Page 1

STORCH

CL, HS, S VERSION

MAINTENANCE MANUAL

(VALID FOR ROTAX 912 UL/S, 582 UL DCDI AND JABIRU 2200 ENGINES)

01 20/apr/05 Updated manual M. Fiorindo R. Ciotti R. Ciotti

Num.

Date Description

REVISION

Preparation Verify Approvation

The FlySynthesis s.r.l. it reserves him to terms of law the exclusive ownership of the present and it also forbids the partial reproduction of it.

Page 2

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 2 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

Log of revisions

All revisions to this Maintenance Manual must be recorded in the following table.

Revision Number Revision Date Signature

01

Updated manual Apr.05 M. Fiorindo

Page 3

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 3 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

Log of effective pages

Page Date

1 Aprile 2005

2 Aprile -2005

3 Aprile -2005

4 Aprile -2005

5 Aprile -2005

6 Aprile -2005

7 Aprile -2005

8 Aprile -2005

9 Aprile -2005

10 Aprile -2005

11 Aprile -2005

12 Aprile -2005

13 Aprile -2005

14 Aprile -2005

15 Aprile -2005

16 Aprile -2005

17 Aprile -2005

18 Aprile -2005

19 Aprile -2005

20 Aprile -2005

21 Aprile -2005

22 Aprile -2005

23 Aprile -2005

24 Aprile -2005

25 Aprile -2005

26 Aprile –2005

Page 4

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 4 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

INDEX

Log of revisions 2

Log of effective pages 3

1 ROUTINE MAINTENANCE 5

1.1 GENERAL 5

1.2 MAINTENANCE SCHEDULE 5

1.3 PRE-FLIGHT INSPECTION 7

1.4 DAILY INSPECTION 7

1.5 10-HOURS INSPECTION 9

1.6 20-HOURS INSPECTION 10

1.7 50-HOURS INSPECTION 11

1.8 100-HOURS INSPECTION 13

1.9 150-HOURS INSPECTION 14

1.10 200-HOURS INSPECTION OR TWO-YEAR INSPECTION (whichever occurs first). 15

1.11 300-HOURS INSPECTION OR TWO-YEAR INSPECTION (whichever occurs first). 15

1.12 ANNUAL INSPECTION 16

2 LUBRICATION 17

SCHEDULE INDEX

fig. 1 Routine Maintenance Table..........................................................................................6

fig. 2 LUBRICANTS and SEALANTS...............................................................................17

fig. 3 Routine Maintenance Schedule - Power plant ............................................................18

fig. 4 Special Inspections Only for Rotax 912 Engine..........................................................22

fig. 5 Routine Maintenance Schedule - Airframe .................................................................23

1

Page 5

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 5 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1. ROUTINE MAINTENANCE

1.1 GENERAL

No other factors are quite important for the safety and reliability of, the aircraft and its components as a

regular and diligent attention to the routine maintenance steps carried out within the recommended

intervals.

The same applies for a prompt corrective action , introduced for all minor troubles found during the

aircraft in-service life.

This chapter contains the maintenance instructions and checks to be performed on the air-frame,

equipments and engine.

For detailed instructions applicable to the engine and its components (e.g. disassembly, cleaning,

inspection, testing, repair, lubrication, torque loads and reassembly), the operator should refer to the

Operator's Manual and Spare Parts List, last issues, published by engine manufacturer.

1.2 MAINTENANCE SCHEDULE

The maintenance schedule for STORCH is based upon 10 inspections to be accomplished within the

following limits.

PRE--FLIGHT INSPECTION: to be accomplished before each flight.

DAILY INSPECTION: to be accomplished daily, before beginning the flight activity.

10-HOURS INSPECTION: to be accomplished after 10 flight hours.

20-HOURS INSPECTION: to be accomplished after 20 flight hours.

50-HOURS INSPECTION: to be accomplished after 50 flight hours.

100-HOURS INSPECTION: to be accomplished after 100 flight hours.

150-HOURS INSPECTION: to be accomplished a after 150 flight hours.

200-HOURS INSPECTION: to be accomplished after 200 flight hours.

300-HOURS INSPECTION: to be accomplished after 200 flight hours.

ANNUAL INSPECTION: to be accomplished once a year independently of flight hours totalised.

GENERAL OVERHAUL: to be accomplished an airframe and engine at the manufacturer’s facilities after150 flight hours.

