE AND REFUELLING OPERATIONS

The fuel circuit draining procedure must be done before the first flight of the day, 10 minutes

after the refueling and if the aircraft has remained parked for more than three hours between

two flights.

The fuel circuit draining is performed through the Gascolator filter, situated in the right lower

part of the firewall. Use a transparent and clean container, drain about 80 - 100 cc of fuel.

Verify the absence of water.

CAUTION: Perform the fuel circuit draining operation before moving the airplane from the

parking area, to avoid any mixing of condensate water if present on the fuel tanks. If water is

present repeat the fuel circuit draining operation until no water is evident.

Refuel through the fuel filler located on the upper layer of the wings, either by jerry cans or

directly with the gasoline pump.

CAUTION: As the Texan employs an overflow fuel system that returns excess fuel to the

Right hand side tank, it is recommended to always use the right side fuel tank. When the

right tank is near empty use the left tank. To avoid the right tank being overfilled with excess

fuel, frequently alternate the use of both fuel tanks during the cruise. The drawing of fuel

simultaneously from both tanks is not recommended.

Page 30

Identification: POH_TC_LSA Rev.0

Page: 30 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

4.4 PRE-FLIGHT INSPECTION

WARNING: Before every flight the pilot must check completely the airplane with great

attention and accuracy.

In this section there is a standard pre-flight checklist. (Valid for each version)

The pre-flight inspections must be carried out BEFORE EVERY FLIGHT. The pilot in

command is responsible for such inspections. The inspection does not require any special

tooling, although a flashlight can be useful for inspecting dark areas. The purpose of the pre

flight inspection is to verify that there’s no evidence of defective parts or problems that can

endanger the safety of flight.

Page 31

Identification: POH_TC_LSA Rev.0

Page: 31 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Remove all the protections

1. Pitot-cover,

2. Wheel stops,

3. Mobile surfaces stops,

4. Canopy covering,

5. Propeller protection,

6. Fuel draining procedure.

Left main landing gear (I)

Leg no distortion, bolts locked, no sign of cracks on weldings

Brake assembly condition and tightness

Tire general good condition, inflated correctly

Wheel fairing good condition and free space between the wheel and mounting

bracket.

Left wing (II)

Wing surface absence of buckling, absence of delamination

Karman absence of delamination, fixed correctly

Leading edge absence of delamination,

Wing tip no defects, fixed correctly

Trailing edge absence of delamination, no signs of cracks

Flap & aileron absence of delamination, no signs of cracks, free movement, no

excessive play on hinges, fixed correctly, balancing mass fixed correctly,

no signs of lateral movement.

Fuselage left side (III)

Fuselage surface absence of buckling, absence of delamination, inspection holes closed

Empennage (IV)

Vertical fin absence of buckling, absence of delamination

Rudder absence of delamination, hinges fixed correctly

CAUTION: Lower the tail of the aircraft to lift the nose wheel, check the free movement of

the rudder, any problem on the hinge.

Bowden cables fixed correctly.

Stabilator free movement during all travel range, absence of buckling,

absence of delamination

Stabilator hinge absence of delamination, fixed correctly, no play

Balancing mass fixed, no play

Hinge pins fixed correctly

Trim tab free movement, absence of defects, and no play.

Page 32

Identification: POH_TC_LSA Rev.0

Page: 32 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Fuselage right side (V)

Fuselage surface absence of buckling, absence of delamination, inspection holes closed

Right wing (VI)

Wing surface absence of buckling absence of delamination

Kerman absence of delamination, fixed correctly

Leading edge absence of delamination,

Wing tip no defects, fixed correctly

Trailing edge absence of delamination, no signs of cracks

Flap & aileron absence of delamination, no signs of cracks, free movement, no

excessive play on hinges, fixed correctly, balancing mass fixed correctly,

no signs of lateral movement.

Pitot tube no defects, no blockage and fixed correctly

Right main landing gear (VII)

Leg no distortion, bolts locked, no sign of cracks on weldings

Brake assembly condition and tightness

Tire general good condition, inflated correctly

Wheel fairing good condition and free space between the wheel and mounting

bracket.

Nose wheel (VIII)

Fixing axle bolts check correct tightness

Wheel fairing good conditions and free space between the wheel and

mounting bracket.

Tire general good condition, inflated correctly

Damper no signs of cracks or distortion, free movement

Nose wheel support structure no signs of cracks or distortion.

Propeller (VIII)

Hub & blades no signs of cracks and is clean.