Page 6

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 6 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

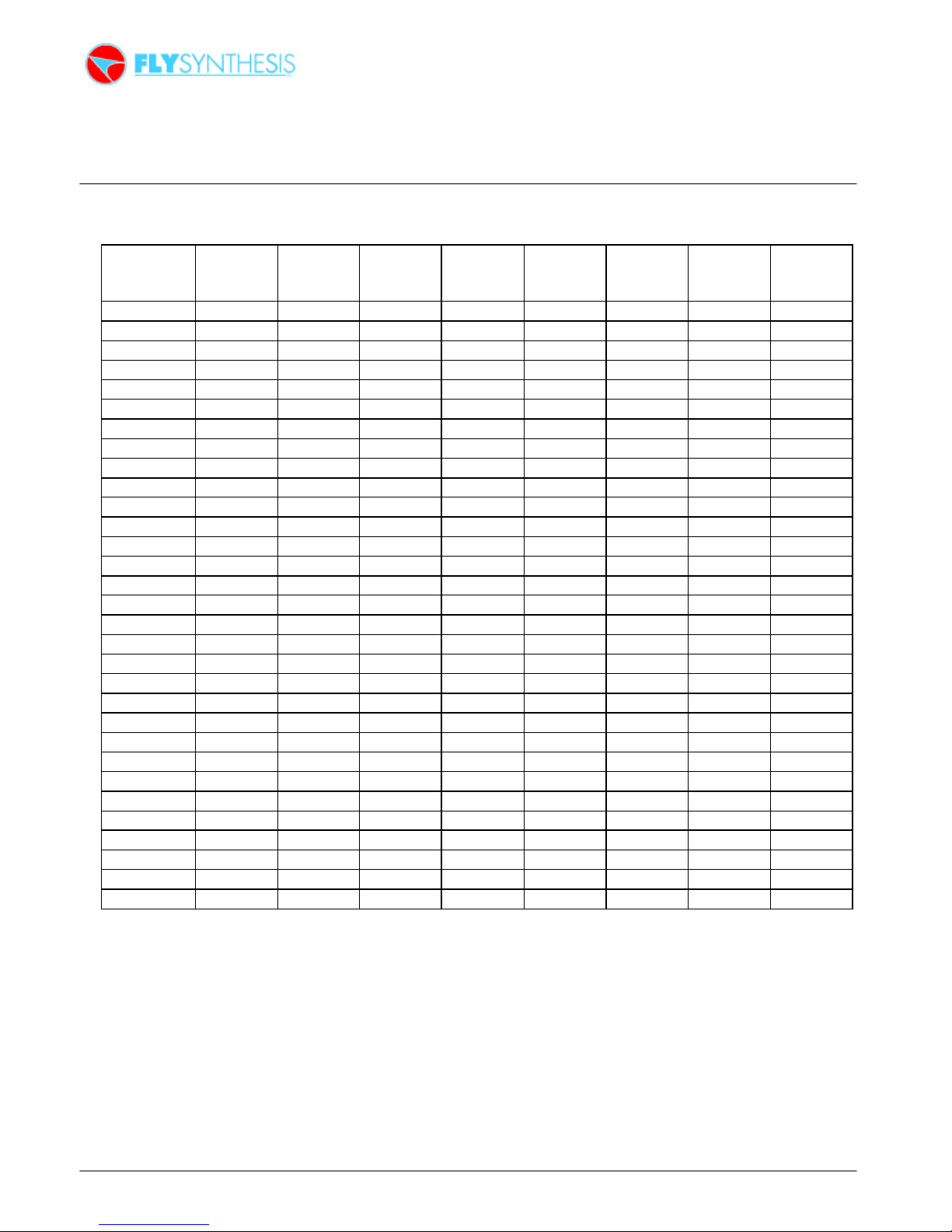

fig. 1 Routine Maintenance Table

Flight hours

totalised

New and

General

Inspection

10h

Inspection

20h

Inspection

50h

Inspection

100h

Inspection

150h

Inspection

Q.P.O.

200h

Inspection

Q.P.O.

300h

Inspection

Q.P.O.

New X

10 h X

20 h X X

30 h X

40 h X X

50 h X X

60 h X X

70 h X

80 h X X

90 h X

100 h X X X X

110 h X

120 h X X

130 h X

140 h X X

150 h X X X

160 h X X

170 h X

180 h X X

190 h X

200 h X X X X X

210 h X

220 h X X

230 h X

240 h X X

250 h X X

260 h X X

270 h X

280 h X X

290 h X

300 h X X

Q = Qualified P = Personnel O = Only

Page 7

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 7 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.3 PRE-FLIGHT INSPECTION

Refer to related paragraph of Flight Manual - last issue.

1.4 DAILY INSPECTION

Accomplish a complete Pre-Flight Inspection and the following additional operations:

(1) Ensure that the ignition key is REMOVED.

(2) Remove the upper and lower engine cowlings.

(3) Drain the fuel tanks as written in Flight Manual.

(4) In spect the carburettor rubber socket or rubber -flange for damage and security of attachment.

(5) Remove the floating chamber from the carburettor and inspect for cleanliness and absence of

water.

(6) Verify the air filter for security of attachment.

(7) Inspect the ignition cable terminals for security of connections to spark plugs.Inspect. all

other- electrical connections for security.

(8) Verify the electrical starter for security of attachment.

(9) Verify the battery for security of attachment.

(10) Inspect the rubber shock absorbers and of engine mount for condition.

(11) Verify the fuel pump, the fuel filter and relevant hoses f-or security of attachment and fuel

(12) Verify the attaching bolts of drive reduction unit supporting plate for tightening.

(13) Turn the propeller by hand and inspect -For abnormal noise.

(14) Verify engine control cables for security.

(15) Check tires pressure for proper- inflation:

- Main wheels 1.2 - 2.2 kg/cm2 (17 - 31 P.s.i.)

- Nose wheel 0.7 - 1.0 kg/cm

2

(10 - 14 P.s.i.)

Page 8

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 8 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

For aircraft equipped with ROTAX 582 UL engine:

In addition to inspections/checks listed in the previous item (1) through (15), accomplish the following additional

operations:

(16) Verify the radiator mounting -For security. Inspect the radiator for damage and leaks.

(17) Check the coolant level and security of filling cap.

(18) Inspect the coolant hoses for security, leaks and chafing.

(19) Inspect the cylinder heads cylinders and water pump for leaks.

(20) Verify the lubrication oil content in the rotary valve and security of filling cap.

(21) Inspect the oil hoses relevant to rotary valve gear lubrication and oil injection systems for

Security, leaks and chafing.

(22) Verify the integrity of safety locking wires of gearbox, drain and oil level plugs.

(23) BY pushing and pulling the engine shaft along its axis, check the bearings for abnormal play.

For aircraft equipped with ROTAX 912 UL engine:

In addition to inspections/checks listed in the previous item (1) through (15), accomplish the following additional

operations:

(24) Verify the oil and water radiator mounting -For security. Inspect the radiator for damage and leaks.

Check the coolant level and security of filling cap.

(25) Inspect the coolant hoses for security, leaks and chafing.

(26) Inspect the cylinder heads cylinders and water pump for leaks.

(27) Verify the lubrication oil content and security of filling cap.

(28) Inspect the oil hoses relevant to gear lubrication and oil injection systems for Security, leaks

and chafing.

(29) Verify drain and oil level plugs.

(30) BY pushing and pulling the engine shaft along its axis, check the bearings for abnormal play.

Page 9

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 9 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.5 10-HOURS INSPECTION

(1) Ensure that the ignition key is REMOVED.

(2) Check the manifold attaching bolts and the cylinder head nuts (only air-cooled engines) for proper

torque. Above check should be performed after the first 10 flight hours only.

For sequence and torque loads refer to engine Operator's Manual - last issue.

(3) Inspect the air and fuel filters for clogging.

(4) Inspect the rewind starter rope for conditions (this interval is applicable to aircraft equipped with

engine manual starting only).

Worn or -Frayed ropes are not acceptable. For replacement procedure, refer to engine Operator's Manual - last

issue.

(5) For aircraft equipped with drive belt reduction unit, check: belt tension as follows:

(a) Apply a force of 10 Kg (22 lbs) in the middle of each belt.

(b) Measure the deflection on each belt which should result 7 mm approx. (0.270 in). If

necessary adjust the belt tension as detailed the subsequent items (c), (d), (e) and

(f).

(c) Remove the spinner (if installed) and the propeller.

(d) Using a socket wrench unloose the self-locking nut; for this operation apply an

opposite torque on the proper housing located in the eccentric. To increase the belt

tension turn the eccentric clockwise.

(e) Torque the self-locking nut to 60 Nm (5:1,2 Lbs.in).

(f) Reinstall the propeller. Torque the attaching bolts to 15 Nm (133 lbs.in).

(6) Remove and check the spark plugs for condition. For evaluation criteria consult the engine

Operator's Manual. Spark Plug torque load: 27 Nm (240 lbs-in). Using a suitable solvent ,

clean the ignition cables terminals.

(7) Carefully inspect the whole exhaust system (manifold, muffler, elbow) for cracks; verify the

serviceability of retaining -springs and rubber buffers.

(8) Using a suitable, neutral, aqueous, free of solvents and abrasives detergent, clean the wings

and empennage.

In performing this operation take care that some detergent does not penetrate inside the

airframe: this to avoid contaminations and corrosions in not inspection able places.

Page 10

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 10 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.6 20-HOURS INSPECTION

(1) Ensure that the ignition key is REMOVED.