Spinner no signs of cracks, fixed correctly

Engine (VIII)

Upper cowling remove

Oil tank check level

Coolant tank check level

Radiator and air inlet no signs of cracks, free from obstructions

Engine clean, no oil or coolant leakage

Muffler & silencer manifold no signs of cracks and muffler springs hooked.

Oil and coolant tube system correct functionality, no leakage

Ignition & electrical wiring correct functionality.

Throttle & choke cables free movement

Upper cowling reinstall and check tightness.

Page 33

Identification: POH_TC_LSA Rev.0

Page: 33 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Check inside cabin (IX)

Instruments panel - fixed correctly, all placards present

Master switch ON - all instruments ON

Master switch OFF - all instruments OFF

Control stick - full free movement, fixed correctly in its support

Rudder pedals - no distortion or signs of cracking, correct operation of

centering system and support fixed correctly.

Throttle & choke levers - free movement, fixed correctly in the support

Brake lever & parking brake - remove parking brake lock and check lever functionality.

- Insert parking brake.

Trim lever - check correct functionality

Safety belts - check correct functionality

Seats, - fixed correctly.

Canopy - clean, no signs of cracks, correct functionality of locking

system.

Windshield - clean, fixed correctly on fuselage

Luggage - secured.

Weight & balance - calculated.

Flight logbook - record the airtime.

BEFORE STARTING ENGINE

Pre-flight check - completed

Seats - adjusted

Safety belts - adjusted and fastened

Canopy - closed and locked

Parking brake - ON

Flight controls - free

Fuel faucets - RH open, LH closed

Trim - Neutral

ENGINE START

Engine cold - ON Choke lever (all rearward)

Engine warm - OFF Choke lever (all forward)

Electric fuel pump - ON for 10 sec. then OFF

Throttle - At minimum + 1 cm.

Master switch - ON

Generator warning lamp - ON

Ignition magnets key - each magnetos ON

WARNING: Ensure that the propeller area is clear of any person or object “CLEAR PROP”

Start procedure - Max 20 sec of starting, rest one minute before retrying

Throttle - 2500 RPM for R912 -1200 RPM for Jabiru 2200

Oil pressure - Green arc in 5 sec.

Generator warning lamp - OFF

Electric fuel pump - OFF

Page 34

Identification: POH_TC_LSA Rev.0

Page: 34 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

BEFORE TAXIING

Electrical system - ON and checked

Navigation instruments - Checked

Flaps - Position to take off (15°)

Parking brake - OFF

TAXIING

Brakes - Check both operate equally

Flight control - Free full movement, stick and pedals

Flight instruments - Check magnetic compass and set altimeter and set

gyro’s if fitted.

Throttle - As necessary

ENGINE CHECK

Rotax 912 ULS Jabiru 2200

Parking brake - ON - ON

Fuel tank faucets - RH Open, LH Closed - RH Open, LH Closed

Temperature & pressure - Within limits, in green arc - Within limits, in green arc

Trim - Neutral - Neutral

Flight controls - Free - Free

Check magnetos - 3000 RPM maximum decrease - 2000 RPM maximum decrease

300 RPM for each magnets 300 RPM for each magnets

Throttle - All forward, check minimum - All forward, check minimum

5000-RPM +/- 150 for 5 sec. 3000-RPM +/- 150 for 5 sec.

Check minimum RPM - 1400 RPM - 900 RPM

CAUTION: Don't apply full power before 60° C of CHT.

During taxing don’t allow the engine CHT to exceed 135° C

BEFORE TAKE-OFF

Flight controls - Full Free and Correct

Trim - Neutral

Electric fuel pump - ON

Flaps - Set for take-off (15º)

Fuel tank faucets - RH Open, LH Closed

Engine instruments - Within limits

Flight instruments - Check and regulated

Safety belts - Adjusted and fastened

Canopy - Check 4 locks are engaged and locked

- Check canopy open lamp OFF

Parking brake - OFF

Page 35

Identification: POH_TC_LSA Rev.0

Page: 35 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

TAKE-OFF

Aircraft - Align with runway

Throttle lever - Full open smoothly

At (40KTS) - Rotation

WARNING: for a take off from short runway with an obstacle of 15 m, use flap with 20°.