(2) Check: the electrolyte level in the battery.

Replace the spark plugs. For replacement procedure

consult the engine Operator's Manual - last issue.

When engine is cold torque the spark plugs to 27 Nm

(240 lbs-in).

(3) Check the propeller attaching bolts for proper torque.

Required torque load: 15 Nm (133 lbs-in).

(4) Check the- driven wheel self locking nut for proper torque.

Required torqu e load: 60 Nm (532 lbs-in).

(5) Check the driving wheel attaching bolt for proper torque.

Required torque load: 60 Nm (532 Lbs-in).

(6) Check for proper torque the self-locking nuts and securing the engine to its housing and to the engine

mount respectively.

Torque loads required: nuts: 8 Nm (337 lbs-in); nuts: 22 Nm (195 lbs-in).

(7) Check for proper torque the self-locking nuts securing the engine mount to the fuselage. Torque

load, required: 10 Nm (89 lbs-in).

(8) Check for proper torque the self-locking nuts securing the shock absorbers and to the engine mount .

Torque load required: 10 NT, (89 lbs-ini).

(9) Check for proper torque the bolts securing the-engine cowling to the cylinder heads.

Torque load required: 15 Nm (133 lbs.in).

(10) Carefully inspect the brake control cables for condition (e.g. wear, broken wires) and security of

attachments.

Check that cables conduits are not bended or damaged.

(11) Inspect the push-pull control cables (55), (116) and the trim control cable (103) for general

conditions and, in particular, for cleaning and security of attachments.

(12) Ref. I.F'.C. Fig. 3: check tightening of self-locking nuts (5) and (3) securing the wings to

the tubular framework.

(13) Ref. I.P.C. Fig. 3: check tightening of self locking nuts (42) securing the wing brace struts.

(14) Ref. I.F'.C. Fig. 3: check tightening of self-locking nuts (14), (25), (32) securing the aileron control

1inkages.

(15) Ref. I.P.C. Fig. 3.. check tightening of bolts (21), (28) attaching the aileron hinge supporting plates

(19), (20), (26), (27) to the wings.

(16) Ref. I.P.C. Fig. 7, sheet 4 of 4: check tightening of self-locking nuts (119) attaching the

push-pull control cable to the rudder and (141), (145) securing the rudder hinge pins.

(17) Ref. I.P.C. Fig. 7, sheet 2 of 4: check tightening of self-locking nuts (58) attaching the push-pull

control cables to stabilator hinge support and nuts (72) securing the hinge pin (70).

The same check should be performed on nuts (66) attaching the stabilator to its hinge support

(67) and nut (79) connecting the hydraulic damper (77) to the same support (67).

(18) Ref. I.P.C. Fig. 7, sheet 2 of 4: check tightening of

self-locking nuts (90), (95), (99), (102), relevant to the anti-tab tension/regulator device.

Check the operating rod (96) for abnormal play.

(19) Check: all fuel hose connections for security.

(20) For engines equipped with drive reduction gear only: check oil level in the gearbox.

Page 11

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 11 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.7 50-HOURS INSPECTION

(1) Ensure that the ignition key is REMOVED.

(2) Remove the exhaust manifold and carefully inspect the cylinders and piston crowns for carbon

deposits.

If deposit thickness is higher than 0,5 mm (.02 in) decarbonising is required.

For decarbonising, remove the cylinders and the piston rings. Clean the piston ring grooves, piston

crowns and cylinders.

Replace all gaskets and/or rubber rings.

Qualified personnel should accomplish this operation only.

(3) Using a suitable plastic tool move each piston sideway and check for ring sticking in grooves.

Replace gaskets and reinstall the exhaust manifold. Torque the attaching bolts to 22 Nm (195 lbs x

in).

(4) For aircraft equipped with engine electrical starter: remove the electric starter and check the pinion

gear for wear. Reinstall the Assembly and torque the attaching nuts to 22 Nm (195 lbs.in).

(5) Check engine control cables for proper tension and interference with other equipments.

Clean and lubricate as necessary.

On the carburettor: verify the RPM and CHOKE operating levers for freedom of movement.

(6) Check the carburettor for cleaning and proper adjustment in accordance with engine Operator's

Manual - last issue.

(7) Using a flashlight and a mirror carefully inspect the flight control linkages located behind the

fuselage main frame (just behind the seats) and under the cabin floor ensuring that all self-locking

nuts are securely tightened.

Check all linkage components for wear, smooth operation and interference.

Clean the affected area as necessary.

(8) Thoroughly clean the control stick articulations and examine the assembly for damage and wear.

Verify that all components are secured and the articulation movements are smooth.

Lightly lubricate all moving parts and rod end bearings without rubber protection in accordance with

paragraph. 2 - LUBRICATION.

(9) Ref. I.P.C. Fig. 7, sheet 2 of 4: check tightening of self-locking nuts (76) securing the stabilator

hinge supporting plates (73).

(10) Ref. I.P.C. Fig. 7, sheet 3 of 4: check tightening of pedals hinge bolts (109) and retaining screws

(111).

I

(11) Check main landing gear wheels and nose wheel for freedom of rotation. Ensure that bearings are

not noisy and without abnormal play.

(12) Replace the oil in the hydraulic shock strut of nose landing gear.

For this proceed as follows:

Page 12

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 12 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

(a) Remove the lower screw located in the cylinder bottom and the upper one located in the strut;

completely drain the existing oil.

(b) Once the drain is completed reinstall the lower screw and refill through the threaded hole of

upper screw.

Use 140 cc of oil specified in the paragraph. 2 LUBRICATION.

(13) Check the shock strut piston for abnormal play; both transversal and longitudinal play should be 2 -

3 mm max. (.078 in - .120 in max).

Check for no torsional play between pedals and nose wheel.

(14) Ref. I.P.C. Fig. 4: check tightening of self-locking nuts (5), (8), (13), (16), (20), (24).

(15) Re-F. I.P.C. Fig. 5: support the aircraft and remove the main landing gear RH and LH struts (14);

clean the strut housings located in the tubular framework (1) and in the axle assemblies (18), (19).

Lubricate strut housings as necessary in accordance with paragraph. 2 LUBRICATION.

(16) Ref. I.P.C. Fig. 5: reinstall the main landing gear struts and check the self-locking nuts (5), (8), (11),

(17), (24), (33) for tightening.

Page 13

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 13 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.8 100-HOURS INSPECTION

(1) Ensure that the ignition key is REMOVED.

(2) Ref. I.P.C. Fig. 6: replace the 6 ea. Exhaust system-retaining springs (28).

(3) Ref. I.P.C. Fig. 6: replace the 3 ea. Muffler buffers

(4) Ref. I.P.C. Fig. 8: replace the fuel filter (7) cartridge.

(5) Ref. I. P.C. Fig. 6: inspect the carburettor air r filter cartridge (7) for damage and clogging.

Replace if necessary or carefully clean the same.

(6) If the aircraft normally operates in very dusty environment, an accurate inspection to piston and

cylinders is required.

To accomplish this inspection the cylinders and pistons removal is reques ted.

Under normal environment conditions this check should be performed during the 150-hours

inspection.

For what above-mentioned the relevant operations are listed in the relative paragraph.

(7) Remove the fuel pump and clean it inside.

Check the pump for general conditions.

For engines equipped with drive reduction gearbox:

(8) Replace the gearbox, lubrication oil.

The oil replacement is also required after 2 years from last filling. Apply whichever occurs

first.

For relevant procedure, refer to the engine Operator's Manual - last issue.

(9) Check and adjust the preload of "knuckle -joint" spring washers (applicable to gearboxes type A-B).

The adjustment should be performed by qualified personnel only (see ROTAX Service Bulletin

6UL86/E dated Dec. 1986).

(10) For ROTAX -582 UL engines only: replace the rotary valve gear 1Librication oil. For relevant

procedure refer to engine Operator's Manual - last issue.

(11) Ref. I.P.C. Fig. 6: using a 10X magnifying glass Carefully inspect all welding relevant to, engine

housing (4) and engine mount (11) for cracks.

(12) Check tightening of self-locking nuts securing the seat belts (I.P.C. Fig.2, items 10 - 14 and Fig. 5

item 11).

(13) Remove the main landing gear wheels and check the brake linings for wear.

Lubricate the brake operating levers (see paragraph 4.2.10 - LUBRICATION).

(14) Control handles in the cabin: disconnect all control cables and check for wear and broken wires;

check terminals for security.

Replace cables if necessary.

(15) Control handles in the cabin: carefully inspect all handles for cleanliness, damage, wear (abnormal

play) and security of attachment.

(16) Support the fuselage and remove the landing gear legs (2 ea.).

Check each leg for linearity.

Distortion allowed: 10 mm MAX (.40 in MAX) measured on one end.

Check if there are flaws with a magnifying glass. If found replace legs.

Clean the housing of legs and legs and put new graphite grease.

Page 14

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 14 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.9 150-HOURS INSPECTION

WARNING

DUE TO THEIR COMPLEXITY, QUALIFIED PERSONNEL SHOULD ACCOMPLISH

THE FOLLOWING OPERATIONS ONLY.