- Rotation - (45 KTS) Then level and accelerate

- Climb speed - (Vx) (60 KTS)

At an altitude of 100 m (300 ft), if a steep climb is necessary to clear obstacles

Flaps - Up

Trim - As necessary

Speed - Vx or Vy

Throttle - As necessary

Electric fuel pump - Off

CAUTION: Don't maintain the flaps extended with speed higher than (70 KTS) (Vfe).

CLIMB

Rotax 912 ULS Jabiru 2200

Engine RPM - 5000 RPM. - 3000 RPM.

Engine instruments - Within limits - Within limits

Trim - As necessary - As necessary

CRUISE

Rotax 912 ULS Jabiru 2200

Throttle - As necessary - As necessary

Engine RPM - Max cont power 5500 RPM - Max cont power 3300 RPM

Engine instruments - Within limits - Within limits

CAUTION: Check frequently engine instruments and do not exceed limits.

DESCENT

Altimeter - Setting

Warm air to carburetor system - As necessary

Throttle - As necessary

Trim - As necessary

Engine instruments - Within limits

LANDING

Speed - 57 knots

Flap - As necessary

Trim - As necessary

Throttle - As necessary

Electric fuel pump - ON

Page 36

Identification: POH_TC_LSA Rev.0

Page: 36 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Parking brake check (see note b) - Check, should be off

Final Approach speed - (65 KTS)

Touch down speed - (55 KTS)

CAUTION: a) in conditions of strong cross wind or in presence of wind shear, increase the

landing speed by at least (5 KTS)

b) Before landing check brake system pressure by operating the brake lever a couple of

times if the braking system is serviceable you should feel the resistance when pressure is

applied.

TOUCH & GO

Throttle - All forward

Trim - As necessary

Flap - 15°

Speed - Vx o Vy

If you touch the ground repeat take off procedure.

AFTER LANDING

Throttle - Idle

Flaps - UP

Electric fuel pump - OFF

Brakes - Check functionality with “warm brakes”

ENGINE SHUTDOWN

Throttle - Idle

Parking brakes - ON

Electrical consumers - OFF

Magnetos - OFF (one by one) check RPM drop

Master switch - OFF

Fuel tank faucets - closed

4.5 FLIGHT INSIDE OF HEAVY RAIN

WARNING: Flying inside heavy rain is prohibited

Flying inside heavy rain is forbidden as visibility and performance of the flight is reduced,

however if unavoidable reduce speed to (80 KTS) and remember to increase the landing

speed by at least (5 KTS) with wet wing.

Page 37

Identification: POH_TC_LSA Rev.0

Page: 37 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SECTION 5 - Performances

Title Page

5.1 General information 37

Page 38

Identification: POH_TC_LSA Rev.0

Page: 38 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

5.1 GENERAL INFORMATION

This section contains all the performance data required for accurate pre-flight planning.

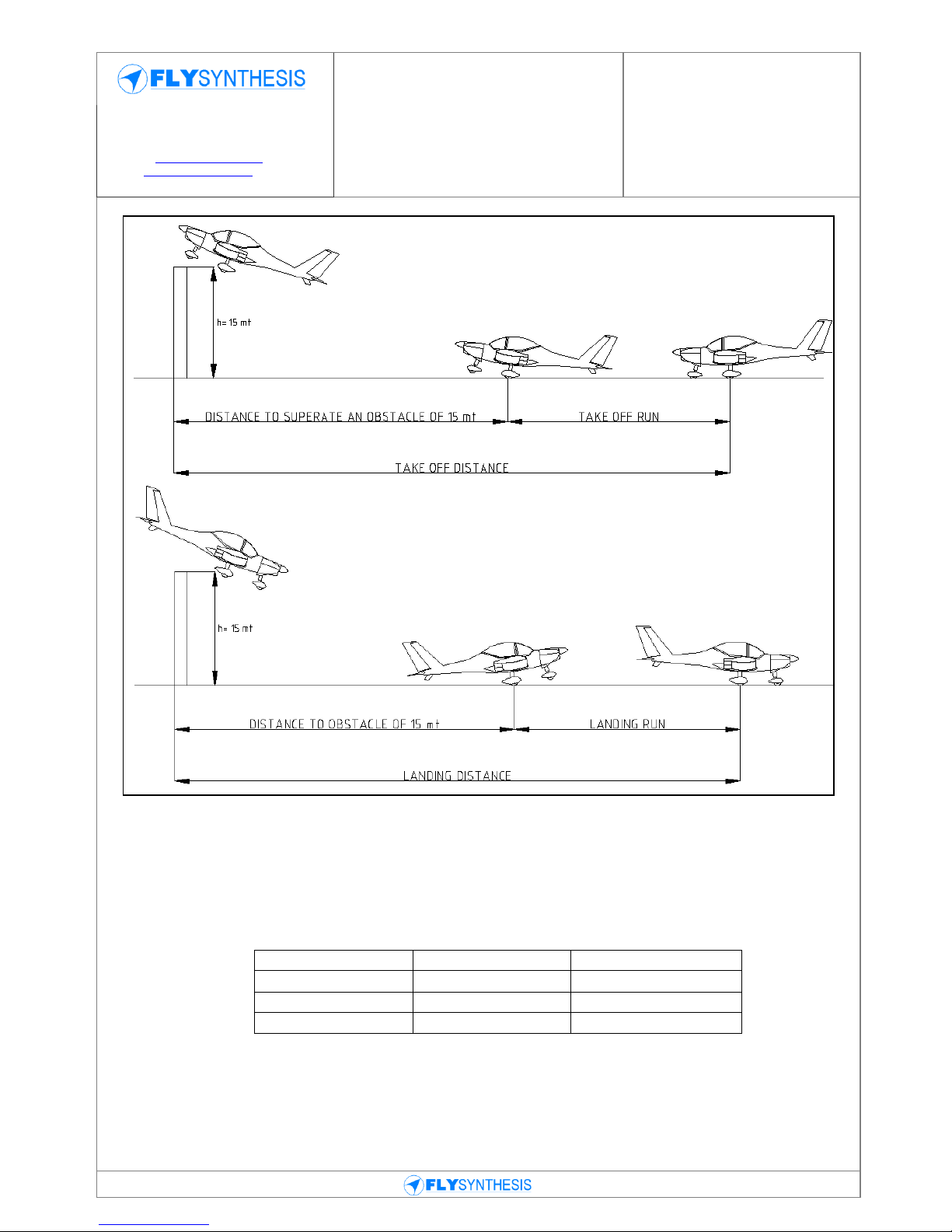

SCHEME OF TAKE-OFF & LANDING PHASES

Figure 5-1 show the take-off and landing phases and medium value recorded

SPEED CONVERSION (DENSITY ALTITUDE)

The density altitude chart (figure 5-2) is provided to determine the density altitude for outside

air temperature and pressure altitude combinations.