FOR DETAILED INSTRUCTIONS AND TECHNICAL DATA APPLICABLE TO ENGINE,

MAINTENANCE REFERS TO OPERATQR’S MANUAL LAST ISSUE.

(1) Ensure that the ignition key is REMOVED.

(2) Ref. ROTAX Spare parts List, Fig. 15 (-For 503 engine) and Fig. 14 (for 582 engine): remove from

the carburettor the jet needle (4) and needle jet (15)-, carefully examine these items for damage and

ovalization. Replace if necessary.

(3) Remove the cylinder heads and cylinders assemblies than proceed as follows:

- Examine the barrel and cylinder heads -f or condition and carbon deposits. Decarbonise as necessary.

- Examine the piston ring grooves for condition.

- Check piston and barrel diameters verifying the clearance between each piston and associated barrel,

which should result 0.07 - 0.08 mm (0.0028 - 0.0032 in).

- Check the axial play of lower piston ring (with rectangular section).

- Examine inside the barrels +or scorings.

- Examine the crankshaft for damage, corrosion, wear and abnormal noise.

(4) On the reassembling replace the following items:

- cylinder gaskets;

- cylinder head gaskets / rings;

- crankshaft outer seals;

- exhaust manifold gaskets;

- piston pins and needle bearings.

(5) Accomplishing the engine reassembly it is recommended to strictly observe the torque

loads required which are in the Operator's Manual and in the "Description" of Spare Parts

List - last issues.

(6) General airframe overhaul.

Page 15

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 15 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.10 200-HOURS INSPECTION OR TWO-YEAR INSPECTION (whichever occurs first).

(1) Ensure that the ignition key is REMOVED.

(2) Check all push-pull control cables and replace if necessary (4 ea.).

(3) Check all flexible control cables and replace if necessary(5 ea.).

(4) Check the ailerons hydraulic dampers ( old models) (6 ea.),

(5) Overhaul the stabi1ator hydraulic damper ( old models) (1 ea.),

(6) Check the front (2 ea.) and rear (2 ea.) engine mount shock absorbers and replace them if

necessary

1.11 300-HOURS INSPECTION OR TWO-YEAR INSPECTION (whichever occurs first).

(1) Check all push-pull control cables and replace if necessary (4 ea.).

(2) Check all flexible control cables and replace if necessary (5 ea.).

(3) Check the front (2 ea.) and rear (2 ea.) engine mount shock absorbers and replace them if

necessary

(4) Replace legs of main landing gear

Page 16

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 16 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

1.12 ANNUAL INSPECTION

(1) Ensure that the ignition key is REMOVED.

(2) Using a suitable torque wrench check the cylinder head securing nuts for proper torque. Torque load

required: 22 Nm (195 lbs.in).

(3) Carefully examine all rivets for security of attachment. Rivets loosened should be replaced.

(4) Bolts and self-locking nuts relevant to the installations listed below should be checked for

tightening:

- Light controls and associated supporting devices;

- connections engine - airframe;

- engine controls and associated supporting devices;

- landing gear.

(5) Verify the nose landing gear for proper operation of hydraulic shock absorber.

(6) Using a 10 X magnifying glass carefully inspect for cracks all welding relevant to:

- tubular framework interconnecting the wings;

- tubular framework supporting the main landing gear;

- nose gear drag struts (2 ea.);

- wheel axles (2 ea.);

- aileron torque tubes (2 ea.);

- pedals assemblies;

- stabilator hinge support;

- exhaust system components (manifold - elbow muffler);

- engine mount.

(7) Front and rear wing fittings: using a vernier slide gauge check the hole diameters by taking two

measures at right angle each other (one vertically and the other horizontally).

Ovalization allowed: 0,5 mm MAX (.02 in MAX).

(8) Carefully examine the wing fitting attaching bolts (4 c-,a.) for damage, distortion and corrosion.

Indentations on bolt working area are not acceptable.

(9) Wing brace strut end fittings:

using a vernier slide gauge check the hole diameters by taking two measures at right angle each

other (one along the fitting centre line and the other at right angle).

Ovalization allowed: 0,4 mm MAX (.(D16 in MAX).

(10) Wing brackets for brace struts:

with the same method used in the previous item (9) check the hole diameters.

Ovalization allowed: 0,4 mm MAX (.016 in MAX).

Page 17

AQ 002 Rev.00 Issued/Verify/Approval M. Garofolo 13/july/02

Identification: MM 002 Rev 01

Page: 17 of 26

Date: 20/april/2005

Issued: M. Fiorindo

Verify: R.Ciotti

Approval: R. Ciotti

Revisions description:

Updated manual

Storch CL, HS, S

Maintenance Manual

(for Rotax 912 UL/S, 914 UL and

Jabiru 2200 version)

2 LUBRICATION

Effective lubrication forms the most important single item in the servicing of any mechanical equipment. The

lubricants specified in Table 4 have been selected to provide an effective lubrication aver the widest aircraft

operating conditions.

To lubricate the parts shown -in Fig. 4-2, 4-3, 4-4, 4-5, 4-6, 4-7, 4-8 use lubricants sparingly providing a

preventive, cleaning.

In Table 4 are also Listed the sealing products used; sealants

should be applied after each removal of

concerned parts and/or whenever, during the inspection, the sate are found loosened.

fig. 2 LUBRICANTS and SEALANTS

CODE

DESCRIPTION

PRODUCT

A Waterproof and high adhesively spray lubricant HHS 2000

Art. 0893 106 - 500 ml

Art. 0893 106 - 150 ml

Manufacturer:

WURTH Srl

39018 Terlano - Settequerce (Bz) Italy

B Anti seizing compound MOLYCOTE

DOW Corning GmbH

Monaco (Germany)

Cat n° 57236

C Sealant medium grade AREXONS

Cod. n° 4705

D Sealant high grade LOCTITE 270

Cat. n° 27046

E Sealant for joints LOCTITE 572

Cat. n° 57236

F Hydraulic oil for nose landing gear shock absorber Type LI/22

Manufacturer:

RAFFINERIA OLII LUBRIFICANTI

20093 COLOGNO MONZESE (Mi)

Italy

Page 18

fig. 3 Routine Maintenance Schedule - Power plant

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

1. torque exhaust manifold

bolts

X

2. Torque cylinder head

nuts (air-cooled engines

only)

X

3. Check air filter and fuel

filter for conditions

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

4. Check rewind starter rope

for conditions (manual

start engine only)

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

5. Check belt tension of

drive reduction unit

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

6. Inspect spark plugs for

conditions and clean

ignition cable terminal

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

7. Check exhaust system for

cracks and serviceability

of retaining springs and

rubber buffers

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

8. Check level of electrolyte

in the battery

X X X X X X X X X X X X X X

9. Replace spark plugs

X X X X X X X X X X X X X X

10. Torque propeller

mounting bolts

X X X X X X X X X X X X X X

11. Torque self-locking nut

and mounting bolt of

driven and driving

wheels in the reduction

unit (belt type)

X X X X X X X X X X X X X X

12. Torque self-locking nuts

relevant to engine

installation on its

housing and assembly on

engine mount

X X X X X X X X X X X X X X

Page 19

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 19/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

13. Torque engine mount

self-locking nuts

X X X X X X X X X X X X X X

14. Torque shock absorber

self-locking nuts

X X X X X X X X X X X X X X

15. Torque cylinder head

cowling retaining bolts

X X X X X X X X X X X X X X

16. Check oil level in

gearbox

X X X X X X X X X X X X X X

17. Inspect cylinder and

cylinder heads for

carbon deposits.

Replace exhaust

manifold gaskets.

Cylinder and cylinder

heads gaskets should be

replaced if these items

are removed only.

X X X X X

18. Inspect piston rings for

sticking

X X X X X

19. Inspect electric starter

pinion gear for wear

X X X X X

20. Check engine control

cables for proper

tension and control

handles for smooth

operation. Clean and

lubricate as necessary.

X X X X X

Page 20

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 20/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

21. Check carburettor for

cleanliness and proper

adjustment.

X X X X X

22. Replace exhaust

muffler retaining spring

X X

23. Replace exhaust

muffler buffers

X X

24. Replace cartridge in

the fuel filter

X X

25. Replace or clean the

cartridge in the air filter

X X

26. Inspect pistons and

cylinders for condition

(if the aircraft normally

operates in very dusty

environments)

X X

27. Clean inside the fuel

pump

X X

28. Replace oil in the

gearbox

X X X

29. Check/adjust the spring

washers of “knuckle

joint” in the gearbox

(A-B) types only)

X X

30. Replace rotary valve

lubrication oil (582 UL

engine only)

X X

Page 21

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 21/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

31. Check needle and jet of

the carburettor

X

32. Check cylinders,

cylinder heads, pistons,

ring grooves and crank

shaft for condition

X

33. Check cylinders and

pistons for proper fit.

Check axial play of

lower piston ring

X

34. Replace crankshaft

outer seals, pistons pins

and needle bearings.

X

35. Replace cylinder and

cylinder heads gaskets

X

36. Using a 10X

magnifying glass

inspect all welding of

engine housing and

engine mount for cracks

X X

37. Replace front and rear

engine mount shock

absorbers

X

38. Engine general

overhaul

X X

Page 22

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 22/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

fig. 4 Special Inspections Only for Rotax 912 Engine

Inspection Items 100 h 200 h 600 h A.M.E.