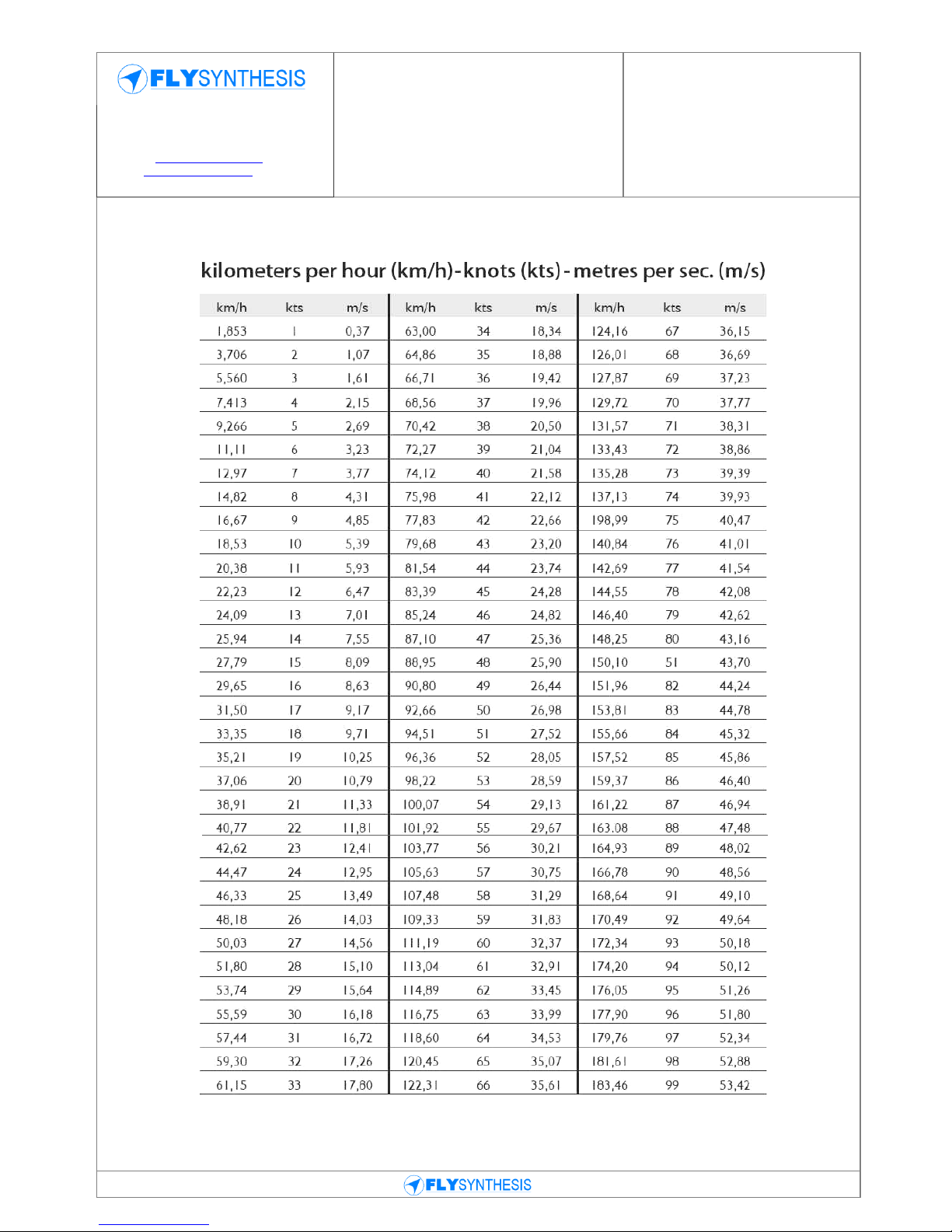

UNIT CONVERSION

Figure 5-3 shows the linear scales for conversion of [Km/h – KTS – m/s].