1. remove upper and lower cowling, check for cracks, overheated areas, deformations, loose or missing

fasteners. Clean cowlings if dirty.

x x x

2. Perform engine compression test (engine warm, throttle open)

cyl. 1 ________ cyl. 2 ________

cyl. 3 ________ cyl. 4 ________

* x x

3. Check spark plug electrode gap, adjust if necessary (0.7-0.8mm / 0.028-0.031in.) x

4. Replace spark plugs, type NGK 12 DCPR7E x x

5. Drain oil while engine is warm x x x

6. Check engine and reduction gear housing for oil leakage x x x

7. Replace oil filter and add a light film of oil to oil filter seal x x x

8. Check oil filter and both magnetic screws for metal particles and foreign matter

CAUTION

If metal particles are found, the problem must be corrected by authorized personnel, the oil system must

be flushed and the oil radiator must be replaced.

x x x

9. Fill engine with max 3.0 litres (3.2 US qts) of engine oil according to manufacturer data. Check oil

level.

x x x

10. Clean engine x x x

11. Check ignition harness for heat defects and insecure attachment. Check harness for chafing, in

particular under attachment brackets.

x x x

Page 23

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 23/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

fig. 5 Routine Maintenance Schedule - Airframe

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

1. Aircraft cleaning

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

2. Inspect brake control

cables for conditions

and security

X X X X X X X X X X X X X X

3. Inspect push-pull

control cables for

conditions and security

X X X X X X X X X X X X X X

4. Check wing fittings selflocking nuts for

tightening

X X X X X X X X X X X X X X

5. Check wing brace struts

self-locking nuts for

tightening

X X X X X X X X X X X X X X

6. Check aileron torque

tubes self-locking nuts

for tightening

X X X X X X X X X X X X X X

7. Check aileron hinge

self-locking nuts for

tightening

X X X X X X X X X X X X X X

8. Check self-locking nuts

relevant to connection

of push-pull control

cables to rudder and to

hinge pins for

tightening

X X X X X X X X X X X X X X

Page 24

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 24/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

9. Check for tightening

self-locking nuts

relevant to the

following conditions:

- push-pull control cables

to stabilator hinge

support

- stabilator hinge pin

- hydraulic damper to

hinge support

X X X X X X X X X X X X X X

10. Check self-locking

nuts of anti-tab

connection for

tightening and

operating rod for

abnormal play

X X X X X X X X X X X X X X

Inspection / Checks ---

Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

11. Inspect fuel hoses for

security

X X X X X X X X X X X X X X

12. Inspect flight control

mechanism located

behind the seats and

under the cabin floor

for security and smooth

movement. Clean as

necessary

X X X X X

Page 25

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 25/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

Inspection / Checks --- Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

13. Inspect control stick

articulations for

security and smooth

movement. Clean and

lubricate as necessary.

X X X X X

14. Check stabilator

supporting plates selflocking nuts for

tightening

X X X X X

15. Check rudder pedals

hinge bolts and nylon

housing attaching

screws for tightening

X X X X X

16. Check main and nose

wheels for freedom of

rotation, bearings noise

and abnormal plays

X X X X X

17. Replace oil in the nose

landing gear hydraulic

shock absorber

X X X X X

18. Check transversal and

longitudinal plays on

hydraulic shock

absorber strut

X X X X X

19. Check for tightening the

self-locking nuts relevant

to nose landing gear

strut, drag struts and axle

X X X X X

Page 26

AQ 002 Rev.00 Prep/Ver./App. M. Garofolo 13/luglio/2002

Identification: 002 Rev 01

Page : 26/26

Date: 20/april/2005

Preparation: M. Fiorindo

Verify: R.Ciotti

Approvation: R. Ciotti

Revisions description:

Updated manual

Maintenance Manual

Storch CL, HS, S

(valid for Rotax 912 UL/S, 582 UL

DCDI and Jabiru 2200 engines)

Inspection / Checks Hours

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300

20. Clean and lubricate the

main landing gear leg

housing

X X X X X

21. Check safety belts selflocking nuts for

tightening

X X

22. Check main landing

gear brake linings for

wear and lubricate

operating levers

X X

23. Check cables and their

attachments to control

handles (anti-tab,

brakes, throttle, choke)

for security and

condition

X X

24. Clean control handles

and check for wear

X X

25. Replace all push-pull

control cables

X

26. Replace aileron

hydraulic dampers

X

27. Remove and overhaul

the stabilator hydraulic

damper

X

28. General overhaul of

the airframe

X X

Loading...

Loading...