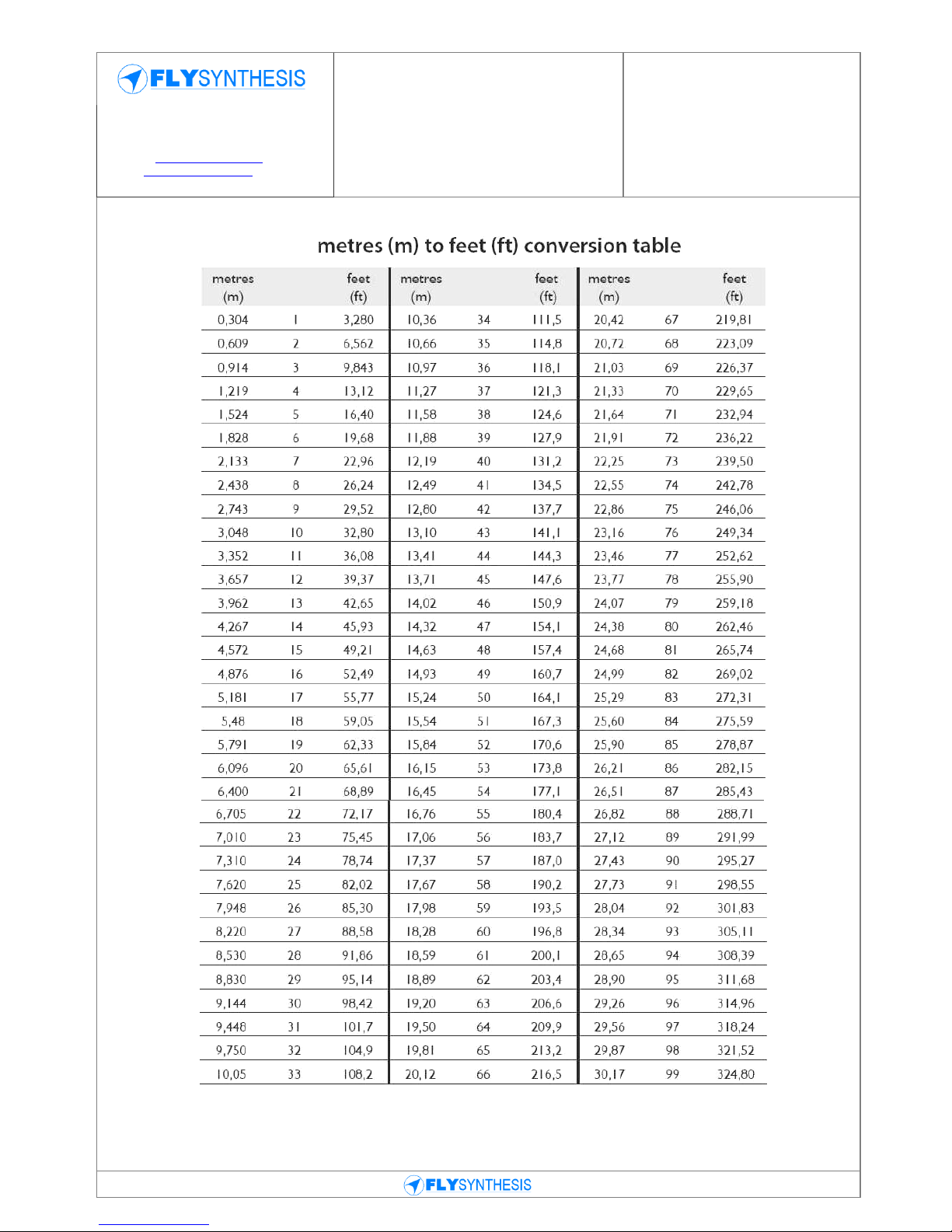

Figure 5-4 shows the linear scales for conversion of [m/s - feet/min and KTS – m/s].

Figure 5-5 shows the linear scales for conversion of [m –feet].

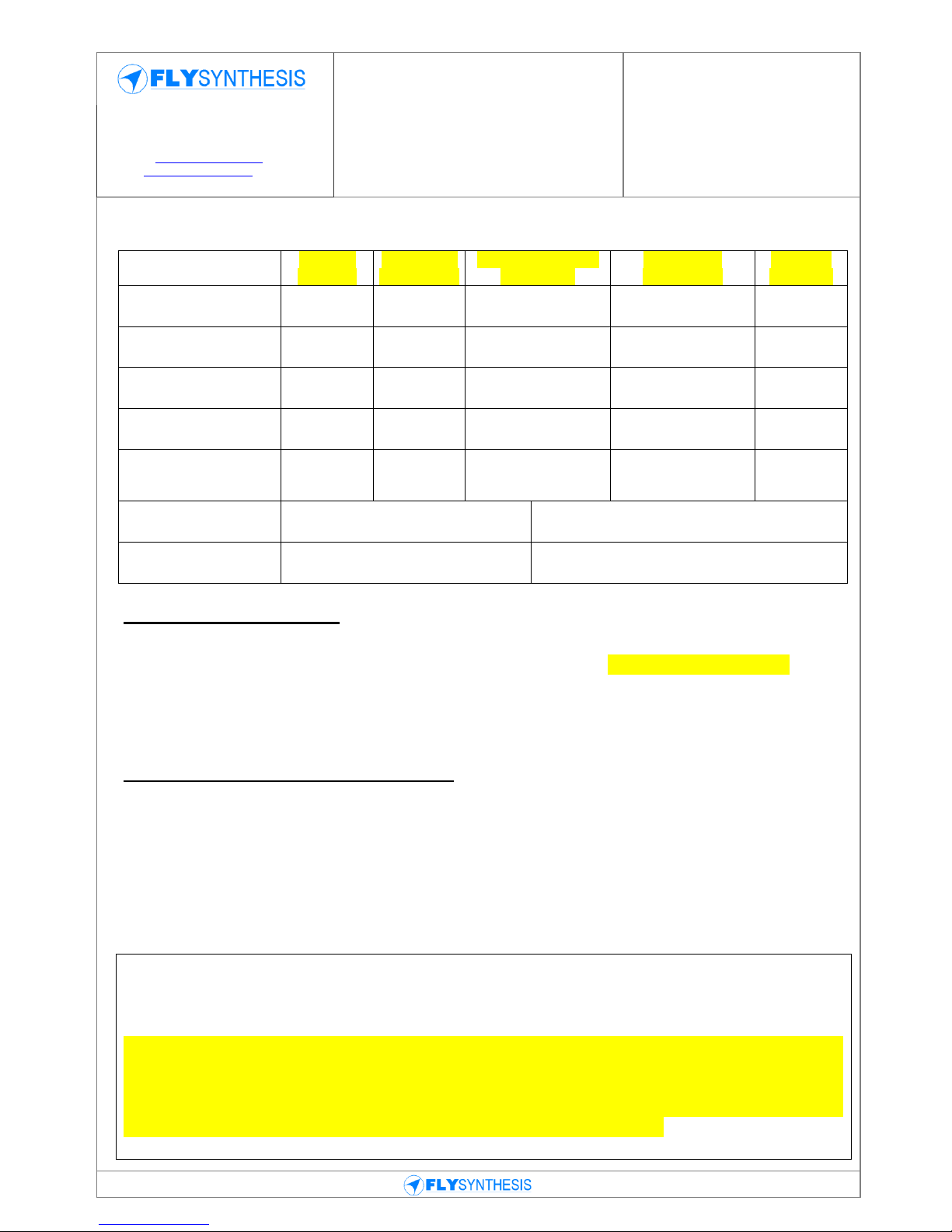

DEMONSTRATED CROSS WIND COMPONENT

The maximum demonstrated crosswind is 17 KTS

Figure 5-6 shows the RELATIVE WIND DIAGRAM VERSUS WIND COMPONENT

ENVELOPE DIAGRAM

Figure 5.7 shows the envelope diagram.

Page 39

Identification: POH_TC_LSA Rev.0

Page: 39 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Figure 5-1

Take off run

Take off distance

Take off speed

120 m

360m

55 KTS

Landing distance

Landing run

Landing speed

275 m

65 m

55 KTS

Page 40

Identification: POH_TC_LSA Rev.0

Page: 40 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SPEED CONVERSION (DENSITY ALTITUDE)

This table helps you to calculate the TAS (true airspeed) from the IAS (indicated airspeed)

using the simplified formula:

TAS = IAS*Cor. factor

Figure 5-2

Page 41

Identification: POH_TC_LSA Rev.0

Page: 41 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

UNIT CONVERSIONS

Figure 5-3

Page 42

Identification: POH_TC_LSA Rev.0

Page: 42 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Figure 5-4

Page 43

Identification: POH_TC_LSA Rev.0

Page: 43 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Figure 5-5

Page 44

Identification: POH_TC_LSA Rev.0

Page: 44 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

CROSS WIND TABLE

Figure 5-6

Page 45

Identification: POH_TC_LSA Rev.0

Page: 45 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

ENVELOPE DIAGRAM

Vso

Stall Speed with flap 45°

45 KTS

Vs

Stall Speed without flap

50 KTS

Vfe

Maximum speed with extended flap

70 KTS

Va

Maneuvering speed

78 KTS

Vne

Never exceed speed

129 KTS

Page 46

Identification: POH_TC_LSA Rev.0

Page: 46 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

SECTION 6

Weight & balance

Title Page

6.1 Introduction 46

6.2 Weighing conditions 46

6.3 Weight & balance report 47

Page 47

Identification: POH_TC_LSA Rev.0

Page: 47 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

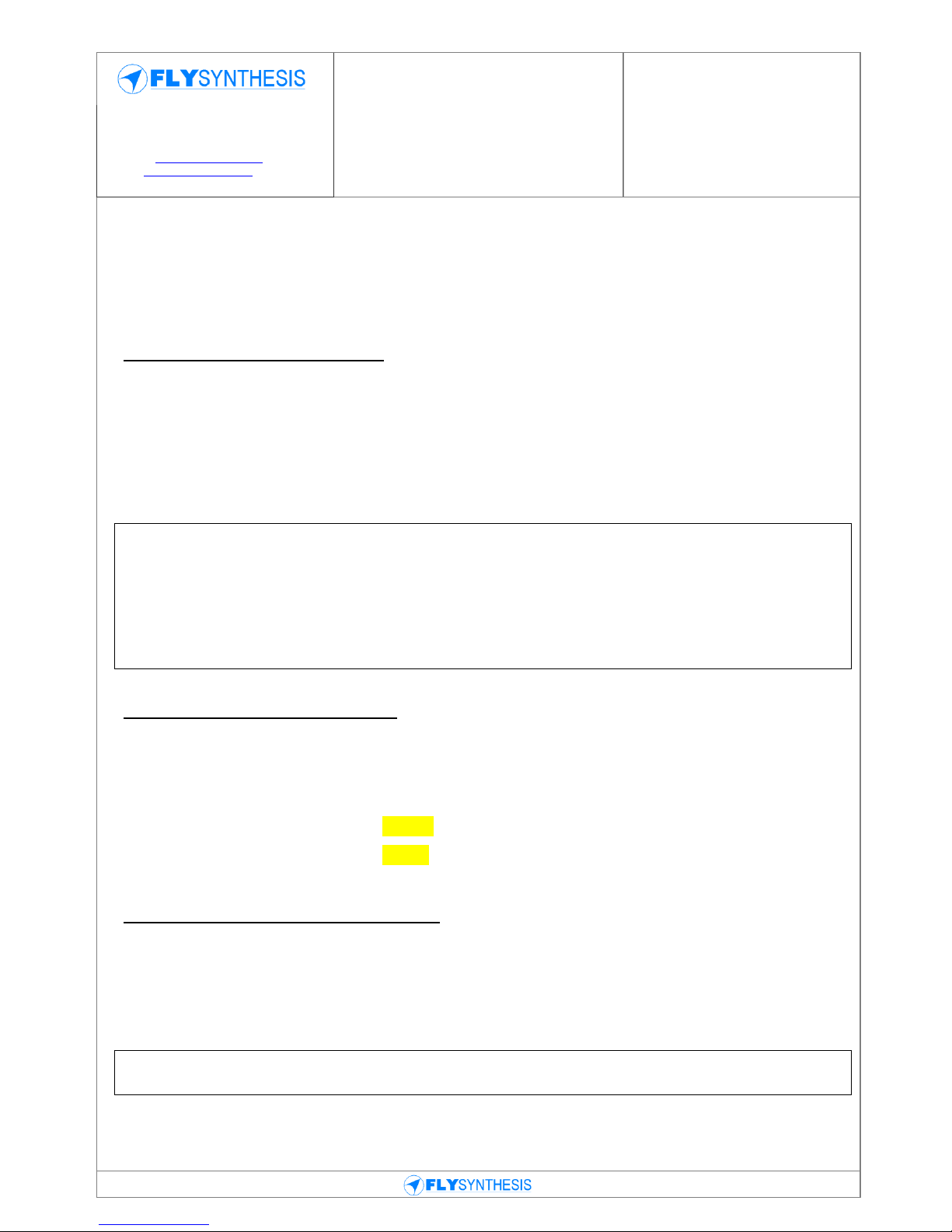

6.1 INTRODUCTION

This section contains the information to affect a correct procedure of weight and balance of

the aircraft.

WARNING: exceeding the Centre of Gravity limits can provoke serious problems of stability

and govern-ability of the aircraft.

6.2 WEIGHING CONDITIONS

For the weighing of the aircraft, the followings conditions apply:

- The equipment installed must be approved by the factory for the aircraft in question.

- Must be included the brake fluid, engine oil, water coolant and the non-usable fuel.

- Must use three independent scales for each tire horizontal plan and of a thread to

lead.

- To determinate the empty weight and the position of the Center of Gravity, the aircraft

must be positioned on three autonomous scales, one for each wheel. It is

fundamental that the longitudinal and lateral axes of the aircraft are both in the same

horizontal plane. You can verify the horizontal datum position when the fuselage side

reaches 5° with reference to ground level, as shown in the figure below.

Using a plum bob mark a line on the ground directly beneath the leading edge of the wing.

This point is your reference datum RD. Measurements are to be taken from this point.

X1 is the distance from nose wheel axle centerline to projection of RD.

X2 is the distance from main wheel axle centerline to projection of RD.

The standard distance is:

X1 = 925mm (±0.5%)

X2 = 655mm (±0.5%).

The formula for CG calculation is as follows:

Xt = ML / PT . [CofG position in mm on the wing chord]

Page 48

Identification: POH_TC_LSA Rev.0

Page: 48 of 59

Date: 14/05/07

Issued: M. Fiorindo

Verified: M. Fiorindo

Approved: C. Pinzana

Revision Description:

New manual issue

Pilot Operating Handbook

FLY SYNTHESIS TEXAN

TOP CLASS 550 LSA

(for Rotax 912 ULS and

Jabiru 2200 engines versions)

Provincial Road n.78 Km 12.150

33050 Mortegliano (UD) – Italy

Tel. +39.(0)432.992482 – +39.(0)432.993557

Fax +39.(0)432.931280

Sito web: www.flysynthesis.com

e-mail: info@flysynthesis.com

Where:

ML = (P2DX + P2SX) x X2 - P1 x X1

Xt% = (Xt / MAC) x 100 [CG position in percentage to the wing chord]

ML = Empty weight moment

P2DX , P2SX = Weight measured on main wheel

P1 = Weight measured on nose wheel

NOTE: DX = RHS SX = LHS

For greater W&B detail refer to the maintenance manual.

6.3 WEIGHT & BALANCE REPORT